Showing 3923 items matching "machining"

-

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionFunctional object - Mug

The 20th Light Horse (Victorian Mounted Rifles) was raised in 1920 as part of the 3rd Cavalry Brigade, 2nd Cavalry Division, Citizen Military Forces, with Headquarters at Seymour and depots along the Goulburn Valley from Mansfield to Tocumwal in southern NSW. In December 1941, 20th Light Horse (Victorian Mounted Rifles) converted from horse to mechanised, initially as 20th Motor Regiment. In 1943 redesignated 20th Pioneer Battalion and deployed to Merauke, Dutch New Guinea. The regiment was disbanded at the end of the war, 1945. 20th Light horse was the only light horse unit to serve overseas in WWII. Lieutenant Fyffe enlisted at the outbreak of war and served as VX 42774 with the 9th Division Cavalry Regiment in North Africa and was promoted to captain. During the attack on Trig 22 on 17 July 1942, Captain Fyffe, commanding a composite squadron, manoeuvred his tanks to knock out machine guns and anti-tank guns enabling 2/32 Battalion to capture the objective. Captain Fyffe was awarded the Military Cross for his leadership and courage in the action. This was 9th Division Cavalry's first tank action of the war. This is one of a collection of mugs presented by Officers of a Light Horse regiment drawn from rural and regional Victoria in the period between the World WarsSilver plated mug with handle and inscribed on side"20th Australian Light Horse Officer's Mess. Presented by Lieutenant H.G. Fyffe" and on base "Rigert EPNSAI 10 "officers' mess, 20th light horse, fyffe h g -

Vision Australia

Vision AustraliaAdministrative record - Text, Braille and Talking Book Library Annual Report 1894-1983, 1983

Annual report of the Braille & Talking Book Library including Minutes of the AGM, Board of Director's Report, President's report and financial statements. Items also included are: the structural re-organisation, increased borrowing has required increase in staffing, the entire share portfolio has been sold however 4 staff were retrenched and remaining staff undertook an 8% pay cut for 8% less hours (with many continuing to work the same hours), decision to phase out Clarke & Smith machines in favour of cassettes, due to lower staffing a waiting list for borrowers need to be established with up to an 8 week delay to join, braille interleaved books developed to allow sighted parents of blind children (or vice versa) to enjoy a book together, establishment of LBA allows for segregation of alternative production and sales of book to other organisations, Braille Book of the Year panel of Barrett Reid, Joyce Nicholson and Lloyd O'Neil, opening of Benalla Studio on 7 December 1982, and as library declared a free public library in May 1980, library receives state government funding at 3% of the state budget.1 volume of text and illustrationsbraille and talking book library, annual report -

Vision Australia

Vision AustraliaAdministrative record - Text, Royal Victorian Institute for the Blind annual report 1957-1958, 1958

Events that occurred during the year : further expansion of nursery with 3 children under the age of 3 admitted, first Aboriginal child (Alexander Marks) was admitted, children gained 23 swimming certificates, some Scouts met Lady Baden Powell, Board approved revised sketch plans for 42 acre site at Box Hill, doubling of Talking Book Library service with additional 60 machines purchased at a subsidised cost courtesy of the Nuffield Foundation, Alberta Tutton is taking a break from Auxiliary President duties with J. A. Duncan filling the temporary vacancy, thanks to Mabel Nelson for acting as accompaniste to concert artists, resignation of Alban Whitehead as a Country Concert Party manager and appointment of Denis Bandel in the position, outgoing Council member Cr. W.J. Wrens was recognised as Companion of the Order of the British Empire, and Captain Semmens and crew of 'Triaster' provided play equipment for playground. Dick Sutcliffe led the blind orchestra as it played 'There'll Always Be An England" as Queen Mother drove by the Institute and stopped when she saw the crowd of blind children and workers waiting for her, accepting a bouquet of gardenias from Margaret Oliphant.1 volume of text and illustrationsannual reports, royal victorian institute for the blind -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Sydney William Phefley

Sydney William Phefley was born in Wodonga, Victoria on 5th November 1896 to Christian Phefley and Martha nee Schultz. He was their third son and eighth child in a family of 17 children. Sydney enlisted in Melbourne on 4th August 1915 and was allocated to 29th Battalion Machine Gun Section. On 10th November 1915 he embarked from Melbourne on the HMAT Ascanius and saw service in Egypt and on the Western Front. In March 1916 Sydney was promoted to Sergeant. During that year he was also hospitalised for a minor case of mumps in Cairo in March and then for a case of trench foot in England in December. In February 1918, Sergeant Phefley was accepted into the Officer Cadet Battalion which included the completion of an Officers Training Course at Oxford. In October 1918 he was transferred to the 32nd Battalion and was promoted to the rank of Lieutenant in December 1918. Lieutenant Phefley returned to Australia on 15th May 1919 and was discharged on 22nd August 1919. Sydney was later employed by the Victorian Railways as an Engine Driver. He married Mary Johanna Hogan on 15th October 1924. Sydney William Phefley died in Moe, Victoria on 16th January 1973.This image is significant because it portrays a member of a prominent Wodonga family who served Australia during World War I.A framed black and white image of Sydney William Phefley in Uniform.private sydney william phefley, phefley family wodonga, world war 1 servicemen -

