Showing 227 items

matching wood cut

-

Eltham District Historical Society Inc

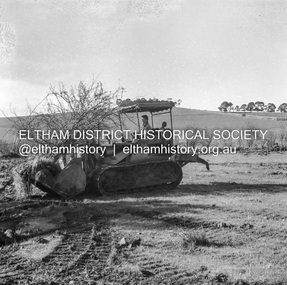

Eltham District Historical Society IncNegative - Photograph, J.A. McDonald, Kangaroo Ground-Queenstown Road, Aug. 1960

(Kangaroo Ground-St Andrews Road) “Rymers” Corner – shifting Hawthorn hedges on Tompkins property Council’s Drott 6 Woods Drott 9 August 1960 Showing hedge in rear already transported EDHS_05569-55 (EDHS_05577-3/4) and EDHS_05569-56 (EDHS_05577-5/6) - Hawthorn Hedges, Kangaroo Ground 50-50 ELTHAM, CUT THE HEDGES! While all of us are talking about the road toll, Eltham Council must have been in long recess. Around Kangaroo Ground are farmers’ hawthorn hedges shrouding dangerous corners on busy roads. If the council does not insist on their removal for a distance clear enough for safe driving, then it must be held culpable for the accidents that are bound to happen. – WAKE UP (Melbourne) ELTHAM, CUT THE HEDGES! 50-50 (1960, 6 January), The Sun (News clipping held in SEA_74-1_007) ‘BAD HEDGES’ WILL GO “We know there are some bad hedges on corners in the Kangaroo Ground area, but roadworks this year will eliminate them,” the Eltham Shire secretary, Mr Maxwell B. Watson, said yesterday. A reader in 50-50 yesterday complained of farmers’ hawthorn hedges obscuring drivers’ views at bad corners on busy roads in the Kangaroo Ground district. Mr Watson said the roadworks were deviations to remove the sharp turns, and the road would cut back into paddocks. The hedges would go at the same time. Meanwhile, the shire had power to require owners to cut back hedges, and this would be done if specific instances were reported and found justifiable. ‘BAD HEDGES’ WILL GO (1960, January 7), The Sun (News clipping held in SEA_74-1_007)Record of various Shire of Eltham infrastructure works undertaken during the period of 1952-1962 involving bridge and road reconstruction projects, sometimes with Eltham Shire Council Project Reference numbers quoted. It was during this period that a number of significant improvements were made to roads and new bridges constructed within the shire that remain in place as of present day (2022). In many situations, the photos provide a tangible visible record of infrastructure that existed throughout the early days of the Shire. The album was put together by or under the direction of the Shire Engineer, J.A. McDonald.infrastructure, shire of eltham, 1960-08, garden hill, kangaroo ground, kangaroo ground-queenstown road, kangaroo ground-st andrews road, rymers corner, bulldozer, drott -

Eltham District Historical Society Inc

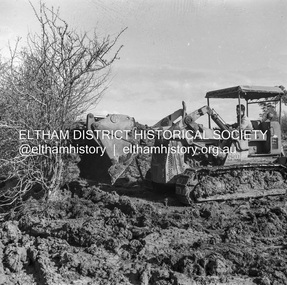

Eltham District Historical Society IncNegative - Photograph, J.A. McDonald, Kangaroo Ground-Queenstown Road, Aug. 1960

