Showing 315 items

matching pitch

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Nail, circa 1825

Nails such as this solid copper nail were forged by blacksmiths. A nail of this length could have been used for the ship's decking. It was recovered from the shipwreck of the barque Children. The Children wrecking: The barque Children was one of the first vessels to be lost in the Western District the vessel was wrecked to the east of Warrnambool on 14th January 1838. When it ran ashore in hurricane-force winds, 22 passengers and crew were fortunate to escape being battered to death on the rocks. The Children broke up within 20 minutes, sweeping sixteen of those on board to their deaths. After eleven days, the survivors, all of whom were injured, were rescued and taken to Portland. According to Lloyd's Shipping Register 1837-1839, the Children was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. Registration number 123/1837, James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered in 1837” at Launceston registered number 6/1837. In 1838 the Children, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year carrying a general cargo including house bricks used for ballast. On the 11th of January 1839, the Children sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the Children were “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane-force storms, eventually clearing on the early morning of the 14th. However, it was too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The Children collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost including 8 children. The Henty brothers contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for James Henty and his brothers, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of establishing the Portland settlement stating. “Six stations have been occupied, one at Portland Bay three at the open country about 60 miles inland called ‘Merino Downs’ They have erected two houses at Portland Bay and two others at Merino Downs”.This nail is significant as part of the vessels original fixtures. The Children was delivering cargo intended for the Portland Bay settlement of her owners the James Henty brothers The wreck is also significant as one of the first vessels to have been lost in the Western District of Warrnambool. As a result the shipwreck of the Children is registered with the Victorian Heritage Register S116. Ship's nail, copper, with a washer attached. The nail has a round head, solid round shank and a flat end. It is bent, twisted and has indentations in the centre section. The nail was recovered from the wreck of the CHILDREN.warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, shipwreck artefact, the children, nail, copper nail, ship's nail, children shipwreck -

Federation University Historical Collection

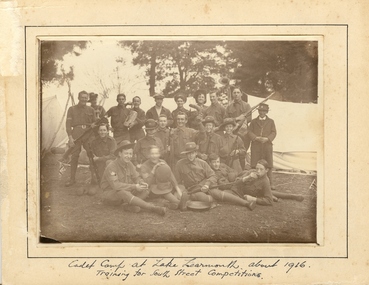

Federation University Historical CollectionPhotograph - Photograph - Sepia, Ballarat School of Mines Cadets, 1916, c1916

