Showing 395 items matching "inventions"

-

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Electric Toaster, Hecla Electrics Pty Ltd, c1940s

Hecla produced a wide range of appliances for domestic use, beginning with heaters and later branching out to a wider range of kitchen appliances Hecla was established by Clarence William Marriott, a young Melbourne metal worker. He began manufacturing Australia's first carbon filament electric radiators in 1899. He originally worked for his father James Marriott who commenced business in Melbourne as an art metal worker in 1872 and was, in 1907, appointed as the official art metal worker to the Victorian Government producing items including the ornate iron gates and gas lamp standards outside Melbourne's Parliament House. With the invention of nickel chromium wire after 1900, C.W. Marriott began making more efficient heating elements using this new material in 1916. After being influenced by the eruption of Mount Hekla in Iceland, on 19 December 1918, Clarence registered the brand name "HECLA" with an erupting volcano as its logo. The company Hecla Electrics Pty Ltd was officially registered in 1922. In 1928 the company adopted the advertising slogan, 'By Hecla, it's Good'. The Hecla range rapidly expanded to include electric heaters and radiators, electric foot warmers, electric kettles, ceramic & metal electric jugs, immersion hot water elements, electric fans, electric coffee percolators, electric toasters, electric grillers and stoves, electric irons and electric frypans, clocks and curling wands. Electric blankets were introduced shortly after WWII.In 1930, a controlling interest in Hecla Electrics Pty Ltd was acquired by General Electric Corporation. Clarence William Marriott died in June 1967 in Melbourne, Victoria.This item is representative of a common domestic appliance used throughout Australia. It was manufactured by a pioneering Australian company.A small chrome steel toaster manufactured by Hecla Australia. It has a door on either side which flips down to insert or remove a slice of bread on each side, Each door has two black Bakelite knobs. The electric element is placed down the centre of the cavity. A detachable electric cord is included.240 Volts, 600 Watts. Cat. No. T4 Submitted to Electrical Approval Board Ref Application A1/AD01 SECV 240 Volt 600 Watt MANFED. IN AUSTRALIA SOLID BRASSelectrical appliances, hecla corporation australia, clarence william marriott, domestic appliances -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, mens' 'Gillette' safety razor, c1950

A safety razor is a shaving implement with a protective device positioned between the edge of the blade and the skin. The initial purpose of these protective devices was to reduce the level of skill needed for injury-free shaving, thereby reducing the reliance on professional barbers for providing that service and raising grooming standards. The term was first used in a patent issued in 1880, for a razor in the basic contemporary configuration with a handle attached at right angles to a head in which a removable blade is placed (although this form predated the patent). 1847 William S. Henson. patented a "comb tooth guard or protector" which could be attached both to the hoe form and to a conventional straight razor. May 1880 by Fredrik and Otto Kampfe of Brooklyn, New York, improved the 'safety razor' and it differed from the Henson design in distancing the blade from the handle by interposing,, "a hollow metallic blade-holder having a preferably removable handle and a flat plate in front, to which the blade is attached by clips and a pivoted catch. 1900 King C. Gillette had the revolutionary idea of disposable blades so thin and so strong they were deemed impossible to forge by MIT-trained scientists. By 1901, he’d proven them wrong with his breakthrough innovation. The success of Gillette's invention was largely a result of his having been awarded a contract to supply the American troops in World War I with double-edge safety razors as part of their standard field kits (delivering a total of 3.5 million razors and 32 million blades for them). The returning soldiers were permitted to keep that part of their equipment and therefore easily retained their new shaving habits. The subsequent consumer demand for replacement blades put the shaving industry on course toward its present form with Gillette as a dominant force. Plastic disposable razors and razors with replaceable disposable blade attachments, often with one to three cutting edges (but sometimes with four and as of recently, five cutting edges), are in common use today. A steel 'Gillette' safety razor gillette co ltd, cheltenham, moorabbin, maynard dennis, sfety razors, safety razor blades -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Edison Home Phonograph

Thomas Edison was one of the world’s most prolific inventors, holding over 2,000 different patents. One of his earliest inventions was the phonograph. The Edison Phonograph Company was formed on October 8, 1887, to market Edison's machine. The original machine went through many modifications. The Patent information on this machine indicates that it was manufactured after May 1906. Sound was recorded on wax cylinders. Edison cylinders were the earliest commercial medium for recording and reproducing sound. These hollow cylindrical objects have an audio recording engraved on the outside surface which can be reproduced when they are played on a mechanical cylinder phonograph Beginning in 1889, pre-recorded wax cylinders were marketed. They featured professionally made recordings of songs, instrumental music or humorous monologues in their grooves. The earliest cylinders were made from soft wax and later hard wax was utilised. Further developments by several companies, led to the introduction of celluloid cylinders. In late 1908, Thomas Edison had introduced wax cylinders that played for about four minutes (instead of the usual two) under the Amberol brand. The Amberols were manufactured with flat rim-ends, to prevent confusion with the earlier bevel-edged two-minute version. In 1912, the Edison company eventually acquired patents to the celluloid technology, and almost immediately started production of the new brand as Edison Blue Amberol Records. Cylinder records continued to compete with the growing disc record market into the 1910s. In 1912, Columbia Records, which had been selling both discs and cylinders, dropped the cylinder format, while Edison introduced his Diamond Disc format, played with a diamond stylus. From 1915, new Edison cylinders were re-recordings from Edison discs. Although his cylinders continued to be sold in steadily dwindling quantities, Edison continued to support the owners of cylinder phonographs by making new titles available in that format until the company ceased manufacturing all records and phonographs in November 1929.This item is significant because it is representative of early home entertainment in the late 19th and early 20th century.An Edison Home Phonograph in a wooden case. No trumpet included.On outer case' Edison On metal plate: Thomas A Edison TRADE MARK On large metal plate: Detailed inscription of Patent informationphonograph, thomas edison -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageOctant, Mid to late 19th Century