Bendigo Military Museum

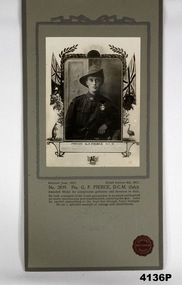

Bendigo Military MuseumPhotograph - REMEMBRANCE PHOTO, Vincent Kelly, Post 1919

George Frederick PIERCE No 2839 AIF. The photo shows him wearing the award of the “DCM” which has been superimposed on the photo. George enlisted on 29.6.1915 age 20 years in the 9th Reinforcements 6th Bn AIF, embarked for Eygpt 9.10.1915, embarked for France 2.4.1916, Awarded the Distinguished Conduct Medal in 1917, KIA Belgium 4.10.1917, no known grave. DCM award. For Conspicious Gallantry and Devotion to Duty. He took Command of his Lewis Gun Section in an attack and bombed an enemy Machine Gun post single handed and captured the Gun. He later carried ammunition to the front line through heavy barrages. He set a splendid example of devotion and courage. This photo has been cropped out of the original which had 3 soldiers in it. Refer Cat No 5459P This is the first item in a large collection that belonged to William (Bill) Thomason. Bill served in the RAN from 1947 - 1949. He was the Author of 3 books: "Marching On", Cat No 4821, "March to Ranau", Cat No 862 and "March to Waikato", Cat No 5289. Bill was a collector and ran a small Military Museum in View Street Bendigo for a time.Photo B & W, portrait of a soldier with studio background pasted onto a larger grey background with flowers, flags, kangaroo, emu and details under. On the cardboard, writing relates to the award of the “DCM”. The grey background has a darker surround and red stamp in the right hand corner.“No 2839 Pte G.F.PIERCE DCM (Infy)”photography, military, remembrance -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - Floor Board Clamp

A flooring clamp (or cramp) is used for holding tongue and groove floorboards in place whilst laying a new floor. The ratchet handle is used to apply horizontal pressure to hold boards firmly in place until they are secured. “The General and Commercial Directory of the Borough of Birmingham, and six miles round; including Wolverhampton, Bilston, Walsall, West Bromwich” published in 1858 lists William Bissell as an ironmonger in Union Street, Wolverhampton. In the catalogue for the 1862 London Exhibition, three items manufactured by William Bissell were listed, including:- “BISSELL'S PATENT FLOORING CRAMP. The force of this cramp is fully equal to 1 ton. It is adapted to joists from 2 to 4 in. and is the most expeditious and easy in working of any cramp in use.” In the 1864 edition of “Williams's Manufacturers' Directory, for London and Principal Market Towns in England”, page 445, in listings for Wolverhampton, W Bissell is listed as a Patentee of flooring cramps, lifting jacks and proprietor of mortise locks; mortising machines, bench and vertical saw-frames". By 1871 the business was operating as Messrs. J. G. Bissell and Co. and the trademark on this item in our Collection was phased out. This information assists in allocating the provenance of this item to the late 1860s.This item is significant because it is representative of housing construction tools used in the Wodonga District which have evolved into present day tools.A cast iron clamp used to install tongue and groove floorboards. Maker's mark on on side. W. B. BISSELL PATENTEE WOLVERHAMPTONcarpenters' tools, housing construction -

Eltham District Historical Society Inc

Eltham District Historical Society IncAudio - Audio Recording, Audio Recording; 2018-04-11 AGM and Briar Hill Timber and Trading with Bob Manuell, 11 Apr 2018

April Meeting (Newsletter No. 239, Apr. 2018) Our Annual General Meeting includes the presentation of annual reports and the election of office bearers for the coming year. At this meeting we are pleased to be able to show a film of the early activities of the Briar Hill Timber and Trading Company, in Sherbourne Road, Briar Hill. This film details the various operations involved in this business during the 1950s/60s, from sourcing trees from the forest, to machining the timber and then manufacturing various building materials and components. A copy of this film has been generously donated to our Society by Bob Manuell, who was an active part of this family owned business, established by his mother-in-law Mrs Hazel Squire. We are fortunate that Bob has agreed to attend our meeting to add his comments and insights about some of the scenes shown. Bob Manuell was a former Shire President and Councillor at the Shire of Eltham, from 1980 until 1994, when following municipal restructure the Shire ceased upon the establishment of the Shire of Nillumbik. Bob’s father-in law Fred Squire was also a former Eltham Shire President and Councillor, having served between 1945 and 1953.1:26:38 duration Digital MP3 File 30 MB audio recording, bob manuell, briar hill timber & trading, eltham district historical society, meeting, society meeting -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryMachine - Anaesthetic machine, Minnitt, 1930 - 1937

