Showing 525 items

matching use of machinery

-

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, 1941-42

Used by donor in family home.Portable electric singer sewing machine, rotating shuttle. There is a separate knee action control lever. Serial no. EG588844 .Black base with gold decoration. The wooden case top has 'Singer' on front. Motor K605945Singerdomestic items, sewing, textile machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, c1880

Machine used by Francesca Schwerkolt, August Schwerkolt daughter -in - law. She was the grandmother of the donor.Hand and foot operated transverse shuttle sewing machine with ornate foot treadle. Wooden top with mechanism in centre. Base of mechanism has mother of pearl inlay. Ornate iron supports. Two drawers on either side with ornate handles. Centre drawerOn Sewing Mechanism - ' Syst 182/Manufactured in Germany/Specially for/Hugo Wertheim'|On Base - 'Griffin' in ironwork|'Wertheim' in ornate ironwork on sides|S No. 6778165domestic items, sewing, textile machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Vehicle - Orchard Spray Unit, C1915

It is presumed that the spray unit was imported in 1915 and a local manufacturer (unknown) made the wooden barrel and cart and mounted the Ballarat made motor and the imported spray unit.|Following the purchase of the R.E.Gray property, Nunawading Council Engineer, John Herbertson on finding the Spray Unit suggested that it become part of the Implements display at Schwerkolt Cottage.Myer Orchard Spray. It consist of the spray unit which is driven by a Ronaldson-Tippet Motor. The large wooden barrel spray container (mounted on the cart) contained approx 100 gallons of highly corrosive spray (hence the use of wood). The Myer pump is a twin plunger type.Myer 4078 on the barrel of the pump. Myer 3573 0n the inspection plate.rural industry, orcharding, machinery, engines - internal combustion, pumps -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Lawn Mower - Motor, c1930

Given by Harold Bake and was used by him.|2007 - Seized gearbox repaired.Petrol driven motor Qualcast lawn mower (motor - Villiers Midget made in England) with a large roller.Qualcastdomestic items, gardening, machinery, engines - internal combustion -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, 1883-1915

Black sewing machine and cover. Model A6? Vibrating shuttle. Serial no. S907389. Machine has coloured decorations of flowers and leaves. Set on wooden base with inlaid decorated edge.|An equipment drawer contains instructions for use of machine, attachments, needles needle threaders and five spools, one empty.'Freya'domestic items, sewing, textile machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel, used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Hand forged steel used for holding hot steel whilst it was being forged.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

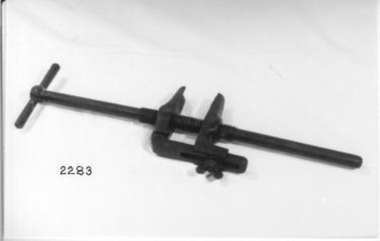

Whitehorse Historical Society Inc.Tool - Clamp, c1920

Clamp - consisting of two tightened by 'T' screw having a left and right threads. Possibly used by a wheelwright.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Farrier's Hammer, c1920

Hand forged steel used by farrier for shaping horse shoes.rural industry, farm machinery, trades, farriery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Hand forged steel used for holding hot steel whilst it was being forged.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

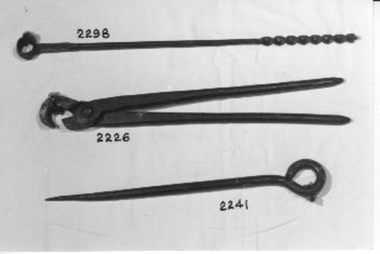

Whitehorse Historical Society Inc.Tool - Wood Auger, c1920

Hand forged steel, used for boring holes through timber.rural industry, farm machinery, trades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Coke Sieve, c1920

Sheet metal frame with metal mesh sieve. Used for sieving 'breeze' or dust from coke to help in maintaining a clean fire.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Anvil, c1920

See NA2323 for history of donor and photo.Anvil - made from forged steel and used by the blacksmith as a table to hand forge hot steel etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

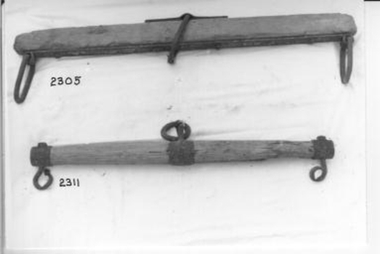

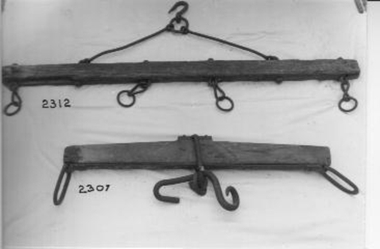

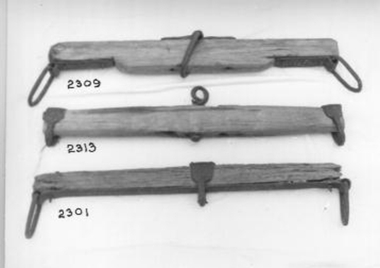

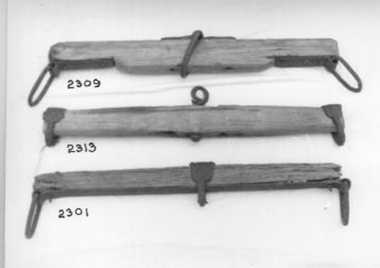

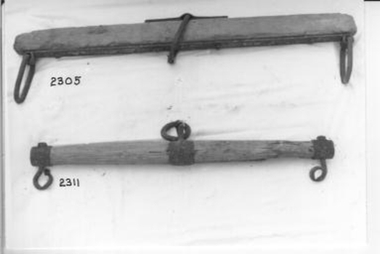

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

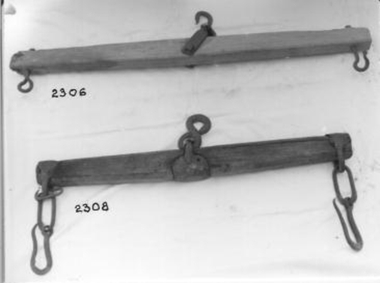

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

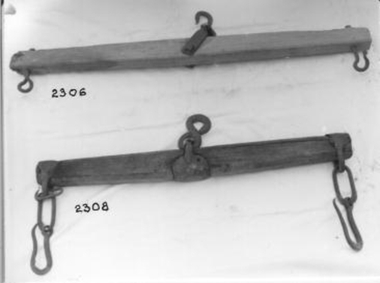

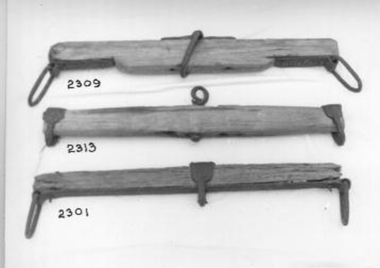

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Swingle Tree, c1920

... Mitcham melbourne rural industry farm machinery The swingle tree ...The swingle tree was used to enable a horse to turn when drawing a plough or similar implement.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel; whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery