Showing 291 items

matching wholesale

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Weight

The disc-shaped design of these 1LB and 2 LB metal weights enables them to be stacked one on top of the other. The weights are used with a balance scale to accurately weigh the mass of items such as grain, sugar, meat or potatoes. They could have been used in retail or wholesale businesses like a general store or a grain merchant’s premises. The user would place either one or both of these weights on one side of a balance scale. Goods would then be placed onto the other side of the scale until the beam between both sides of the scale was level, showing that the weight of the goods was as heavy as the weight or weights on the other side. These two weights are marked in Imperial units. An Imperial Standard 1LB is equal to 453.592grams. The British Weights and Measures Act of 1824 defined official standards for weights and measurements. This ensured that uniform measurements would be used for trade throughout the Empire. Towns and districts would have an official set of Imperial Standard Weights and Measures. Inspectors periodically used this official set to check the accuracy of traders’ own weights and measures. There would be penalties such as fines or imprisonment for people who broke these laws. The State of Victoria had its own Weight and Measures Act in 1862 and a decade later the inspectors in local councils used their local set of weights and measures to test the local businesses measuring equipment. In the nineteenth century the Victorian Customs Department carried out this role but this was handed over to the Melbourne Observatory at the beginning of the twentieth century. The Measures Branch then followed on with this task from the 1940s until 1995. Australia began converting to the metric system in the 1960s, beginning with its money. The conversion from imperial to metric units of measurement in Australia took place from 1970 and was completed in 1988 when metric units became the only legal unit of measurement. Imperial Standard weights; set of two disc-shaped weights designed to stack one upon the other. Inscriptions are marked in relief. "IMPERIAL STANDARD 1LB" [weight 1], "IMPERIAL STANDARD 2LB" [weight 2]warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, wieght, weights and measures, imperial standard weight -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Weight

The disc-shaped design of this 2 LB metal weight enables it to be stacked on top of another similarly shaped weight. The weight is used with a balance scale to accurately weigh the mass of items such as grain, sugar, meat or potatoes. It could have been used in retail or wholesale businesses like a general store or a grain merchant’s premises. The user would place the weight on one side of a balance scale. Goods would then be placed onto the other side of the scale until the beam between both sides of the scale was level, showing that the weight of the goods was as heavy as the weight on the other side. This weight is marked in Imperial units. An Imperial Standard 1LB, or one pound, is equal to 453.592grams. The British Weights and Measures Act of 1824 defined official standards for weights and measurements. This ensured that uniform measurements would be used for trade throughout the Empire. Towns and districts would have an official set of Imperial Standard Weights and Measures. Inspectors periodically used this official set to check the accuracy of traders’ own weights and measures. There would be penalties such as fines or imprisonment for people who broke these laws. The State of Victoria had its own Weight and Measures Act in 1862 and a decade later the inspectors in local councils used their local set of weights and measures to test the local businesses measuring equipment. In the nineteenth century the Victorian Customs Department carried out this role but this was handed over to the Melbourne Observatory at the beginning of the twentieth century. The Measures Branch then followed on with this task from the 1940s until 1995. Australia began converting to the metric system in the 1960s, beginning with its money. The conversion from imperial to metric units of measurement in Australia took place from 1970 and was completed in 1988 when metric units became the only legal unit of measurement.Weight; 2 lbs. Metal disc designed for stacking. Inscription marked in relief. Imperial Standard weight, 2 pounds weight."IMPERIAL STANDARD", "2lbs"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, standard measure, imperial standard, weight, 2lb weight, imperial standard weight -

Bendigo Historical Society Inc.

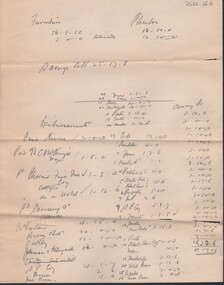

Bendigo Historical Society Inc.Document - CONNELLY, TATCHELL, DUNLOP COLLECTION: ACCOUNTS ESTATE OF ESTHER ISABELLE CANNING, 1893 - 1894

Document. Various legal papers. 1 - 1894 - Account from Transton Geo, Wholesale Tobacconist, Bath Buildings, Bendigo to Mrs Canning. 2 - 1894 - Account from Boyd James D, Dr, Physician, Surgeon and Accoucheur, View Point, Bendigo to Canning Mr, Hopetoun Hotel for medical attendance upon the late Mrs Canning. Dated Jan 1894. 3 - 1894 - Accounts from Barry Bros, Manufacturers of Carriages, Buggies, Phaetons, Wagonettes, Lyttleton Terrace East, Bendigo to Executors of the Estate of Mrs Canning, deceased, instructing to pay Rawlings E G for phaeton. 4 - 1894 - Letter from Connelly, Tatchell and Dunlop to Canning Thos, Hopetoun Hotel Mitchell Street asking him to prepare an inventory of 'things in your possession which form the subject of the arrangement with your Mother'. Dated 19 Jan 1894. List includes 1 ladies gold watch & chain, cameo brooch, 2 family pictures, 1 box of clothes belonging to Mother, 16 fowls, phaeton, small table. Canning. Executors to John Canning marked on outside. 17 Jan 1894. 5 - 1893 - Letter dated 29 Dec 1893 from Connelly, Tatchell and Dunlop to Connelly, Tatchell and Paling re Canning deceased. 6 - Blank Probate Jurisdiction Form. Prepared by Cuthbert & Co., Law Stationers, Chancery Lane, Melbourne. 7 - Re Canning deceased. Statement of Assets and Liabilities. Mentions properties Golden Age Hotel in High St, Golden Square; 2 weatherboard cottages in High St Golden Square rented by Leach? And Gourlay; and land at Cnr High & Elm Streets, Golden Square.cottage, miners, connelly, tatchell and dunlop, transton geo, boyd james d, barry bros, canning mrs, rawlings e g, canning thos, hopetoun hotel, canning john, connelly, tatchell and paling, cuthbert & co., golden age hotel, leach, gourlay -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumMedicine, pills, between c.1870-c.1924

