Showing 555 items

matching inventors

-

Federation University Historical Collection

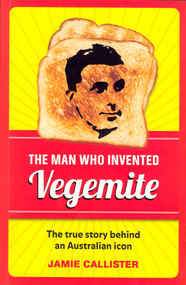

Federation University Historical CollectionBook, Jamie Callister, The Man Who Invented Vegemite, 2012

Cyril Percy Callister, a chemist by training, became a food technologist and the inventor of the well known spread 'Vegemite'. A Ballarat School of Mines (SMB) student around 1910, Callister then went to Melbourne University where he obtained his B.Sc. in 1914, M.Sc. in 1917 and D.Sc. in 1931. With Sir David Rivett in 1931 he secured the royal charter for the Royal Australian Chemical Institute, becoming president of the Society of Chemical Industry of Victoria in 1935-36. Vegemite, a yeast based spread, and perhaps one of most famous trademarks in Australia, was discovered around 1922 by Cyril Percy Callister. He was hired by the Fred Walker Company (a Melbourne based manufacturer later known as Kraft) as a laboratory assistant to develop a yeast extract spread. It took some years but by 1954 the special Vegemite song 'Happy Little Vegemites' demonstrated the popularity of the spread. Callister was also known for packing cheese in a can to preserve it and developing Kraft processed cheese. he son of a school teacher and postmaster he was born at Chute on 16 February 1893 and died on 5 October 1949. His brother Reginald Clive Callister (1889-1971) was also a student of SMB. (http://www.ballarat.edu.au/about-ub/history/art-and-historical-collection/ub-honour-roll/c/cyril-callister-1893-1949)Red and yellow soft covered book of 208 pages relating to Cyril Callister who invented Vegemite. On Frontispage signed "11th Oct 2012 James Callister"ballarat school of mines, callister, cyril callister, vegemite, william callister -

Federation University Historical Collection

Federation University Historical CollectionUnknown - Object, Allan Mine Cage Safety Brake, c1873, c1873

A mining safety cage was used in a mine lift. It was fitted with mechanisms to prevent the cage from dropping if the lifting rope broke. In the 1870s in Victoria, deaths and injuries from falling cages in vertical shafts of gold mines were a major problem. The inventor of this safety cage was Robert Allan, a machinery maker of Creswick Rd, Ballarat. He said his cage featured a ‘dissolving’ fulcrum. Others called it an eccentric (off centre) system. Note the pair of clutch levers designed to grab the side guides if tension ceases in the suspending rope from the poppet head pulley. Also, the hinged ‘lids’; designed to protect miners trapped in a braked cage from falling rope, and to enable rescue of the miners. This model was presented to The Ballarat School of Mines Council in November 1876. This model was shown at the Smeaton Show in November 1874, Ballarat School of Mines Museum from 1876, and examined by the 1879 Victorian Board of Inquiry (Pg 15 of FedUni Catalogue 3437) From the Argus of 13 November 1874: At Smeaton Show, Robert Allan of Ballarat won 1st prize for a Model of a Mining Cage, a Butter working machine, a Cheese press and a Curd Mill. By 1878 an Allan Safety-Cage was in operation in the Number 6 shaft of the Band and Albion Consols mine in Ballarat. This cage was judged the best inspected by the Victorian Board of Inquiry by 1879, p. 39.Mining was a big industry in Ballarat in the late 1800s and a lot of deaths were recorded because of mining accidents, the development of the mining safety cage brake limited the deaths and injuries from falling cages in vertical shafts. The model also has links to the Ballarat School of Mines, being presented to the council in 1876. Ballarat School of Mines is the oldest Technical School in Australia and is a predecessor of Federation University. The model is significant to Ballarat's mining history.Model of a mine safety cafe. A grey painted wooden frame with metal model of cage and safety brake system. When tension ceases in rope a pair of crutch levers grab strongly onto the wooden guide strips which run down the sides of a vertical shaft. This safety cage was discussed in "Safety Mining Cages. Report of the Board of Enquiry on Safety Cages 1878-9; together with proceedings of the Board and Appendices".safety cage, mine cage safety brake, robert allan, model, safety cage model, machine maker, millwright, mining, gold mining, tools, equipment, victorian board of inquiry -

Puffing Billy Railway

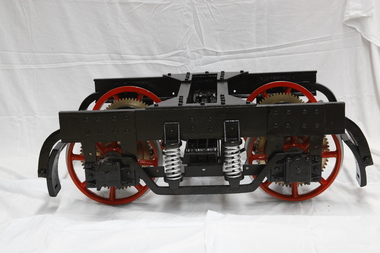

Puffing Billy RailwayBogie - Break of Gauge, Circa 1920

Designed and built in the early 1920’s by Charles Robert Prosser , a Melbourne Engineer, for an enquiry by the Commonwealth Government into ways of solving the break of gauge problem. Breaks or changes in railway gauges existed at most state borders of Australia during the first half of the 20th century. Upon completion of this model, it was placed on display in the Federal Parliament then located in Parliament House, Melbourne. Patents on the Break of Gauge Bogie Application number Title Applicant(s) Inventor(s) Filing date 1921000390 Improved means of adjusting the wheels of rolling stock to suit railway tracks of different gauges Charles Robert Prosser Charles Robert Prosser 1921-02-01 1917004843 Improvements in and connected with railway or other ticket supply tubes Charles Robert Prosser Charles Robert Prosser 1917-08-09 1915016191 IMPROVEMENTS IN AND CONNECTED WITH THE ADAPTATION OF RAILWAY ROLLING STOCK TO DIFFERENT GAUGES Charles Robert Prosser Charles Robert Prosser 1915-05-01 1915015980 Improvements in and connected with the adaptation of railway rolling stock to different gauges Charles Robert Prosser Charles Robert Prosser 1915-04-09 1914012931 Improvements in and connected with the adaptation of railway rolling stock to different gauges Charles Robert Prosser Charles Robert Prosser 1914-04-20 The Sydney Morning Herald Fri 2 Sep 1921 Page 6 BREAK OF GAUGE DEVICE. http://nla.gov.au/nla.news-article28088233 Historic - Railway Invention Break of Gauge Bogie Break of Gauge Bogie made of iron and wrought iron & brassboggie, break of gauge, puffing billy -

