Showing 275 items

matching textile manufacturing

-

National Wool Museum

National Wool MuseumAnnual Report, Geelong R.S.&S. Co. Ltd; 39th Annual Report, 1959

"Geelong R.S.&S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd. 39th Annual Report 1959".RSS Mill Annual Report for 1959.textile mills, returned soldiers and sailors mill -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R.S.&S. Co. Ltd; 48th Annual Report, 1968

"Geelong R.S.&S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd. 48th Annual Report 1968".textile mills, returned soldiers and sailors mill -

National Wool Museum

National Wool MuseumAnnual Report, Geelong R.S.&S. Co. Ltd; 53rd Annual Report, 1973

"Geelong R.S.&S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd. 53rd Annual Report 1973".RSS Mill Annual Report for 1973. Detail of RSS Mill logo from the back cover of the 1973 annual report.textile mills, returned soldiers and sailors mill -

National Wool Museum

National Wool MuseumCertificate, South Australian Chamber of Manufactures Centennial Exhibition, 1936

Certificate awarded to the Geelong RSS Mill for winning the gold medal for the most attractive still grouped exhibit at the South Australian Chamber of Manufactures Centennial Exhibition in 1936.Certificate awarded to the RSS Mill for the most attractive still grouped exhibit at the South Australian Chamber of Manufactures Centennial Exhibition, 1936.South Australian Chamber of Manufactures / INCORPORATED. / Centennial Exhibition / MARCH 20th to MAY 16th, 1936. / GOLD MEDAL / AWARDED TO / GEELONG RETURNED SAILORS' & SOLDIERS' / WOOLLEN & WORSTED MANUFACTURING CO. LTD. / Most Attractive Still Grouped Exhibit. / Section A. / H.E. WINTERBOTTOM, Secretary. / Modern Printing Company, Chancery Lane, Adelaide. Phone, Central 283.woollen mills history, textile mills, returned soldiers and sailors mill, 1918: australians in france - exhibition (19/02/2000 - 30/04/2000), woollen mills - history -

National Wool Museum

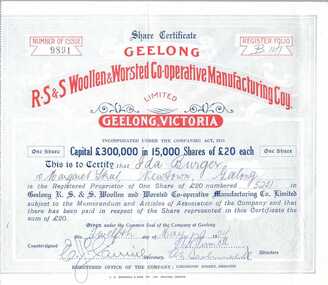

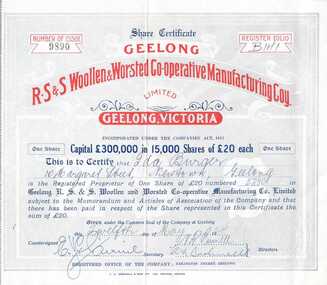

National Wool MuseumShare Certificate

R.S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd share certificate No. 9891 for Ida Burger, 12/5/1954. Share worth 20 pounds. Signed by RSS Mill company secretary E.J. Fairnie.RSS Mill share certificate, 1954.textile mills management, textile mills, returned soldiers and sailors mill, fairnie, mr edward john - returned soldiers and sailors mill, textile mills - management -

National Wool Museum

National Wool MuseumShare Certificate

R.S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Ltd share certificate No. 9891 for Ida Burger, 12/5/1954. Share worth 20 pounds. Signed by RSS Mill company secretary E.J. Fairnie.RSS Mill share certificate, 1954.textile mills management, textile mills, returned soldiers and sailors mill, fairnie, mr edward john - returned soldiers and sailors mill, textile mills - management -

National Wool Museum

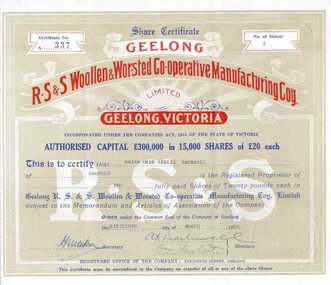

National Wool MuseumShare Certificate

Share certificate from R.S. & S. Woollen and Worsted Co-operative Manufacturing Coy. Limited Geelong, Victoria dated 16 March 1964 in the name of Brian Owen Leslie Backwell of Leopold. Share certificate no. A 337.RSS Mill share certificate, 1964.textile mills management, textile mills, returned soldiers and sailors mill, textile mills - management -

National Wool Museum

National Wool MuseumFunctional object - Yarn Spinner and Accessories, John Nesbitt, 19th Century