Field Marshal Viscount Kitchener of Great Britain was invited by Prime Minister Deakin in 1909 to visit Australia and advise on the best way to provide Australia with a land defence. Kitchener’s report echoed the bill, introduced to Parliament in 1909 and supported by the Opposition Labor Party at its 1908 conference, to introduce compulsory military training in peace time (referred to as universal training). On 1 January 1911, the Commonwealth Defence Act 1911 (Cth) was passed as law and all males aged 12 to 26 were required to receive military training. Men were divided according to age, with junior cadets comprising boys 12-14 years of age, senior cadets comprising boys 14-18, and young men aged 18-26 assigned to the home militia defence. The support of schools was vital to the success of the scheme, since the system of cadet training began in the primary schools, with physical training prescribed by military authorities. Junior cadet training was entirely in the hands of school teachers, who had first been trained by military officers. This early training was less military in nature than focused on physical drill and sport. It also acted to inculcate boys with the notions of loyalty to country and empire. At this age, uniforms were not worn, although there were schools with pre-existing uniformed cadet units, who continued to do so. Senior Cadets were organised by Training Areas, administered by Area Officers. If a school had at least 60 senior cadets, they could form their own units. Unlike their junior counterparts, Senior Cadets were issued uniforms, a rifle, and learned the foundations necessary for service in any arm of the defence forces. Boys and men could be exempted from compulsory training if they lived more than five miles from the nearest training site, or were passed medically unfit. Those who failed to register for training were punished with fines or jail sentences, and the severity of this punishment generated some of the strongest opposition to the scheme. While institutions such as the political parties and most churches generally supported universal training, some in the broader labour movement were less enthusiastic, as evidenced in the Daily Herald newspaper’s editorials and letters. Universal military training persisted after the conclusion of World War 1, with the Junior Cadet scheme the first to go, in 1922. Senior cadets and service with the militia was suspended in November 1929. (http://guides.slsa.sa.gov.au/content.php?pid=575383&sid=4788359, accessed 29/10/2015) According to Neil Leckie, Manager of the Ballarat Ranger Military Museum: * Originally 12 – 14 year olds went to Junior Cadets attached to their school. * From age 14 – 17 they were Senior Cadets attached to the local militia unit. * After 1 July of the year a Cadet turned 18, the Cadet left the Senior Cadets and became a member of the Citizen Military Force. * In October 1918 the AIF, Militia and Cadets were renamed to give some connection to the AIF battalion raised in the area. Ballarat saw: 8th Australian Infantry Regiment comprising: * 8th Battalion AIF renamed 1st Battalion 8th Australian Infantry Regiment * 70th Infantry Militia renamed 2nd Battalion 8th Australian Infantry Regiment * 70th Infantry Cadets renamed 3rd B, 8th Australian Infantry. 39th Australian Infantry Regiment comprising: * 39th Battalion AIF renamed 1st Battalion 39th Australian Regiment * 71st Infantry Militia renamed 2nd Bn, 39th Australian Infantry Regiment * 71st Infantry Cadets renamed 3rd Bn, 39th Australian Infantry Regiment Prior to the reorganisation in 1918 the 18th Brigade was the 70th, 71st and 73rd Infantry. It is thought that the 18th Brigade Cadet units in 1920 were those that came from the old: * 69th Infantry (Geelong/Queenscliff) * 70th Infantry (Ballarat/Colac) * 71st Infantry (Ballarat West) * 72nd Infantry Warrnambool) * 73rd Infantry (NW Vic) The next name change came in 1921!Mounted sepia photograph of 21 young males. They are the Ballarat School of Mines Cadets on a training camp at Lake Learmonth. Back row left to right: Harold Wakeling; ? ; T. Wasley; H. Witter; H.V. Maddison (staff); Lieutenant S.J. Proctor, Joe ? ; ? ; B.C. Burrows. Centre left to right: Howard Beanland; ? ; F.N. Gibbs; H. Siemering; P. Riley; ? : E. Adamthwaite. Front row left to right: Albert E. Williams; Francis Davis (RAAF Dec.); A. Miller; W. Shattock; T. Rees From the Ballarat School of Mines Magazine, 1916 "Our Competition Team, 1916 At a parade, held on the 25th August competition teams were called from from the three colleges - Ballarat College, St Patrick's College, and the School of Mines. In each case, a large muster was obtained, twenty-nine volunteering fro the School of Mines. On account of the number in a team being limited to 21, some had to be weeded out. The team decided to have a camp at Learmonth in the vacation for the benefit of training for the coming competitions. The tents, within our baggage, were brought to the Junior Technical School at 10 a.m. on Monday, 11 September. Everything was carted to the station on a lorry, which was very kindly lent by Mr C. Burrow. ... Arriving at our camp, which was in the Park, we first raised the tents. This was done in record time. Three large tents, A.B.C., were pitched one behind the other. We also pitched a smaller one to act as a provisions tent. The provisions supplied by each cadet were placed in this tent. Dinner was ready by 3.30, and was prepared by the three senior non-coms., who also acted as orderlies. Things went alright Monday night, the two senior non-coms. acting as sentries for the first two hours. On Tuesday morning Reville sounded at 7. There was no need for it, however, as nearly all the cadets were up before daylight, owing to their beds being too hard. After physical exercises were gone through we had breakfast. We then had rifle exercises until Messrs A.W. Steane and F.N. King arrived. The former put the team through the table of physical exercises set down for competition work, many valuable points being obtained. The visitors remained for dinner, afterwards returning to Ballarat. Wednesday was uneventful, until the soldiers arrived at about 11 a.m., stopping at the park for lunch. As we handed over the coppers, etc., to them, our lunch was delayed. Two more visitors arrived after lunch, and after taking a few photos returned home. That night we had a "Sing-a-long" in C Tent until "Lights out" sounded at 9.30. After physical exercises ad breakfast on Thursday, we went for a six mile route march round the lake, doing skirmishing on the way. In the afternoon we practised rifle exercises and the march past. A concert was arranged for that night, the chief singers being cadets H. Siemering and W. Shattock. Supper was served at the end of the entertainment. On Friday, Reveille sounded at 6.30 instead of 7, and, as usual, we had physical exercises before breakfast, after which the team went through skirmishing at the reserve. In the afternoon, section drill and the march past were practised. Friday night, being our last night in camp, leave was granted until 10 p.m., "lights out" sounding at 11. Reveille sounded on Saturday at 4.30, the reason being that all kits, tents, etc., had to be packed away ready to catch the 8.15 train to Balalrat. At 7.30 we were all ready to leave for the station. We had a very enjoyable time in the train, each cadet having a chip in at the patriotic songs. On arriving at Ballarat, we found the lorry awaiting us. The luggage was carted to the Junior Technical School, the team following. The team were here dismissed, everyone feeling that he had had a very good time. F.G. Davis"Written in ink on front 'cadet camp at Lake Learmonth about 1916. Training for South Street Competitions. ballarat school of mines, cadets, ballarat school of mines cadets, lake learmonth, world war one, boomerang, camp, cadet camp, h.g. wakeling, harold wakeling, f.g. davis, albert w. steane, f.n. king, h. siermering, w. shattock, francis davis, harold wakeling, t. wasley, h. witter, h.v. maddison, s.j. proctor, b.c. burrows, howard beanland, f.n. gibbs, h. siemering, p. riley, e. adamthwaite, albert e. williams; francis davis, a. miller, w. shattock, t. rees, photography, foto, boxing gloves -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Urinal, circa 1825

