Showing 22157 items

matching sider

-

Phillip Island and District Historical Society Inc.

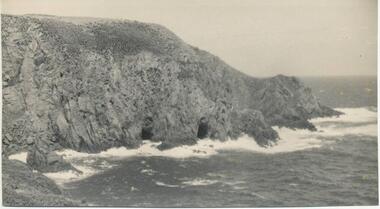

Phillip Island and District Historical Society Inc.Photograph, Bryant West

One of a collection of over 400 photographs in an album commenced in 1960 and presented to the Phillip Island & Westernport Historical Society by the Shire of Phillip IslandPhotograph of waterline with caves southwest side of Cape Woolamai.local history, photography, photographs, coastline, cape woolamai, phillip island, caves, john jenner, bryant west -

![Advertising Leaflet, Watsonia Primary School Open Day 16 March [2019], 2019_03](/media/collectors/4f729f5697f83e03086015b8/items/5cf86eb121ea6708e0be7f93/item-media/5cfc7a6521ea670f4c834c91/item-fit-380x285.jpg) Greensborough Historical Society

Greensborough Historical SocietyAdvertising Leaflet, Watsonia Primary School Open Day 16 March [2019], 2019_03

Watsonia Primary School Open Day and school fair, 10.00 - 2.00 pm, 16/03/2019.Printed on one side in green and pink on white paperAddress, email and telephone numberwatsonia primary school -

Greensborough Historical Society

Greensborough Historical SocietyBusiness card, Health Land, 2019_

Health Land is a health and wellness massage service, located at 3/83 Main Street GreensboroughPart of a collection relating to local businesses.Printed in green and orange on white card, on both sidesTelephone no., address and services informationhealth, main street greensborough -

Greensborough Historical Society

Greensborough Historical SocietyBusiness card, John's Barber Shop, 2019_

John's Barber Shop is a men's hairdresser at 4 Hailes Street East GreensboroughPart of a collection relating to local businesses.Printed on one side in red and blue on white cardTelephone no. and addresshairdessers, hailes street greensborough -

Greensborough Historical Society

Greensborough Historical SocietyBusiness card, Transfixed automatics: automatic transmission specialist, 2019_

Transfixed Automatics are automatic transmission specialist located at 24 The Concord BundooraPart of a collection relating to local businesses.Business card, printed both sides in red and blueAddress, telephone and fax nos. and email, with services description and appointment space.motor cars, transfixed automoatics, the concord bundoora -

Greensborough Historical Society

Greensborough Historical SocietyArticle, The Adams Family, 2019_

George Adams and later his son Thomas, ran the Adams Butchery at 13 Watsonia Road Watsonia between about 1949 and 1980.2p doubled sided, text, advertisement and col. photographadams family, adams butchery, watsonia road watsonia -

Greensborough Historical Society

Greensborough Historical SocietyLeaflet, with Document, Climate change Q & A, 14/11/2019

Leaflet advertising a community meeting on climate change on 14/11/2019, with notes on the meeting by Rosie Bray.Col. leaflet printed both sides, with typed notesclimate change, kate thwaites, mark butler -

Greensborough Historical Society

Greensborough Historical SocietyBusiness card, Buckingham and Company Estate Agents, Buckingham & Company Estate Agents, 2018c

Business located at 104 Grimshaw Street Greensborough. Other offices at Eltham and MontmorencyBusiness card, printed both sides, reverse in colourJayne Cavaggion, Marketing & Advertising Managerlocal businesses, buckingham & company real estate agents, grimshaw street greensborough -

Greensborough Historical Society

Greensborough Historical SocietyCorrespondence, Colin Brooks, North East Link - connecting our community, 2018_05

Circular letter sent by Colin Brooks MP to Mrs Marilyn Smith, discussing the proposed North East Link.Single sheet, printed in both sides, col. photographs.north east link, marilyn smith, colin brooks -

Greensborough Historical Society

Greensborough Historical SocietyProgram, Melbourne Moomba Festival, Melbourne Moomba Festival 1955, 12/03/1955

Program for Melbourne Moomba Festival; March 12-26, 1955. (Copy)Photocopy of double-sided A4 page, folded once.moomba, melbourne moomba festival 1955 -

![Menu, Clay Oven [Formerly Dobell's Cafe], 18/11/2015](/media/collectors/4f729f5697f83e03086015b8/items/56e0d9922162f111f86be043/item-media/5700c7ec2162f110a47ed0ea/item-fit-380x285.jpg) Greensborough Historical Society

Greensborough Historical SocietyMenu, Clay Oven [Formerly Dobell's Cafe], 18/11/2015