An octant is an astronomical instrument used in measuring the angles of heavenly bodies such as the sun, moon and stars at sea in relation to the horizon. This measurement could then be used to calculate the altitude of the body measured, and then the latitude at sea could also be calculated. The angle of the arms of an octant is 45 degrees, or 1/8 of a circle, which gives the instrument its name. Two men independently developed the octant around 1730: John Hadley (1682–1744), an English mathematician, and Thomas Godfrey (1704–1749), a glazier in Philadelphia. While both have a legitimate and equal claim to the invention, Hadley generally gets the greater share of the credit. This reflects the central role that London and the Royal Society played in the history of scientific instruments in the eighteenth and nineteenth century's. There were also two others who are attributed to having created octanes during this period, Caleb Smith, an English insurance broker with a strong interest in astronomy (in 1734), and Jean-Paul Fouchy, a mathematics professor and astronomer in France (in 1732) In 1767 the first edition of the Nautical Almanac tabulated lunar distances, enabling navigators to find the current time from the angle between the sun and the moon. This angle is sometimes larger than 90°, and thus not possible to measure with an octant. For that reason, Admiral John Campbell, who conducted shipboard experiments with the lunar distance method, suggested a larger instrument and the sextant was developed. From that time onward, the sextant was the instrument that experienced significant development and improvements and was the instrument of choice for naval navigators. The octant continued to be produced well into the 19th century, though it was generally a less accurate and less expensive instrument. The lower price of the octant, including versions without a telescope, made it a practical instrument for ships in the merchant and fishing fleets. One common practice among navigators up to the late nineteenth century was to use both a sextant and an octant. The sextant was used with great care and only for lunar sightings while the octant was used for routine meridional altitude measurements of the sun every day. This protected the very accurate and pricier sextant while using the more affordable octant for general use where it performs well. The invention of the octant was a significant step in providing accuracy of a sailors latitude position at sea and his vessels distance from land when taking sightings of land-based landmarks.Octant with metal handle, three different colored shades are attached, in wooden wedge-shaped box lined with green felt. Key is attached. Two telescope eyepieces are in box. Some parts are missing. Oval ink stamp inside lid of box, scale is graduated to 45 degrees. Ink stamp inside lid of box "SHIPLOVERS SOCIETY OF VICTORIA. LIBRARY"instrument, flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, octant, navigation, nautical instrument, navigation instrument, john hadley, sextant, astronomical instrument -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph Horn, Thomas A. Edison, Edison Laboratory, c.1909

This external horn is part of an Edison Fireside Phonograph made in c.1909. The horn was attached to the machine when in use. The rings on the side of the horn allowed the horn to be suspended above the machine. The narrow opening on the horn was attached to the sound outlet on the machine and the conical shape of the horn amplified the sound. The horn was suspended to allow a clear sound. This was done by attaching the ring fitted to the outside of the horn to a chain or chord, which in turn was attached to a curved wire fitted to the phonograph machine. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adapted the idea used when sending messages over a telegraph machine. He patented the phonograph in early 1878. The phonograph was able to record sound and play it back sound. This amazing invention opened up a whole new world of entertainments, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He started the Edison Spring Motor factory in 1895 and then the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external horn was produced in 1912 due to the much more robust records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929. [NOTE: a phonograph machine plays cylinders, a gramophone plays records]This Edison external phonograph horn is significant for its connection to the c.1909 Edison Fireside phonograph model. The phonograph machine brought a new era of music into the homes of everyday people but was only popular for a few decades due to the growing popularity of records, which gave a much higher quality sound and were more robust.Phonograph horn; open horn, a conical shape with the lower part flaring out. The horn's shape on the opening half is octagonal, made from eight joined sheets of metal with a scalloped finish at the opening. The narrow end is hollow and ready to fit onto a phonograph outlet. There are two rings attached together on the side of the horn, perhaps for storing on a hook. The inner surface of the horn has remnants of deep red paint. This horn is from the Edison Fireside phonograph. (There is a mark on the outside of the horn where the Edison brand would be)flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, external horn, edison phonograph company, wax cylinders, edison spring motor factory, national phonograph company, thomas a. edison inc, phonographic cylinder, sound reproduction -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Grater

François Boullier of France and Isaac Hunt of England both took credit for inventing the cheese grater in the 1540s. Ingredient supplies, mainly milk, ebbed and flowed in both France and England, as they have in the United States during this coronavirus pandemic. Boullier originally aimed to use up an overabundance of cheese in Paris. An avoidance of meat led French farmers to convert their meat herds (often boys) to dairy-producers (girls), which led to more milk and even too much milk, which led to a market flooded with cheese. Boullier made his first cheese grater out of pewter to grate hard, sometimes dried out cheeses, which turned them into a sort of condiment. Pewter is known as a rather soft metal, and Boullier’s original grater is reportedly on display in a museum in Le Havre, France. Isaac Hunt wanted to stretch cheese due to a shortage in England, so he grated and melted it for Welsh rarebit and other dishes. Grating cheese allowed more even distribution of the cheese to melt it in cooking and still does. During the Great Depression of the 1930s, Philadelphia cheesemonger and entrepreneur Jeffrey Taylor also wanted to stretch cheese for to bulk up cheese features, including vegetables, to make them look like more filling food during difficult economic times. Taylor read about Boullier’s invention and made his own by sharpening the holes of a metal shower drain. For the last century, many companies have tried to improve the cheese grater and invent a new “latest” one that we all must-have. Graters are now made of all sorts of materials including bamboo, wood, and various metals. Some are decorated with clowns’ heads, some are shaped like plastic frogs, while others bear knuckle protectors. They vary in size, shape, and function. Grating slots come with different angles and shapes of slots and can grate everything from zucchini, onions and cheese, to cooked eggs, coconut, potatoes, cabbage, and lemon and orange peel, and possibly even create wood shavings. Smaller graters grate ginger and garlic. https://www.cheeseprofessor.com/blog/antique-cheese-gratersThe grater has been used for hundreds of years and has proved its worth in the kitchen throughout history.Grater metal (3 parts) Tripartite with hinges for folding.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, grater -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Pudding Mould