(Kangaroo Ground-St Andrews Road) “Rymers” Corner – shifting Hawthorn hedges on Tompkins property Council’s Drott 6 Woods Drott 9 August 1960 Showing method of lifting clumps of Hawthorn EDHS_05569-55 (EDHS_05577-3/4) and EDHS_05569-56 (EDHS_05577-5/6) - Hawthorn Hedges, Kangaroo Ground 50-50 ELTHAM, CUT THE HEDGES! While all of us are talking about the road toll, Eltham Council must have been in long recess. Around Kangaroo Ground are farmers’ hawthorn hedges shrouding dangerous corners on busy roads. If the council does not insist on their removal for a distance clear enough for safe driving, then it must be held culpable for the accidents that are bound to happen. – WAKE UP (Melbourne) ELTHAM, CUT THE HEDGES! 50-50 (1960, 6 January), The Sun (News clipping held in SEA_74-1_007) ‘BAD HEDGES’ WILL GO “We know there are some bad hedges on corners in the Kangaroo Ground area, but roadworks this year will eliminate them,” the Eltham Shire secretary, Mr Maxwell B. Watson, said yesterday. A reader in 50-50 yesterday complained of farmers’ hawthorn hedges obscuring drivers’ views at bad corners on busy roads in the Kangaroo Ground district. Mr Watson said the roadworks were deviations to remove the sharp turns, and the road would cut back into paddocks. The hedges would go at the same time. Meanwhile, the shire had power to require owners to cut back hedges, and this would be done if specific instances were reported and found justifiable. ‘BAD HEDGES’ WILL GO (1960, January 7), The Sun (News clipping held in SEA_74-1_007)Record of various Shire of Eltham infrastructure works undertaken during the period of 1952-1962 involving bridge and road reconstruction projects, sometimes with Eltham Shire Council Project Reference numbers quoted. It was during this period that a number of significant improvements were made to roads and new bridges constructed within the shire that remain in place as of present day (2022). In many situations, the photos provide a tangible visible record of infrastructure that existed throughout the early days of the Shire. The album was put together by or under the direction of the Shire Engineer, J.A. McDonald.infrastructure, shire of eltham, 1960-08, garden hill, kangaroo ground, kangaroo ground-queenstown road, kangaroo ground-st andrews road, rymers corner, bulldozer, drott -

Eltham District Historical Society Inc

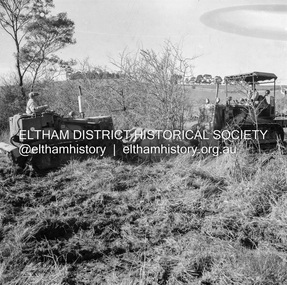

Eltham District Historical Society IncNegative - Photograph, J.A. McDonald, Kangaroo Ground-Queenstown Road, Aug. 1960

(Kangaroo Ground-St Andrews Road) “Rymers” Corner – shifting Hawthorn hedges on Tompkins property Council’s Drott 6 Woods Drott 9 August 1960 Showing method of lifting clumps of Hawthorn EDHS_05569-55 (EDHS_05577-3/4) and EDHS_05569-56 (EDHS_05577-5/6) - Hawthorn Hedges, Kangaroo Ground 50-50 ELTHAM, CUT THE HEDGES! While all of us are talking about the road toll, Eltham Council must have been in long recess. Around Kangaroo Ground are farmers’ hawthorn hedges shrouding dangerous corners on busy roads. If the council does not insist on their removal for a distance clear enough for safe driving, then it must be held culpable for the accidents that are bound to happen. – WAKE UP (Melbourne) ELTHAM, CUT THE HEDGES! 50-50 (1960, 6 January), The Sun (News clipping held in SEA_74-1_007) ‘BAD HEDGES’ WILL GO “We know there are some bad hedges on corners in the Kangaroo Ground area, but roadworks this year will eliminate them,” the Eltham Shire secretary, Mr Maxwell B. Watson, said yesterday. A reader in 50-50 yesterday complained of farmers’ hawthorn hedges obscuring drivers’ views at bad corners on busy roads in the Kangaroo Ground district. Mr Watson said the roadworks were deviations to remove the sharp turns, and the road would cut back into paddocks. The hedges would go at the same time. Meanwhile, the shire had power to require owners to cut back hedges, and this would be done if specific instances were reported and found justifiable. ‘BAD HEDGES’ WILL GO (1960, January 7), The Sun (News clipping held in SEA_74-1_007)Record of various Shire of Eltham infrastructure works undertaken during the period of 1952-1962 involving bridge and road reconstruction projects, sometimes with Eltham Shire Council Project Reference numbers quoted. It was during this period that a number of significant improvements were made to roads and new bridges constructed within the shire that remain in place as of present day (2022). In many situations, the photos provide a tangible visible record of infrastructure that existed throughout the early days of the Shire. The album was put together by or under the direction of the Shire Engineer, J.A. McDonald.infrastructure, shire of eltham, 1960-08, garden hill, kangaroo ground, kangaroo ground-queenstown road, kangaroo ground-st andrews road, rymers corner, bulldozer, drott -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, J.A. McDonald, Kangaroo Ground-Queenstown Road, Aug. 1960