TROVE : Earliest entry for Duerdin, Sainsbury, and Co. The Argus (Melbourne, Vic. : 1848 - 1957) Tuesday 28 June 1870 p 4 Article Shipping Intelligence IMP0RTS.-June 25. Childwall Abbey, from London.-360 cases starch, , 4 tanks, 50 cases brushware, 15 casks blacking, Virgoe, Son, and Co. ; 62 tanks malt, Gough and Smith ; 71 bales, Wilson and Mackinnon ; 1 case jewellery. 4 cases hardware, Thos. Williams ; 36 packages drugs, Duerdin, Sainsbury, and Co. ; 9 cases confectionary,...........' C.1924 Dueridin & Sainsbury became a 'limited' company. TROVE: The Argus (Melbourne, Vic. : 1848 - 1957) Saturday 29 November 1924 p 32 Article Duerdin and Sainsbury Ltd. The first annual meeting of Duerdin and Sainsbury Ltd, was held at the company's offices, Flinders lane, Melbourne, yesterday. . Mr. Henry G. McRoberts presided............' TROVE : Gippsland Times (Vic. : 1861 - 1954) Thursday 17 May 1923 p 1 Article GiPPSLAND HOSPITAL -----: O: --------, PAYMENTS Wages £3, £32/2, £83/1SIS, 1.!'/1/8, £26/9/, Kodak Co. £3/14/, Hicks Atkinson & Sons £13/0/8, Duerdin & Sainsbury £2/0/3, Denyer's Pty. £3'/.......' TROVE : Last entry for Duerdin, Sainsbury, and Co. Weekly Times (Melbourne, Vic. : 1869 - 1954) Saturday 31 March 1934 p 57 Article "OLD READER" (Hamilton). — Moulds and wicks for candles:— D. & W Chandler Ltd.. 234 Flinders Lane, Melbourne, CI Mention this paper (2) If you have large quantity of gum you could offer It to wholesale chemists such as Rocke Tompsitt & Co., Flinders Street, or Felton Grimwade and Duerdin Sainsbury. 342 Flinders Lane. ✏Fix this text 18/6, Francis & Co. £2/9/1, Melbourne ✏Pink paper packaging (damaged) around a two page leaflet containing a squat cylindrical wooden box with lid, Box with a paper label on the lid, contains round ball shaped cream coloured pills.Paper label of pills box 'Dr. Hains Antibilious Pills', Proprietors....uer....& Sainsbury 340-351 Flinders La. MELBOURNE. 6d Per Box of 24 PILLS'pills, medicine, pharmacy, drug houses of australia -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a poor copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0211Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a reasonable copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0048Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO SALEYARDS COLLECTION: FAT CATTLE SALE BENDIGO 28/11/95

Continuous twenty two page report for Sale No. 87 Fat Cattle Sale Bendigo dated 28/11/95. Report issued on the 28/11/95 by Ron Laird. Report lists the buyers name and the number of head purchased each time from each agent and the total number purchased. Agents names are abbreviated. Buyers names are: Woolworths, Australian Meat Hildi, Bennetts Meats Pty Ltd, Bennets Wholesale Meats, Boydies Butchers, KJ Carruthers, Clifford Quality Meats, Dalgety Farmers Ltd 210160, Dalgety Farmers Pty 210171, Elders Ltd, Ellis Nuttall & Compa, Friswell K, Garfield, R J Gilbertson 210263, R J Gilbertson 640, Gregory J, Grenfell N, Hardwick GF & VC, ICM1, ICM4, ICM5, Mackenzie & Mackenzie, Maher L, Masons Meat Pty Ltd, JJ McAllister, McCasheney & Co, McGillivary GK & GY, McIvor Meats, McKean W & Co, Nevins FP & Co, Newman Livestock Sales 153, Newman Livestock Sales N 546, Newman Livestock Sales N 257, Newman Livestock Sales 3 269, Newman Livestock Sale No 271, Newman Livestock Sale No 282, Oakey C/- T Newman, O'Connor G & K Pty Ltd, J H Ralph & Son, Safeway No 188, Andrew Schenk, Starr A, Top Meats, Wagstaff Cranbourne P, D & K Webb, Welsh, M/S K & J Wignall, RH Woodward & Co 442, RH Woodward & Co 454, RH Woodward & Co 466, Woodhead B, RH Woodward & Co 571, RH Woodward & Co 405, RH Woodward & Co 417, Woolworths, Anderson, R Truscott, C Mulvihill, I Sinclair, J Dalrymple, Vincent and McKenzie & McKenzie.bendigo, council, cattle markets, bendigo saleyards collection - fat cattle sale bendigo 28/11/95, ron laird, woolworths, australian meat holdi, bennetts meats pty ltd, bennetts wholesale meats, boydies butchers, kj carruthers, clifford quality meats, dalgety farmers ltd, dalgety farmers pty, elders ltd, ellis nuttall & co, friswell k, garfield, rj gilbertson, r j gilbertson, gregory j, grenfell n, hardwick gf & vc, icm1, icm4, icm5, mackenzie & mackenzie, maher l, masons meat pty ltd, jj mcallister, mccasheney & co, mcgillivary gk & gy, mcivor meats, mckean w & co, nevins fp & company, newman livestock sales 153, newman livestock sales 546, newman livestock sales 257, newman livestock sales 3 269, newman livestock sale no 271, newman livestock sale no 282, oakey c/- t newman, o'connor g & k pty ltd, j h ralph & son, safeway no 188, andrew schenk, starr a, top meats, wagstaff cranbourne p, d & k webb, welsh, m/s k & j wignall, rh woodward & co 442, rh woodward & co 454, rh woodward & co 466, woodhead b, rh woodward & co 571, rh woodward & co 405, rh woodward & co 417, woolworths, anderson, r truscott, c mulvihill, i sinclair, j dalrymple, vincent, mckenzie & mckenzie -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CONNELLY, TATCHELL, DUNLOP COLLECTION: ACCOUNTS ESTATE OF ESTHER ISABELL CANNING, 1893 - 1894

Document. Various legal papers. 1 - 1893 - Draft Inventory, Probate Jurisdiction in the Will of Canning Esther Isabell, late of Golden Square, Hotel Keeper. An inventory of her Real Estate and Personal Estate. 2 - 1893 - Account from McFarlane James, Tailor, 64 Pall Mall, Bendigo. Original letterhead states Gray St Hamilton - crossed out. Account to Canning Mr. 3 - 1894 - Phoenix Fire Office of London Insurance. Receipt for Cottage - High Street. 4 - Pencilled notes concerning Canning Disbursements. 5 - 1894 - Account to Canning Mr from Budden William, Wholesale Coffee and Spice Merchant, Sandhurst Steam Coffee Works, Williamson St Bendigo. 6 - 1893 - Letter to Connelly and Tatchell from McFarlane James, Tailor and Outfitter written on Dr to J McFarlane sheet. Mentions that McFarlane's wife has a certain amount of money to pay to Hunter Mr for licence of the Golden Age Hotel, Golden Square. 7 - 1893 - Letter to Connelly and Tatchell from the Cohn Bros, Victoria Brewery Company (Limited), Cohn Magnus, Manager. Re Golden Age Hotel (taking of furniture at Valuation). 8 - 1894 - Probate in the Will of Canning Esther Isabell stating that she had real estate valued at 760 pounds and personal estate valued at 172 pounds and 3 pence at the time of her death on 26 Nov 1893. Executors of her Will - Stone Henry, Sheepwash Creek, Eucalyptus manufacturer and Tatchell George Henry, Williamson Street, Bendigo, Solicitor. 9 - 1894 - Court summons. Gourley Mary Ann, Defendant to Gourley Mary Ann of Bendigo for rates on property at High Street. Attached receipt from City of Bendigo from Teague Thos. H - Asst. Rate Collector. Other names:- Stone Henry, Tatchell George Henry, Gourley Mary Ann, Teague Thos. H. City of Bendigo.cottage, miners, connelly, tatchell and dunlop, canning esther isabell, mcfarlane james, canning mr, phoenix fire office of london insurance, budden william, sandhurst steam coffee works, hunter mr, cohn bros, victoria brewery co. (ltd), cohn magnus, golden age hotel -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CONNELLY, TATCHELL, DUNLOP COLLECTION: ACCOUNTS ESTATE OF ESTHER ISABELLE CANNING, 1893 - 1894