It is probable that the urinal was situated in the forward part of the ship rather than the stern, being one of two placed on either side of the deck and housed immediately adjacent to the doors into for-castle, or crew sleeping quarters. The toilets on maritime vessels were (and still are) called the ‘heads’, after the sanitation arrangements common until the end of the eighteenth century. The name was given to the ‘head’ of the ship, forward of the forecastle and around the beak or bowsprit. These first lavatories were floored with grating or nets so the force of the sea could wash them clean, and they were always used on the lee or non-weather side so the effluent fell directly into the water rather than back on board. The Children wrecking: The barque Children was one of the first vessels to be lost in the Western District the vessel was wrecked to the east of Warrnambool on 14th January 1838. When it ran ashore in hurricane-force winds, 22 passengers and crew were fortunate to escape being battered to death on the rocks. The Children broke up within 20 minutes, sweeping sixteen of those on board to their deaths. After eleven days, the survivors, all of whom were injured, were rescued and taken to Portland. According to Lloyd's Shipping Register 1837-1839, the Children was built in 1825 at Liverpool and operated by owners Gordon & Co, of London. Registration number 123/1837, James Henty then bought her in 1837 as a three-masted barque of 254 tons, with a hull of “part pitch pine, felt sheathed” and “coppered in 1837” at Launceston registered number 6/1837. In 1838 the Children, under her master Captain H. Browne, completed a successful round trip from Launceston to London (carrying wool and whale oil loaded in Portland), returning in late November of that year carrying a general cargo including house bricks used for ballast. On the 11th of January 1839, the Children sailed from Launceston for Adelaide, with 24 passengers, 14 crew, and an awkward mixed cargo, including 1500 sheep, 8 bullocks, 7 horses, and farming implements, and six whaleboats with associated whaling gear. One account states that when the Children were “put out from port she was light and badly ballasted”. The vessel immediately encountered four days of hurricane-force storms, eventually clearing on the early morning of the 14th. However, it was too late to take accurate measurements of the sun or stars to establish their position relative to the coast. The Children collided with a limestone stack at the entrance of Childers Cove, and the seas smashed her into pieces within half an hour. All the cargo and 16 lives were lost including 8 children. The Henty brothers contributed £150 towards a fund for the 22 survivors at a memorial service held in Launceston later that year. It was a major financial setback for James Henty and his brothers, but one from which they recovered. In a submission to the Governor of New South Wales dated 24 March 1840, the Henty’s summarised their work over the previous six years of establishing the Portland settlement stating. “Six stations have been occupied, one at Portland Bay three at the open country about 60 miles inland called ‘Merino Downs’ They have erected two houses at Portland Bay and two others at Merino Downs”.This urinal is significant as part of the vessels original fittings he Children was delivering cargo intended for the Portland Bay settlement of her owners the James Henty brothers The wreck is also significant as one of the first vessels to have been lost in the Western District of Warrnambool. As a result the shipwreck of the Children is registered with the Victorian Heritage Register S116. A lead urinal with a rounded back at the top splash plate with an attached semi-circular receptacle or basin (20cm deep and projecting forward 30cm). At the sides are flanges with bolt holes connecting to a ship's wall. The urinal is drained by a funnel-shaped outlet also made of lead, reducing from a 10cm radius to a joined 5 cm pipe. The urinal was recovered from the wreck of the CHILDREN.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, shipwreck artefact, the children, lead ship’s plumbing, crew urinal, the ‘heads’, ship plumbing, james henty, portland bay, urinal, ship's urinal -