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design.Custom made wooden hinged box with a hook latch. Brass yarn spinner, attached to a mahogany wood plinth base, which spins fibre into cord/yarn/thread. It has dials to set the rate that it spins. Metal plaque with black inlaid enamel lettering. Small cork inlay. Brass rod with hinge and wingnut, and ball at end. Ball at end has an adjustment mechanism. Rod also has an adjustable circular collar. Pair of curved tweezers. Circular magnifying glass on long thin handle. Glass has two concave lenses. Weaving sample in shades of blue, green and brown. Twill weave. Alternate pattern samples separated by red thread.Brass plaque on base of spinner: 42 MARKET St / John Nesbitt / REGd TRADE MARK / LIMd / MANCHESTER Underside of wooden plinth: 4976apparatus, textile, testing, spinning, nino corda, magnifyer, tools, brass, mahogany, tweezers, yarn, spinner, design, john nesbitt, manchester, england, 19th century, engineering, manufacturing -

National Wool Museum

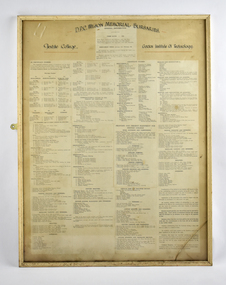

National Wool MuseumPhotograph - Framed Printed Coursework, Gordon Institute of Technology, Textile College, 1950

Framed papers outlining the courses and coursework for the Textile College at the Gordon Institute of Technology in 1950. The courses include Woolcombing, Worsted Spinning, Woollen Yarn Manufacture, Designing, Weaving and Turning and Finishing. A digital copy of this item was made for the National Wool Museum Collection, with the original remaining with the donor. Digital TIFF file, 100 MB, showing image of framed printed paper.D.P.C. WILSON MEMORIAL BURSARIES. / Textile College / Gordon Institute of Technology. / GENERAL INFORMATION / TERM DATES 1950 ...courses, gordon institute of technology, textile college, geelong, woolclassing, weaving, spinning, coursework, 1950 -

National Wool Museum

National Wool MuseumTextile - Blanket, Albany Woollen Mills, Albany Woollen Mills blanket, c 1950s

Note from collector: I love the generous size and thickness of Albany blankets and know someone who collects from this Mill only. The colour shades and combinations Albany used are still so gorgeous. From Western Australia. Note from collector - "For more than 100 years blankets were made all over Australia in over 100 woollen mills. My aim, is to preserve 100 examples of these wonderful pieces of history. Ten years ago I started collecting the iconic Onkaparinga travel rugs, so that on movie nights at home there would be plenty to go around. Everyone had their favourite; even the cat had his own – a small red tartan one. Keeping an eye out for those travel rugs at op-shops and markets, collectable stores and bazaars, led to noticing vintage blankets. I'd never really thought about them before or paid much attention though of course I had grown up with them at my grandmother's. When I discovered my first Laconia cream blanket with blue stripes, my eyes just went gaga. Well that was it, I was hooked and since then over 500 blankets have passed through my hands. These common, everyday items, found in all households for so many decades, were traditional engagement gifts. Pairs were prized wedding presents turning into family heirlooms. They were fashionable dressers of beds, givers of warmth, bestowers of security and reliability. The comfort found in these objects resonates with almost all of us; we grew up with them ourselves or fondly recall them in a grandparent’s home. There is no modern replacement with the integrity of these old blankets, many of them now older than most of us. They are romantic, sensible, special, familiar, nostalgic and nothing else feels so appropriate in so many situations. No offense to the great Aussie doona, but from hippie to hipster, at a music festival, picnic, campsite or couch, a vintage blanket is something coveted by all. This industry that employed tens of thousands and must have been such a huge contributor to the economy is almost completely lost now. Blanket Fever is an ode to everything that came before: the land, the sheep, the shearers, the hands, the mills, the weavers, the designers, the distributors, the department stores. To the grandparents that gave them, the people that received them, the families that kept them; thank you. I’m passionate about my collection of Australian blankets manufactured in mostly Victoria, South Australia and Tasmania from the 1930s to the end of the 1960s. The collection has blankets from each of these four decades representing the styles and fashions of their time and includes dated advertisements which help determine the eras the blankets are from. " Checked blanket, blues and creamAlbany Woollen Mill/Blanket/All Pure Wool/Emblem: A, Albany blanket, blanket fever, wool, albany, albany woollen mills -