(Kangaroo Ground-St Andrews Road) “Rymers” Corner – shifting Hawthorn hedges on Tompkins property Council’s Drott 6 Woods Drott 9 August 1960 EDHS_05569-55 (EDHS_05577-3/4) and EDHS_05569-56 (EDHS_05577-5/6) - Hawthorn Hedges, Kangaroo Ground 50-50 ELTHAM, CUT THE HEDGES! While all of us are talking about the road toll, Eltham Council must have been in long recess. Around Kangaroo Ground are farmers’ hawthorn hedges shrouding dangerous corners on busy roads. If the council does not insist on their removal for a distance clear enough for safe driving, then it must be held culpable for the accidents that are bound to happen. – WAKE UP (Melbourne) ELTHAM, CUT THE HEDGES! 50-50 (1960, 6 January), The Sun (News clipping held in SEA_74-1_007) ‘BAD HEDGES’ WILL GO “We know there are some bad hedges on corners in the Kangaroo Ground area, but roadworks this year will eliminate them,” the Eltham Shire secretary, Mr Maxwell B. Watson, said yesterday. A reader in 50-50 yesterday complained of farmers’ hawthorn hedges obscuring drivers’ views at bad corners on busy roads in the Kangaroo Ground district. Mr Watson said the roadworks were deviations to remove the sharp turns, and the road would cut back into paddocks. The hedges would go at the same time. Meanwhile, the shire had power to require owners to cut back hedges, and this would be done if specific instances were reported and found justifiable. ‘BAD HEDGES’ WILL GO (1960, January 7), The Sun (News clipping held in SEA_74-1_007)Record of various Shire of Eltham infrastructure works undertaken during the period of 1952-1962 involving bridge and road reconstruction projects, sometimes with Eltham Shire Council Project Reference numbers quoted. It was during this period that a number of significant improvements were made to roads and new bridges constructed within the shire that remain in place as of present day (2022). In many situations, the photos provide a tangible visible record of infrastructure that existed throughout the early days of the Shire. The album was put together by or under the direction of the Shire Engineer, J.A. McDonald.infrastructure, shire of eltham, 1960-08, garden hill, kangaroo ground, kangaroo ground-queenstown road, kangaroo ground-st andrews road, rymers corner, bulldozer, drott -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white photographs, James (Jim) Pleasance, Pruning Display

Black and white photographs of various sizes pasted on cardboard for display purposes. Some annotated. (1) (2) Difference between leaf and fruit buds. (3) "The 'rod' or whip is most suitable plant to commence training." (4) Planted and pruned fruit tree. "School of Horticulture and Primary Agriculture Burnley B. 1 " stamped on reverse. (5) "Pear Tree-Unpruned (1) June." (6) "Same Pear Tree-Pruned (2) June." (7) Young unpruned "William bon Chretien". Reverse, Burnley Stamp. (8) Same tree pruned. Reverse, Burnley Stamp. (9) Unpruned pear tree. (10) "Narrabben" plum before inserting branch spreaders. (11) With branch spreaders. (12) Close up of some of its branches without spreaders. (13) Close up of branch with seaders. (14) Plum tree with spreaders. (16) Close up of fruiting spurs. (17) "Apple Blossom Oct. Reverse, p 163(Oct." )(18) Same photograph enlarged. (20) Close up of fruiting buds. (21) Old unpruned apricot tree. (22) "Unpruned branch of apricot tree." (23) Close up of apricot branch. (24) "Same branch-apricot-pruned June Reverse, p99 (June)."(25) Pruned branch stump of mature fruit tree.(26) "Clean saw cuts with sharp knife." (27) "Treat all large wounds on trees to avoid infection by wood rotting fungus." (28) "Apply coating of lead paint or grafting mastic." (29) "Branch of lemon-unpruned Aug. Reverse, p157 (Sept.)." (30) "Same branch of lemon-pruned Aug. Reverse, p 157 Aug."(31) "Young climbing rose-ready for planting-July." (32, 33) Grape vine before pruning. (34) Same vine pruned and trained. (35) Older vine pruned.fruit bud, rod, whip, school of horticulture and primary agriculture, burnley, pear tree, spreaders, plum tree, apricot tree, fungus, lead paint, lemon, roses, grape vine, leaf bud, training, fruiting spurs, apple blossom, grafting mastic, teaching, a w jessep -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumMemorabilia - Framed Photograph, Private Robert Mactier VC