National Wool Museum

National Wool MuseumClothing - Jacket, 1978

The wool for this jacket began on the back of two sheep many kilometres apart. The first fleece for the warp was shorn from a single Merino at Currotha in Moree, NSW. The wool was 21-22 micron and the bloodline is a cross between Bundemar, Rossmore and Eural. The second sheep that provided wool for the weft was shorn in Beaufort, Victoria. It was a single Corriedale fleece shorn at Niawanda. The distance between these two towns is approximately 1250kms; a 15-hour car ride between paddocks. The two fleeces were spun and weaved together by the donor’s mother, Marjorie Allnutt. A level of talent is required to spin Merino fleeces. It is easier to spin cross bred wool, such as Corriedale, because it is less dense and much easier to comb, card and then tease out for a spinning wheel. The donor Philip Allnutt had a suit tailored out of the completed fabric at Ravensdale J & Son, 37 Swanson Street, Melbourne. The tailor was then a member of the Master Tailors Federation of Victoria. The business closed around 1986. Adding to the jacket’s story is its relationship to the household board game “Squatter”. Marjorie Allnutt was the sister-in-law of Robert Crofton Lloyd, the inventor of the wool themed boardgame. With more than 500,000 games sold in Australia as of 2007, it is the most successful board game ever produced in the country. The original “Squatter” board game is located within the National Wool Museum’s Collection. Philip Allnutt donated the Jacket to the National Wool Museum Collection in 2021. Cream singled breasted jacket with a narrow overlap and one column of buttons for fastening. The jacket features notched lapels of a medium width and two buttons of a cream & brown marble. The jacket has three visible pockets. A jetted pocket with no flap is on the right breast. A further two jetted no flap pockets finish an inch above the hem, on either side of the opening. Internally, the jacket features a further two pockets and a white silk lining for comfort. At the cuffs, the jacket utilises another 2 buttons of the same cream & brown marble.merino, currotha, moree, nsw, niawanda, corriedale, beaufort, victoria, hand spun, hand weaved -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageOpera Glasses & case, Early 20th Century

Opera Glasses came into existence as a result of a long line of inventions, and further improvements upon those inventions. The process started in the year 1608 when a Dutch optician by the name of Hans Lipperhey developed the first pair of binoculars with a magnification capability of X3. Less than a year later, a well-known inventor and philosopher by the name of Galileo developed what became known as the Galilean telescope. Advertisements were first found for opera glasses and theatre binoculars in London as early as 1730 in the form of a long collapsible telescope. The "Opera Glass" as it was referred to; was often covered in enamel, gems, ivory, or other art and paintings. For almost 100 years opera glasses existed merely as telescopes. In Vienna, in 1823 the first binocular opera glasses and theatre binoculars began to appear. They were two simple Galilean telescopes with a bridge in the centre, each telescope focused independently from the other by extending or shortening the telescope until the desired focus was achieved, which was useful, yet very cumbersome. Two years later in Paris, Pierre Lemiere improved on this design and created a centre focus wheel. This allowed the focusing of both telescopes together. After this development, opera glasses and theatre binoculars grew in popularity because of the superior view they facilitated in opera and theatre houses. The beautiful design of the glasses themselves also added appeal to the opera-going crowd. By the 1850's opera glasses and theatre, glasses had become a must-have fashion accessory for all opera and theatergoers.Not very significant as not associated with a historic event or person and made during the first half of the 20th Century and many are still available and easily sourced.Vintage Pair of Opera Glasses, with cow bone barrels and eyepieces, both barrel pieces have split in them, both metal end barrels each have a minor dent, optics are pretty clear no mould although have very minor dust spots inside, they look like they were gilded at some point but most of this has rubbed off glasses have a black leather case with blue lining. No markings whatsoever anywhereflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, binoculars, opera glasses, theatre glasses, optical instrument, cow bone -

Flagstaff Hill Maritime Museum and Village

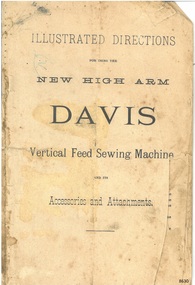

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Opera Glasses, 1920s

Opera Glasses came into existence as a result of a long line of inventions, and further improvements upon those inventions. The process started in the year 1608 when a Dutch optician by the name of Hans Lipperhey developed the first pair of binoculars with a magnification capability of X3. Less than a year later, a well-known inventor and philosopher by the name of Galileo developed what became known as the Galilean telescope. Advertisements were first found for opera glasses and theatre binoculars in London as early as 1730 in the form of a long collapsible telescope. The "Opera Glass" as it was referred to; was often covered in enamel, gems, ivory, or other art and paintings. For almost 100 years opera glasses existed merely as telescopes. In Vienna, in 1823 the first binocular opera glasses and theatre binoculars began to appear. They were two simple Galilean telescopes with a bridge in the centre, each telescope focused independently from the other by extending or shortening the telescope until the desired focus was achieved, which was useful, yet very cumbersome. Two years later in Paris, Pierre Lemiere improved on this design and created a centre focus wheel. This allowed the focusing of both telescopes together. After this development, opera glasses and theatre binoculars grew in popularity because of the superior view they facilitated in opera and theatre houses. The beautiful design of the glasses themselves also added appeal to the opera-going crowd. By the 1850's opera glasses and theatre, glasses had become a must-have fashion accessory for all opera and theatregoers. A vintage pair of 1920s opera glasses probably made in France by an unknown maker the item is significant due to it's provenance that can be traced and it's completeness as a useful social item and fashion accessory used by theatergoers from the mid 19th century and well into the 20th century. Some people still use modern variants of theater glasses today to improve their enjoyment of the theater.Both glasses and case are covered with black and white snake skin. Case lined with purple velvet, and has brass closure clip.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, flagstaff hill maritime village, great ocean road, opera glasses, serpentine opera glasses, binoculars, accessories, optical instrument, scientific instrument, theater glasses, french opera glasses, hans lipperhey -