National Wool Museum

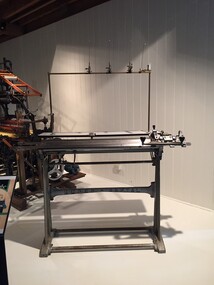

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

National Wool Museum

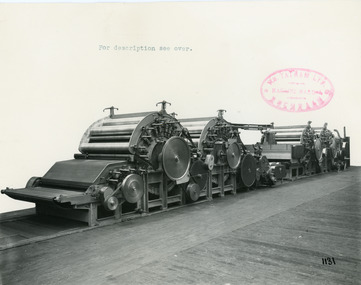

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

National Wool Museum

National Wool MuseumPhotograph - Product Photograph, Tape Condenser

... by William Tatham Ltd, a textile engineering company based ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A Tape Condenser is a device that receives the wide fibre web from a woollen card, divides it, and rubs each section into a sliver. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of a Tape Condenser in a landscape format. The first photo is of the front of the machine, the second is of the rear.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1138 Rear - Showing new model Tape Condenser with all-Perspex Guards, new gear box type of main drive to Condenser. New mounting of all Tape Rollers, cross shaft drive to Variable Speed Gear Box for drive to rubber shaft and many other improved features. 8038.2 - Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1140 Rear - New Model Four-teir Tape Condenser showing rubbing motion side Note greatly improved guarding completely enclosing rubbing motion and gearing, also Variable Speed Drive to Rubbing Motiom via heavy ‘V’ Belt. The drive is taken by cross-shaft from the main gearing of the Condenser. Rubbing Motion has all roller bearing eccentrics throughout.textile machinery, tatham, wool manufacture, tape condenser -

National Wool Museum

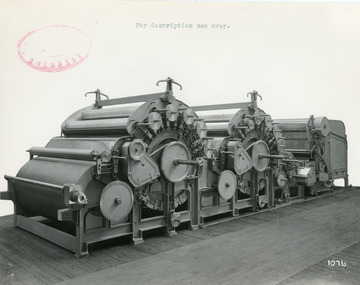

National Wool MuseumPhotograph - Product Photograph, Two-Part Scribbler

... machine was made by William Tatham Ltd, a textile engineering ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The scribbler was the first part of a group of machines known collectively as the carding engine. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Two-Part Scribbler in a landscape format.Front - top margin: For description see over. Front bottom right corner - 1076 Rear - Two-Part Scribbler, Semi-Continental Type with Patent Automatic Feed having Extended Hopper. Cylinders in this case are 50” diam. Doffers 36” diam. Drive to strippers and other parts by ‘V’ Belts. Note improved guarding to Fancy Chain Drives, also feeder gearing.textile machinery, tatham, wool manufacture, scribbler, carding -

National Wool Museum

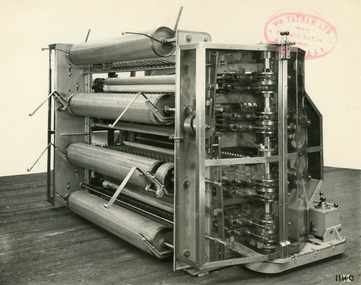

National Wool MuseumPhotograph - Product Photograph, Patent Parallel Fibre Feed

... machine was made by William Tatham Ltd, a textile engineering ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Patent Parallel Fibre Feed machine is used for connecting Breaker and Finisher Card Sections. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Parallel Fibre Feed in a landscape format. Black wiritng on the rear, typed with a typewriter. Front - top margin: For description see over. Front mid left edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1106 On machine bottom right quadrant - TATHAMS Rear - New Patent Parallel Fibre Feed for connecting Breaker and Finisher Card Sections. This Machine incorporates a completely new type Plaiter Motion, the operation of which is quite unique.textile machinery, tatham, wool manufacture, carding, patent parallel fibre feed machine -

National Wool Museum

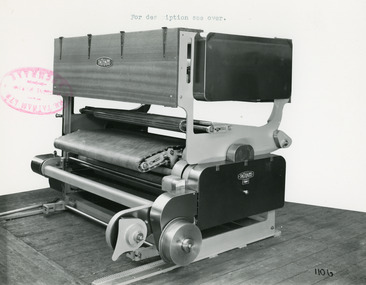

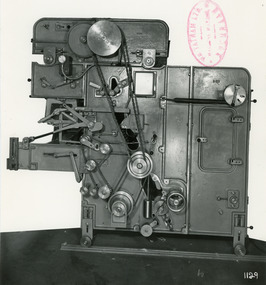

National Wool MuseumPhotograph - Product Photograph, Patent Automatic Feed Machine