This Minnitt machine was owned by Dr Mary Clementina DeGaris. Dr DeGaris qualified from medicine, MB BS, at the University of Melbourne in 1905. She continued her studies, becoming only the second woman in Victoria to qualify MD, in 1907. With the outbreak of war, DeGaris attempted to enlist as a doctor with the Australian Army but was refused. Undeterred she travelled to England, where she joined the Scottish Women's Hospitals for Foreign Service, a medical group made up entirely of women. After the war, she returned to Australia and set up practice as an obstetrician in Geelong, Victoria. Subsequently, the Geelong Hospital named a wing after her, "DeGaris House", which is now part of Geelong Private Hospital. DeGaris was awarded the St Saba medal, 3rd class, for her work during WWI. Robert James Minnitt introduced the concept of self-administered analgesia, using an apparatus designed and built in conjunction with London scientific instrument-maker, Charles King. The Minnitt apparatus met with considerable success and led to further modifications, including the introduction of the Queen Charlotte gas-air analgesia apparatus in 1936.Brown leather suitcase with brass locks and leather handle. Inside the case is metal equipment, with arms for attaching cylinders. On top of the case, located underneath the handle, is a small brass plate, bearing the name of the owner in black printed script on a piece of card or paper held inside the plate.Printed in black ink on name plate: Dr Mary C. De Garis.minnitt, geelong, scottish women's hospitals, world war i, obstetrician -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPolisher Floor, Hoover Appliances, Meadowbank

This appliance was a time saving method of cleaning floors. It appeared at a time (after World War II) when the domestic pressures faced by mothers and domestic staff was on the increase. The necessary "working parents" was through necessity becoming part of the "typical" family environment. It was the start of the ever increasing demand, from an economical reason, for both parents to work outside their property. Historically the period of the 1950s was one of extreme changes. It was an era where established role models were under pressure from an ever increasing demand for new and advancing consumerism. Communication levels via radio, newspapers and television was expanding at an ever increasing rate. Relatively isolated rural areas were opening up (post war) to foreign ideologies of consumerism. The basic restraints of "this will be alright mate, she'll do" was under a slow but effective take over. "I can get this done faster by this new whiz bang gadget that I saw on the TV last night!" was the new way to live by.This item is very significant in that it demonstrates the new consumerism at its infant stage of the social changes occurring due to greater communication levels between the rural Australian communities and other advancing communities world wide. The Kiewa Valley residents (mainly from the intermingling of rural and post World War II refugees working at the construction of the Victorian Hydro electricity installations, resulted in this rural area becoming integrated to new ways of living (both socially and economically). Once the attitude of "we have always done it this way mate!" was challenged and overcome, the acceptance of new time saving "gadgets" which started to pour in from foreign markets, the relative isolation of the Kiewa Valley (being mainly psychological entrenched), was over.This hoover electric floor scrubber and polisher has a main base containing two brushes (can be replaced with polishing pads). The two brushes/pads are fastened or removed from the base unit by pulling/pushing the heads from the small hexagonal shaft on the bottom of the machine motor. A pressure sensitive wire is inlaid at the brush/pad end to hold the brush/pad unit onto the shaft. The discs body and main body covering the electric motor are made from sturdy plastic. The rest of the appliance materials i.e. upright handle and the u framed attaching arm are made from lightweight powder coated steel. A small (350mm) red coloured foot switch protrudes from the back of the motor to release the the upright handle from the storage position to the action position.There are two fork shaped brackets on the rear of the handle, for securing the 6.5 metre long electrical cord and plug. There is no on/off switch on the appliance. A small stainless steel "u" framed clip (for hanging the appliance in the vertical position) for cupboard storage. Within the circle of the cleaning brush is stamped "1 above S.A.B.351" and on the opposite side P/No: 5023792". On the main plastic head of the brush discs are "TO CLEAN" and under this "USE ONLY WARM(underlined) WATER AND SOAP" on the opposite side, and within a circle is the Hoover Trademark. On the front of the blue coloured plastic dome covering the electric motor is (on a raised domed shaped plaque (on a red background) Hoover in slanted print from left to right(in a diagonal level)domestic appliances, floor cleaning, electric floor scrubbers and polishers -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Photocopy, Lloyd Jenkins, Oral History Transcripts, 1987

Photocopy of a transcript prepared by Lloyd Jenkins and draft copy with corrections in blue and black ink of an interview with Mrs. Edna Mader and Mrs Valda Busch at 220 Drummond St. South Ballarat on 28 January 1987. Mrs. Busch was 79 at the time, and Mrs Mader 74. Both worked at the ESCo and SEC offices in the customer accounts section, preparing accounts and associated paperwork. Reviews the system of accounts, meter readers, working conditions. Mrs Mader left the SEC in 1945, (first child) then returned later on as a machine operator until retirement at age 62 in 1974. Mentions some tramway staff. Notes Mr. W. J. K Dunstan who was the office manager in Ballarat, Mr. Charles Trethowan who commenced as the office boy in Ballarat and rose to be the Chairman of the SEC. Also notes social activities, WWII and the take over of ESCo by the SEC. Interview comprises 11sheets of A4 paper. The draft copy comprises 23 pages.trams, tramways, oral history, audio tape transcripts, sec, esco, accounting -

Bendigo Military Museum

Bendigo Military MuseumUniform - POLYESTER UNIFORM, ARMY, Australian Defence Industries

1. Shirt - Khaki, polyester/cotton fabric, long sleeves with button cuffs, shoulder epaulettes, two front pockets with button down flap, brown plastic buttons. Cotton manufacturers labels top back of shirt and bottom back of shirt, with black print information. 2. Trousers - Khaki, polyester/cotton fabric, fob pocket, two side pockets, on back pocket with button down flap, metal zipper fly, brown plastic buttons. Three cotton manufacturers labels inside back waistband and back pocket lining with black print information. Polyester lining waistband and pockets. 3. Necktie - khaki cotton knit fabric with unfinished ends. 4. Lanyard - gold cotton cord with knots.Cotton label information - black ink print. 1. Top back of shirt "CLASS - 8405/66 - 017-2261/REGIMENTAL NO./NAME". Bottom back of shirt 'MACHINE WASHABLE/DO NOT BOIL/ DRIP DRY/ WARM IRON/ SALIO/ VICTORIA, 1966^" 2. Back right inside waistband "REGIMENTAL NO./ NAME". Back left inside waistband "Dry clean only/ repress on original creases/ use damp cloth or medium/TO HOT STEAM IRON/ Mending patch attached". Label on back pocket lining. John Sackville - sons/ -Aust - Pty Ltd/ Victoria 1966/^ size 31 RB/ W.31" 1/L 30 1/2/ CLASS 8405/66-018-5518. uniform, army, polyesters -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - Digital, Troopship Wiltshire, 1918, c1918

The HMAT A18 Wiltshire (1912-1922) weighed 10,390 tons with an average cruise speed of 13.5 knots or 25.00 kmph. Described as a refrigerated steamship it was b uilt 1912 by John Brown, Clydebank for the Federal S N Co Ltd, London and was propelled by a twin screw, quadruple expansion engine 2 x 4 cylinders each 6500 hp. Owned by the Commonwealth & Dominion Line Ltd, London, it was leased by the Commonwealth until 2 October 1917. It embarked from Egypt on 2 February 1918. On 18 October 1914 at Melbourne embarked the 4th Light Horse Regiment (Victoria) A, B & C squadron & their Machine Gun Section, the 2nd Field Ambulance (Victoria) First Division. The disembarked the 4th Light Horse Regiment in Egypt on 10 December 1914. On 01 November 1914 The Wiltshire assembled with the first convoy at King George's Sound, Albany Western Australia in transporting the first detachment of the Australian and New Zealand Imperial Expeditionary Forces. It completed nine transport voyages from Australia commencing 18 October 1914 until final voyage from Sydney 9th November 1918. During that time The Wiltshire carried the 4th Field Artillery Brigade (Victoria) 2nd Division Artillery and their 1st Reinforcements, 1st Division Ammunition Column 1st Division Artillery 4th Reinforcements, thirty-four Infantry Battalion Reinforcements, the 10th, 11th & 12th Field Artillery Battery (Victoria) 4th Field Artillery Brigades, the 4th Brigade Ammunition Column 4th Field Artillery Brigade, the 1st Siege Artillery Brigade 15th Reinforcements, the 4th Light Horse Regiment (Victoria) A, B & C squadron & their Machine Gun Section, six Light Horse Brigade Reinforcements, the 1st Veterinary Section (New South Wales) 11th Reinforcements, the 1st Mobile Veterinary Section (New South Wales) 1st Division 11th Reinforcements, the 2nd Mobile Veterinary Section (Victoria, New South Wales) 2nd Division 11th Reinforcements, the 1st Cyclist Battalion (New South Wales and Queensland) 3rd Reinforcements, the 2nd Field Ambulance (Victoria) First Division & Medical Officers. After the conclusion of World War One is was wrecked Rosalie Bay, Great Barrier Island New Zealand 31 May 1922 on passage London for Dunedin. Onboard was a crew of 103 plus 1 stowaway, and 10,000 ton of general cargo. No lives lost and is now a well frequented 'Dive' wrecksite. (http://www.flotilla-australia.com/hmat.htm#A18)Photographic postcard of the troopship Wiltshire out at sea.world war one, world war, wiltshire, troop ship, mmm -

Monash University Museum of Computing History

Monash University Museum of Computing HistoryFerranti Sirius mainframe computer, 1961

The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius computer was built in a period of rapid growth in computing technology. The first stored program computers appeared in the late 1940s and used individual designs with valve technology. By the mid-1950s valve technology was replaced by transistors and the first mass produced commercial computers became available. The Ferranti Sirius was announced in 1959 and offered a “small” academic computer. It was designed and built by the English company Ferranti Ltd and sold through a local office of the company in Melbourne. The Sirius was manufactured at the Ferranti Ltd.’s West Gorton, England factory from 1959 to 1963 and, in all, the company produced probably 22 installations although only 16 were actually recorded as sold; this included one at Ferranti’s Bureau in London and one at Ferranti’s Melbourne Bureau. Only 7 were exported and 4 of these 7 were located in Melbourne, Australia. All four were associated with computing at Monash University – the Sirius in the MMoCH collection was purchased by Monash University in 1962, a smaller Ferranti Sirius was used on the Caulfield campus (prior to amalgamation with Monash University) from 1963, the Ferranti company had its own Ferranti Sirius initially temporarily installed at Clayton campus in 1962 and then placed in their office in Queens Road, Melbourne. A fourth computer was purchased by ICIANZ (now Orica) in 1962 and was transferred to Clayton campus in 1967. Only two of these Melbourne examples have survived; one in the MMoCH collection and one at Museums Victoria. There is an example of the Ferranti Sirius in the Science Museum Group collection in the UK as well. The Ferranti Sirius in the MMoCH collection was the first computer purchased by Monash University and it was shipped to Australia to be installed by November 1962. The University had a similar model computer on loan from Ferranti Ltd during the first part of the year and it was returned to the office of the company in Queens Road, Melbourne once the University’s own machine was installed. The computer was placed on site at Clayton campus, Monash University. The computer operated from 1962 until 1972 when it was officially decommissioned. The Ferranti Sirius was sold to Mr Paul Stewart in late 1974 and removed from Monash University. Mr Stewart later donated the computer back to the University in 1988 and it was transferred to the collection of the Monash Museum of Computing History after 2001. The Ferranti Sirius is an electronic second-generation transistor computer and is one of three remaining examples of this machine left in the world. It was an important addition to the computing facilities at Monash University in the early 1960s and provided access for computer programming and research for many early computer professionals, academics and teachers. The Ferranti Sirius is of scientific (technological) significance as one of the early transistor digital computers that transitioned computing from first-generation valve computers to second generation commercial installations. This example of the Sirius is of historical significance in its role as a part of the Computer Centre, Clayton campus, Monash University which provided computing facilities in Melbourne in the early 1960s when there were few installations available for academic, administrative and commercial users. Staff and students were able to undertake investigative research and learn programming techniques. The Computer Centre encouraged the use of the computer across all disciplines and this provided the base to establish computer science as a subject offering and, later, a new department in the University. This growth in computer education eventually culminated in the establishment of the Faculty of Information Technology, Monash University. The Ferranti Sirius in the collection at Monash Museum of Computing History has a main unit with a CPU and memory combined with input/output equipment and one extra cabinet of memory. The Central Processing Unit is a floor-standing unit which contains the computer circuits, power supplies and has a decimal digit display panel and a normal clock. A moveable control panel is placed in front of the Unit (Currently set on a recreated desk/filing cabinet support in the display). The Sirius base unit uses acoustic delay line memory with 1000 word store. An additional 3000 word memory cabinet is set adjacent to the CPU and can be connected to increase the memory. The computer is supported by a range of input/output devices. There is a Ferranti Paper tape reader, located on desk in front of CPU. Red label on front “Ferranti tape reader. Type TR 5. Serial No. 477”. Adjacent to the CPU is a set of Simplified tape editing equipment in three pieces which includes a (1) Table unit with switches on front face. Metal tag on reverse reads “Creed & Co. Model No. S4060. Serial No. 1457. Original Customers Marking GRP7 V706”. The table has a numbered internal tag “Table Serial No. 198579. (2)Creed teletype set on table unit. Metal tag on reverse “Creed & Co. Model No. 75RPR K4M4. Serial No. 5897 Made in England”. (3)Creed paper tape reader set on table unit. This set of equipment could read paper tape and print it, or copy paper tape while allowing it to be edited, or allow a programmer or data preparation person to type and punch a new program or data. It has no electrical connection to the computer. Paper tapes were usually torn off and carried across to the computer. There is also another table unit with switches on front face and changeable setting switch on front right side which holds a Ferranti Westrex paper tape punch set. Label on reverse “Teletype Code BRPE11” This was the Computer’s only output device. BRPE-11 is a teletype model number. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