Menu collected at GHS function. This restaurant was formerly Dobells. Black & white paper menu printed both sidesAbel 18/11/15 and others, signed by staff on frontclay oven restaurant, dobells -

Greensborough Historical Society

Greensborough Historical SocietyTicket, Metropolitan Transit, Inner Plus One Travelcard, 1986_07

Single use ticket used 1 August 1986 in Greensborough neighbourhood for train or bus trip.Travelcards were used in the Melbourne Metropolitan area until the introduction of the Myki card.Card, printed both sides, blue and yellow ink.travel ticket, transportation -

Greensborough Historical Society

Greensborough Historical SocietyInvitation, Banyule City Council, 2014 Banyule Mayoral Ball, 03/10/2014

Invitation to Rosie Bray to the 2014 Banyule Mayoral Community Ball, The Centre Ivanhoe, 275 Upper Heidelberg Road Ivanhoe, 3 October 2014Card, printed both sides in colour, with postage envelopebanyule city council, rosie bray -

Greensborough Historical Society

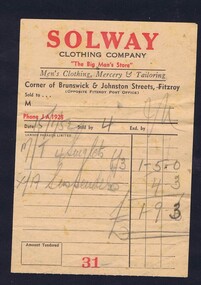

Greensborough Historical SocietyReceipt, Solway Clothing Company, Solway Clothing Company 1952, 15/01/1952

Receipt for purchase of four singlets and suspenders value pound 1/9/3 from Solway Clothing Company 15/1/1952.Printed on one side in red and black on white paperHand-written receipt.solway clothing compay, black family -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDomestic object - Tea Towel, 1930s

Belonged to Mrs Jane Rose, Portland (Mother of donor)Unused, linen, red check along side borders.domestic, housework, tea towel -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionAccessory - Pen holder, n.d

Part of Graham Collection, donated by the Family of Misses Mary and Edith Maude Graham, of 4 Blair Street, Portland.Rectangular glass shallow dish with cut pattern in sides. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionLetter - Poem, n.d

Light card, hand written both sides, poems -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - unidentified building, Portland, n.d

Coloured photograph of the side of a house, including chimney - unidentifiedphotography, building, house -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSlide - Slide - Construction Portland/Cashmore Airport, c. 1980

Coloured slide. View of side of building under construction. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Eltham Community Centre, Pitt Street, Eltham

Colour photograph of Eltham Community Centre, north sidecommunity centre, public buildings, pitt street, main road, eltham -

Ringwood and District Historical Society

Ringwood and District Historical SocietyPhotograph, Coach and Horses Hotel, Whitehorse Road, Ringwood. 1924

Appears to be reproduction of newspaper photograph. South Side of highway.Written below one photograph, "Photo of Coach and Horses Hotel, corner of White Horse Road and Madden Street. Enter Estate at Madden Street". 1924. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Federation University Historical Collection

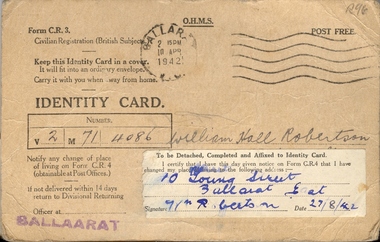

Federation University Historical CollectionDocument - Identity card, Untitled, William Hall Robertson's identity card, 1924-10/4/1942

This card was witnessed by Elizabeth Ann Robertson of 1004 Mair St, Ballarat. It most probably has something to do with security during World War 2.Double sided card with handwritten details on a printed cardworld war two, william hall robertson, william robertson, identity card, letterhead, brinds propriety limited, federal distilleries -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumWicker Mantle

Over mantle, scrolled design with four side shelves.furniture, mantle, wicker, shelves -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumTurkey Stone, 1800s

Oblong stone. All sides show evidence of rubbing.turkey stone, chinese, goldfields, harrietville -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumDaisy Wheel, Bourke's, Prior to 1901

Brass daisy needle with long hook attached to the side. -

Federation University Historical Collection

Federation University Historical CollectionDocument, Education Department, Victoria, Education Department Victoria Merit Certificate Examination for English, 2017, 20/11/2017

Double sided printed English Merit Certificate Examination.examination, victorian education department, english examination, merit certificate -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Tug, n.d

Port of Portland Authorityport of portland archives, tug, slipway -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Tanker Berth, Portland, n.d

Port of Portland Archives Authorityport of portland archives, tanker berth, harbour, facilities, marine, portland -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - dredging, n.d

Port of Portland Authority archivesFront: (no inscriptions) Back: (no inscriptions) pencil crop marks over back.port of portland archives, portland harbour trust, dredging