... , The photographed machine was made by William Tatham Ltd, a textile ...These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. An Automatic Feeding Machine automatically and sequentially supplies uncarded wool to carding machines, The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.A black and white photo of a Patent Automatic Feed Machine in a portrait format. Black wiritng on the rear, typed with a typewriter.Front - mid left corner - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1129 Rear - Patent Automatic Feed with Extended Hopper fitted with balanced pressure plate which operates through Variable Speed Device to regulate speed of spiked lattice in accordance with material in Hopper. Electro-Magnetic Clutch Drive to spiked lattice controlled by Mercery Switch on scale arm. Diagonal Scale Pan with improved knife edge suspension. Dual Trap Doors over Pan actuated by Solenoid. Automatic device to slow spiked lattice just prior to weigh being obtained. Ball or roller bearings to main shaft, combs and other parts. Self-aligning bearing to timing shaft etc.textile machinery, tatham, wool manufacture, carding, automatic feeding machine, wool -

National Wool Museum

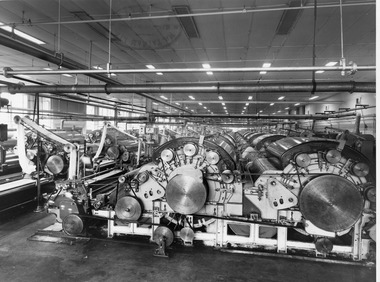

National Wool MuseumPhotograph - Carding Machines

... . textile machinery wool manufacture carding wool Glasgow On rear ...Sales photograph for William Tatham Ltd. of Rochdale, to showcase new Carding Machines in a newly developed textile factory. The photograph was taken in Glasgow, Scotland.A black and white photo of a room filled with working Carding Machines in a portrait format. A man is working at the end of the closest machine.On rear - top margin - Showing Card Sets in new Card Room. Bottom right corner - Commercial Artists photographers and blockmakers Scottish Studios and Engravers LTD. 196 Clyde st. Glasgow. C C.P.D 6893 Dtextile machinery, wool manufacture, carding, wool, glasgow -

National Wool Museum

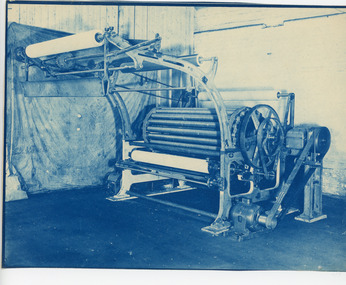

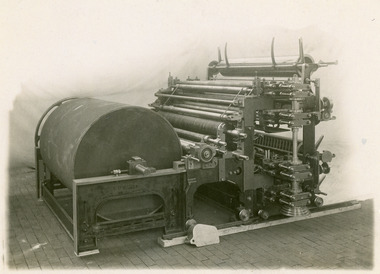

National Wool MuseumPhotograph, Q-VEE Machine, 29/06/1937

... manufacture, leaving the fabric soft and fluffy. The photographed ...Photographs were most likely used for promotional purposes. The Q-VEE machine is a scouring machine. When fabric is removed from the loom it is often stiff, rough or uneven. Scouring removes the oils and dirt picked up from manufacture, leaving the fabric soft and fluffy. The photographed machine was made by J. Stone & Co, a British marine and railway engineering company based in Deptford in south east London.Four black and white, blue tinged photos of a Scouring Machine from different angles. Black writing on the rear, typed with a typewriter and stamped with the company stamp.8051.1 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 849 8051.2 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 856 8051.3 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 851 8051.4 - front on machine - FIY Chain Gear J.Stone & Co Ltd London rear - P.I.V. Dial Control Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 853textile machinery, wool manufacture, wool, scouring -

National Wool Museum

National Wool MuseumPhotograph, Loom, Unknown

... -1895) of Holmfirth. textile machinery wool manufacture wool ...Photograph of a Hutchinson, Hollingworth and Co. Limited Loom gears and mechanisms. Hutchinson, Hollingworth and Co. was an Oldham-based loom manufacturer estalished in 1860 by Messrs. John Hutchinson (c.1816-1888) of Cawthorne and James Hollingworth(c.1834-1895) of Holmfirth.Three black and white photographs in portrait format of a looms gear mechanisms.8052.1 - front on machine mid left quadrant - Hutchinson, Hollingworth and Co 8052.2 - front on machine mid left quadrant - Hutchinson, Hollingworth and Cotextile machinery, wool manufacture, wool, loom -