Document. Accounts Estate of Esther Isabelle Canning. 1 - 1894 - Ac from Mackay & Co, Bendigo Advertiser Office. 2 - 1893 - Ac from Transton Geo, Wholesale Tobacconist, Bath Buildings Bendigo. 3 - 1894 - City of Bendigo Rate Account to Gourlay, Mary Ann for property in High St. 4 - 1893 - Note from McKenzie Rosa stating she received from Canning two weeks wages from the Golden Age Hotel. Attached accounts from the Kent Brewery Co, Bendigo and Hunter Bros, MCCrae St Bendigo. 5 - 1894 - Receipt from Phoenix Fire Office of London, Victorian Branch. 60 Market Street Melbourne. Received from Storie H. Executors late E I Canning. 6 - 1894 - Account from Hinchcliffe Edwin, M. D. View St, Bendigo dated July 20th 1894. 7 - 1894 - Account from W Beebe & Son, Steam Granite, Marble & Stone Sawing Works. Mitchell St and Lyttleton Terrace for fixing headstone and re gilding old inscription etc. Dated Oct 1894. 8 - 1893 - Receipt from Phoenix Fire Office of London, Victorian Agency - Phoenix Chambers 52 Market St Melbourne dated Feb 2 and Feb 4 1893. 9 - 1894 - Ac from Hinchcliffe Edwin, M. D. View St Bendigo for professional attendance. Estate of the late Mrs Canning Golden Square, Golden Age Hotel, dated Jan 11th 1894 (document torn. 10 - Various receipts pinned together. 1893 - 1894 from City Brewery Company, High St, Bendigo, Ale and Porter Brewers Thros Canning, Golden Square. Also memorandum from Johnston & Illingworth?, City Brewery Co, Golden Square to solicitors requesting payment of accounts in the estate of the late Mrs Canning of Golden Square.cottage, miners, connelly, tatchell & dunlop, mackay & co, bendigo advertiser office, transton geo, city of bendigo, gourlay mary ann, mckenzie rosa, golden age hotel, kent brewery co, hunter bros, phoenix fire office of london, storie h, hinchcliffe edwin, w beebe & son -

Ballarat Clarendon College

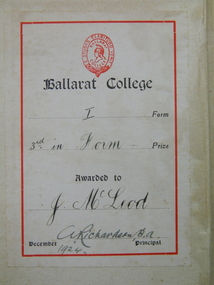

Ballarat Clarendon CollegeBook, The watches of the trails

John Anning MacLeod John was born in Ballarat as the second generation of Ballarat MacLeod’s, with his grandfather arriving in Geelong on the Hornet in 1857 as an 11 year old child with his 60 year old father John and mother Mary aged 37 years and 5 brothers and one sister. He grew up on the corner of Drummond Street and Mair Streets, opposite what became St John of God hospital, at his parents house of Dunvegan. John entered Ballarat College as a junior student in 1923. He received 3rd in Form prizes in both 1924 and 1925. His sister Margaret, attended Clarendon Ladies College. The household employed a chauffeur, a cook, a gardener and a ladies maid to care for them. In the 1930’s his father lost his fortune in the collapse of the jute future’s market so the staff were dismissed and he left Ballarat to go to Geelong College as a boarder. He was an officer in the Geelong College cadet corps and joined the Army as a private and rose to the permanent rank of Major after meritorious performance in the intelligence area of operations. He served in North Africa, in Palestine, Egypt, Moratai, the Philippines, Java and New Guinea. He was awarded his Military MBE by King George VI for exceptional devotion to duty and for brilliant coordination work amongst the allied intelligence team. During the war he met Mary Monica Carrol Bateman, a lietenant in the 2/4th Army General Hospital at a dinner party in Brisbane. The couple had four children, Hamish John Torquil born in 1945, Rory Hugh Alexander born in 1947 and twins Ian Donald and Katriona Margaret born in 1948. After the Second World War he worked for Lumley’s Insurance Brokers in London for a couple of years to follow up his accountancy training and then returned to Ballarat due to his father’s failing health and took over the management of John MacLeod and Co, Wholesale grocers and Merchants in Lydiard Street, Ballarat. The business had been started by his great grandfather and they produced the famous Sirdar brand of products and a special tea blend called Afternoon Cup. There was a spice mill in nearby Market Street and there they roasted peanuts, coffee and ground spices for packaging and distribution to the small corner shops who were the mainstay of commercial grocery. In the 1950’s John MacLeod and Co merged with James McKay and Sons to form McKay MacLeod Pty Ltd., wholesale tobacco, wine and spirits and grocery merchants who also manufactured the Sunny South brand of sweet mustard pickles, brewed vinegar and tomato sauce. He introduced the semi-automated system for extensions and financial records on the Bradma plates that saved staff the problems of sorting out the calculations for sales tax, miscellaneous charges etc. that greatly sped up the transactions at the checkout points. A new warehouse and office complex was built in Mair Street east up near Humffray Street, with the manufacturing factory on the opposite side of the street. They had a shop in St Arnaud and one in Geelong which was the local wholesaler for supplying to the corner shops of the greater Geelong area. With the development of supermarkets the demise of the corner store began and so the sales profiles began to diminish. He unsuccessfully stood for Liberal Party pre-selection for the seat of Ballarat in 1948 and served on the Liberal state finance and executive team for many years before resigning over the issue of conscripts being sent to Vietnam. He was instrumental in leading a group of Ballarat academics in opposition to the Vietnam war and publicly resigned from the Liberal Party over their foreign policy. John MacLeod saw the writing on the wall of the business in the early 1970’s and suggested that the firm restructured with focusing on tobacco, wine and spirits. His partners did not agree and so he sold out and retired to Barwon Heads. After a few years of golfing and surfing he became frustrated and joined SCORE, the Service Corp of Retired Executives. In this role he worked for ten years in the Geelong area solving accounting problems for Geelong small businesses and so helped Beaumont’s bakery back onto its feet. He worked gentlemen’s hours of 10 am to 3 pm which allowed him to have time for a round of 9 holes on the golf course at the end of the day and to have a surf before breakfast. He fully retired at the age of 65 and had ten years of voluminous reading of local library books before dying of burns at the age of 75. His war record has been documented in other archives at the College. He was a member of the Naval and Military Club and of the Barwon Heads Golf Club. He had good crafting skills and built a series of steam driven boats for his four children that used to be sailed at home on Lake Wendouree, Lake Learmonth and on the sheltered waters of the Barwon River. The boats are now being restored to operational order to be sailed by his great grandson Grayson Girardi. Red cloth bound book with title printed in gold lettering on spine, embossed publisher's mark centre of front cover and school crest in gold relief on front cover; book plate inside front cover. Book plate inside front cover: School crest / Ballarat College / I form / 3rd in form Prize / Awarded to / J MacLeod / December 1924 A Richardson B A Principaljohn-macleod, ballarat-college, book-prize, 1924 -