One of the first documented mentions of pudding can be found in Homer's Odyssey where a blood pudding roasted in a pig's stomach is described. This original meaning of a pudding as a sausage is retained in black pudding, which is a blood sausage originating in the United Kingdom and Ireland made from pork or beef blood, with pork fat or beef suet, and a cereal. Another early documented recipe for pudding is a reference to asida, found in a tenth century Arabic cookbook by Ibn Sayyar al-Warraq called Kitab al-Ṭabīḫ (Arabic: كتاب الطبيخ, The Book of Dishes). It was described as a thick pudding of dates cooked with clarified butter (samn). A recipe for asida was also mentioned in an anonymous Hispano-Muslim cookbook dating to the 13th century. In the 13th and 14th centuries, in the mountainous region of the Rif along the Mediterranean coast of Morocco, flour made from lightly grilled barley was used in place of wheat flour. A recipe for asida that adds argan seed oil was documented by Leo Africanus (c. 1465–1550), the Arab explorer known as Hasan al-Wazan in the Arab world. According to the French scholar Maxime Rodinson, asida were typical foods among the Bedouin of pre-Islamic and, probably, later times. In the United Kingdom and some of the Commonwealth countries, the word pudding can be used to describe both sweet and savoury dishes. Unless qualified, however, the term in everyday usage typically denotes a dessert; in the United Kingdom, pudding is used as a synonym for a dessert course. Puddings had their 'real heyday...', according to food historian Annie Gray, '...from the seventeenth century onward'. It is argued that 'the future of the boiled suet pudding as one of England's national dishes was assured only when the pudding cloth came into use' and although puddings boiled in cloths may have been mentioned in the medieval era, one of the earliest mentions is in 1617 in a recipe for Cambridge pudding, a pudding cloth is indicated; 'throw your pudding in, being tied in a fair cloth; when it is boiled enough, cut it in the midst, and so serve it in'. The pudding cloth is said, according to food historian C. Anne Wilson, to have revolutionised puddings. 'The invention of the pudding-cloth or bag finally severed the link between puddings and animal guts. Puddings could now be made at any time, and they became a regular part of the daily fare of almost all classes. Recipes for them proliferated.' https://en.wikipedia.org/wiki/PuddingPuddings and pudding making have evolved over the years, and continue to do so. White ceramic pudding bowl with fluted decoration on the outside.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, puddings, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Corkscrew

The design of the corkscrew may have been derived from the gun worm, which was a device from at least the early 1630s, used by men to remove unspent charges from a musket's barrel in a similar fashion. The corkscrew is possibly an English invention, due to the tradition of beer and cider, and the 'Treatise on Cider' by John Worlidge in 1676 describes "binning of tightly corked cider bottles on their sides", although the earliest reference to a corkscrew is, "steel worm used for the drawing of Corks out of Bottles" from 1681. In 1795, the first corkscrew patent was granted to the Reverend Samuel Henshall, in England. The clergyman affixed a simple disc, now known as the Henshall Button, between the worm and the shank. The disc prevents the worm from going too deep into the cork, forces the cork to turn with the turning of the crosspiece, and thus breaks the adhesion between the cork and the neck of the bottle. The disc is designed and manufactured slightly concave on the underside, which compresses the top of the cork and helps keep it from breaking apart. The winged corkscrew, sometimes called a cork extractor, butterfly corkscrew, owl corkscrew, Indian corkscrew, or angel corkscrew, has two levers, one on either side of the worm. As the worm is twisted into the cork, the levers are raised. Pushing down the levers draws the cork from the bottle in one smooth motion. The most common design has a rack and pinion connecting the levers to the body. The head of the central shaft is frequently modified to form a bottle opener, or foil cutter, increasing the utility of the device. Corkscrews of this design are particularly popular in household use. In 1880, William Burton Baker was issued British Patent No. 2950 for his double lever corkscrew, with both levers sliding onto the upper end of the shank. The first American patent was in 1930 granted to the Italian Domenico Rosati who emigrated to Chicago, Illinois, to work as bartender before prohibition. Rosati's design had an exposed rack and pinion mechanism. Such design was adapted by other brands as the wine-market grew in popularity. The winged owl version, with two side-plates covering the rack and pinion mechanism, was first designed and manufactured in 1932 by the Spanish industrial designer David Olañeta for his brand BOJ and was later adopted by others, such as the 1936 US Patent No. 98,968 by Richard Smythe marked HOOTCH-OWL https://en.wikipedia.org/wiki/CorkscrewThis object is significant as an example of an item in common use in the 19th and early 20th centuries, and that was developed further in the 1930s.Winged corkscrew with a T-shaped wooden handle, metal spring and worm-wheel screw section.None.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, corkscrew, beverages, kitchen equipment, bottle opener -

Glen Eira Historical Society

Glen Eira Historical SocietyPlan - Pritchard Steam Power Company

... Inventions ...This file contains one item: 1/A draft of a plan for a museum exhibit from the Spirit of Enquiry Workbook, by Denis Shephard, and dated 07/08/2007, pertaining to alternative energy research within the suburbs of Melbourne between 1950 and 1980. Much of the content is irrelevant to Glen Eira. However; one of the two principle subjects of the exhibit, discussed between pages 20 and 28, is the work of Ted Pritchard, who was based out of Caulfield. Ted and his father, Arnold Pritchard, aspired to reinvent the steam engine for use within the contemporary era. To that end, they fitted a Chevrolet pickup truck with one of their prototypes – with the result being one of the main items constituting the exhibit. Ted’s interest in steam power had been spurred by a working tabletop model of a steam engine that Arnold built for him – which constitutes another of the exhibit’s items. Also included is a brief history of the development of Caulfield. The plan is embellished with numerous images, with relevant ones including maps of Caulfield and black-and-white photographs of the Pritchards’ truck, model and workshop.engines, engineering, engineers, inventions, inventors, steam engines, steam power vehicles, pritchard ted, pritchard arnold, pritchard steam power company, caulfield, shephard denis, pritchard mrs., trucks, pritchard edward, holland grove, balaclava road, workshops, grants, pritchard automotive steam designs, caulfield racecourse, caulfield technical school, caulfield trades school, caulfield technical college, chisholm institute, camden town, southdown knitting company, home street, fl hutchison, fowler street, vale knitting mills, nepean road, winterfold spinning mills, acme knitting mills, glen eira road, mj ryan knitwear, leather industry, lane joseph, hotham street, casey william, glen huntly road, pickering william, paris leather manufactory, woorayl street, tv tatchell, premier wire works, webb street, chesterfield ha, manufacturing industry, victory milk plant, bl coram & sons -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf ink bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history.Ink bottle or ink well; cylindrical shaped, salt-glazed, mid-brown ceramic bottle. It has a small round mouth, rounded lip that extend past the short neck, wide shoulders, straight sides, flat bottom. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, 1890s to 1902