Private Robert Mactier VC from Tatura VictoriaLarge dark wooden frame with a gold wood inner frame, with glass. A piece of brown plywood to fit frame has 4 holes cut, 2 small at top, 1 large in middle and 1 square at bottom. The top left square has a picture of the VC medal, the other square on right is a red and brown triangle square. The large middle cut out has a picture of Robert Mactier. The bottom square has a short description about Robert Mactier. Across the top is Pte Robert Mactier in fancy writing. private robert mactier, vc medal -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Vertebrae, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Whalebone The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The bone of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as whalebone. Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale bone Vertebrae with advanced stage of calcification as indicated by deep pitting. Off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Jaw Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale jaw bone one side, long & curved with advanced stage of calcification off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Ballarat Tramway Museum

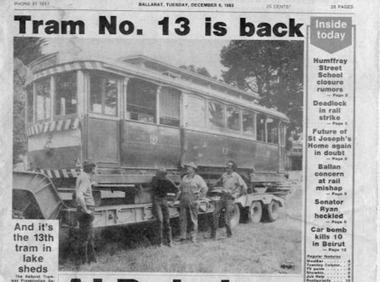

Ballarat Tramway MuseumNewspaper, The Courier Ballarat, "Tram No. 13 is back", 6/12/1983 12:00:00 AM

Yields information about the arrival back in Ballarat of No. 13 from Lake Goldsmith, prior to unloading.825 Front page (& rear page) of the Ballarat Courier of Tuesday Dec. 6, 1983 featuring with a photograph of the return of the SECV Ballarat No. 13 to the BTPS depot. Sub heading of "And its the 13th tram in the lake sheds". Mentions owners, Lake Goldsmith and work needed to return the tram to service. Has photograph of Peter Winspur, Garry Wood, Peter Allen and Warren Doubleday standing by the truck with tram prior to unloading. 825.1 Newspaper Clipping of above, item cut out with only date on the top edge. See Reg Item 3830 for a print of the actual photograph used.trams, tramways, tram recovery, 13, btps -

Vision Australia

Vision AustraliaPhotograph - Image, 2005 Kodak Carols by Candlelight launch and burying of time capsule, 25/11/2005

On November 25, 2005 the Kodak Carols by Candlelight launch was held in the browsing library at Kooyong with a large number of staff and guests in attendance. Speeches were made by Gerard Menses, Graeme Innes, Greg McKibbin, Marjorie West and Marina Prior. The crowd got to open Christmas crackers and hear some songs from Marina Prior before a cake was cut and shared. Afterwards everyone headed outside for the burying of the time capsule by Jarryd Clifford and Reuben Ryan, in the garden outside the cafe. Then Marina posed for some photographs and the Kodak printing kiosk was demonstrated in the browsing library.119 images of attendees at the Carols launch and burying of time capsulecarols by candlelight, vision australia, gerard menses, marjorie west, graeme innes, greg mckibbin, jarryd clifford, ania zamecznik, sandra alder, andrew ferrarese, joanne, cherry johnson, tony clarke, lynne kells, rita townsend-booth, jennifer gibbons, roberta ashby, david blyth, margaret bashfield, colleen thom, peter lowrey, kevin murfitt, kodak, karen knight, tony shepherd, peter north, anna fairclough, ashley wood, stephen jolley, time capsule, reuben ryan -

Melbourne Tram Museum

Melbourne Tram MuseumPlaque, Swanston Trams, "Service to Melbourne's Trams 1919 - 1999", 1999

Item was given to Swanston Trams employees at the time of the changeover of ownership of Swanston Trams from Government to Private in August 1999. Swamston trams later became known as M>Tram. See reference.Demonstrates an action by Swanston Trams to recall 80 years of Government operated trams in Melbourne at the time of privatisation.Wood block with bevelled edges, with a brass coloured MMTB emblem and a engraved piece "Service to Melbourne's Trams 1919 - 1999". Has a wall hanging cut out on the rear. Contained within a cardboard box with the MMTB emblem and title on the front and Swanston Trams logo and name on the rear.tramways, swanston trams, m>tram, privatisation, employees, momentoes, plaque -