Ballarat Clarendon College

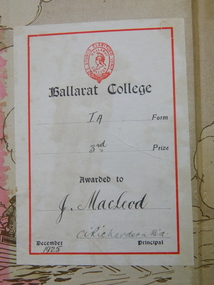

Ballarat Clarendon CollegeBook, The school across the road

John Anning MacLeod John was born in Ballarat as the second generation of Ballarat MacLeod’s, with his grandfather arriving in Geelong on the Hornet in 1857 as an 11 year old child with his 60 year old father John and mother Mary aged 37 years and 5 brothers and one sister. He grew up on the corner of Drummond Street and Mair Streets, opposite what became St John of God hospital, at his parents house of Dunvegan. John entered Ballarat College as a junior student in 1923. He received 3rd in Form prizes in both 1924 and 1925. His sister Margaret, attended Clarendon Ladies College. The household employed a chauffeur, a cook, a gardener and a ladies maid to care for them. In the 1930’s his father lost his fortune in the collapse of the jute future’s market so the staff were dismissed and he left Ballarat to go to Geelong College as a boarder. He was an officer in the Geelong College cadet corps and joined the Army as a private and rose to the permanent rank of Major after meritorious performance in the intelligence area of operations. He served in North Africa, in Palestine, Egypt, Moratai, the Philippines, Java and New Guinea. He was awarded his Military MBE by King George VI for exceptional devotion to duty and for brilliant coordination work amongst the allied intelligence team. During the war he met Mary Monica Carrol Bateman, a lietenant in the 2/4th Army General Hospital at a dinner party in Brisbane. The couple had four children, Hamish John Torquil born in 1945, Rory Hugh Alexander born in 1947 and twins Ian Donald and Katriona Margaret born in 1948. After the Second World War he worked for Lumley’s Insurance Brokers in London for a couple of years to follow up his accountancy training and then returned to Ballarat due to his father’s failing health and took over the management of John MacLeod and Co, Wholesale grocers and Merchants in Lydiard Street, Ballarat. The business had been started by his great grandfather and they produced the famous Sirdar brand of products and a special tea blend called Afternoon Cup. There was a spice mill in nearby Market Street and there they roasted peanuts, coffee and ground spices for packaging and distribution to the small corner shops who were the mainstay of commercial grocery. In the 1950’s John MacLeod and Co merged with James McKay and Sons to form McKay MacLeod Pty Ltd., wholesale tobacco, wine and spirits and grocery merchants who also manufactured the Sunny South brand of sweet mustard pickles, brewed vinegar and tomato sauce. He introduced the semi-automated system for extensions and financial records on the Bradma plates that saved staff the problems of sorting out the calculations for sales tax, miscellaneous charges etc. that greatly sped up the transactions at the checkout points. A new warehouse and office complex was built in Mair Street east up near Humffray Street, with the manufacturing factory on the opposite side of the street. They had a shop in St Arnaud and one in Geelong which was the local wholesaler for supplying to the corner shops of the greater Geelong area. With the development of supermarkets the demise of the corner store began and so the sales profiles began to diminish. He unsuccessfully stood for Liberal Party pre-selection for the seat of Ballarat in 1948 and served on the Liberal state finance and executive team for many years before resigning over the issue of conscripts being sent to Vietnam. He was instrumental in leading a group of Ballarat academics in opposition to the Vietnam war and publicly resigned from the Liberal Party over their foreign policy. John MacLeod saw the writing on the wall of the business in the early 1970’s and suggested that the firm restructured with focusing on tobacco, wine and spirits. His partners did not agree and so he sold out and retired to Barwon Heads. After a few years of golfing and surfing he became frustrated and joined SCORE, the Service Corp of Retired Executives. In this role he worked for ten years in the Geelong area solving accounting problems for Geelong small businesses and so helped Beaumont’s bakery back onto its feet. He worked gentlemen’s hours of 10 am to 3 pm which allowed him to have time for a round of 9 holes on the golf course at the end of the day and to have a surf before breakfast. He fully retired at the age of 65 and had ten years of voluminous reading of local library books before dying of burns at the age of 75. His war record has been documented in other archives at the College. He was a member of the Naval and Military Club and of the Barwon Heads Golf Club. He had good crafting skills and built a series of steam driven boats for his four children that used to be sailed at home on Lake Wendouree, Lake Learmonth and on the sheltered waters of the Barwon River. The boats are now being restored to operational order to be sailed by his great grandson Grayson Girardi. john-macleod, ballarat-college, 1925, book-prize -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Standard measure, Mid to late 19th Century