Eltham District Historical Society Inc

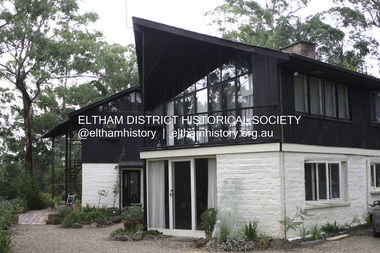

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Downing-Le Gallienne house, Yarra Braes Road, Eltham, 30 January 2008

The property is a classic example of what made Eltham famous from the late 1940s to the 1960s. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p149 The first view of the large double-storey house at Yarra Braes Road, Eltham South, is of a jutting roofline over a balcony, reminiscent of a large sailing vessel or galleon – very appropriate, considering the name of one of the first owners, Le Gallienne. The Downing-Le Gallienne property is a classic example of what made Eltham famous from the late 1940s to the 1960s and attracted so many artists and intellectuals to the area. Set in a largely indigenous bush-style garden, the mud-brick and timber house was built by Alistair Knox. It was built for economist Richard Downing, to become a founder of the welfare state in Australia and Chairman of the Australian Broadcasting Commission, and musician and composer Dorian Le Gallienne. Le Gallienne was a pioneering composer of modern music in Victoria before 1945, whose works included the Symphony in E.1 He wrote several pieces of film music for Eltham Films, including The Prize, working with its writer and artistic director Tim Burstall. Le Gallienne was also a music critic for The Argus and later for The Age. In 1967 the music critic Roger Covell argued that Le Gallienne’s Symphony, was ‘still the most accomplished and purposive . . . written by an Australian’. According to Alan Marshall the main inspiration behind the building that evolved from 1948 to 1964 was Le Gallienne. ‘He was able to see value in the simplest things and many who worked there had their eyes opened for the first time to the Eltham environment, to the bush and the trees and the fauna which lived there.’ The garden included no formality, no lawns, nor exotic plants. ‘Natural informal growth came right up to their doors and so did the indigenous birdlife.’ This informal style – consisting of mass and void – was to be developed and popularised by landscaper Gordon Ford from the 1950s. The large mud-brick and timber house, which was built in four stages and has three separate but linked sections, began as a small weekend retreat for the couple. In 1948, Downing and Le Gallienne (Dick and Dor to their friends), asked Knox to build the 36 x18 foot (11mx5.4m) building with a pitched slate roof. It was built on a concrete slab and included a fireplace, which is still in use. The second wing was built in 1954 after Downing had returned from working at the International Labour Office and the couple decided to live there full-time. The third section was built after the death of Le Gallienne in 1963, aged 48. He is buried in the Eltham Cemetery. When Downing married widow, Jean Norman (nee McGregor) and had to accommodate a large family, including her six children and one of their own, the last stage was built by 1964. At that time the house was considered one of the largest mud-brick houses in Victoria. It consists of five living areas, including a small ballroom. Several artists helped Knox build the Downing-Le Gallienne house, which was one of his first of mud-brick. They included painter Clifton Pugh, artist John Howley and actor Wynn Roberts. Ellis Stones had landscaped the first wing and Gordon Ford set the boulder steps and made a pool as part of the landscaping he completed. Inside, the mud-bricks are largely whitewashed with pine-lined ceilings and Oregon beams. A winding timber staircase in the front extends behind a glass window from the ground floor to the top. The property, of a little more than 0.5 ha, is bordered by Parks Victoria land, which extends to the Yarra River.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, dorian le gallienne, downing-le gallienne house, eltham, mudbrick construction, mudbrick houses, richard downing, yarra braes road -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Great Hall, Montsalvat, 8 January 2008