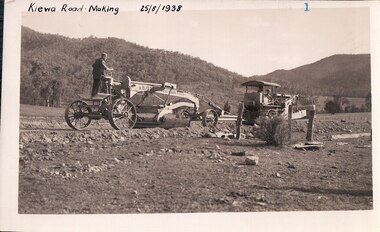

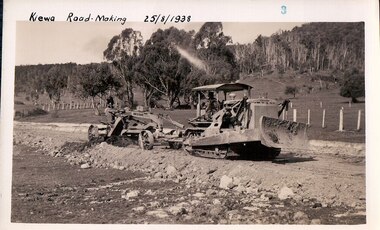

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making, 25/08/1938

Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment . A black and white photograph showing the type of machinery used for road making in the 1930's. It shows a grader being towed by a caterpillar tractor.On the top left hand corner of the photograph , hand written in black ink is the words 'Kiewa Road Making 25/8/1938'. On the right hand side of the photo has been stamped in blue the Number 1. It has been developed on Velox paper (marked on back of photo) with a gloss finish.road making, state electricity commission, caterpillar tractor, kiewa -

Kiewa Valley Historical Society

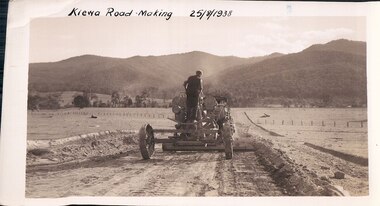

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/08/1938 No. 2, 25/08/1938

Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer ( Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route let immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km.) had been surfaced. (see KVHS 0328)The purchase of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment.A black and white photograph of road making near Mt. Beauty in 1938. Mount Beauty hills can be seen in the background with cleared land for grazing in the fore ground.Hand printed in black ink at the top of the photograph is 'Kiewa Road Making 25/8/1938'. On the right hand corner has been printed the number 2. It has been printed on gloss Velox paper.road making, state electricity commission, caterpillar tractor, kiewa, secv -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/8/1938(No. 3 in a series of 8), 25/08/1938

Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trail builders (angle dozers)). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939,the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commission's Engineers in purchasing such new and innovative equipment.A black and white photograph of a Caterpillar diesel crawler tractor and a hydraulically operated trailbuilder (angle dozer) making a road in the Mt. Beauty area.Hand written in black ink in the top left hand corner are the words "Kiewa Road Making 25/8/1938". On the upper right hand of the photograph has been stamped the number 3. On the back is stamped the word 'Velox' severaly times, which is the make of the photograhic paper. roadmaking, caterpillar tractor, kiewa, state electricity commission -

Ballaarat Mechanics' Institute (BMI Ballarat)

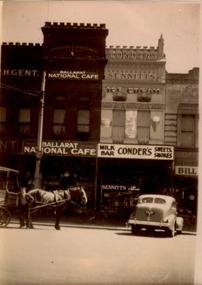

Ballaarat Mechanics' Institute (BMI Ballarat)Conder's Sturt St

This photograph is held in the Ballaarat Mechanics' Institute Audio Visual Collection. Please contact BMI for all print and usage inquiries. Donated by Marilyn Stewart, her father was Jack Conder, owner of the well known Sturt St candy store known as ‘Conder’s.’ Jack started the business in 1941 when he was only 25, and ran it into the mid 80s with his wife Joyce at the counter beside him. Marilyn remembers the delicious banana spilts that would come with three scoops of icecream and plentiful whipped cream and toppings like syrups and nuts, with wafers to complete the dish. Conder’s was a popular meeting place to visit before and after the dances and movies, and would often be full of people. Along with candy and chocolates, the shop also sold sandwiches, pies and pasties, along with cigarettes, papers, & bread from the bakery on weekend. Jack also had the first Espresso coffee machine in Ballarat! He was always up with the latest trends in the shop but also with cars. Marilyn recalls his love of American cars, with the big fins, and he had many over the years. It would have been a familiar sight seeing him drive down Sturt St with his chevrolet or latest stylish model. ballarat, shop, candy, milk bar, sturt st, conder's, sennitts, icecream, horse, cart, car, 1950s -