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. J & M Ewan History: J&M Ewan was a Melbourne firm that began by selling retail furniture and wholesale ironmongery. They had substantial warehouses situated at the intersection of 81-83 Elizabeth and Little Collins Streets, the business was established by James M Ewan in 1852. Shortly afterwards he went into partnership with William Kerr Thomson and Samuel Renwick. When Ewan died in 1868 his partners carried on and expanded the business under his name J & M Ewan. The business was expanded to provide a retail shop, counting-house and private offices. Wholesale warehouses adjoined these premises at 4, 6 and 10 Little Collins Street, West. This company provided and sold a large and varied amount of imported goods into the colony that consisted of agriculture equipment, building materials, mining items as well as steam engines, tools of all types and marble fireplaces. They also supplied the Bronze measuring containers in the Flagstaff Hill collection and the probability is that these containers were obtained by the local Melbourne authority that monitored weights and measures in the mid to late 19th century. The company grew to employ over 150 people in Melbourne and opened offices at 27 Lombard St London as well as in New Zealand and Fiji. The company also serviced the Mauritius islands and the pacific area with their steamship the Suva and a brig the Shannon, the company ceased trading in 1993. Robert Bate History: Robert Brettell Bate (1782-1847) was born in Stourbridge, England, one of four sons of Overs Bate, a mercer (a dealer in textile fabrics, especially silks, velvet's, and other fine materials)and banker. Bate moved to London, and in 1813 was noticed for his scientific instrument making ability through the authority of the “Clockmakers Company”. Sometime in the year 1813 it was discovered that one Robert Brettell Bate, regarded as a foreigner in London had opened a premises in the Poultry selling area of London. He was a Mathematical Instrument maker selling sundials and other various instruments of the clock making. In 1824, Bate, in preparation for his work on standards and weights, leased larger premises at 20 and 21 Poultry, London, at a rental of four hundred pounds per annum. It was there that Bate produced quality metrological instruments, which afforded him the recognition as one of one of the finest and principal English metrological instrument-makers of the nineteenth century. English standards at this time were generally in a muddle, with local standards varying from shire to shire. On 17 June 1824, an Act of Parliament was passed making a universal range of weights, measures, and lengths for the United Kingdom, and Bate was given the job of crafting many of the metrological artifacts. He was under instruction from the renown physicist Henry Kater F.R.S. (1777-1835) to make standards and to have them deposited in the principal cities throughout the United Kingdom and colonies. Bate experimented with tin-copper alloys to find the best combination for these items and by October 1824, he had provided Kater with prototypes to test troy and avoirdupois pounds, and samples with which to divide the troy into grams. Bate also cast the standard for the bushel, and by February 1825, had provided all the standards required of him by the Exchequer, Guildhalls of Edinburgh, and Dublin. In 1824, he also made a troy pound standard weight for the United States, which was certified for its accuracy by Kater and deposited with the US Mint in 1827. Kater, in his address to the Royal Society of London, acknowledged Bate's outstanding experimentation and craftsmanship in producing standards of weights, measures, and lengths. An example of a dry Bronze measuring container made specifically for J & M Ewan by possibly the most important makers of measurement artefacts that gives us today a snapshot of how imperial weights and measures were used and how a standard of measurement for merchants was developed in the Australian colonies based on the Imperial British measurement system. The container has social significance as an item retailed by J & M Ewan and used in Victoria by the authorities who were given legal responsibility to ensure that wholesalers and retailers of dry goods sold in Victoria were correct. The container was a legal standard measure so was also used to test merchants containers to ensure that their distribution of dry goods to a customer was correct.Maker Possibly Robert Brettell Blake or De Grave, Short & Co Ltd both of LondonContainer bronze round shape for measuring dry quantities has brass handles & is a 'half-bushel' measurement"IMPERIAL STANDARD HALF BUSHEL" engraved around the top of the container. VICTORIA engraved under "J & M Ewan & Co London and Melbourne" engraved around the bottom of the container.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, standard measure, bronze, peck measurement, j & m ewan, victorian standard dry measurement, bronze container, victorian standards, melbourne observatory, robert brettell bate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Standard measure, Mid to late 19th Century

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. J & M Ewan History: J&M Ewan was a Melbourne firm that began by selling retail furniture and wholesale ironmongery. They had substantial warehouses situated at the intersection of 81-83 Elizabeth and Little Collins Streets, the business was established by James M Ewan in 1852. Shortly afterwards he went into partnership with William Kerr Thomson and Samuel Renwick. When Ewan died in 1868 his partners carried on and expanded the business under his name J & M Ewan. The business was expanded to provide a retail shop, counting-house and private offices. Wholesale warehouses adjoined these premises at 4, 6 and 10 Little Collins Street, West. This company provided and sold a large and varied amount of imported goods into the colony that consisted of agriculture equipment, building materials, mining items as well as steam engines, tools of all types and marble fireplaces. They also supplied the Bronze measuring containers in the Flagstaff Hill collection and the probability is that these containers were obtained by the local Melbourne authority that monitored weights and measures in the mid to late 19th century. The company grew to employ over 150 people in Melbourne and opened offices at 27 Lombard St London as well as in New Zealand and Fiji. The company also serviced the Mauritius islands and the pacific area with their steamship the Suva and a brig the Shannon. Robert Bate History: Robert Brettell Bate (1782-1847) was born in Stourbridge, England, one of four sons of Overs Bate, a mercer (a dealer in textile fabrics, especially silks, velvet's, and other fine materials)and banker. Bate moved to London, and in 1813 was noticed for his scientific instrument making ability through the authority of the “Clockmakers Company”. Sometime in the year 1813 it was discovered that one Robert Brettell Bate, regarded as a foreigner in London had opened a premises in the Poultry selling area of London. He was a Mathematical Instrument maker selling sundials and other various instruments of the clock making. In 1824, Bate, in preparation for his work on standards and weights, leased larger premises at 20 and 21 Poultry, London, at a rental of four hundred pounds per annum. It was there that Bate produced quality metrological instruments, which afforded him the recognition as one of one of the finest and principal English metrological instrument-makers of the nineteenth century. English standards at this time were generally in a muddle, with local standards varying from shire to shire. On 17 June 1824, an Act of Parliament was passed making a universal range of weights, measures, and lengths for the United Kingdom, and Bate was given the job of crafting many of the metrological artifacts. He was under instruction from the renown physicist Henry Kater F.R.S. (1777-1835) to make standards and to have them deposited in the principal cities throughout the United Kingdom and colonies. Bate experimented with tin-copper alloys to find the best combination for these items and by October 1824, he had provided Kater with prototypes to test troy and avoirdupois pounds, and samples with which to divide the troy into grams. Bate also cast the standard for the bushel, and by February 1825, had provided all the standards required of him by the Exchequer, Guildhalls of Edinburgh, and Dublin. In 1824, he also made a troy pound standard weight for the United States, which was certified for its accuracy by Kater and deposited with the US Mint in 1827. Kater, in his address to the Royal Society of London, acknowledged Bate's outstanding experimentation and craftsmanship in producing standards of weights, measures, and lengths. An example of a dry Bronze measuring container made specifically for J & M Ewan by possibly the most important makers of measurement artifacts that gives us today a snapshot of how imperial weights and measures were used and how a standard of measurement for merchants was developed in the Australian colonies based on the Imperial British measurement system. The container has social significance as an item retailed by J & M Ewan and used in Victoria by the authorities who were given legal responsibility to ensure that wholesalers and retailers of dry goods sold in Victoria were correct. The container was a legal standard measure so was also used to test merchants containers to ensure that their distribution of dry goods to a customer was correct. Bronze round container with brass two handles used as a legal standard for measuring dry quantities & is a 'peck' measurement. "IMPERIAL STANDARD PECK" engraved around top of container with " VICTORIA" engraved under.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, standard measure, bronze, peck measurement, j & m ewan, victorian standard dry measurement, bronze container, victorian standards, melbourne observatory, robert bettell bate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Standard measure, Mid to Late 19th Century