National Wool Museum

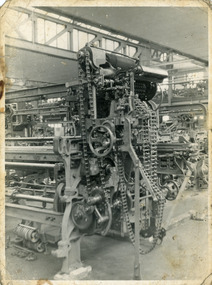

National Wool MuseumPhotograph, Yarn Spinning Machine, Unknown

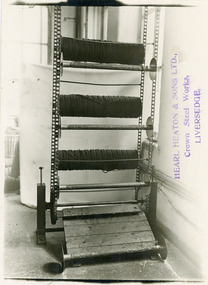

... in Britain’s Industrial Revolution, providing bobbins to the textile ...Photographs most likely used for promotional purposes. The photographs are of a yarn spinning machine used to place yarn onto bobbins. The machine was made by Hearl Heaton and Sons Ltd, founded in 1809. The company played an important part in Britain’s Industrial Revolution, providing bobbins to the textile mills across the North of England.Four black and white photographs of a yarn spinning machine. The first two photos show the machine in the lower floor of the building and the last two are on the upper floor. The are connected by the two chains working the machine.8053.1 - Front right edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.2 - Rear middle - No.1 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.3 - Front top edge - Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge. 8053.4 - No. 2 Hearl Heaton & Sons Ltd Crown Steel Works, Liversedge.textile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumPhotograph, Carding Machine, Unknown

... established in 1899. textile machinery wool manufacture wool spinning ...Photograph most likely used for promotional purposes. The machine possibly could have been manufactured by Chadwick Machine Co Ltd, a British textile machine company established in 1899.Two black and white photographs of a carding machine. The first photo is of the rear of the machine, the second the front.8054.1 - rear handwritten top edge - Chadwicks left edge - unknown 8054.2 - a calculation of numberstextile machinery, wool manufacture, wool, spinning -

National Wool Museum

National Wool MuseumBook - Textile Industry Award 1974, Australian Textile Workers’ Union, 1974

Forty seven page book with metal binding and black and white printed text. A piece of paper is stapled to the inside cover page. Cover is grey, with printed black text. front: [printed] TEXTILE INDUSTRY AWARD / Printed privately by / CHAMBER OF MANUFACTURES INDUSTRIAL SERVICE unions, textile workers union, award, legal document, textile industry, woollen, worsted -

Wodonga & District Historical Society Inc

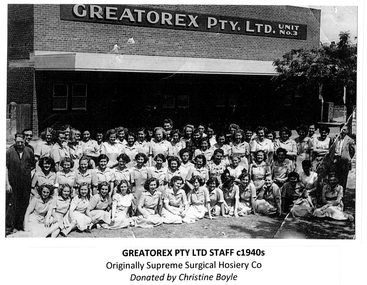

Wodonga & District Historical Society IncPhotograph - Greatorex/ Supreme Surgical Hosiery Co. Wodonga

The Greatorex company came to Wodonga in August 1945 under the Cain Government decentralisation policy. It initially had premises in Beechworth Road, around the corner from Tallangatta Road (now Thomas Mitchell Drive). Due to expansion they later relocated to the corner of Tallangatta Road and Anne Street Wodonga in 1952. Greatorex had its main manufacturing plant in Melbourne, Victoria. At their peak Greatorex Pty Ltd. which also operated as Supreme Surgical Hosiery Co., manufactured brassieres, swimsuits, elastic thread, surgical hosiery and employed 90 staff in Wodonga. The company which was operated by Thomas Greatorex with Mr M. P. Brain as Manager, also owned Fulflex Yarns Pty. Ltd. Fulflex produced elastic yarns to be used in the manufacture of garments at Supreme Surgical Hosiery. In 1960, due to the increasing cost of freight charges for moving raw materials and manufactured goods to and from Melbourne, the company was forced to close down. Plant and machinery valued at over £30,000 was moved to Melbourne. Some personnel were given the opportunity to also transfer to the parent company. In 2024, the company still operates as Greatorex Textile Industries P/L in Moorabbin, Victoria.These images are significant because they document an industry which operated in Wodonga in the 1940s and 1950s.A collection of black and white photos of workers at the Greatorex / Supreme Surgical Hosiery Co. in Wodonga.Names listed beneath one of the images.greatorex industries, wodonga industries -