This design of ink bottle or ink well was commonly referred to as a ‘penny ink well’ because it was very inexpensive to produce. It is also known as a dwarf bottle. It was recovered from the wreck of the 1895-1902 ship Inverlochy and is part of the John Chance Collection. Pen and ink has been in use for hand writing from about the seventh century up until the mid-20th century. Up until around the mid-19th century a quill pen made from a bird’s feather was used. In the 1850s the steel point pen was invented and could be manufactured on machines in large quantities. In the 1880s a successful portable fountain pen was designed, giving a smooth flowing ink and ease of use. Ink wells, used with steel nib dip pens, were commonly used up until the mid-20th century. The pens only held a small amount of ink so users had to frequently dip the nib of the pen into an ink well for more ink. Hand writing with pen and ink left wet writing on the paper, so blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased, ready to use, or in the powdered form, which needed to be mixed with water. After the invention of fountain pens, which had a reservoir of ink, and then ballpoint pens, which also had ink that flowed freely, the dip pen was slowly replaced. However, artisans continue to use nib pens to create beautiful calligraphy. INVERLOCHY 1895-1902 - The Inverlochy was a steel sailing barque built in Scotland in 1895 for international trade. In 1902 the Inverlochy left Liverpool under the command of Captain E.R. Kendrick. There were 21 officers and crew and the captain’s wife Mrs Kendrick, on board, bound for Australia with cargo that included tools, chemicals, liquor (beer, whisky, stout, rum, and brandy), steel, iron, wire netting, hoop iron, tinplate and pig iron), and steel wire for the Melbourne Tramway Company, tiles, soap, soft goods and earthenware. On December 18 almost at their destination, the Inverlochy ran aground on Ingoldsby Reef at Point Addis, near Anglesea. The crew and passengers left the ship via lifeboat and landed at Thompson’s Creek, then walked about 20 kilometres to Barwon Heads. Salvagers were interested in the 10 miles of cable in the hold. Mrs Kendrick’s ‘high grade’ bicycle was amongst the items salvaged but she lost her jewellery and two pianos. By February 1903 the ship had broken up and objects such as bottles and casks of liquor were washed ashore. Bad weather shook the wreck in June 1903, causing the ship’s spars and figurehead to be washed ashore. This ink bottle is historically significant as it represents methods of hand written communication that were still common up until the mid-20th century, when fountain pens and ballpoint pens took over in popularity and convenience. The Ink bottle also has significant as it was recovered by John Chance, a diver from the wreck of the Inverlochy in the late 1960s to early 1970s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. This Ink bottle is significant because of its historical connection to the barque Inverlochy, which is an example of a commercial international steel sailing barque and is listed on the Victorian Heritage Database VHR S338. The Inverlochy is significant for its cargo, which is a snapshot of the kind of goods imported into Australia at the turn of the 19th century, including cable for the Melbourne Tramway Company. The wreck of the Inverlochy is important as an accessible dive site that shows the remains of a large international trading vessel and its contents. It is valuable for an insight into Victorian era of shipping and maritime history. Ink bottle, glazed, prange-brown ceramic cylinder, ring of clay on top for lip, narrow mouth, very short neck on wide shoulder that reaches out to edge of of straight-sided body, flat base. On the shoulder, close to the neck, are concentric lines in the clay. There are dark areas around the lip and mouth opening. The clay appears to have a fold line on its body. The material has flecks of darker material in it. Sediment around shoulder. Handmade. Also called a Penny Ink Well.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, inverlochy, scotland, captain e.r. kendrick, melbourne tramway company, tramway cable, ingoldsby reef, point addis, anglesea, thompson’s creek, barwon heads, ink bottle, writing equipment, writing accessory, office equipment, stationery, domestic, stoneware, clay, ceramic, pottery, ink well, inkwell, penny ink well, nib pen, dip pen, ink, hand writing, record keeping, household, business, vintage, blotting paper, dwarf ink -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Ship Log

The ship's log part, called a fish, is likely to be from a mechanical taffrail log system. It was recovered from the wreck site of the barque, the 1840-1852 Grange. There are no marks on the fish to identify its maker or model. It is part of the John Chance Collection. This ‘fish’ is part of an early to mid-1800s ship's log. It would likely have been part of a taffrail log connected to a rotor (also called propeller, spinner) by a strong line, and the other end connected by a line to a dial mounted on the taffrail, or stern rail, at the stern of the vessel. As the propeller rotated through the water it would spin the log, which in turn would cause a number to register on the dial, showing the current speed in knots; one knot equals one nautical mile per hour. TAFFRAIL LOGS A taffrail log is a nautical instrument used for measuring the speed of a vessel, providing vital navigational information to be calculated, such as location and direction. A log has been used to measure the speed of a vessel since the 1500s. A simple piece of wood was tied to a long line and thrown into sea at the back of the vessel. The rope was knotted all along at equal distances apart. On a given signal the log line was pulled back into the vessels, the knots counted until the log came up, then the figures were calculated by a navigator In 1802 the first successful mechanical log available for general use was invented by Edward Massey. It had a rotor 'V' section connected to a recording mechanism. The water’s movement rotated the rotor, which intern sent the movement to the recorder. There are examples of this invention available to see in some of the maritime museums. Thomas Walker, nephew of Edward Massey, improved on Massey’s design, and Walker and his son took out a patent on the A1 Harpoon Log. In 1861. Both Massey and Walker continued to improve the designs of the taffrail log. New designs were still being introduced, even up to the 1950s. THE GRANGE, 1840-1858- The wooden barque ’Grange’ was a three-masted ship built in Scotland in 1840 for international and coastal trade. On March 22, 1858, the Grange set sail from Melbourne under Captain A. Alexander, carrying a cargo of ballast. The barque had left the Heads of Phillip Bay and was heading west along the Victorian coast towards Cape Otway. The ship struck Little Haley’s Reef at Apollo Bay due to a navigational error and was stuck on the rocks. The crew left the ship carrying whatever they could onto the beach. Eventually, the remains of the hull, sails and fittings were salvaged before the wreck of the Grange broke up about a month later. About 110 years later, in 1968, the wreck of the Grange was found by divers from the Underwater Explorers Club of Victoria. They were amazed to find a unique, six to nine pound carronade (type of small cannon) and a cannonball on the site. There have been no other similar carronades recorded. In that same year the anchor of the Grange was recovered by diver John Chance and Mal Brown. The ship’s log is significant historically as an example of hardware used when building wooden ships in the early to mid-19th century. The ship’s log is historically significant as an example of the work and trade of blacksmith. The ship’s log also has significant as it was recovered by John Chance, a diver from the wreck of the Grange in the 1968. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The ship’s log is historically significant for its association with the 1840s wooden barque, the Grange. The Grange is an historical example of a Scottish built vessel used for international and coastal trader of both cargo and passengers in the mid-19th century. The Grange is an example of an early ship, designed with a wooden hull. It is significant as a ship still available to divers along the south coast of Victoria, for research and education purposes. The Grange is an example of a mid-19th century vessel that carried a weapon of defence onboard. Ship log fitting, called a fish; part of a brass navigational instrument, likely to be from a taffrail log. The metal is a tan colour and has rough surface with a sheen, and discolouration in places. Its basic shape is a hollow cylinder with ends tapering to a smaller size. In the centre there are opposing openings cut out, showing a rough texture inside. One end on the cylinder is closed with a ring and shank installed, fixed by an embedded screw through the end of the cylinder. There are no inscriptions.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, west coast trader, apollo bay, mid-19th century shipwreck, the grange, scottish barque, little henty reef, captain a alexander, underwater explorers club of victoria, vhr 5297, coastal trader, wooden shipwreck, john chance, wooden ship, taffrail log, marine instrument, marine technology, navigation, nautical instrument, mechanical log, nautical navigation, navigation equipment, scientific instrument, ship log, ship log register, ship speed, taff rail log, patent log, towed log, taffrail log fish, edward massey, thomas walker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Furphy Water Cart, J. Furphy & Sons, c. 1942