The beginning of standardised weights and measures began In Victoria when the Melbourne Observatory received sets of standard weights and measures, which had been tested in Britain against the then British Imperial standards. These included the primary standard yard and pound for the Colony of Victoria. Other standards of weights and measure held by shires and the administrative body's within the colony could then be compared to these primary standards. A Weights and Measures Act was passed in Victoria in 1862, establishing local inspectors throughout the colony. By the 1870s each local council and shire in Victoria held a set of standards that were used to test scales, weights and dry measures used by wholesalers, factories and shops. Every ten years the councils’ standards would themselves need to be rechecked against the Victorian Standards. The checking was done by the Victorian Customs Department in the 19th century, but with the transfer of responsibility for customs to the Federal Government in 1901, weights and measures function was retained by the Victorian Government and was shifted to the Melbourne Observatory. In 1904, a new building was erected at the south end of the Great Melbourne Telescope House, where the standard weights and measures and testing equipment was installed. This room had a large whirling apparatus for testing air meters and became known as the Whirling Room. When the Melbourne Observatory closed in 1944, the Weights and Measures Branch was formed to continue and this branch remained at the Observatory site unit until 1995. J & M Ewan History: J&M Ewan was a Melbourne firm that began by selling retail furniture and wholesale ironmongery. They had substantial warehouses situated at the intersection of 81-83 Elizabeth and Little Collins Streets, the business was established by James M Ewan in 1852. Shortly afterwards he went into partnership with William Kerr Thomson and Samuel Renwick. When Ewan died in 1868 his partners carried on and expanded the business under his name J & M Ewan. The business was expanded to provide a retail shop, counting-house and private offices. Wholesale warehouses adjoined these premises at 4, 6 and 10 Little Collins Street, West. This company provided and sold a large and varied amount of imported goods into the colony that consisted of agriculture equipment, building materials, mining items as well as steam engines, tools of all types and marble fireplaces. They also supplied the Bronze measuring containers in the Flagstaff Hill collection and the probability is that these containers were obtained by the local Melbourne authority that monitored weights and measures in the mid to late 19th century. The company grew to employ over 150 people in Melbourne and opened offices at 27 Lombard St London as well as in New Zealand and Fiji. The company also serviced the Mauritius islands and the pacific area with their steamship the Suva and a brig the Shannon. Robert Bate History: Robert Brettell Bate (1782-1847) was born in Stourbridge, England, one of four sons of Overs Bate, a mercer (a dealer in textile fabrics, especially silks, velvet's, and other fine materials)and banker. Bate moved to London, and in 1813 was noticed for his scientific instrument making ability through the authority of the “Clockmakers Company”. Sometime in the year 1813 it was discovered that one Robert Brettell Bate, regarded as a foreigner in London had opened a premises in the Poultry selling area of London. He was a Mathematical Instrument maker selling sundials and other various instruments of the clock making. In 1824, Bate, in preparation for his work on standards and weights, leased larger premises at 20 and 21 Poultry, London, at a rental of four hundred pounds per annum. It was there that Bate produced quality metrological instruments, which afforded him the recognition as one of one of the finest and principal English metrological instrument-makers of the nineteenth century. English standards at this time were generally in a muddle, with local standards varying from shire to shire. On 17 June 1824, an Act of Parliament was passed making a universal range of weights, measures, and lengths for the United Kingdom, and Bate was given the job of crafting many of the metrological artifacts. He was under instruction from the renown physicist Henry Kater F.R.S. (1777-1835) to make standards and to have them deposited in the principal cities throughout the United Kingdom and colonies. Bate experimented with tin-copper alloys to find the best combination for these items and by October 1824, he had provided Kater with prototypes to test troy and avoirdupois pounds, and samples with which to divide the troy into grams. Bate also cast the standard for the bushel, and by February 1825, had provided all the standards required of him by the Exchequer, Guildhalls of Edinburgh, and Dublin. In 1824, he also made a troy pound standard weight for the United States, which was certified for its accuracy by Kater and deposited with the US Mint in 1827. Kater, in his address to the Royal Society of London, acknowledged Bate's outstanding experimentation and craftsmanship in producing standards of weights, measures, and lengths. An example of a dry Bronze measuring container made specifically for J & M Ewan by possibly the most important makers of measurement artefacts that gives us today a snapshot of how imperial weights and measures were used and how a standard of measurement for merchants was developed in the Australian colonies based on the Imperial British measurement system. The container has social significance as an item retailed by J & M Ewan and used in Victoria by the authorities who were given legal responsibility to ensure that wholesalers and retailers of dry goods sold in Victoria were correct. The container was a legal standard measure so was also used to test merchants containers to ensure that their distribution of dry goods to a customer was correct.Maker Possibly Robert Brettell Blake or De Grave, Short & Co Ltd both of LondonContainer brass round for measuring quantities- Has brass handles & is a 'Bushel' measurement. 'Imperial Standard Bushel Victoria' engraved around container. Container bronze round shape for measuring dry quantities has brass handles & is a 'Bushel' measurement"IMPERIAL STANDARD BUSHEL" engraved around the top of the container. VICTORIA engraved under "J & M Ewan & Co London and Melbourne" engraved around the bottom of the container.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, standard measure, bushel, bushel measurement, j & m ewan, dry measurement, victorian measurement standard, bronze container, melbourne observatory, robert brettell bate -

Bendigo Historical Society Inc.

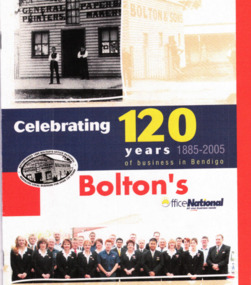

Bendigo Historical Society Inc.Booklet - Boltons Office National Celebrating 120 years of Business in Bendigo, 2005

Parry Collection History tells us that Benjamin Bolton and his two eldest sons, William and Arthur, began a printing business known as Bolton & Sons on March 25, 1885. But the Bolton name could just as easily have been erased from the annals of Bendigo during the treacherous sea journey that brought them from England in 1883. Benjamin, his wife and eight children (the youngest of whom was only three months old), boarded the “clipper” ship Ivanhoe on 17 July 1883 with little idea of what lay in store for them. Halfway through their 84-day journey, the Ivanhoe found itself in the midst of an equinoxial gale. For two days and nights, the ship was battered by huge seas and winds, while the Boltons and other passengers were battened down below deck with just a few candles and no fresh food or water. The ship and its passengers survived, but many of the crew were injured, and the ship was badly damaged. Having survived the gale, a week later, the Ivanhoe was hit with sleet, hail and snow, and the peril of icebergs. It must have been a great day for the Bolton family when Cape Otway appeared out of the fog, and the cry of “land ho!” echoed about the ship. The Bolton’s had arrived, and a Bendigo institution was about to be born. The location of the original printing business was in High Street but later moved to Williamson Street where the business underwent a name change to Bolton Bros and expanded into manufacturing paper bags and other stationery lines. In 1902, Bolton Bros moved to 43 Mitchell Street, which housed the retail stationery department and the main office, while the printing factory was on the second and third floors. Next door at 47 Mitchell Street, the wholesale division and machine service department operated. William and Arthur Bolton and their sons travelled throughout central and northern Victoria selling their own products and representing other companies. They are credited with being the innovators of the loose-leaf ledger. Today, of course, the business is back in Williamson Street with an even greater presence but the same entrepreneurial flair that has seen it survive and flourish through everything history has thrown at it. Having gone through five generations of family ownership, current company director-David Bolton, is proud of his company’s history and contribution to the local economy.Boltons Office National Celebrating 120 years of Business in Bendigo - 41 pages covering 1885-2005history, bendigo, merle lummis collection, boltons office national bendigo -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bellows, 1862-1875