Falls Creek Historical Society

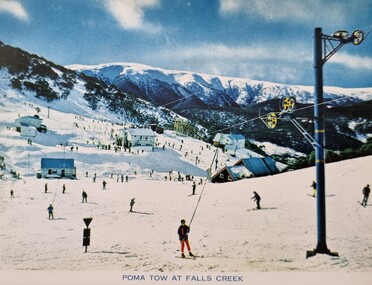

Falls Creek Historical SocietyPostcard - Poma Tow at Falls Creek

These photographs were taken in and around Falls Creek by Samuel Keith Pearce and printed for him as a foldout postcard by NuColor Vue. The postcards state they were printed for S. K. Pearce Pty. Ltd of Tawonga and Mount Beauty. Samuel Keith Pearce was born on 24 June 1917 in Armadale, Victoria. By the late 1940s he owned the Mt Beauty Supermarket, Newsagency, Drapery and Hardware store at Mount Beauty and also a store at Tawonga in partnership with his brother Gordon Cathew Pearce. For some time, they operated as Pearce Brothers. In the early 1960s Keith also opened a mini mart In Falls Creek. As well as being a keen photographer and an astute businessman, Keith Pearce was a well-known identity in the Kiewa Valley, making many contributions to the development of the area over a long period. This included serving as a member of the Bright Shire Council for many years. He worked hard to promote the interests of the Upper Kiewa Valley. As a sign of recognition and appreciation for his contribution to the community, the park opposite the grocery store in Mount Beauty was named the SK Pearce Gardens in his honour. Samuel Keith Pearce died on 7 July 1994 in Mount Beauty, Victoria. The first Poma tow to open at Falls Creek was the Nursery Poma in 1964. The name "Poma" originates from the inventor of this style of lift Jean Pomagalski who was born in Krakow, Poland, He fled Poland with his family and settled in France. As an engineer he developed the first surface lift with a tow rod which was installed in Alpe d'Huez (France) in 1934.This collection of postcards and images is significant because they were commissioned by a highly successful businessman in Falls Creek, Victoria.A colour image of skiers on the chair lift at Falls Creekfalls creek, falls creek chairlifts, poma lift falls creek -

Falls Creek Historical Society

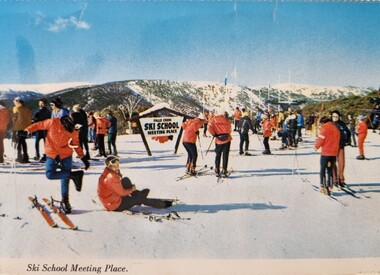

Falls Creek Historical SocietyPostcard - Ski School Meeting Place, Falls Creek

These photographs were taken in and around Falls Creek by Samuel Keith Pearce and printed for him as a foldout postcard by NuColor Vue. The postcards state they were printed for S. K. Pearce Pty. Ltd of Tawonga and Mount Beauty. Samuel Keith Pearce was born on 24 June 1917 in Armadale, Victoria. By the late 1940s he owned the Mt Beauty Supermarket, Newsagency, Drapery and Hardware store at Mount Beauty and also a store at Tawonga in partnership with his brother Gordon Cathew Pearce. For some time, they operated as Pearce Brothers. In the early 1960s Keith also opened a mini mart In Falls Creek. As well as being a keen photographer and an astute businessman, Keith Pearce was a well-known identity in the Kiewa Valley, making many contributions to the development of the area over a long period. This included serving as a member of the Bright Shire Council for many years. He worked hard to promote the interests of the Upper Kiewa Valley. As a sign of recognition and appreciation for his contribution to the community, the park opposite the grocery store in Mount Beauty was named the SK Pearce Gardens in his honour. Samuel Keith Pearce died on 7 July 1994 in Mount Beauty, Victoria. The first Poma tow to open at Falls Creek was the Nursery Poma in 1964. The name "Poma" originates from the inventor of this style of lift Jean Pomagalski who was born in Krakow, Poland, He fled Poland with his family and settled in France. As an engineer he developed the first surface lift with a tow rod which was installed in Alpe d'Huez (France) in 1934.This collection of postcards and images is significant because they were commissioned by a highly successful businessman in Falls Creek, Victoria.A colour image of skiers and instructors gathered at the Meeting Place, Falls Creekfalls creek, falls creek chairlifts, poma lift falls creek -

Mission to Seafarers Victoria

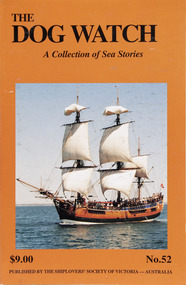

Mission to Seafarers VictoriaJournal (item) - Periodicals-Annual, Shiplovers' Society of Victoria, The Annual Dog Watch

This journal provides the reader with glimpses of the adventures and hardships of a seaman's life. Many of the stories are of sailing ships.Contributes to our knowledge of the importance of shipping and places on record those stories of the sea which would otherwise be lost.Contents Editorial - - 5 Adelaide to Sydney on the Endeavour - P. Kelly - 7 A tribute to Capt. G.A. Molyneux - T.E. Goldfinch - 27 The Bos’n’s Chair - R.N. Thiele - 29 A Gallant Steward - B. Springthrope - 33 The Australians return to the Phillipines - W.S. McUtchen - 35 Sunbathing is good for the eyes - Capt. R. Hart - 49 William Thomas, The Liverpool Shipowner & the Holyhead — wrecked on Point Lonsdale - G.I. Hawkes - 50 “Seahorses” - G.M. Naug - 56 Henry Greathead 1757-1813 Inventor of the Lifeboat - B.M. Morris - 57 The Milag Book - K. Shewan - 63 Life & Death of a Shipyard - E. Pennell - 65 A Donkey’s Breakfast & Parish Rig - W.P. Shemmeld - 69 The Indian Rope Trick — witnessed - R.A. Bloom - 74 MV Otaio, Training for the Sea at Sea - J. Giles - 77 “Sailorman” - N. Smith - 85 Can you solve the mystery? K.S. - 87 A Norwegian apprentice in the 1930s - Capt. G. Skomedal - 88 Snippets from the papers of Alexander McLennan — Sailmaker - J. McLennan - 103 A Mother’s Letter - B.M. Morris - 106 The Carrick ex City of Adelaide - R.C. Shepherd - 108 Book Reviews - - 111sailing ships, steamships, shipping, seafaring life, shiplovers' society of victoria, dog watch -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Iron, Mrs Florence Potts, Late 19th to early 20th century