Woodend RSL

Woodend RSLUniform - Apron

Apron manufactured for military purposes. This item has significance as an example of uniform likely worn ny nurses and/or other medical staff, associated with Australian military campaigns. White fabric apron. One piece comprised of fabric square, white cotton bib, convex shaped side flaps, and square shaped lower apron with rounded corners. Fabric edges are folded over and hemmed with white thread in straight stitch, 5mm distance from edge of apron. Underside is overlocked with white thread. Top of bib is attached to a white fabric neck loop near bib corners by machine sewn white thread, with a criss-cross shape enclosed in a square; stitching is visible on front of apron. Apron has a white fabric tie on each side, attached in similar fashion to neck loop. Bib features red fabric red cross, stitched onto bib using zig zag stitch in red thread, edges of cross are raw fabric. Both ties and neck loop are hemmed with straight stitch and overlocked in white thread. military, war, apron, uniform, medical, hospital, women, female, outfit, nurse, fashion, textiles -

Woodend RSL

Woodend RSLNeck Gaiter (Tour De Cou), Circa 1990

... De Cou) Textiles Manufactures Picardie Textiles Manufactures ...French army accoutrements, as part of uniform allocation.Army green (dark) wrap-around neck warmer, wool and elastin blend (?), rib stitch, two tags stitched into interior end, one which reads 'Antimite Definitiv' (Anti-Moth)' the other reads 'T.M.P AMIENS'. Overlock stitched at both ends.Two tags stitched into interior end, one which reads 'Antimite Definitiv' (Anti-Moth)' the other reads 'T.M.P AMIENS'.neck warmer, tour de cou, snood, uniform, the french armed forces -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Cloth Chart, A.E. Putnam Co. Iowa, U.S.A, c. 1896

This item was used to measure accurately the length of cloth on a bolt of material without unwinding it. It also measured lace, all types of textiles and spools of ribbon. It is surmised it would have been used in general stores or department stores in the late 19th and early 20th centuries. This item was discovered in the late 1980s behind an old safe at Swintons Stores in Timor Street in Warrnambool. The item appears to have been used extensively and would have been very useful during a stocktake. It may have been used in the Swinton Stores which were first established in Timor Street in 1865 with one section of the stores selling furnishings, furniture, clothing and clothing materials. The item was manufactured by A.E. Putnam of Iowa, U.S.A. There was a patent registered in 1896 and a later 'improved' model with a patent date of 1907. This item is of considerable interest because of its rarity and survival, its connection to Warrnambool General Stores in the past and its value as a research tool in local social and economic history. The possible connection to Swintons Stores is important as this business operated from 1865 to 2024 and was one of the longest-surviving family businesses in Australia. This is a rectangular-shaped wooden pole with one slightly flattened side and numbers marked on each side in patterns resembling brick walls. At the top of the pole are two wooden pieces attached to the pole by metal clips held by screws. The two wooden pieces are attached at a slight angle to the pole. The lower wooden piece is movable along the pole and has incised numbers. The wooden pieces are rectangular in shape with a large curved piece cut out to form the shape of a pennant. The maker's name is incised into the metal on the top attached wooden piece. Putnam's Cloth Chart Copyrighted 1896 Patent Pend'ggeneral stores in warrnambool, swintons stores in warrnambool, vintage measuring instrument for cloth -

National Wool Museum

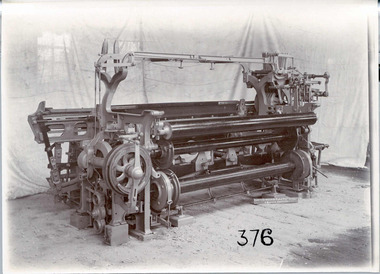

National Wool MuseumPhotograph - Loom, David Sowdon's and Sons, Yarra Falls Mills

Photograph probably for promotional purposes, of a "David Sowden and Sons" loom. Photograph was with other photographs in an envelope from Yarra Falls Mill.Black and white photograph showing a loom. 376textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving, yarra falls mill, loom, manufacturing industry, wool industry -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Cane Laundry Basket, 1959