This horse-drawn, two-wheeled cart with a tank, is known as a Furphy Farm Water Cart that was made in Shepparton, northern Victoria, c. 1942. John Furphy (1842-1920) was born in Moonee Ponds, in 1842 to Irish immigrant parents and subsequently raised in the Yarra Valley before the family moved to Kyneton in central Victoria, where he completed an apprenticeship with the firm Hutcheson and Walker. Murphy began operations of his own at a site on Piper Street in Kyneton in 1864. He relocated for a business opportunity and founded the first blacksmiths and wheelwrights shop in the newly surveyed town of Shepparton in 1873. Furphy invented many farming tools and machines including a patented grain-stripper, and won awards at the 1888-89 Melbourne International Exhibition. His most famous invention is the Furphy Farm Water Cart, designed in the 1880s, at a time when water for most households and farms was carted on wagons in wooden barrels. The Furphy’s water cart is a single item that combines a water metal tank and a cart. The design of the cart was simple yet effective, and became popular very quickly and established itself as a vital piece of farming equipment. The water cart has had a number of words cast into its ends over many years. References to the foundry’s location in Shepparton, as well as advertising of other products also manufactured by J. Furphy & Sons were present on the ends. However, the most significant set of words to feature on the tank, was a poem encouraging continual improvement: ‘Good Better Best, Never Let it Rest, Until your Good is Better, And your Better Best’. During The Great War (1914-1918), the water cart was used by the Australian militarily at a large AIF (Australian Imperial Force) camp in Broadmeadows (Melbourne) where thousands of men were camped for months, before being transported aboard. Furphy Water Carts provided water to the troops, and were usually placed near the camp latrines, which was one of the few places the troops could share gossip and tall tales away from the prying eyes and ears of their officers. The water cart drivers were also notorious sources of information, despite most of their news being hearsay, or totally unreliable. By the time the men of the AIF were in engaged in combat on the Gallipoli Peninsula and the Western Front, the carts used for water supply had no markings and became simply referred to as Furphys. This owed as much to the coining of the term ‘Furphy’, Australian slang for suspect information or rumour. After a number of decades as principally a soldier’s word, 'Furphy' entered the broader Australian vernacular and was used mainly by the political class until recently when the term was taken up by a Australian brewer as a beer brand. This Furphy Water Cart was purchased by Friends of Flagstaff Hill in 2014. The support of local individuals, organisations and businesses enabled its restoration and later its installation alongside the existing late-19th century water pipe stand and 1940s hand pump The Furphy Farm Water Cart is of historical significance as it represents a famous Australian time-saving and energy-saving invention of the 1880s, replacing the labour intensive activity of collecting and dispensing water from barrels and casks on the back of carts. The water cart’s connection with manufacturing companies J. Furphy & Sons and Furphy Foundry are significant for being early Australian businesses that are still in operation today. Furphy carts are of military significance for the role they played during The Great War (1914-1918) in Australian army camps, and theatres of war in Europe and the Middle East, to supply the AIF troops with fresh water. A wooden framed, two-wheeled, horse-drawn cart, fitted with a horizontally mounted, cylindrical metal tank. The tank is made of rolled, sheet steel with a riveted seam, and cast iron ends with cast iron ends. The spoked metal wheels have fitted flat iron tyres and metal hubs. A metal pipe is joined to the outlet. The tank is silver coloured, the ends, wheels and trims are crimson, and the script lettering on tank sides is black. There are inscriptions on the tank, ends, and hubs. The water tank was made in 1942 in Shepparton, Australia, by J. Furphy & Sons and has a capacity of 180 gallons (848 litres). Hub perimeter, embossed “J. FURPHY & SONS” “KEEP THE / BOLTS TIGHT” Hub centre embossed [indecipherable] Tank, each side, painted “J. FURPHY & SONS / Makers / SHEPPARTON” Tank ends, embossed – “FURPHY’S FARM WATER CART” “BORN ABOUT 1880 – STILL ‘GOING STRONG’ 1942” “j. FURPHY & SONS / MAKERS / SHEPPARTON - VIC “ “S - - - - - L MANUFACTURERS” [SPECIAL] “SPIKE ROLLERS” “SINGLE TREES” “PLOUGH WHEELS” “IRON CASTINGS” “LAND GRADERS” “STEEL DELVERS” “CAST IRON PIG” “CHAIN YOKES” “GOOD – BETTER – BEST / NEVER LET IT REST / TILL YOUR GOOD IS BETTER / AND YOUR BETTER – BEST” Image [Stork carrying a baby] above shorthand, transcribed "Produce and populate or perish" Image [Furphy Pig Feeder] beside ‘Cast Iron Pig’ Shorthand, transcribed “"Water is the gift of God but beer and whiskey are concoctions of the Devil, come and have a drink of water"warrnambool, flagstaff hill maritime museum, water cart, furphy cart, furphy tank, furphy farm water cart, furphy, john furphy, john furphy & sons, furphy foundry, kyneton, shepparton, mobile water tank, jinker, hutchinson & walker, blacksmith, farm equipment, implement maker, tool maker, horse drawn, stork and baby, good, better, best, barrel, tank, first world war, wwi, eastern front, gallipoli, j furphy & sons -