Sad irons of the 19th century were so named because of the weight 1.8Kg that was needed to press wrinkled clothes and sheets. They were made of solid metal, including the handle. When the iron was heated, this meant that the handle would also heat up. The user would have to use a thick cloth or a mitt of some sort before they could pick up the iron. Even so, burns and blisters, as well as strained, tired arms, were a normal part of the “ironing day.” Mrs Mary Florence Potts of Ottumwa, Iowa, brought a change to the world of ironing. At the age of 19, in 1870, she invented her first sad iron. It had a hollow metal body that could be filled with a non-conducting material such as plaster of Paris. In 1871, Mary invented the removable wood handle, so that it could be changed from the cool iron to one that was hot and ready to use. A final improvement was the shape: Mary made both ends pointed so its user could iron in either direction. All of these inventions were patented under her name, a rarity for the time. Mary, with the help of her husband, tried unsuccessfully to market her invention on her own. It wasn't until she sold the sales rights to the American Manufacturing Company that sales took off. Advertised as "Mrs Potts' sad iron," it became a sensation. The company manufactured the iron from about 1876 to 1951. Mrs Potts' sad iron became a household word and a standard for future inventors to have to surpass. This didn't happen until 1882 when Henry W. Seely patented the first electric iron. The item is significant not only as a usable domestic tool, but it was, at the time of its creation, a revolutionary labour-saving device. Mrs Potts invention remains associated with a housewife's answer to the domestic drudgery of ironing.Iron,"Mrs Potts" pattern iron. Semi-circular or 'D' shaped wood handle and wood knob.Mrs Pottsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, clothes iron, flat iron, laundry, sad iron, mrs potts -

Glen Eira Historical Society

Glen Eira Historical SocietyPlan - Pritchard Steam Power Company

... Inventors ...This file contains one item: 1/A draft of a plan for a museum exhibit from the Spirit of Enquiry Workbook, by Denis Shephard, and dated 07/08/2007, pertaining to alternative energy research within the suburbs of Melbourne between 1950 and 1980. Much of the content is irrelevant to Glen Eira. However; one of the two principle subjects of the exhibit, discussed between pages 20 and 28, is the work of Ted Pritchard, who was based out of Caulfield. Ted and his father, Arnold Pritchard, aspired to reinvent the steam engine for use within the contemporary era. To that end, they fitted a Chevrolet pickup truck with one of their prototypes – with the result being one of the main items constituting the exhibit. Ted’s interest in steam power had been spurred by a working tabletop model of a steam engine that Arnold built for him – which constitutes another of the exhibit’s items. Also included is a brief history of the development of Caulfield. The plan is embellished with numerous images, with relevant ones including maps of Caulfield and black-and-white photographs of the Pritchards’ truck, model and workshop.engines, engineering, engineers, inventions, inventors, steam engines, steam power vehicles, pritchard ted, pritchard arnold, pritchard steam power company, caulfield, shephard denis, pritchard mrs., trucks, pritchard edward, holland grove, balaclava road, workshops, grants, pritchard automotive steam designs, caulfield racecourse, caulfield technical school, caulfield trades school, caulfield technical college, chisholm institute, camden town, southdown knitting company, home street, fl hutchison, fowler street, vale knitting mills, nepean road, winterfold spinning mills, acme knitting mills, glen eira road, mj ryan knitwear, leather industry, lane joseph, hotham street, casey william, glen huntly road, pickering william, paris leather manufactory, woorayl street, tv tatchell, premier wire works, webb street, chesterfield ha, manufacturing industry, victory milk plant, bl coram & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log, 1880-1890

The John E. Hand & Sons Company was founded in Philadelphia in 1873, quickly gaining a reputation as competent manufacturers of nautical instruments and compass adjusters. In fact, John Enos Hand, the company founder, is recognised as the first man in America to adjust a compass aboard an iron ship. The Hand Company built navigational equipment for all varieties of floating vessels, and operated a chain of retail outlets with “service stations” in numerous port cities, including Baltimore and New Orleans, until 1956. Service stations sold Hand instruments as well as other nautical paraphernalia and provided compass adjusting services. Additionally, John E Hand and his two sons, John L Hand and Bartram Hand, were inventors in their own right who patented design improvements for numerous instruments that were employed in the company’s work. Commercial and private contracts dominated the firm’s business until the late 1930s when the United States military began preparations for World War II. Although the Hand Company never completely abandoned its involvement with private industry, after World War II, military contracts monopolised their business. The Company obtained contracts with the Navy, Coast Guard and Marines to develop new instruments, and to build military-engineered nautical equipment. Of note are the wrist compass, developed for the Navy beginning in the 1950s, and the Mark VII Model 5 Navy Standard Binnacle. Although it moved numerous times, the Hand Company headquarters and factory remained in the Delaware Valley, occupying several buildings in Philadelphia and southern New Jersey. Maintaining its central office in Philadelphia well into the 1900s, the factory was moved to Atco, New Jersey around the turn of the twentieth century and subsequently to Haddon field, New Jersey. It moved one last time in the 1960s to Cherry Hill, New Jersey. In 1997, California-based Sunset Cliffs Merchandising Corporation purchased the Hand Company and all its assets for $100,000. "HAND" brand taffrail log by John F. Hand and Sons Co. Register is enclosed in log, has a glass front and 3 dials on an enameled surface, the first dial registers the miles up to 100, the second registers the units up to 10 mile, the third registers quarters of a mile. The item is rocket shaped with a three blade rotor and a rope ring attachment at one end; the rotor will spin when a rope is attached, allowing the apparatus dials to measure the ship's speed when it is dragged behind a ship. Diagram of the 'Hand' trademark with a compass card in the middle, inscription reads "John F Hand and Sons Co" and "PHILA-BALTO" ( Abbreviation for: Philadelphia / Baltimore) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bartram hand, john enos hand, john f. hand and sons co, john l hand, john hand & sons instrument makers, john hand & sons of philadelphia, marine instrument, marine service station, mechanical ship log, nautical instrument, nautical navigation, navigational equipment, scientific instrument, ship log, ship log register, ship’s speed, sunset cliffs merchandising corporation, speed log, rocket log, harpoon log, taffrail log, taff rail log -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, c 1929-1950's ref: AGM mark on bottle base