Ballaarat Mechanics' Institute (BMI Ballarat)

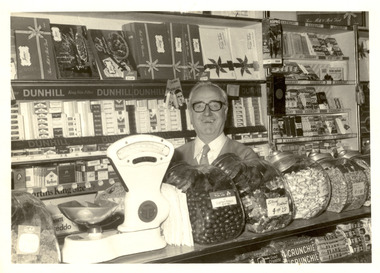

Ballaarat Mechanics' Institute (BMI Ballarat)Jack Conder in shop

This photograph is held in the Ballaarat Mechanics' Institute Audio Visual Collection. Please contact BMI for all print and usage inquiries. Donated by Marilyn Stewart, her father was Jack Conder, owner of the well known Sturt St candy store known as ‘Conder’s.’ Jack started the business in 1941 when he was only 25, and ran it into the mid 80s with his wife Joyce at the counter beside him. Marilyn remembers the delicious banana spilts that would come with three scoops of icecream and plentiful whipped cream and toppings like syrups and nuts, with wafers to complete the dish. Conder’s was a popular meeting place to visit before and after the dances and movies, and would often be full of people. Along with candy and chocolates, the shop also sold sandwiches, pies and pasties, along with cigarettes, papers, & bread from the bakery on weekend. Jack also had the first Espresso coffee machine in Ballarat! He was always up with the latest trends in the shop but also with cars. Marilyn recalls his love of American cars, with the big fins, and he had many over the years. It would have been a familiar sight seeing him drive down Sturt St with his chevrolet or latest stylish model.ballarat, shop, candy, milk bar, sturt st, conder's, sweets, smokes, counter, jack conder -

National Wool Museum

National Wool MuseumTool - Knitting Pins, 1960-69

The donor (Lynn Fitzpatrick) purchased these knitting needles 20 years ago from an opportunity shop. Aero Knitting Pins are a discontinued brand that were popular in the 1960s, 70s and 80s. They are made of smooth, aircraft-quality anodized aluminium. To this day, they are a popular and sort after knitting needle. Being a long-lasting product, they are often given as heirlooms. Abel Morrall was a major needle manufacturer from Studley, a town near Redditch. In 1785, Michael Morrall who was taught the art of needle making by a maternal uncle, moved to Studley. He founded the Abel Morrall company with his brother Abel, and another unnamed brother-in-law. Within five years the company was producing 40% of the 2.5 million needles that were made each week in the Redditch area. In 1811 the company introduced the concept of creating the eyes by using a stamping press. Additional machines were invented by them throughout the 19th century leading to major improvements in the way needles were produced. Abel Morrall demonstrated their needle making machinery at the Great Exhibition of 1851 and Queen Victoria personally inspected it. The company selected the demi-griffin for its trademark in 1861, which can be seen on older products produced by the company. Set of four knitting needles stored within paper packaging. Packaging features black, red, and white ink, detailing the selling points of the Aero Knitting Pins. The packaging folds with 3 main sections, each providing different insights into the knitting needles. Examples of this are " CANNOT SOIL LIGHT WOOL", "...SPECIALLY TAPERED POINTS WHICH WILL NOT INJURE THE FINGERS" and "RUSTLESS-NON-GLITTER FINISH". As the packaging unfolds, the grey knitting needles become visible. The needles can be removed from the packaging by sliding them through small bands of paper that hold the needles secure while in transportation. The four knitting needles are a “NEUTRAL” grey colour finished in a double point style.Printed. Orange, White and Black Ink Numerous, see multimediaabel morrall, knitting needles, knitting pins, 1960s home knitting -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Image - Black and White, Macaroni Factory, Hepburn Springs, 1900, 1900

"MACARONI MANUFACTORY. On the pretty road to the Hepburn Mineral Springs, and not far from where the health-laden waters gush plentifully from the earth, is a two-storied brick it is that Messrs Lucini and Co, carry building, dedicated to the manufacture of macaroni, vermicelli, and the Italians' own especial delight— spaghetti. Here on operations, and Mr Lucini himself was good enough to show the writer around and explain the various proces ses of a manufacture which is little known to Australians. The finest wheat and the mineral waters fresh from the springs are utilised, and by means of a most ingenious machine, the hollow rods of macaroni are turned out in large numbers. Finally, they are packed in boxes and cases, and sent off to the prin cipal agent in Daylesford, Mr J. W. King, who in turn forwards them to all parts of the country. Mr Blackett, thv Govrnment Analyst, writes in most lau datory manner of the productions of the factory, and says that on testing them he found the various sam ples were of excellent quality, and quite equal to any of Italian manufacture. Visitors to the springs should not fail to call in at Messrs Lucini's, which is one of the show places of the district, and will well repay an inspection.A number of women, members of the Lucini family, make macroni and the macaroni factory in Hepburn Springs. lucini, macaroni factory, hepburn springs, spaghetti, macaroni -