This laundry basket was made by Mr Walter Bullock helped by his son John at his workshop behind his house at No 35 High Street, Wodonga. This business was known as "Cantetex" and was given as a wedding present to Colin and Jennifer Hore in 1959. Mr Bullock passed away in Wodonga on 20 November 1973. Colin Hore is the son of Jack Hore, a very prominent member of the Wodonga Community. Jack Hore was awarded the Order of the British Empire, MBE in January 1962 for service as a Councillor of the Wodonga Shire Council. He held a Council seat continuously for 32 years, including eight terms as President. He also served two terms as Chairman of the Wodonga District Hospital Board 1961-62, having been a member of the board since 1954. He held a seat on the Victorian Country Fire Authority for many years until his death in 1970, having been a member of Wodonga Urban Fire Brigade since 1940. Jack played football with Wodonga for 14 years and coached the team to premiership honours in the Chiltern and District League in 1926. He was club treasurer from 1926 to 1940. Jack was also a Foundation member of Wodonga Show Society.This item is significant because it belonged to a member of a prominent Wodonga family and was manufactured in Wodonga.A laundry basket made from rattan cane work. The lid is cover in blue and white textile.walter bullock, cane furniiture, jack hore mbe -

Warrnambool and District Historical Society Inc.

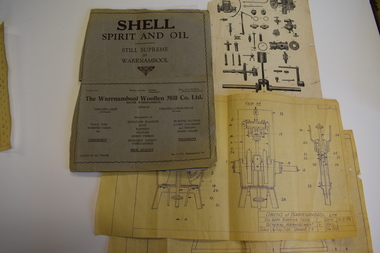

Warrnambool and District Historical Society Inc.Documents, Atlas Automatic Fire Services Pty Ltd, Woollen Mill, late 20th century

These items are from the Warrnambool Woollen Mill and relate to the fire protection services operating at the factory in the late 20th century. The Warrnambool Woollen Mill was commenced as a local public company and opened in 1910 in South Warrnambool with the first manager, John Bennett. During World War Two there were 700 employees at the mill due to wartime demand. In 1958 the factory became the first in Australia to manufacture electric blankets. In 1968 the mill was purchased by the Dunlop company and in 1982 Dunlop sold out to Onkaparinga Woollen Company which was taken over by Macquarie Worsteds and became known as Warrnambool Textiles. When Macquarie Worsteds ceased operations in Warrnambool the Smith Family managed the factory on behalf of the owners, the Warrnambool City Council. In 2000 the Woollen Mill closed and the site has been sold and developed as a housing estate.These items are of minor interest as mementoes of the Warrnambool Woollen Mill and will be added to the Woollen Mill collection in the Historical Society archives. .1 A sheet of white paper showing a sketch plan in black of the Warrnambool Woollen Mill with three areas coloured pink, yellow and blue .2 the same as .1 except that there are no shaded areas. .3 A sheet of lightweight card with black and yellow printing and a diagram of a machine Fire Plan For Insurance Purposes Atlas Automatic Fire Services Pty Ltd warrnambool woollen mill, history of warrnambool, onkaparinga woollen company, dunlop company -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document - Instruction manual, Details of component parts for Broadbent suspended steam driven Hydro Extractors, C 1926

Thomas Broadbent $ sons Ltd was established in 1864 in Huddersfield England. They are an engineering firm , specialists in heavy duty engineering products. By 1893 Broadbent had progressed to steam powered engines for the textile industry. Some of these machines operated for upwards of 50 years Today Broadbent is a leading world designer in the manufacture and maintenance of advanced centrifuges. This document is a manual for a suspended direct steam driven hydro extractor. It shows the various parts , maintenance instructions and erection and working instructions. While it is stamped as Albion Woollen mills which were situated at Geelong, it is likely to have connections to the Warrnambool Woollen Mills.This document is a good example of machinery manual. It is possibly linked to the Warrnambool Woollen Mill. The fact that the company which manufactured these items is still in existence today after 150 years is testament to the quality of the items produced.Cream coloured document with mainly black text with some red text for headings contained in the document. It is printed front and back and is folded in three sections.Stamp at top "Albion Woollen mills Pty Ltd" .4H x 4 in red pencil in top RHC. Printed on front page. Thomas Broadbent & Sons Ltd Central Iron Works Huddersfield. warrnambool, warrnambool woollen mill, broadbent direct steam driven hydo extractors,, broadbent centrifuge