Flagstaff Hill Maritime Museum and Village

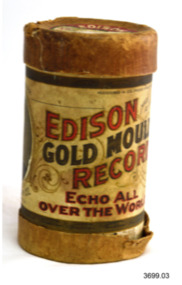

Flagstaff Hill Maritime Museum and VillageAudio - Gramophone Cylinder, B & H Jack, 1907

Edison Records was one of the early record labels that pioneered sound recording and reproduction, and was an important player in the early recording industry. The first phonograph cylinders were manufactured in 1888, followed by Edison's foundation of the Edison Phonograph Company in the same year. The recorded wax cylinders, later replaced by Blue Amberol cylinders, and vertical-cut Diamond Discs, were manufactured by Edison's National Phonograph Company from 1896 on, reorganized as Thomas A. Edison, Inc. in 1911. Until 1910 the recordings did not carry the names of the artists. The company began to lag behind its rivals in the 1920s, both technically and in the popularity of its artists, and halted production of recordings in 1929. Thomas A. Edison invented the phonograph, the first device for recording and playing back sound, in 1877. After patenting the invention and benefiting from the publicity and acclaim it received, Edison and his laboratory turned their attention to the commercial development of electric lighting, playing no further role in the development of the phonograph for nearly a decade. Start of the Recording Industry: In 1887, Edison turned his attention back to improving the phonograph and the phonograph cylinder. The following year, the Edison company introduced the ”Perfected Phonograph”. Edison introduced wax cylinders approximately 4+1⁄4 inches (11 cm) long and 2+1⁄4 inches (5.7 cm) in external diameter, which became the industry standard. They had a maximum playing time of about 3 minutes at 120 RPM, but around the turn of the century the standard speed was increased to (first 144) and then 160 RPM to improve clarity and volume, reducing the maximum to about 2 minutes and 15 seconds. Several experimental wax cylinder recordings of music and speech made in 1888 still exist. The wax entertainment cylinder made its commercial debut in 1889 at first, the only customers were entrepreneurs who installed nickel-in-the-slot phonographs in amusement arcades, saloons and other public places. At that time, a phonograph cost the equivalent of several months' wages for the average worker and was driven by an electric motor powered by hazardous, high-maintenance wet cell batteries. After more affordable spring-motor-driven phonographs designed for home use were introduced in 1895, the industry of producing recorded entertainment cylinders for sale to the general public began in earnest. Blank records were an important part of the business early on. Most phonographs had or could be fitted with attachments for the users to make their own recordings. One important early use, in line with the original term for a phonograph as a "talking machine", was in business for recording dictation. Attachments were added to facilitate starting, stopping, and skipping back the recording for dictation and playback by stenographers. The business phonograph eventually evolved into a separate device from the home entertainment phonograph. Edison's brand of business phonograph was called the Ediphone. The collection of three phonograph cylinders are an example of early recorded music use for domestic entertainment. They are significant as they represent the beginnings of the modern recording industry.Cardboard tube-shaped gramophone cylinder box with lid. The printed label on the outside of the box advertises the maker and patent details. The Catalogue Number and Title are either printed or hand written on the cylinder’s lid. This cylinder contained Record no. 49, “B & H Jack” and was made at the Edison Laboratory USA. C. 1905On lid “Edison Record No. 49”, written in pencil “B & H Jack” (it looks like this) On cylinder “EDISON GOLD MOULDED RECORDS ECHO ALL OVER THE WORLD” Patents listed for 1904 & 1905warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, gramophone record, gramophone cylinder, edison cylinder, edison record, home entertainment, music recording, edison laboratory orange nj, usa, national phonograph company of australia ltd sydney, thomas a. edison -

Flagstaff Hill Maritime Museum and Village

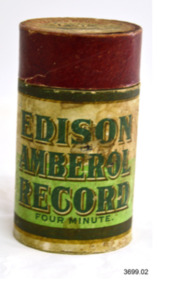

Flagstaff Hill Maritime Museum and VillageAudio - Gramophone Cylinder, National Phonograph Co, Poor old England, 1908

Edison Records was one of the early record labels that pioneered sound recording and reproduction, and was an important player in the early recording industry. The first phonograph cylinders were manufactured in 1888, followed by Edison's foundation of the Edison Phonograph Company in the same year. The recorded wax cylinders, later replaced by Blue Amberol cylinders, and vertical-cut Diamond Discs, were manufactured by Edison's National Phonograph Company from 1896 on, reorganized as Thomas A. Edison, Inc. in 1911. Until 1910 the recordings did not carry the names of the artists. The company began to lag behind its rivals in the 1920s, both technically and in the popularity of its artists, and halted production of recordings in 1929. Thomas A. Edison invented the phonograph, the first device for recording and playing back sound, in 1877. After patenting the invention and benefiting from the publicity and acclaim it received, Edison and his laboratory turned their attention to the commercial development of electric lighting, playing no further role in the development of the phonograph for nearly a decade. Start of the Recording Industry: In 1887, Edison turned his attention back to improving the phonograph and the phonograph cylinder. The following year, the Edison company introduced the ”Perfected Phonograph”. Edison introduced wax cylinders approximately 4+1⁄4 inches (11 cm) long and 2+1⁄4 inches (5.7 cm) in external diameter, which became the industry standard. They had a maximum playing time of about 3 minutes at 120 RPM, but around the turn of the century the standard speed was increased to (first 144) and then 160 RPM to improve clarity and volume, reducing the maximum to about 2 minutes and 15 seconds. Several experimental wax cylinder recordings of music and speech made in 1888 still exist. The wax entertainment cylinder made its commercial debut in 1889 at first, the only customers were entrepreneurs who installed nickel-in-the-slot phonographs in amusement arcades, saloons and other public places. At that time, a phonograph cost the equivalent of several months' wages for the average worker and was driven by an electric motor powered by hazardous, high-maintenance wet cell batteries. After more affordable spring-motor-driven phonographs designed for home use were introduced in 1895, the industry of producing recorded entertainment cylinders for sale to the general public began in earnest. Blank records were an important part of the business early on. Most phonographs had or could be fitted with attachments for the users to make their own recordings. One important early use, in line with the original term for a phonograph as a "talking machine", was in business for recording dictation. Attachments were added to facilitate starting, stopping, and skipping back the recording for dictation and playback by stenographers. The business phonograph eventually evolved into a separate device from the home entertainment phonograph. Edison's brand of business phonograph was called the Ediphone. The collection of three phonograph cylinders are an example of early recorded music use for domestic entertainment. They are significant as they represent the beginnings of the modern recording industry.Cardboard tube-shaped gramophone cylinder box with lid. The printed label on the outside of the box advertises the maker and patent details. The Catalogue Number and Title are either printed or hand written on the cylinder’s lid. This cylinder contained Record no. 13619, the recording “Poor old England” published by Castling and Godfrey, sung by Billy Williams. Made by National Phonograph Company USA. C.1907On lid “Edison Record” and “This record should turn at 160 revolutions per minute, no faster” Written on lid in blue pen “Trumpet”, “EDISON AMBEROL RECORD / FOUR MINUTE”warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, gramophone record, gramophone cylinder, edison cylinder, edison record, home entertainment, music recording, edison laboratory orange nj, usa, national phonograph company of australia ltd sydney, thomas a. edison -