TROVE : The Argus (Melbourne, Vic. : 1848 - 1957) Thursday 14 February 1867 p 1 Article 'THE EXHIBITION. OFFICIAL DISTRIBUTION OF PRIZES. The culminating point in the history of the Intercolonial Exhibition of 1866-7, was reached yesterday, when His Excellency Sir Henry Manners Sutton, Governor of Victoria, publicly received the reports of the jurors, and formally declared their awards. .........................CHEMICAL AND METALLURGICAL PRODUCTS AND PROCESSES....................... MEDALS - VIctoria .............John Kruse, chemist, Melbourne - For his fluid magnesia...........................'. Haines, Gregory, 1994, Á History of Pharmacy in Victoria, The Australian Pharmaceutical Publishing Company in association with the Pharmaceutical Society of Australai (Victoria) Ltd, Melbourne, Australia.opp. page 54, photo of 'John Kruse' and of 'John Kruse's pharmacy, Russell Street, Melbourne, 1866'. TROVE : Melbourne Punch (Vic. : 1855 - 1900) Thursday 21 January 1897 p 3 Article A Musical Genius. BY X. THERE is a chemist's shop in Hawthorn in the drawingroom over which some of the best, music that has ever been heard under the Southern Cross has been discoursed. Here John Kruse, the famous violinist , has delighted his late father with his violin. Here Nellie Mitchell's (Madame Melba's) voice found appreciative admiration long before she became famous. It is the shop of John Kruse, chemist and druggist, the inventor of fluid magnesia, insecticide and a world of well-known articles of daily consumption. The old mail died some time back, but lived long enough to gratify his chief wish, viz,, to see his famous son, Herr Johann Kruse. John journeyed from Germany to see his dying father. His brief but brilliant sojourn amongst us will be remembered by all lovers of music. TROVE: Colac Herald Friday 1 September 1876, page 4, Article. TROVE: The Argus Tuesday 2 July 1867, page 3, Advertisement. 'Felton Grimwade, 125 Russell Street, Melbourne'Clear glass bottle, oval shaped in section with text embossed on both sides and on base. Embossed on base 'M65' over '1923 6' over 'AGM'. Side 1 : 'KRUSES PRIZE MEDAL MAGNESIA' Side 2 : 'THIS BOTTLE IS THE PROPERTY OF FELTON GRIMWADE & CO PTY. LTD. MELBOURNE'. Over the numeral '1'.chemist, magnesia -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, C. 1866 - 1895

TROVE : The Argus (Melbourne, Vic. : 1848 - 1957) Thursday 14 February 1867 p 1 Article 'THE EXHIBITION. OFFICIAL DISTRIBUTION OF PRIZES. The culminating point in the history of the Intercolonial Exhibition of 1866-7, was reached yesterday, when His Excellency Sir Henry Manners Sutton, Governor of Victoria, publicly received the reports of the jurors, and formally declared their awards. .........................CHEMICAL AND METALLURGICAL PRODUCTS AND PROCESSES....................... MEDALS - VIctoria .............John Kruse, chemist, Melbourne - For his fluid magnesia...........................'. Haines, Gregory, 1994, Á History of Pharmacy in Victoria, The Australian Pharmaceutical Publishing Company in association with the Pharmaceutical Society of Australai (Victoria) Ltd, Melbourne, Australia.opp. page 54, photo of 'John Kruse' and of 'John Kruse's pharmacy, Russell Street, Melbourne, 1866'. TROVE : Melbourne Punch (Vic. : 1855 - 1900) Thursday 21 January 1897 p 3 Article A Musical Genius. BY X. THERE is a chemist's shop in Hawthorn in the drawingroom over which some of the best, music that has ever been heard under the Southern Cross has been discoursed. Here John Kruse, the famous violinist , has delighted his late father with his violin. Here Nellie Mitchell's (Madame Melba's) voice found appreciative admiration long before she became famous. It is the shop of John Kruse, chemist and druggist, the inventor of fluid magnesia, insecticide and a world of well-known articles of daily consumption. The old mail died some time back, but lived long enough to gratify his chief wish, viz,, to see his famous son, Herr Johann Kruse. John journeyed from Germany to see his dying father. His brief but brilliant sojourn amongst us will be remembered by all lovers of music. TROVE: Colac Herald Friday 1 September 1876, page 4, Article. TROVE: The Argus Tuesday 2 July 1867, page 3, Advertisement. 'Felton Grimwade, 125 Russell Street, Melbourne' Clear glass ellipse in section bottle, with embossed text on both sides and initials and numerals on base.'KRUSES PRIZE MEDAL MAGNESIA', 'This bottle is the property of FELTON GRIMWADE & CO Pty Ltd Melbourne on sides. 'S1935' 'AGM' on base.magnesia, kruse, felton, grimwade, chemist -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationStand, pump & tank

Was the stand for a Chance Brothers air & oil containers fitted with pump handle & pressure gauges.This type of installation was once common and relied on the lightkeeper having to pressurise the cylinders manually at regular intervals throughout the hours of darkness. The oil was fed under pressure to the burner mantle. It is all that remains of an air and kerosene oil tank installation, with each rounded side formerly supporting a heavy iron tank. The containers would have been fitted with a pump handle and pressure gauges. An intact assemblage is displayed in the AMSA offices, Canberra with a text that explains ‘This type of installation was once common and relied on the lightkeeper having to pressurise the cylinders manually at regular intervals throughout the hours of darkness’.The system involved vaporising kerosene under pressure and mixing it with air and then burning the vapour to heat an incandescent mantle. The use of kerosene as a fuel to light the lantern became the most common system of illumination from the 1860s after the oil industry in the United States began to develop. The kerosene vapour burner was created in 1901 by British inventor Arthur Kitson (1859-1937) and perfected by Chance Bros for burning a more intense light in their renowned lenses. The lamp had to be watched throughout the night in case a mantle broke, and the tanks needed to be maintained by hand-pumping each hour or so. The Point Hicks lantern was initially lit by a six-wick Trinity house kerosene burner. This was replaced by the more efficient and brighter 55mm vaporised kerosene mantle burner in 1905, and the tank stand is probably original to this apparatus. Electricity eventually replaced kerosene at Point Hicks in 1964 making the tank installation obsolete, and the last kerosene system in an Australian lighthouse was replaced in 1985. Gabo Island Lightstation has a pair of tanks that are not attached to the optical system and are no longer in the lighthouse. They are also missing the pressure gauges that were formerly attached to the top of each cylinder. An intact tank assemblage is displayed at the Cape Schanck Lighthouse Museum it is detached and not original to the lighthouse. Although corroded, the remnant Point Hicks tank stand has first level contributory importance to the lightstation. It is significant for its provenance and historical value as part of the Chance Bros vaporised kerosene burner introduced in 1905 to intensify the light and improve the efficiency of the system. The rusted iron stand rests on four short legs and is shaped like a pair of spectacles. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Home Phonograph