This bellows was used at the Warrnambool Racecourse by Master Farrier, Brian Chapman (1931-2017), during the 1970s but its history before then is still being investigated. The bellows have continued to be used from 1978 at Flagstaff Hill's blacksmith's workshop. Even today, in 2021, this same bellows are used by a volunteer blacksmith as he demonstrate the skills and tells of the importance of the blacksmith trade to colonial Australia. This 1860s double-action bellows is a typical form of blacksmith's or shipsmith's bellows. The end is forge-fitted with an iron nozzle or tube, called a tuyere or Tue iron, which concentrates the air to fan the fire or furnace. Tuyeres were traditionally made of cow horn. The double-action design of this bellows efficiently moves air both in and out of the chambers in the one movement of the long handle. The bellows was manufactured by John C. Onions of Birmingham, England, between 1862 and 1875. The stamp with the text, Gold Medal 1862, was also used on the business’ advertising. In 1875 the company was registered and began using the name John C. Onions Limited. JOHN C. ONIONS - John C. (Collingwood) Onions (1841-1904) was the son of a bellows maker of the same name. Onions (born 1841) and his wife Helen married in 1867 and they named one of their children John Collingwood Onions (1868-1913), as was the family tradition. He was well known as a Birmingham manufacturer of patented bellows and other forge-related equipment. He sold to the wholesale and retail markets for both local and overseas customers, including the British colonies. An 1862 advertisement points out that John C. Onions was a “Bellows manufacturer and contractor to Her Majesty’s Honourable Board of Ordinance” and His Imperial Majesty the Emperor of the French [Napoleon Bonaparte]”. The advertisement includes a sketched portrait of the Emperor Napoleon III, and an Imperial Autograph Letter dated May 23, 1854, from Napoleon, Palace of the Tulleries to Mr J C Onions of Bradford Street, Birmingham. In 1863 the company registered a patent on portable forges. In 1871 there were eight employees. John C. Onions Limited became a registered company in 1875. In 1876 an advertisements included that the company were smiths for hearths and tools in general and showed a row of six medallions including one with “Napoleon III, Emperor” and his portrait, and another “ _ _ _ 1862 MEDAL”. Their advertising motto was “For Excellence of Quality”. In 1885 the company merged with William Allday and Sons to become Allday and Onions. This mid-19th century bellows has local historical significance as it were once used by blacksmiths at the Warrnambool Racecourse in the annual racing event that continues today. This bellows is significant as a working example of equipment used in the 1800 and 1900s in the trace of blacksmiths and other metal working smiths. The bellows is technologically significant as it shows the progress from simple bellows to the double-action bellows, a time saving and efficient improvement. The manufacturer John C. Onions is historically significant as a family business that began in the 1600s and continued up until the 1980s.Bellows; large, oval, mechanical double-action smith’s bellows, manually operated, in working condition. The paddles of wood that form the top, middle sections and base of the bellows have flexible leather pieces attached firmly between them, forming airtight double lungs. Cut-outs in the panels allow the bellows to fill with air then force it out. A long handle is connected to pump the bellows and control the quantity and force of the air. The blasts of air are forced through the metal nozzle or tuyere at the end of the bellows and into the forge’s fire. Inscriptions are impressed into the wood on the upper paddle or board of the bellows. There are three circular stamps containing text. Text impressed in the wooden upper paddle of the bellows has been assumed to read “JOHN C. ONIONS, PATENTEES & MANUFACTURERS, BIRMINGHAM””?” “EXTRA” “AWARDED FOR EXCELLENCE OF QUALITY”, made from the following readable text :- “JOHN C ONIONS“ “PATENT - - - & MAN - - - - - - - - -“, “BIR - - - - HAM“, “ _ ERA - - - - “- XTRA-“, “- - - - - - - FOR EXCELL-“ “OF - - - - ITY” Text in the stamp “ - - ECE - - “, “ - - - - - / 1862 / MEDAL”, “- ITY” flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john collingwood onions, john c onions, allday and onions, bellows, smith’s bellows, 19th century bellows, double-action bellows, double-acting bellows, double lung bellows, double chamber bellows, blacksmith tools, blacksmith trade, blacksmith craft, blacksmith equipment, forging equipment, john c onions patented double-action bellows, brian chapman, warrnambool racecourse, blacksmith, shipsmith, iron smith, mechanical bellows -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Precious Opal

In Australia, precious opal is found in Cretaceous age sandstones and mudstones. These sedimentary rocks were deeply weathered and this weathering released silica into the groundwater.Australia is the only part of the world where opalised animal and plant fossils have been found. Opal artefacts several thousands of years old have been discovered in East Africa. As early as 250 BC the Romans prized opals, thought to have come from mines in Eastern Europe, the ancient world's main source of opals. There are many aboriginal dreamtime stories that feature opal. Australian opals discovered during the late 1800's found little favour with European markets but their commercial value increased in the 1900's and in 1932 Australia took over as the major producer of opals in the world and remains the largest producer to this day. Opal is found around the world (Brazil, Mexico, Honduras and the western US) however Australia produces 95% of the world's precious opal and it is our official national gemstone. Opal was first mined commercially at Listowel Downs in Queensland in 1875 and later at White Cliffs in NSW. Today, Coober Pedy (SA) is the main producer of white opal, though in recent years this field has expanded and all types of opals are found. Other centres in SA include Andamooka and Mintabe. Lightning Ridge (NSW) is renowned for black opal and formerly White Cliffs was a large producer of high quality opal. Boulder opals (opals in concretionary ironstone) are mined in Queensland from numerous localities in a zone extending from the Eulo and Cunnamulla district in the south and northwest for a distance of over 700 km to Kynuna in the north. The towns of Quilpie, Yowah and Winton are the main opal mining and wholesale centres. Opals are considered gemstones and have been used in jewellery for thousands of years.Throughout much of history, opals were actually believed to be good luck. The Romans thought that opals were one of the luckiest gemstones and a symbol of hope. In the Middle Ages, opals were believed to be bestowed with all the positive properties of coloured gemstones due to its rainbow-like play of colour. Finally, there is a superstition that you should not wear an opal unless it is your birthstone otherwise misfortune will befall you. This, of course, is far-fetched, but the notion could have been promoted in the late 19th and early 20th Centuries by diamond traders who were trying to increase sales of diamonds and deter people from buying opals. Possibly related to this is the thought that you should set opal jewellery with diamonds as their powers of good fortune will override any negativity held by the opal. The great majority of opal does not show play of colour and is called common opal or potch however this is not the case with a precious opal. Opal is a precious gemstone, like rubies, emeralds or diamonds. Opal is rare, and it is expensive to prospect and mine for.Silica is one of the most common minerals on the planet, but precious opal is very rare – far more rare than diamonds. Precious opal is rare because the natural processes that create it rarely occur.Most (at least 95%) of the opal found by miners is common opal without gem colour. In Australia we call it potch. It can be white, grey, black or amber coloured. Even when a miner finds gem-coloured opal, most of it can’t be cut into gemstones because it’s too thin, or sandy. This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.It is not known where this opal originated, except that it is probably from Victoria, as it has been recorded from many localities in the State. Common Opal is formed from silica-rich water circulating through rocks near the Earth’s surface. It consists of minute spheres of silica arranged in different ways. In common opal, the spheres are of different sizes and randomly arranged, unlike in precious opal where the spheres are of similar size and uniformly arranged in three dimensions. These differences account for common opal generally being translucent to opaque and without the play of colours, or opalescence, displayed by precious opal. Common opal is found in many localities and different geological environments throughout Australia and the world. Precious opal requires special conditions to form and is much less common. Australia produces most to the world’s precious opal. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, precious opal, opal, brazil, mexico, honduras, queensland, coober pedy, gemstones, jewellery, play-of-colour, light blue -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionAdministrative record - Hire Purchase Agreement, c. 1939