Melbourne Tram Museum

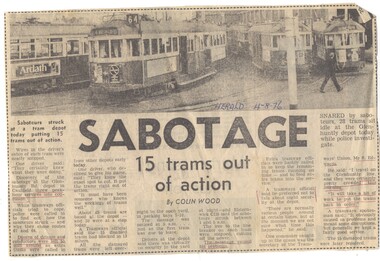

Melbourne Tram MuseumNewspaper, The Melbourne Herald, Colin Wood, "Sabotage 15 trams out of action", 4/08/1976 12:00:00 AM

Newspaper clipping from the Melbourne Herald, 4-8-1976, titled "Sabotage 15 trams out of action", with a photo of a number of trams at Glenhuntly depot, including No. 347 when wires in the cabs of 15 trams were cut, blocking another 13 trams in the depot. Item written by Colin Wood.Some parts of the item have been underlined in red.trams, tramways, mmtb, melbourne, incidents, electric failure -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Adze

An Adze is versatile cutting tool similar to an axe but with the sharp cutting edge perpendicular to the handle rather than parallel. The wooden handle of this adze is shaped like an axe handle and the blade also has a slight curve. They are used for smoothing or carving wood such as sleepers An adz, with its long handle, cuts with the grain, and the nature of the chips is different from an axe. While they have a similar shape, they should never be confused with a hoe used or mattock for agriculture and horticulture.Carpenter's adze or cutting adze The tapered eye in the adze and tapered handle end forces the head to tighten when swung; but enables removal of the head for sharpeningtimber tools -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionCrosscut saw set gauges

The tips of each cutting tooth of a saw are bent (set) slightly away from the plane of the saw. Alternate teeth are set (and sharpened) in opposite directions. The set helps prevent the saw binding in the wood by cutting a kerf (the slot in the wood) that is slightly wider than the saw's thickness. Too little set and the saw binds; too much set results in more work to cut the wider kerf and could lead to too much side movement of the saw and a curving cut. The saw set gauge is used to measure the set of the saw tooth. The amount of set can be from almost nothing in dry hardwood to perhaps 1mm for some softwoods. The spider has three legs of the same length and a longer fourth leg. On a flat surface, the three short legs contact the surface while the long leg is just shy of the surface by the degree of 'set'. The spider is placed such that the three short legs are on the face of the saw with the longer leg touching the tip of the tooth - the tooth is bent to match the gauge.metal spiders used to set the teeth of crosscut sawsforests commission victoria (fcv), hand tools -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - The Honorable H.V. MacLeod, MLC JP, c. 1950

Portland Town CouncilRetouched (colour) photograph of a man in a suit, posed in ¾ view, upper torso. He has grey hair, cut short, glasses and is wearing a badge on his left lapel. Framed in decorative paper mache/plaster and wood frame, painted gold, in gold mount.Front: Portland/Town Council (Black and red text, upper centre) The Honorable/H.V. MacLeod MLC JP/Mayor 1946-49 (black and red text, lower centre) Back: (no inscriptions)hv macleod, civic photography, civic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCraft - Ship Model, Sovereign of the Seas, Made between 1930-1955

