Showing 257 items matching "priorities"

-

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red cardigan embroidered with decorative tuck stitches and floral motifs on front panel, crochet around collar in blue, white and green. Closes at centre front with 5 plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD ALL WOOL / 20 /CREATED BY ROBERT BLAKEchildren's knitwear, knitwear, children's clothing, clothing, cardigan, manufacturing, fashion textile production, machine knitting, embroidery, hand embroidery, floral embroidery, floral motif, tuck stitch -

National Wool Museum

National Wool MuseumTextile - Diaper Set, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White diaper set. Short sleeved white top with two inverted box pleats along whole length, stitched at shoulder and mid chest. Embroidered in half cross stitch with two blue dogs on front. Closes in centre back with three plastic pearlescent buttons. White baby diaper shorts with ribbing at waist and leg holes .3 is a sample tag with manufacturing information, including price, size and colours available .4 is a swing tag with manufacturer care instructions.1 [label at back neck of top] Kathryn Reg’d / All Cotton / 18 .3 [sample label] [Obverse] STYLE: 314. Diaper Sat [sic] – Emb top. Combed Cotton. SIZE: 18” PRICE: 26/- COLOR: BLUE. LEMON. WHITE. [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNE .4 [retail label] [obverse] Kathryn PRE-SHRUNK KNITWEAR Style: 314 [handwritten] DESIGNED & MANUFACTURED BY Robert Blake MELBOURNE [reverse] IMPORTANT. Special care should be taken with white and pastel shades. Rinse thoroughly. Do NOT dry in sunlight. WASHING INSTRUCTIONS 1.Wash frequently to AVOID HEAVY SOILING 2.Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. 3.Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. 4.RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. 5.To dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, then safety-pin to line through shoulder tape. 6.To keep Brushed Wool garments like new brush frequently with nylon brush.children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, embroidery, embroiderer, hand embroidery, dog embroidery, animal embroidery, animal motif, dog motif, dog, animal, baby clothes, baby knitwear, baby clothing -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Three-piece brown and yellow outfit consisting of jumper, pants and hat. Jumper is long sleeved with a high crew neck and five yellow stripes above ribbing along bottom. Pants are brown with wide legs that dramatically taper into the ribbed cuff at bottom. Body of hat is brown and tapers into a long point and has a brown and yellow pompom at the tip. The hat is shaped with a tuck at the back neck near cuff..1 [Label at back neck of jumper with blue lettering woven into label] KATHRYN REGD / 24 ALL WOOL CREATED BY ROBERT BLAKEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms, wool -

National Wool Museum

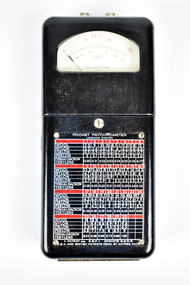

National Wool MuseumInstrument - Psychrometer, Electronova S.A, c.1965

Kathryn Knitwear Collection A Psychrometer is an instrument used to measure humidity using two thermometers, one of which is wet and one is dry. A similar example is housed at laboratoire d'histoire des sciences et des techniques (LHST). Inventory number 603.0509 Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black metal measuring instrument with clear window to view gauge for displaying humidity. Reference table listing values for different fibres is printed in red and white on a black metal plate that is screwed onto the front of the psychrometer. The instrument is housed in brown leather case with zip. It includes a printed paper instruction book with black text and greyscale figures.psychrometer, measuring instrument, humidity, textile manufacturing, fashion textile production -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Forest Green Childrens jumper with geometric ‘alpine’ pattern with long sleeves and ribbed cuffs and round neck collar. Textured geometric pattern is created with purl stitches and extends both on the front and back of the jumper, as well as down the sleeves.[white label at back neck printed with blue ink] KATHRYN REGD SIZE 1 / LENGTH 84cm / WEIGHT 12kg / Made in Australia ACRYLIC/WOOLchildren's knitwear, knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Lace Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream short sleeved jumper with overall open lace design, front yoke with accent lacework and applied lace ruffle edging .2 is a retail tag with style code and size, reverse has washing instructions for acrylic and cotton.1) [white tag back neck, printed blue letters] KATHRYN REGD POLYESTER/VISCOSE MADE IN AUSTRALIA .2 [retail swing tag, numbers handwritten in blue ink] KATHRYN Children’s Knitwear STYLE [handwritten] 363 PRICE SIZE [handwritten] 6children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, machine lace -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White lacework baby romper suit with long sleeves and legs, and enclosed feet. Closes at centre back with two plastic buttons. Zips open around leg inseam. Size 00 .2 is a retail tag marked with the price and size, and refers to the label sewn into the garment for washing instructions..2 [Retail Swing Tag] [Obverse] KATHRYN Children’s Knitwear STYLE PRICE [handwritten] $18 SIZE [handwritten] 00 [Reverse] WASHING INSTRUCTIONS Refer to label sewn in Garment Designed and manufactured by ROBERT BLAKE PTY. LTD., Melb., Aust.children's knitwear, children's clothing, baby clothing, baby knitwear, clothing, knitwear, romper, jumpsuit, manufacturing, fashion textile production, machine knitting, machine lace, baby clothes -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Long sleeved cream baby romper suit with patterned stitch on bottom half and diamond emblem on chest. Closes with two pearlescent plastic buttons at centre back and with three pearlescent plastic buttons at crotch.Kathryn Reg’d / 100% orlon / 20 [handwritten]children's clothing, children's knitwear, clothing, knitwear, romper, jumpsuit, baby clothing, baby clothes, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Baby Swimwear, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White baby’s swimming shorts with stripes on front in navy, cyan and yellowchildren's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, colourwork, swimwear, baby swimwear -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1962-1964