Federation University Art Collection

Federation University Art CollectionWork on paper, 'Sun and Moon Nature' by Kees Hos, 1964

Kees HOS In 1956 Kees and his wife Tina made a new life with their two children in the arts community of New Zealand. In Australia Kees established the art school at Gippsland College of Advanced Education in 1971 with a radical multidisciplinary approach to art education. He generously delivered encouragement and opportunities to many people including lecturers, visiting artists and students. His small team literally built an art school from zero. Temporary accommodation in an old factory and service station in Morwell moved to three student-built studios on the Gippsland Campus. His highest recognition was 1997 when the names of Kees and Albertine Hos were added to the Wall of Honour in the Garden of the Righteous at Yad Vasheem in Jerusalem along with many others who put their lives on the line against the biggest killing machine the world had known. The ‘hiding-place’ in Kees and Tina’s home was discovered but Tina managed to rescue a baby as her own while the Jewish parents were transported to Auschwitz and Dachau. Kees was on the run using his printmaking skills to forge passports but was eventually captured and jailed, the war’s end saving his life. Gippsland Director's Collection, Acquired 1973.Signed and dated lower right in pencil "Kees Hos '64"artist, artwork, kees hos, gippsland campus, gippsland director's collection, printmaking, wall of honour in the garden of the righteous -

Bendigo Military Museum

Bendigo Military MuseumUniform - JACKET, TROUSERS, SHIRT, BATTLE DRESS, ARMY, Australian Defence Industries, 2. 1990 3. 1988

Uniform issued to "P. Green" No. 32045731. Jacket, Khaki colour wool serge fabric. Battle Dress style, belted at the waist with metal buckle. Dark green plastic buttons. Collar, shoulder epaulettes, two front pockets with concealed button down flap, sleeve cuffs. Green colour cotton twill fabric lining to waistband. Manufacturers white cotton fabric label - left pocket lining. Removeable tag on inside collar. 2. Trousers, khaki colour wool serge fabric. Battle Dress style with fob pocket, two side pockets, one back pocket with concealed button down flap. Dark green plastic buttons, metal zipper fly. Manufacturers white cotton fabric label - back pocket lining. Green colour polyester lining. 3. Shirt, Khaki colour cotton/polyester long sleeves, with shoulder epaulettes and cream plastic buttons. Two front pockets with button down flaps. Manufacturers white cotton fabric label inside back below collar.Manufacturers information on labels - black ink print. 1. "ADI P/L/ VICTORIA/ 1990/ ^ / 8405-66-025- 6418/BATCH P/ SIZE 102/104L/ ARMY NO./ NAME/DRY CLEAN ONLY/ CREASE UPPER/ HALF OF LAPELS ONLY" 2. "ADI P/L/ SUB-4 VIC 1990/ ^ / 8405-66-025-6183/ BATCH S/ SIZE 84R W.84/ DRY CLEAN ONLY/ RE-PRESS ON ORIGINAL/CREASES SET BY/ SI-RO SET/ MENDING PATCH ATTACHED/ ARMY NO/ NAME" 3. " A.G.C.F./ 1988/ ^/ SIZE 40/84/ 8405-66-088-7098/ SERVICE NO./ NAME/ DO NOT BOIL OR WRING/ MACHINE WASHABLE/ DRIP DRY/ IRON LIGHTLY/ WITH WARM IRON" Handwritten - blue ink pen "3204573/Green" uniform, army, battle dress, p. green -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Clothing - HELEN MUSK COLLECTION: BLUE SILK DRESS. PART OF A TWO PIECE ENSEMBLE

Floor length dress of royal blue silk fabric with a metallic thread forming a tinsel like pattern. There is a V neck at front with a high round neck at the back. The bodice front is made from two pieces with a centre seam. The bodice is attached to midriff panel of royal blue satin. At the front the bodice is gathered slightly onto the panel with a V shape at t centre front of the panel. At the hip line centre front the midriff panel narrows and then widens and the panel extends to the hem. The centre panel is divided and has a godet insert in the centre. Fifteen decorative fabric covered buttons with roulette loops are attached at centre of midriff panel. The back of the bodice is one piece is gathered slightly into a high waisted skirt made up of four gored pieces. The side opening (21 cm) at the waist on the LHS has three metal hooks with cotton loops and two press studs. The long sleeves are set in with lily point finish at the wrist. The underside of the sleeve at the wrist has ten decorative fabric covered buttons with roulette loops. Machine and hand stitched.costume, female daywear, blue silk dress