Great Hall at Montsalvat built 1938-52, designed by Justus Jorgensen Covered under National Estate, National Trust of Australia (Victoria) State Significance, Victorian Heritage and Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p129 At first glance, Montsalvat, the artists’ community at Hillcrest Avenue, Eltham, could belong to another time and place. The French provincial Gothic-style buildings blend picturesquely with the introduced and native trees and farm animals on the five hectare property. But Montsalvat belongs very much to today’s Eltham, having inspired much of its creative activity and style. The use of mud-brick and recycled building materials, for which Eltham is so well-known, was largely popularised by Montsalvat. Montsalvat – unique in Victoria and probably in Australia – is registered by the National Trust and National Estate.1 Montsalvat, named after the castle of the Knights of the Holy Grail, has attracted artists and intellectuals since it was founded in 1934. For years at weekends, artists, lawyers, philosophers, politicians and others, who shared a love for what Montsalvat stood for, gathered for a meal and stimulating discussion. The focus for this gathering of talent was Justus Jörgensen, an eccentric man with vision and charisma. It was Jörgensen’s foresight that saw the creation of Montsalvat, which in 1975 was formed into a trust to benefit the Victorian people. The property was then valued at about three million dollars. It is now visited by thousands of people annually. Born in 1894 and brought up a Catholic, Jörgensen had trained as an architect. He later studied painting at the National Gallery School under artist, Frederick McCubbin, then joined the studio of artist Max Meldrum. In 1924, Jörgensen married medical student Lillian Smith, and with artist friends they travelled to Europe to study the great masters. In London Jörgensen exhibited in several major galleries. One of his still life paintings was included in the book The Art of Still Life by Herbert Furst, which featured 100 of the greatest ever still life paintings.2 In 1929, Jörgensen returned to Melbourne where Lil, now qualified, worked as an anaesthetist at St Vincent’s Hospital. They bought a small house in Brighton and Jörgensen rented a large building in Queen Street for his studio until the Royal Automobile Club of Victoria bought it in 1955. While designing and overseeing the building of a studio for his friend the famous cartoonist Percy Leason, in Lavender Park Road, Jörgensen decided to buy land for a country retreat in Eltham. So the building of Montsalvat began. Jörgensen gathered around a dozen of his friends and students from his Queen Street studio. They set to work, first at weekends then some decided to live permanently on the site. Jörgensen had seen mud-brick buildings in Spain and recognised that Eltham’s clay soil was ideal for mud-bricks and although labour intensive, it was a very cheap way of building. Jörgensen’s students and friends worked under his direction with the help of local tradesmen, including carpenter, Len Jarrold and later stone mason, Horrie Judd. In return Jörgensen would give the students a painting lesson or two. It was the Great Depression when many were out of work. Jörgensen also inspired people to give generously of money and materials. With their help Jörgensen found second-hand materials for building. Friends donated slate for roofing, discarded firebricks were used for flooring and windows and doors and a cast-iron circular staircase came from a wrecker. The students’ day started at 7am with building and domestic chores, shared equally between the sexes. The first building was used by his friends at weekends and then became a home for his wife Lil. It consisted of three rooms and an attic under a high-pitched roof. Jörgensen then built a similar structure with the same high-pitched roof as a more permanent home for his students. The two buildings were joined together with a tower and a studio for Jörgensen. While excavating for the studio a reef of yellow mud-stone was found and then used in construction. The next building was the Great Hall, to be used for dining, exhibitions and meetings and completed in 1958, after a halt during the war. Whelan the Wrecker donated the stone-framed windows from the building that housed the Victorian Insurance Co. in Collins Street, which had been demolished in the 1930s. The swimming pool was donated and cubicles were built for the students with their initials marked in tiles on each doorstep.1 One of Jörgensen’s great abilities was to recognise how to use material which harmonised. He would comb through wreckers’ yards for what he needed. Regarding his buildings as sculptural pieces, his first consideration was for the aesthetic quality of a building and only then for its functionality.2 At Montsalvat, Jörgensen found he was able to put his ideas into practice without compromise and those who worked with him had to conform to his ideas. With the Jörgensens, the colony’s original nucleus consisted of the Skipper family – Mervyn and wife Lena, daughters Helen and Sonia and son Matcham,who was to become an eminent jeweller and sculptor represented in National Gallery collections throughout Australia and in European museums.3 Other members were Arthur Munday, Lesley Sinclair, Helen Lempriere, Ian Robertson, John Smith, George Chalmers, John Busst and Sue Van der Kellan; also Jörgensen’s three sons – Max, Sebastian and Sigmund – and Saskia, Sonia Skipper and Arthur Munday’s daughter. Montsalvat went through some hard times when local gossips spread rumours of sexual shenanigans at Montsalvat. However Montsalvat also had many local supporters – especially amongst the local tradespeople. The colony was certainly unconventional – with Jörgensen’s wife Lil (and son Max) and life-time partner Helen Skipper, (mother of Sebastian and Sigmund) living at Montsalvat. Sonia Skipper says in her biography that the group were ‘very conscious of their responsibilities to each other and a desire to make their relationships work’.4 By World War Two many buildings around the Great Hall were completed. Jörgensen was a pacifist, as were most of his students. Some of the Montsalvat community enlisted while others engaged in essential services like dairy farming and market gardening for the war effort. It was then that Jörgensen constructed farm buildings. After the war many well-known personalities such as Clifton Pugh, landscape gardener Gordon Ford, and builder Alistair Knox, were drawn to Montsalvat. They learnt that building was not a ‘sacred cow’ only for professionals, but that anyone who was willing to get their hands dirty could do it. The post-war shortage of materials also encouraged builders to follow Montsalvat’s lead in reusing materials. When Jörgensen died in 1975, his influence did not – thanks largely to the vigilance of his son, Sigmund, who became its administrator. The weekend dinners have gone, but in 2008 about 14 artists still work at Montsalvat – some living there – including a couple who have been there since its early days. Under Sigmund’s direction Montsalvat further expanded its activities which included festivals, art exhibitions, concerts and weddings. Sigmund completed the Chapel, then the Long Gallery next to the pool, After the barn burnt down, he replaced it in 1999 (the builder was Hamish Knox, Alistair’s son) with a new gallery and entrance and added a restaurant. Sigmund has been careful that any new building blends in with the character of Montsalvat. In 2006 Montsalvat was restructured for its continued financial viability and with the help of Arts Victoria a new executive officer was appointed. A representative board from the wider community was established, which includes members from the former Montsalvat Trust including Sigmund Jörgensen – who is now the heritage and arts adviser to the new company Montsalvat Ltd.5 Today, visiting Montsalvat one still sees artists, students and visitors enjoying the unique and beautiful surroundings.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham, great hall, montsalvat -