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Pink three piece legging suit, consisting of cardigan, lettings and beanie. Cardigan is knitted with textured stitch and has stocking stitch panel bordered with garter stitch at centre front. Two rows of buttons on garter stitch tab, with a fifth button under left collar. Leggings are plain garter stitch with an elastic waistband and a flap that extends onto the top of the foot with elastic to keep it held under the sole. Hat is in same patterned stitch as cardigan, has ear flaps with ties and a white pompom.1) [Label at back neck with blue lettering woven into label] KATHRYN REGD ORLON / 20 /CREATED BY ROBERT BLAKE [sample label] [OBVERSE] STYLE LS/PWO – 3 PCS – LEGGING SUIT – PEARL PATT. – 80% ORLON 20% WOOL SIZE 18” 20” PRICE 48/6 51/6 COLOR BLUE. LEMON. PINK. WHITE. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Dress, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream baby dress with long sleeves, blue stripe and cream faux cable textured details at yoke and hem. Body is gathered and attaches at yoke. Dress has a drawstring tie at neck accented with cream pompoms and closes at centre back with three pearlescent plastic buttons. Back opening is reinforced with grosgrain ribbon. .2 is a sample tag with manufacturing information, including sizes and colours available .3 is a retail tag with style, care instructions and brand marketing[label stitched into back neck] KATHRYN 100% Orlon .2 [sample label] [Obverse] 802/F – BABIES ORLON FROCK. 16” – LENGTH 24/6 BLUE/WHT LEMON/WHT PINK/WHT WHT/BLUE WHT/LEMON WHT/PINK .3 [Obverse] KATHRYN Children’s Knitwear STYLE [handwritten] 802/F SIZE PRICE [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLYclothing, children's clothing, knitwear, children's knitwear, manufacturing, fashion textile production, colourwork, pom-pom, pom poms -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Children’s two-piece outfit set, consisting of a top and leggings. Knitted in colour blocks of navy, red and white. Top has ribbed navy bodice section with white stripe separating red skirt and closes at back neck with two navy plastic buttons. Leggings are primarily red, with a white stripe at the ankle and navy-blue feet. Leggings are constructed primarily as one piece and seamed up at centre back and inseam, with additional gusset piece..1) [tag stitched into back neck of top] KATHRYN REGD 100% ACRYLIC FIBRE SIZE 0 WEIGHT 10 LENGTH 76 MADE IN AUSTRALIA .3) [blue sample label] STYLE 574/ Pop Top and B’tts S.26. Acrylic. SIZES: 00 0 PRICE: $8.95 COLORS: Navy/Wht/Red Red/Wht/Navy P.Blue/Wht/Navy Dec on Del.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, c.1980

Sample of Kathryn Knitwear Collection, Label style suggests it may not be manufactured by Kathryn Knitwear, but was retained as a sample. Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Two Piece pale blue suit, consisting of jumper and leggings with all-over pattern in double moss stitch and garter stitch border. Jumper opens down the back and closes with three pearlescent plastic buttons. Scalloped motif at bottom and cuff has white accent. Leggings have closed feet and decorative ties at ankle, and are constructed primarily as one piece and seamed up at centre back and inseam, with additional gusset piece.1) [ label at neck of cardigan] SIZE 000 .2) [some letters cut off label] FIT AGE 0-3 MONTHS WEIGHT 6KG ACRYLIC HAND WASH OR GENTLE MACHINE WASH COLD RINSE [D]O NOT TUMBLE DRY WARM IRON [D]RY CLEANABLE (A) [MA]DE IN AUSTRALIAknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1962-1966