Flagstaff Hill Maritime Museum and Village

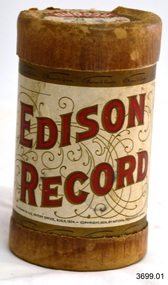

Flagstaff Hill Maritime Museum and VillageAudio - Gramophone Cylinder, Sandy McNab, 1908

Edison Records was one of the early record labels that pioneered sound recording and reproduction, and was an important player in the early recording industry. The first phonograph cylinders were manufactured in 1888, followed by Edison's foundation of the Edison Phonograph Company in the same year. The recorded wax cylinders, later replaced by Blue Amberol cylinders, and vertical-cut Diamond Discs, were manufactured by Edison's National Phonograph Company from 1896 on, reorganized as Thomas A. Edison, Inc. in 1911. Until 1910 the recordings did not carry the names of the artists. The company began to lag behind its rivals in the 1920s, both technically and in the popularity of its artists, and halted production of recordings in 1929. Thomas A. Edison invented the phonograph, the first device for recording and playing back sound, in 1877. After patenting the invention and benefiting from the publicity and acclaim it received, Edison and his laboratory turned their attention to the commercial development of electric lighting, playing no further role in the development of the phonograph for nearly a decade. Start of the Recording Industry: In 1887, Edison turned his attention back to improving the phonograph and the phonograph cylinder. The following year, the Edison company introduced the ”Perfected Phonograph”. Edison introduced wax cylinders approximately 4+1⁄4 inches (11 cm) long and 2+1⁄4 inches (5.7 cm) in external diameter, which became the industry standard. They had a maximum playing time of about 3 minutes at 120 RPM, but around the turn of the century the standard speed was increased to (first 144) and then 160 RPM to improve clarity and volume, reducing the maximum to about 2 minutes and 15 seconds. Several experimental wax cylinder recordings of music and speech made in 1888 still exist. The wax entertainment cylinder made its commercial debut in 1889 at first, the only customers were entrepreneurs who installed nickel-in-the-slot phonographs in amusement arcades, saloons and other public places. At that time, a phonograph cost the equivalent of several months' wages for the average worker and was driven by an electric motor powered by hazardous, high-maintenance wet cell batteries. After more affordable spring-motor-driven phonographs designed for home use were introduced in 1895, the industry of producing recorded entertainment cylinders for sale to the general public began in earnest. Blank records were an important part of the business early on. Most phonographs had or could be fitted with attachments for the users to make their own recordings. One important early use, in line with the original term for a phonograph as a "talking machine", was in business for recording dictation. Attachments were added to facilitate starting, stopping, and skipping back the recording for dictation and playback by stenographers. The business phonograph eventually evolved into a separate device from the home entertainment phonograph. Edison's brand of business phonograph was called the Ediphone. The collection of three phonograph cylinders are an example of early recorded music use for domestic entertainment. They are significant as they represent the beginnings of the modern recording industry.Cardboard tube-shaped gramophone cylinder box with lid. The printed label on the outside of the box advertises the maker and patent details. The Catalogue Number and Title are either printed or hand written on the cylinder’s lid. This cylinder was made by Edison 1908 and contains Record number 53 by Sandy McNab. c. 1908On label “Edison Record No. 53, Sandy McNab" and "Form no. 1130, April 1908. Patented December 6 1904, No. 2109, and December 6 1904 No. 2110. “This record is sold by the National Phonograph Company of Australia Ltd, at Sydney Australia.” Trade Mark Thomas A. Edison warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, gramophone record, gramophone cylinder, edison cylinder, edison record, home entertainment, music recording, edison laboratory orange nj, usa, national phonograph company of australia ltd sydney, thomas a. edison -