From Aussie Velos: Alfred George Healing was born in 1868 in the suburb of Richmond, Melbourne (VIC). Starting in the cycle industry as a cycle builder and repairer in 1898, he obtained the Victorian agency for the English “Haddon” bicycle located on Bridge Road, Richmond. With many years behind him in the bicycle industry in 1907 he opened a small shop from borrowing £50 from his sister and began operating as A.G Healing. Importing bicycle parts Healing was quickly gaining a reputation for his quality and service among the cycling community, with steady business growth, Healing stumbled across an error that had been made in a recent order which resulted in twice the number of bicycle parts received. With no finances to pay for them, Healing decided to cycle around Victoria selling these parts to make the money he needed to fix up the order. As Healing travelled across Victoria he found that there was such a large market place for cycling gear that the order was soon fixed. It became apparent that Healing needed to open cycle shops in various locations. By 1912 Healing decided to open up his own proprietary company in Niagara Lane, Melbourne (VIC), the company was surging with enthusiastic cyclists and commuters and other branches began to spread all over state of Victoria. In 1921 Healing’s son Keith joined the firm and became an apprentice bicycle maker and Healing cycles grew more popular and at peak production 25,000 bicycles were made per year. Shops under the name of Healing were now operating across Australia. The business was now transferred to another location of Melbourne House, Post-office place (MELB). In 1926 Duncan and Co. wholesale and retail distributors of automotive parts was absorbed and was occupied in a larger building in Franklin Street (MELB) to maintain the warehouse operations. A.G Healing was now a public company. By 1933 the firm also began to specialize in importing radios and later began to make their own. One of the many Champions who rode on a Healing cycle was W.K “Bill” Moritz. His achievements included winning all major events in Australia and New Zealand during the years of 1936-37 path racing season. In 1936 Healing released a lightweight cycle that would rule in their supreme line-up, built from the lightest possible materials, the frame and forks were chrome plated, stripped for racing weighed exactly 16 1/2 lbs. It was fitted with special “Osgear” three-speed gear and built specially built for D. Byrant. By 1937, Healing cycles were being ridden by many, at the exhibition board track Jack Molloy won the Victorian ten-mile amateur championship, Bill Moritz captured the five mile professional, and Tassle Johnson the five-mile amateur scratch race. These wins brought up the total championships won in one week by Healing cycles to six.A hire agreement (hire purchase) between H.L. Vivian and R&G Finances Pty Ltd, for a Healing 'A' bicycle, with Eadie Coaster Hub brake. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Guillotine, c. 1880's

This guillotine is a hand operated machine specifically designed to cut through multiple sheets of paper or card. It has a very heavy and sharp single blade knife mounted between vertical guides or runners. The main users of a machine like this is in by the printing and publication binding industry. Book binding companies use a guillotine to evenly trim the pages of a book after it has been bound. The way the guillotine is used is - paper or card is stacked squarely on the flat table and pushed firmly against the back guide - the handle below the table at the front of the machine is wound around, which brings the back guide forward, pushing the paper stack forward and positioning the centre of the stack below the vertical frame - the upper wheel is wound around, which brings the clamp and firmly in position on top of the paper, to hold it very firmly - the large wheel on the side of the machine is turned around to lower the long sharp blade down onto the pages and cut them through. The sharp edge of the blade is protected somewhat from becoming blunt; a block of wood sits in the table under the stack of paper An early model of a guillotine was patented in 1837 by Thirault, who built a model with a fixed blade. Guillotines similar in principal to this one were patented by Guillaume Massiquot in 1844 and 1852. Over the years many improvements have been made and operation has moved from man power to electricity. Oscar Friedheim Ltd. was the importer and wholesaler of a large range of machinery and equipment for the printing and bookbinding industry. He sold most of his equipment under his own name. On this guillotine or paper cutter he refers to the origin of the guillotine’s manufacture only as “German Manufacrure”. A reference book “Commercial Bookbinding: a description of the processes and the various machines used" by Geo. Stephen, 1910, recommends Oscar Friedheim, amongst others, for the supply of “reliable cutting machines for hand or power”. It also recommends Oscar Friedheim’s for a wide range of other printing machinery and processes. OSCAR FRIEDHEIM LIMITED, LONDON Oscar Friedheim Ltd. was established in 1884 and operated from Ludgate in London. The company was an importer and wholesale supplier in the 1880’s, offering machinery and equipment for the printing and packaging industry for the UK and Ireland. The company became incorporated in 1913. An advertisement of 1913 includes a telegraphic code plus two telephone numbers for Oscar Friedheim Ltd and invites readers to call at the Ludgate, London, showrooms to see the machines working. The company later became Friedheim International Ltd. The book titled “Friedheim, A Century of Service 1884-1984 by Roy Brewer, celebrates Oscar Friedheim’s achievements. Friedheim International currently operates from Hemel Hempstead, on the northern outskirts of London UK. It promotes itself as “… the leading supplier of finishing, converting and packaging machinery to the printing, graphic arts, and highly varied packaging industries in the UK and Ireland. The company’s policy is simple – “employ the best people, work with the best equipment manufacturers in the world, and treat our customers as partners!” The company still sells guillotines. The guillotine is significant for its ability to represent aspects of the printing trade in Warrnambool and in a typical port town circa 1850 to 1910. It represents communication methods and processes used in the time before electrically powered equipment became common in industry.Guillotine (or paper cutter), hand operated. Metal framework with vertical guides, stand and metal mechanical parts including wheels and gears. Table with back guide; handle below front of table winds to move the back guide. A wheel at top of machine winds to adjust pressure of the clamp on the work on the table below it. The cutting blade fits between vertical guides; a timber insert in the table below the blade helps minimise the loss of sharpness of the blade. A handle on the side of the machine turns a large spoked wheel, which rotates a large gear, causing the blade to move up and down. Makers details are on a small oval plaque with embossed maker’s details is screwed onto main body. Maker is O Friedheim, London, and the machine is of German manufacture, circa late 1880’s.Maker’s plaque inscribed "O. FRIEDHEIM / London / German Manufacture"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, printing machinery, printer’s guillotine, paper guillotine, paper cutter machine, oscar friedheim ltd london, friedheim international ltd, bookbinding industry, printing industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to Late 19th Century