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. The colourwork dogs from this design are a very popular motif, and were available in both wool and Orlon in multiple styles from at least 1961-1972, including a cardigan and a pullover, selling 4346 of these in winter 1961. This example most likely dates from 1962-1966. An Illustration depicting this style is catalogued under NWM-09026. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children’s machine-knit jumper with white dog motif and green grass colourwork, closes with three red plastic buttons at left shoulder .2 and .3 are sample tags with manufacturing information, including sizes and colours available .4 is a swing tag with manufacturer care instructions.1) [label stitched at back neck] KATHRYN REGD. / 100% ORLON / 24 .2) STYLE: 44/OP – ORLON PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. WHITE. / 20” – 24” SKY BLUE. LEMON. WHITE. REDCOAT. BOTANY BLUE. SULTRY GREEN. NUTTY BROWN. OATMEAL .3) STYLE: 44/PW – WOOL PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. / 20” – 24” SKY BLUE. LEMON. REDCOAT. BOTANY BLUE. / SULTRY GREEN. NUTTY BROWN. NED KELLY GREEN. / .4) Obverse: [handwritten] 5/10 (unintelligible) Kathryn / ORLON KNITWEAR / Style : 44/OP / DESIGNED & MANUFACTURED BY / Robert Blake / MELBOURNE Reverse: STANDARD MEASUREMENTS / FIT EXACTLY / LAUNDER PERFECTLY / HOT WATER WILL DAMAGE / THIS GARMENT / WASHING INSTRUCTIONS / 1. Use lukewarm water and mild soap. / 2. Squeeze water out by hand – DO / NOT WRING. / 3. DO NOT ROLL. Hang on / Clothes hanger to dry. / To keep brushed garments like / new, brush frequently with / Nylon brush. / IRONING [m (handwritten)] ORLON garments require little / or no ironing if drip-dried. If / ironing is necessary, it may be done damp or dry, using / a warm iron. / DO NOT USE / STEAM IRON /knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, dog motif, animal motif, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1953-1961

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. This style of “brushed wool leginette suit” was produced by Kathryn from at least 1953-1964, though this example likely dates from before 1962. In the winter of 1961, the brand sold 4376 suits of this style. It came with an included nylon brush in order to keep the brushed finish of the garments, which can be found under NWM-09016 Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history. This style of “brushed wool leginette suit” was produced by Kathryn from at least 1953-1964, though this example likely dates from before 1962. In the winter of 1961, the brand sold 4376 suits of this style.Four-piece legging suit consisting of cardigan, leggings, hat and mittens in fuzzy yellow brushed wool. Cardigan is double breasted and closes with two rows of yellow plastic buttons, with a fifth button under the collar. Fold-over collar and cuffs are not brushed wool and provide contrasting texture. Leggings have elastic at waist and ankle to go under foot. Bottom of leg has foot flap. Hat is in a bonnet style and has turnback around face and ties under neck. Mittens are each construced in one piece with no additional thumb pocket, and tie at wrists..1) [label at back neck of cardigan] KATHRYN REGD. CREATED BY PURE WOOL / 20 / ROBERT BLAKE .5) [sample label] [OBVERSE] STYLE: LS/W. LEGGING SUIT – BRUSHED WOOL SIZE: 18” 20” PRICE: 39/9 42/6 3 PCE: 42/9 45/6 4 PCE: COLOR: BLUE. LEMON. PINK. WHITE.knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, brushed wool, wool, fluffy -

Federation University Historical Collection

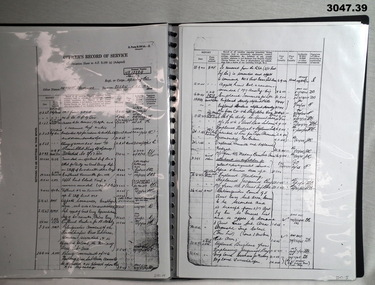

Federation University Historical CollectionDocument - SMB Documents E.J. Barker, Various School of Mines Ballarat Papers collected by E.J. Barker