Thomas Edison was one of the world’s most prolific inventors, holding over 2,000 different patents. One of his earliest inventions was the phonograph. The Edison Phonograph Company was formed on October 8, 1887, to market Edison's machine. The original machine went through many modifications. The Patent information on this machine indicates that it was manufactured after May 1906. Sound was recorded on wax cylinders. Edison cylinders were the earliest commercial medium for recording and reproducing sound. These hollow cylindrical objects have an audio recording engraved on the outside surface which can be reproduced when they are played on a mechanical cylinder phonograph Beginning in 1889, pre-recorded wax cylinders were marketed. They featured professionally made recordings of songs, instrumental music or humorous monologues in their grooves. The earliest cylinders were made from soft wax and later hard wax was utilised. Further developments by several companies, led to the introduction of celluloid cylinders. In late 1908, Thomas Edison had introduced wax cylinders that played for about four minutes (instead of the usual two) under the Amberol brand. The Amberols were manufactured with flat rim-ends, to prevent confusion with the earlier bevel-edged two-minute version. In 1912, the Edison company eventually acquired patents to the celluloid technology, and almost immediately started production of the new brand as Edison Blue Amberol Records. Cylinder records continued to compete with the growing disc record market into the 1910s. In 1912, Columbia Records, which had been selling both discs and cylinders, dropped the cylinder format, while Edison introduced his Diamond Disc format, played with a diamond stylus. From 1915, new Edison cylinders were re-recordings from Edison discs. Although his cylinders continued to be sold in steadily dwindling quantities, Edison continued to support the owners of cylinder phonographs by making new titles available in that format until the company ceased manufacturing all records and phonographs in November 1929.This item is significant because it is representative of early home entertainment in the late 19th and early 20th century.An Edison Home Phonograph in a wooden case. No trumpet included.On outer case' Edison On metal plate: Thomas A Edison TRADE MARK On large metal plate: Detailed inscription of Patent informationphonograph, thomas edison -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Flagstaff Hill Maritime Museum and Village

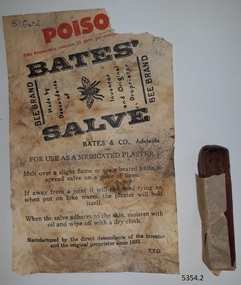

Flagstaff Hill Maritime Museum and VillageArticle - Ointment, Bates & Co. (William Usher), 1851 - mid-1900s

Bates' Salve has been used as a home remedy for the treatment of boils, skin infections, splinters, pimples and insect bites for decades, from the mid-1800s to the mid-1900s. It is a drawing application for bringing out foreign bodies and pusses from a wound. There are still many families who remember using it and others who have been using it and are down to their last ‘inch’. One comment from a reader from Queensland tells how his Dad was a sleeper cutter in the 1950s and on school holidays his brother and he used to help their Dad. When doing this task after a wet season they would be confronted with spear grass about a metre high. Sometimes the spears would enter their skin, and when the spears were wet they would screw like a corkscrew into their flesh. If they left them for too long it was impossible to dig them out with a needle. That's when the Bates Salve was put into action to draw the spearhead out. "It worked wonders. It was a marvellous invention." Many people say that they would love to be able to purchase more of it today and hope that someone will produce a ‘safe’ version of it. There are several versions of a recipe for the salve available online. It appears that the salve is named after Daisy Bates, wife of the Bates’ Salve proprietor, William Usher. William’s son Victor continued making Bates’ Salve well into the mid-1900s, with the business being carried on by Victor’s only son, Alan. There are still descendants in the family home in Norwood, Adelaide. William’s great-grandchild has stated that, despite being subject to the salve during childhood, there have been no noticeable ill effects. A small notice in the Adelaide Advertiser in 1915 made a suggestion “It is said that Bates’ Salve is the popular line with OUR BOYS in Gallipoli. They recently sent to the Adelaide Red Cross for a supply, so it would be a good line to put in soldiers’ Christmas Billies.“ Over 700 ‘Christmas Billies’ were sent from generous Warrnambool citizens to our soldiers in the trenches in Gallipoli. The average cost of filling a billy with gifts was Ten Shillings, calculated at about Fifty-four Dollars in 2021. The contents included Christmas puddings and tobacco. The huge project was coordinated by a local Committee and involved generous businesses and hundreds of kind-hearted community members, with recognition sown by naming many of those involved in an article in the Warrnambool Standard. The project’s idea was initiated by Australia’s Department of Defence and all states were involved in supporting the soldiers in this way. Mr Bates (Theopholis) of Hull, England, was the original owner of the Bates’ Salve recipe. When he died he left his business to William Usher, his son-in-law. William arrived in South Australia in 1851 after he had sold his recipe to an English firm, giving them the rights to make and sell it all over the world, except in Australia. Bates then became the registered proprietor of Bates’ Salve for the Commonwealth and still had a large market for his product. William Usher made the salve at his Norwood home, in a wood-fired copper in the garden within a three-sided enclosure. The ointment was then taken to a room in the house where it was divided, labelled and packaged. It was then sent to Faulding’s Wholesale Chemist for distribution. William and his wife May (or Mary) had three children; Jack, Victor and Ivy. When May died, William married Mary Williams (May’s maid, from Tasmania, twenty years younger than William) and had seven more children. The treatment’s packaging labels it as a POISON. It seems that its active ingredient was lead oxide (22 per cent), which is no longer considered unsafe. A member of the public mentioned that in 2016 they found some Bates’ Salve in an old family medicine chest. Its label stated that the product “contains a minimum of 25.8 per cent of red lead oxide”. That particular sample was made at 470 Wallon Road, West Molesey, Surrey, England. Some people would love to be able to use the product still and even take the risk of poisoning. Instructions for its use are included on the wrapper. Here is a transcription - "Bates' Salve. Bee Brand. POISON. This Preparation contains 22 parts per centum [lead oxide]… Made by Descendants of the Inventor and Original Proprietor. For use as a medicated plaster. Melt over a slight flame or use a heated knife to spread the salve on a piece of linen. If away from a joint it will not need tying as, when put on lukewarm, the plaster will hold itself. When the salve adheres to the skin moisten it with oil and wipe it off with a dry cloth. Manufactured by the direct descendants of the inventor and the original proprietor since 1833."This package of Bates' Salve has been used as a home remedy since the mod-1800s and even up to now in 2019 by those who consider themselves lucky to still have some at home. It was promoted as a 'cure all' treatment and kept handy for use at home and away. It represents our early industry and health management when medical treatment was often difficult to access. The product is the part of many childhood memories of those alive today.Bates’ Salve ointment; oblong stick of firm, brown waxy substance wrapped in waxed paper, with an outer printed wrapper. Text on wrapper warns that it is POISON and includes instructions for use as a medicated plaster, to be heated and spread onto linen then applied to the injury. Made by Bates & Co., Adelaide. The wrapper shows an emblem of a bee. The formula has been used since 1833.Text on wrapper includes "POISO[N]", "BATES' SALVE", "BEE BRAND", "BATES & CO., ADELAIDE". "This Preparation contains 22 parts per centum [lead oxide]" There is an emblem of a bee with wings outstretched.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bates’ salve, bates’ salve medicated plaster, bates and co adelaide, bee brand, medicated plaster, medical treatment, remedy, drawing treatment for infection, medicine cabinet, home remedy, pharmacy treatment, mid 1800s – mid 1900s remedy, topical application, treatment for boils, bites, splinters and infections, poison, preparation for treatment, ointment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wash trough, Melvin Newton Lovell, Mangle was Patented June 10, 1898 by Lovell Trough is possibly of later manufacture by a local unknown cabinet maker between 1900-1920