This meticulously hand crafted ship model is one of the most intricate and challenging projects for a ship modeller to create. Jim Williams took up the challenge, choosing to make all of the components by hand, following a plan of the ship rather than purchasing a pre-made kit. He even made his own tools specifically for working with this model. The “Sovereign of the Seas” 1637-1697 - The magnificent ship “Sovereign of the Seas” was ordered by Charles I of England, who desired a giant Great Ship to be built. It was built by Peter Pett under the guidance of his father Phineas, the King's master shipwright, and launched with 102-guns at Woolwich Dockyard on 13th October 1637, as the Navy’s second three-decker first-rate ship. It was the most extravagantly decorated warship in the Royal Navy, bought with the help of a special 'Ship Money' tax imposed by the King. Soon afterwards the ship was remodelled and cut down to a safer and faster ship. Over the ship’s lifetime it was renamed “Commonwealth”, then in 1650 it became simply “Sovereign” then again after a rebuild in 1660 it was named “Royal Sovereign”. By 1642 the ship’s armament had been reduced to 90 guns. In 1651 Sovereign was made more manoeuvrable by reducing the upper works. It served throughout the wars of the Commonwealth and became the flagship of General Robert Blake. It was involved in all of the great English naval conflicts fought against the United Provinces and France and was referred to as 'The Golden Devil' by the Dutch. By 1660 the armament was changed attain to 100 guns. After the English Restoration, it was rebuilt as a first-rate ship of the line, with flatter gun decks and 100 guns, and most of the carvings were removed. During the First Anglo-Dutch War, in a secret session on 21 October 1652, the States-General of the Netherlands announced reward money for the crews of fire ships that succeeded in destroying enemy vessels; the Sovereign was singled out with an extra prize of 3000 guilders to sink or ruin it. Although repeatedly occupied by the Dutch, the Sovereign was retaken every time by the British and remained in service for nearly sixty years as the best ship in the English fleet. The Sovereign was in regular service during the three Anglo-Dutch Wars, surviving the Raid on the Medway in 1667. After a second rebuild in 1685 the Sovereign was relaunched as a first-rate ship of 100 guns, before taking part in the outset of the War of the Grand Alliance against Louis XIV of France, venturing into the Irish Sea, and later participating in the Battle of Beachy Head in 1690 and the Battle of La Hougue. At this time she was more than fifty years old. It was the first ship in history to fly ‘royals’ above the topgallant sails and a top gallant sail on the jigger-mast. The Sovereign eventually became leaky and defective with age and was laid up at Chatham when, on 27th January 1697, the famous ship caught fire, burning to the waterline. Jim Williams, the model’s maker - Jim (James Bernard) Williams was born in 1888 at The Forth in Scotland. He lived in Tasmania for some time and enlisted to fight in France in WW1. After the war he moved to Warrnambool, Victoria, where he worked at the Cramond & Dickson clothing store until the Great Depression in the 1930’s. He was later employed at Fletcher Jones Menswear, where he worked for 27 years until just before his death in 1959. Jim was a passionate ship model builder. He worked on his model ships between 1930 and 1955, including The Endeavour and The Sovereign of the Seas, which was one of the most intricate historic ship models to build. He had a table set up in a bay window and worked on them on and off using a jeweller's eye glass on the finer pieces. Jim’s long-time employer, Fletcher Jones, knew of Jim’s hobby and skill as a ship model builder and requested Jim to describe the model, Sovereign of the Seas, with the view of putting it on display. When the model was finished there was a full article and photo in The Standard newspaper. Jim described his work on the ship mode “Sovereign of the Seas” in correspondence to his then employer, Fletcher Jones. The document gives us an insight into his skill, patience, and regard for replicating the details of the original ship. Some of the details are: "In making the model the time taken to make certain items might be of interest. For instance "The Great Lantern" on the stern, four weeks, a similar time for the figurehead of St George & the Dragon. "The lower shrouds three to each side about six weeks & the rigging as whole several months. There are nearly 300 blocks and pulleys ranging from nearly 1 / 16 inch in diameter. Dead eyes were bored with 3 to 5 holes. To do this needles of different sizes, set in handles & ground to wedge ends were used. Glass cut and ground to shape were used windows. All gun-port covers (74) hinged. "All guns and anchors made of wood. Nothing for the model was purchased ready-made; everything hand made." Jim’s family donated the ship model along with many associated tools, accessories and papers. The model represents the Sovereign of the Seas. The Royal Navy ship of the line launched in 1637 has a significant British maritime heritage. These days the Sovereign of the Seas still remains one of the most intricate historic ship models to build, representing to the model enthusiast a true challenge to the art of model shipbuilding. The model of Sovereign of the Seas in Flagstaff Hill's collection is an exemplary example of a ship model built and hand crafted from a plan with the making of every item on the model, not a model kit with prefabricated parts. It was made by a local Warrnambool man Jim Williams as a leisure activity in the mid 20th century. The hobby and craft of ship model making has resulted in visual representations of the changes in maritime technology and advances in world-wide navigation. Ship model of HMS Sovereign of the Seas, a 17th century British warship. The handmade model is in wooden framed, airtight glass case. All components were hand crafted. Many of the tools used were made by the model maker, Jim Williams. An inscribed plaque is within the case. Inscribed on plaque "SOVEREIGN OF THE SEAS / 102 GUNS - 1634"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, model ship, vessel sovereign of the seas, jim williams, james bernard williams, the forth tasmania, freda williams, heather williams, phyllis bowditch, fletcher jones staff 1936, 17th century sailing ship, cramond and dickson, sovereign of the seas, royal sovereign, sovereign, charles 1, ship model