Flagstaff Hill Maritime Museum and Village

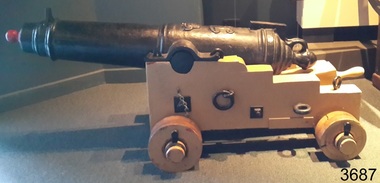

Flagstaff Hill Maritime Museum and VillageWeapon - Carronade, 1840

The carronade was designed as a short-range naval weapon with a low muzzle velocity for merchant ships, but it also found a niche role on warships. It was produced by the Carron Iron Works and was at first sold as a complete system with the gun, mounting, and shot altogether. Carronades initially became popular on British merchant ships during the American Revolutionary War. A lightweight gun that needed only a small gun crew and was devastating at short range was well suited to defending merchant ships against French and American privateers. The invention of the cannon is variously attributed to Lieutenant General Robert Melville in 1759, or to Charles Gascoigne, manager of the Carron Company from 1769 to 1779. In its early years, the weapon was sometimes called a "mellvinade" or a "gasconade". The carronade can be seen as the culmination of a development of naval guns reducing the barrel length and thereby the gunpowder charge. The Carron Company was already selling a "new light-constructed" gun, two-thirds of the weight of the standard naval gun and charged with one-sixth of the weight of the ball in powder before it introduced the carronade, which further halved the gunpowder charge. The theory of its design was to use less powder and had other advantages that were advertised in the company's sales pamphlet of the time, state. The smaller gunpowder charge reduced the barrel heating in action, also reduced the recoil. The mounting, attached to the side of the ship on a pivot, took the recoil on a slider, without altering the alignment of the gun. The pamphlet advocated the use of woollen cartridges, which eliminated the need for wadding and worming, although they were more expensive. Carronades also simplified gunnery for comparatively untrained merchant seamen in both aiming and reloading that was part of the rationale for adopting the gun. Other advantages promoted by the company were. The replacement of trunnions by a bolt underneath, to connect the gun to the mounting, reduced the width of the carriage that enhanced the wide angle of fire. A merchant ship would almost always be running away from an enemy, so a wide-angle of fire was much more important than on a warship. A carronade weighed a quarter as much as a standard cannon and used a quarter to a third of the gunpowder charge. This reduced charge allowed Carronades to have a shorter length and much lighter weight than long guns. Increasing the size of the bore and ball reduces the required length of the barrel. The force acting on the ball is proportional to the square of the diameter, while the mass of the ball rises by the cube, so acceleration is slower; thus, the barrel can be shorter and therefore lighter. Long guns were also much heavier than Carronades because they were over-specified to be capable of being double-shotted, (to load cannons with twice the shot, for increased damage at the expense of range), whereas it was dangerous to do this in a carronade. A ship could carry more carronades, or carronades of a larger calibre, than long guns, and carronades could be mounted on the upper decks, where heavy long guns could cause the ship to be top-heavy and unstable. Carronades also required a smaller gun crew, which was very important for merchant ships, and they were faster to reload. The small bore carronade and carriage is part of a collection of nineteenth Century Flagstaff Hill Guns and Cannon, which is classified as being of significance and was made a few years after the beginning of Queen Victoria's reign in 1837 and fires a 6 lb pound cannon ball. This nineteenth century artillery piece is a rare and representative item of artillery of this era, used predominately on ships, both military and merchant. The artillery piece, individually and as part of the collection, is highly significant for its historical, scientific and aesthetic reasons at the state, national and world level. This carronade represents the methods of artillery technology, its advancement and its modifications to suit dangerous situations that sailors encountered from attacks from free booters (pirates, living from plunder) or others at the time. Carronade firing a 6 lb cast iron ball, with a smooth bore barrel 6.5 cm in dia the item is mounted on stepped wooden carriage with wooden wheels. Cannon barrel can have its elevation adjusted via a wooden wedge. Gun carriage has loops for locating and holding in position to a deck by ropes. Carriage is a replica made 1982Cast into the barrel is the royal emblem of Queen Victoria (VR "Victoria Regina") indicating the carronade was cast during Queen Victoria's reign / 1840 & 4-2-0 denoting the weight of the barrel. Right hand trunnion has a serial number “8708”. Also on top of the barrel is the British "Board of Ordinance" identifying mark a broad arrow indicating the carronade was in military use. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, colonial defences, victoria’s coastal defences, warrnambool fortification, warrnambool garrison battery, warrnambool volunteer corps, ordinance, armaments, garrison gun, smooth bore cannon, carronade, black powder, 12 pounder, 1840, artillery, lieutenant general robert melville, charles gascoigne, carron company, mellvinade, gasconade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Bread Board, Not known

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe use of the wooden chopping board over time. Wooden Rectangular Bread board . Worn (concave in centre). Raw wood.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chopping board, cooking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board

In the high tech, fast paced society that we live in, it’s easy to take some things for granted. Case in point: the wood cutting board on which you’ll probably be preparing the evening’s dinner. Have you ever taken the time to think about the history of the cutting board? Where did it come from, and what did ancient civilizations use to cut their meats, fruits and vegetables? Wood throughout the ages Since the dawn of time, wood has been one of the most available materials used by mankind to build tools and lodgings, so it’s not really surprising to know that wood has been used in the preparation of food since the prehistoric ages. Of course, back then, cavemen probably used an unpolished slab of tree trunk to cut the kill of the day on and they probably didn’t think twice about saving it once the meal was over. Chances are they probably threw it in the fire with the rest of the wood needed to kindle it. Advances in technology Throughout the centuries, mankind evolved and started creating machines from steam, electricity and metal. When the circular saw was invented, nicer, cleaner slabs of wood were cut and used as cutting boards. Since soft wood was the most available type of wood at the time, it was the material of choice for to be used for cutting boards. Boards were made smaller since the slab of wood could now be cut to any desired size. Since they were made smaller, they were also used to eat off of and some people referred to them as trenchers. Trenchers were originally pieces of stale hard bread that were used as substitute plates. Wood trenchers quickly became the replacements of the eatable dinnerware. The butcher block: the cutting board’s larger cousin In the industrial ages, many industries rapidly developed, and the butchery industry followed this trend as well. Before the invention of the cutting board, butchers used tree rounds to carve their meat on. The rounds were often too soft and they rapidly became unsanitary. Hard maple wood butcher blocks were the preferred choice of the industry. They were made to be extremely thick and durable, so durable in fact, that a butcher could use the same block for almost his entire career. Cutting boards around the world As cutting boards began to be more and more used in kitchens around North America, the rest of the world crafted such boards from different materials. The East used thick bamboo as their material of choice. Despite its frail appearance, bamboo is quite strong and made durable cutting boards and butcher blocks. Europe used maple in the crafting of their cutting boards while Persia used flat pieces of polished wood in their kitchens. The world then saw cutting boards that were being made from other materials like plastic and they came in all shapes and sizes, but they always served the same purpose, to provide a household with a safe, clean surface on which to prepare meals for their friends and family members. https://www.woodcuttingboards.com/news/quick-history-of-the-cutting-board-47.aspxThe bread board is an example of kitchen equipment used during Victorian times and similar to those used today.Bread board. Wooden, octagonal, plain sanded light wood. Has decoration around edge and indented circular line to delineate round cutting board section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bread board, cutting board, pastry board, kitchen utensil, kitchen equipment, baking equipment, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bread Board