Flagstaff Hill Maritime Museum and Village

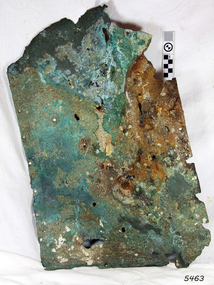

Flagstaff Hill Maritime Museum and VillageCopper Sheathing

This sheet of copper sheathing or muntz metal has been recovered from the sea. It has been damaged by reaction of the metals to the sea, it has encrustations from the sea such as sand, and other damage has caused the edges to break away or fold over. ABOUT MUNTZ Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries the outside of their ships were sheathed in copper sheathing or a combination of 60 percent copper and 40 percent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SCHOMBERG When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery. Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill. The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day Copper sheathing or "Muntz metal" - 60% copper and 40% zinc, used to line the hull of the Schomberg to prevent shipworm infestation. Recovered from the wreck of the Schomberg. There are 11 irregular shaped small pieces. Verdigris, nail holes and slight encrustation.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCopper Sheathing

This sheet of copper sheathing or muntz metal has been recovered from the sea. It has been damaged by reaction of the metals to the sea, it has encrustations from the sea such as sand, and other damage has caused the edges to break away or fold over. ABOUT MUNTZ Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries the outside of their ships were sheathed in copper sheathing or a combination of 60 percent copper and 40 percent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SHOMBERG When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery. Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill. The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day Copper sheathing or "Muntz metal" - 60% copper and 40% zinc, used to line the hull of the Schomberg to prevent shipworm infestation. Recovered from the wreck of the Schomberg. Folded, with verdigris, marine growth and slight encrustation. Irregular shaped 2' 2" long by 2' 1" wide.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper Sheathing, ca 1855

This sheet of copper sheathing or Muntz metal has been recovered from the sea at the wreck-site of the ship SCHOMBERG. . It has been damaged by the reaction of the metals to the sea, it has encrustations from the sea such as sand, and has other damage that has caused the edges to break away or fold over. Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in seawater and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries, the outsides of their ships were sheathed in copper sheathing or a combination of 60 per cent copper and 40 per cent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUTH THE SCHOMBERG- When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery. Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its dayCopper sheathing or Muntz metal recovered from the shipwreck Schomberg. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, coppper sheathing, ship building, sea worm -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCopper Sheathing

This sheet of copper sheathing or muntz metal has been recovered from the sea. It has been damaged by reaction of the metals to the sea, it has encrustations from the sea such as sand, and other damage has caused the edges to break away or fold over. ABOUT MUNTZ Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries the outside of their ships were sheathed in copper sheathing or a combination of 60 percent copper and 40 percent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SCHOMBERG When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery. Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill. The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day Copper sheathing or "Muntz metal" - 60% copper and 40% zinc, used to line the hull of the Schomberg to prevent shipworm infestation. Recovered from the wreck of the Schomberg. With verdigris, marine growth and slight encrustation. Irregular shaped 1' 2½" Wide by 2' 7" long.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCopper Sheathing

This sheet of copper sheathing or muntz metal has been recovered from the sea. It has been damaged by reaction of the metals to the sea, it has encrustations from the sea such as sand, and other damage has caused the edges to break away or fold over. ABOUT MUNTZ Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries the outside of their ships were sheathed in copper sheathing or a combination of 60 percent copper and 40 percent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SCHOMBERG When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned. In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery. Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill. The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day Piece of rectangular Muntz metal from the wreck of the Schomberg. Metal has been bent back on itself at one end. Evidence of nail holes. Metal has verdigris and marine encrustation. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper Sheathing, ca. 1855

This sheet of copper sheathing or muntz metal has been recovered from the sea. It has been damaged by reaction of the metals to the sea, it has encrustations from the sea such as sand, and other damage has caused the edges to break away or fold over. ABOUT MUNTZ Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries, the outsides of their ships were sheathed in copper sheathing or a combination of 60 per cent copper and 40 per cent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SCHOMBERG- When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three-masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first-class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two men drowned when they tried to reach Schomberg, salvage efforts were abandoned.32 In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the cover and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery.33 Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photographs from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its dayCopper sheathing or "Muntz metal" - 60% copper and 40% zinc, used to line the hull of the Schomberg to prevent shipworm infestation. The sheet was recovered from the wreck of the Schomberg. It is irregular in shape with nail holes and slight encrustation.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building, late 19th century sailing ships -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper Sheathing

This sheet of copper sheathing or Muntz metal has been recovered from the sea. It has been damaged by the reaction of the metals to the sea, it has encrustations from the sea such as sand, and has other damage that has caused the edges to break away or fold over. Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in seawater and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries, the outsides of their ships were sheathed in copper sheathing or a combination of 60 per cent copper and 40 per cent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SCHOMBERG- When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oak with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned.32 In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery.33 Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill.The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck, The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day This Muntz sheet was recovered from the wreck of the Schomberg. It has been folded, bent and wrinkled. It has nail holes, Verdigris, marine growth and slight encrustation. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, schomberg, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCopper sheathing