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers). This item is now sought by collectors and is even rarer due to it's combination with a Lovell clothes wringer. Wooden wash trough with 2 troughs & attached a Lovell wringer (or mangle Anchor Brand) Hard to make out as worn off with useflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, wash trough, wringer, mangle, laundry, cleaning, washing, housework, domestic, melvin newton lovell, wooden was trough -

Puffing Billy Railway

Puffing Billy Railway1920's Station Cash Box Tin - Hobbs & Co London, 1920's

1920's Station Cash Box Tin Made by Hobbs & Co London Lever Machine Made Alfred Charles Hobbs (October 7, 1812 – November 6, 1891) was an American locksmith and inventor. Hobbs went to London as a representative of the New York company of Day & Newell, which was exhibiting at the Great Exhibition of 1851. Hobbs had brought with him his boss's (Robert Newell) Parautoptic lock, designed to compete with, and surpass, the locks available at the time in Britain. He was the first one to pick Bramah's lock and the Chubb detector lock at the Great Exhibition of 1851 and forced the lock manufacturers to improve their designs. The lock controversy continues a subject of great interest at the Crystal Palace, and, indeed, is now become of general importance. We believed before the Exhibition opened that we had the best locks in the world, and among us Bramah and Chubb were reckoned quite as impregnable as Gibraltar— more so, indeed, for the key to the Mediterranean was taken by us, but none among us could penetrate into the locks and shoot the bolts of these masters. The mechanical spirit, however, is never at rest, and if it is lulled into a false state of listlessness in one branch of industry, and in one part of the world, elsewhere it springs up suddenly to admonish and reproach us with our supineness. Our descendents on the other side of the water are every now and then administering to the mother country a wholesome filial lesson upon this very text, and recently they have been "rubbing us up" with a severity which perhaps we merited for sneering at their shortcomings in the Exhibition. In 1854 he was awarded a Telford Medal by the Institution of Civil Engineers for his paper 'On the Principles and Construction of Locks'. Sign on a strong room door. Hobbs became one of the founders of the lock making firm of Hobbs Hart & Co. Ltd. The company started in 1851 and was formally registered as Hobbs and Co. in 1852. But by 1855 it had become Hobbs, Ashley and Company. The name then changed to Hobbs, Ashley and Fortescue, with an address at 97 Cheapside in London. Then for the next ninety years the address was 76 Cheapside in London. In 1860 Hobbs returned to America and lived in Bridgeport, Connecticut, and went on to hold a dozen patents for firearm ammunition manufacturing. In 1880 he listed himself as a "Superintendent Of Cartridge Factory" Info from https://en.wikipedia.org/wiki/Alfred_Charles_HobbsHistoric - Railways - Station Cash Box Tin 1920's Station Cash Box Tin - Hobbs & Co London Metal Tin - painted Black, Gold and Red with Brass Lock and HandleHobbs & Co London Lever Machine Made1920's station cash box tin, puffing billy -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumMeldometer, Joly

The Joly meldometer was created to determine the melting point of minerals. W.E. Wilson, an astronomer and author, stated in 1900 that the Joly meldometer consisted of a ‘a strip of platinum on which minute fragments of any mineral can be placed, while any alteration in its length can be determined by means of a micrometer screw which touches a lever connected with one end of the strip. The strip can be heated by an electric current, and is calibrated by observing the micrometer readings corresponding to the temperatures at which some substances of known melting-points melt’i . One reason why the Joly meldometer was seen as a successful addition to science was the small amount of any substance that it required for testing. Only a minute sample was needed for the instrument to work and so a tiny part could be taken from a delicate item without destroying itii . The instrument was originally manufactured by the Irish company Yeates & Son of Dublin. The Yeates family business was established in the early 1790’s and is thought to have operated until approximately 1922iii . Their business slogan was recorded as ‘Instrument makers to the University’, a slogan which proudly exhibited their relationship with Trinity College, Dublin. The company was located directly opposite Trinity College, the place where the Joly meldometer was created. Working in such close proximity must have assisted this business relationship. The inventor of this meldometer was Irishman John Joly. Joly was born in 1857 at the Church of Ireland Rectory, Hollywood House. His education led him to Trinity College Dublin where, by 1891, he had obtained a Bachelor of Engineering degree as well as a Doctorate of Science. The entirety of his working life appears to have taken place at Trinity College although he is known to have travelled in order to consult with other scientists such as the world renowned Sir Ernest Rutherford. The Joly meldometer was used for a variety of different purposes, with scientists often adapting the instrument to suit their own needs. For instance, the previously mentioned astronomer W.E. Wilson adapted the meldometer to assist him in measuring the radiation of the suniv . Joly used his device in an attempt to ascertain the age of the earth. In 1913, along with Sir Rutherford, Joly came to the conclusion that the earth was approximately 400 million years old. They did this by analysing the decay of radioactivity in minerals. According to our present knowledge of the earth this was a much more accurate date than the dates Joly had previously derived. He had first thought that the earth was 97 million years old due to the volume of sodium in the oceans. Joly’s second analysis of the topic had resulted in the age of 80 million years. This figure was based on the accumulation of sediment. Apart from designing his meldometer, Joly is also remembered for his work with colour photography. In 1894 Joly discovered a method for creating colour photographs from a single platev . He also studied the use of radiation as a treatment for cancer and persuaded the Royal Dublin Society to establish the Radium Institute to assist hospitals. In 1933 Joly passed away at the age of seventy-six. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clock, late 1900s early 20th Century

In 1850 the Ansonia Clock Company was formed as a subsidiary of the Ansonia Brass Company by Phelps and two Bristol Connecticut clock makers, Theodore Terry and Franklin C. Andrews. Terry & Andrews were the largest clock manufacturers in Bristol at the time with more than 50 employees using 58 tons of brass in the production of about 25,000 clocks in 1849. Phelps decided to get into the clock making business to expand the market for his brass, while Terry and Andrews got access to better quality brass at better prices. They had then sold 50% of their business to Phelps and moved the business to Ansonia, Connecticut. In 1877 the clock company purchased a factory in New York and moved most of its production thereafter being spun off from the brass company. Henry J. Davies of Brooklyn, himself a clock maker, inventor and case designer, joined the newly reconstituted company as one of its founders. As President, he is thought to have been largely responsible for the figurine clocks, swing clocks and other unusual and desirable novelties for which the Ansonia firm became known. By 1879, a second factory was opened in Brooklyn, New York and by June 1880 employed 360 workers, while the Connecticut factory continued producing clocks as well with a workforce of 100 men and 25 women. Hence, clocks marked "Connecticut" were generally produced before 1879, while those marked "New York" were all produced after 1880 After the New York factory burnt down in 1880 the company rebuilt the factory on the same site, and reopened the expanded factory in 1881, with a capacity to exceed that of the Connecticut factory which by 1883 had closed. By 1886, the company had sales offices in New York, Chicago and London, with more than 225 different clock models being manufactured. In 1899, Phelps' grandson William Earle Dodge Stokes commissioned architect Duboy to build the "greatest and grandest hotel in Manhattan, New York” which became the city's first air-conditioned building. In 1929 the majority of the timekeeping machinery and tooling was sold to the Soviet government's US trading company Amtorg, just before the stock market crash. The parts, machinery and key skilled workers were shipped out of the USA to form the basis, along with the remains of a watch company purchased a year later, of the clock and watch industry in Moscow such as Poljot and Sekonda. In 1969, the rights to the use of the name, trademarks, and goodwill were transferred to Ansonia Clock Co., Inc., Lynnwood, Washington. The item marks the beginning of mass produced clocks in the United States, cheaply priced and available to all. The company had many innervation's during it’s life regards clock and later wrist watch making that led the way for other companies in many different countries to emulate.Clock, pendulum mantle model. Carved scallop "Ginger bread house" cottage clock. Oak case, white enamel face, floral etched glass door. Clock has an hour bell chime. Glass front opens to allow rewinding. Made by Ansonia Clock Co, New York. Marked "Manufactured by Ansonia Clock Co. New York, USA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, mantle clock, clock, pendulum clock, time keeper, horology, ansonia, ansonia clock co, america -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Falkiner Electric Road Train in front of George Leighton's Wodonga Store and Bakery Wodonga 1914

This image of the Ralph Falkiner’s Mueller Petrol-Electric Road Train was taken in Wodonga in February 1914. Imported from Germany by Mr Ralph S Falkiner in late 1913, the train’s inventor, Major W A Mueller with two assistants, came to Melbourne to assemble then commission the train. The train cost Mr Falkiner about £13,000 plus £4,591 import duties. The Falkiner family were sheep breeders in the Western Riverina and he hoped to use the road train primarily to convey wool to the railways for despatch to Sydney. The train was 216 feet long, weighed 43.5 tons with a top speed loaded of 6-8m/h and petrol consumption up to two gallons per mile. Its first Australian journey was to haul 50 tons of cargo to Edmondson & Co at Wagga Wagga, 277 miles away. The journey from Melbourne was plagued with problems including broken cylinders and crank shaft and overheating as it was not designed for Australian climatic conditions. Three months after leaving Melbourne it arrived in Wodonga. A series of problems between Springhurst and Wodonga, including broken cylinders and valves caused an eight day delay. Some of the cargo was off-loaded in Albury, then after repairs the train continued on to Wagga where it arrived in May 1914. After unloading there, the road train was taken to Mr Falkiner's Groongal Station, near Hay and subsequently made several long trips into drought-stricken areas or the Western Riverina. Eventually the dream collapsed when the engines gave out after the train bogged in the sticky black soil of the Hay plain with 251 bales of wool on board. The train was finally railed back to Melbourne and stored but destroyed when the warehouse burnt down. In this photo, the road train is drawn up outside the Wodonga Stores and Bakery owned and operated by George Leighton. Mr Leighton began his business opposite the Terminus Hotel in Sydney Street, Wodonga in 1885. His business included a general store, stocking groceries, ironmongery, drapery, crockeryware, boots and shoes as well as a bakery. He was very actively involved in the community and served on the Wodonga Council for 18 years including three terms as Wodonga Shire President in 1901 – 02, 1910-11 and 1913-14. He was also Chairman of the Wodonga Waterworks Trust for several terms. Mr. Leighton also took a prominent part in the movement to establish a Public Library in Wodonga. His other involvements including being a Founder of the Wodonga Lodge of Freemasons, Honorary Treasurer of the Wodonga Bulldogs Football Club and Secretary of the Wodonga Racing Club. Mr Leighton passed away in Wodonga in 1916.This image is significant because it records a rare event in Wodonga and an experiment in Australian road transport.Black and white images of the Falkiner Road Train in Wodonga and on its first journey from Melbourne to Wagga, NSW It is taken in front of the Wodonga Stores and Bakery operated by George Leighton in Sydney Street, Wodonga.falkiner electric train, early road transport, high street wodonga, george leighton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878