This sheet of copper sheathing or muntz metal has been recovered from the sea. It has been damaged by reaction of the metals to the sea, it has encrustations from the sea such as sand, and other damage has caused the edges to break away or fold over. ABOUT MUNTZ Early timber sailing ships had a problem of the timber hulls being eaten through by the marine animals called Teredo Worms, sometimes called ‘sea worms’ or ‘termites of the sea’. The worms bore holes into wood that is immersed in sea water and the bacteria inside the worms digest the wood. Shipbuilders tried to prevent this problem by applying coatings of tar, wax, lead or pitch onto the timber. In the 18th and 19th centuries the outside of their ships were sheathed in copper sheathing or a combination of 60 percent copper and 40 percent zinc (called Muntz metal). The ships would be re-metalled periodically to ensure the sheathing would remain effective. In more recent times the ships are protected with a toxic coating. ABOUT THE SCHOMBERG When the ship Schomberg was launched in 1855, she was considered the most perfect clipper ship ever to be built. James Blaine’s Black Ball Line had commissioned her to be built for their fleet of passenger liners. At a cost of £43,103, the Aberdeen builders designed her to sail faster than the quick clippers designed by North American Donald McKay. She was a three masted wooden clipper ship, built with diagonal planking of British oat with layers of Scottish larch. This luxury vessel was designed to transport emigrants to Melbourne in superior comfort. She had ventilation ducts to provide air to the lower decks and a dining saloon, smoking room, library and bathrooms for the first class passengers. At the launch of Schomberg’s maiden voyage, her master Captain ‘Bully’ Forbes, drunkenly predicted that he would make the journey between Liverpool and Melbourne in 60 days. Schomberg departed Liverpool on 6 October 1855 with 430 passengers and 3000 tons cargo including iron rails and equipment intended the build the Geelong Railway and a bridge over the Yarra from Melbourne to Hawthorn. The winds were poor as Schomberg sailed across the equator, slowing her journey considerably. She was 78 days out of Liverpool when she ran aground on a sand-spit near Peterborough, Victoria, on 27 December; the sand spit and the currents were not marked on Forbes’s map. Overnight, the crew launched a lifeboat to find a safe place to land the ship’s passengers. The scouting party returned to Schomberg and advised Forbes that it was best to wait until morning because the rough seas could easily overturn the small lifeboats. The ship’s Chief Officer spotted SS Queen at dawn and signalled the steamer. The master of the SS Queen approached the stranded vessel and all of Schomberg’s passengers were able to disembark safely. The Black Ball Line’s Melbourne agent sent a steamer to retrieve the passengers’ baggage from the Schomberg. Other steamers helped unload her cargo until the weather changed and prevented the salvage teams from accessing the ship. Local merchants Manifold & Bostock bought the wreck and cargo, but did not attempt to salvage the cargo still on board the ship. They eventually sold it on to a Melbourne businessman and two seafarers. After two of the men drowned when they tried to reach Schomberg, salvage efforts were abandoned.32 In 1975, divers from Flagstaff Hill, including Peter Ronald, found an ornate communion set at the wreck. The set comprised a jug, two chalices, a plate and a lid. The lid did not fit any of the other objects and in 1978 a piece of the lid broke off, revealing a glint of gold. As museum staff carefully examined the lid and removed marine growth, they found a diamond ring, which is currently on display in the Great Circle Gallery.33 Flagstaff Hill also holds ship fittings and equipment, personal effects, a lithograph, tickets and photograph from the Schomberg. Most of the artefacts were salvaged from the wreck by Peter Ronald, former director of Flagstaff Hill. The Schomberg, which is on the Victorian Heritage Register (VHR S612), has great historical significance as a rare example of a large, fast clipper ship on the England to Australia run, carrying emigrants at the time of the Victorian gold rush. She represents the technical advances made to break sailing records between Europe and Australia. Flagstaff Hill’s collection of artefacts from the Schomberg is significant for its association with the shipwreck. The collection is primarily significant because of the relationship between the objects, as together they have a high potential to interpret the story of the Schomberg. It is archaeologically significant as the remains of an international passenger Ship. It is historically significant for representing aspects of Victoria’s shipping history and for its association with the shipwreck and the ship, which was designed to be fastest and most luxurious of its day Copper sheathing or Muntz metal in concretion. Recovered from the wreck of the Schomberg.warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, schomberg, shipwrecked-artefact, clipper ship, black ball line, 1855 shipwreck, aberdeen clipper ship, captain forbes, peterborough shipwreck, ss queen, muntz, muntz metal, copper sheating,, copper sheathing, teredo worms, sea worms, sea termites, ship building -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Copper sheathing, c. 1855