Showing 304 items

matching wool spinning

-

National Wool Museum

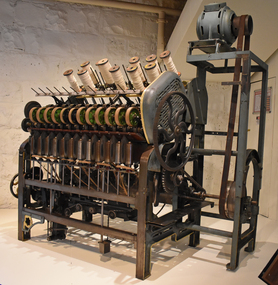

National Wool MuseumMachine - Cap Spinner, 1925

This cap spinner squeezes the thread under the stationary cap and winds them onto the bobbin. Spinning transforms tops into yarns. The tops are pulled out into fine strands known as rovings. They are then twisted to bind the thread together to give the yarn greater strength. The yarns are wound into differently shaped tools. They are then sent off for weaving and knitting.Cap spinning machine.weaving, knitting, cap spinning, cap spinner, machine, textile industry, factory -

National Wool Museum

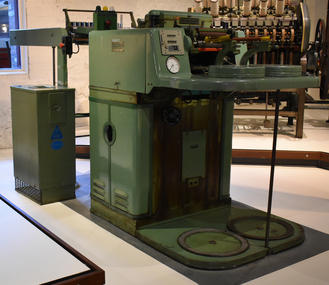

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

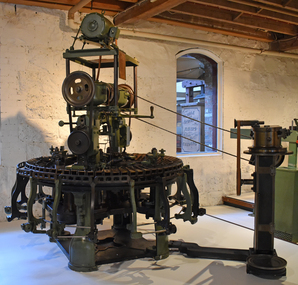

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

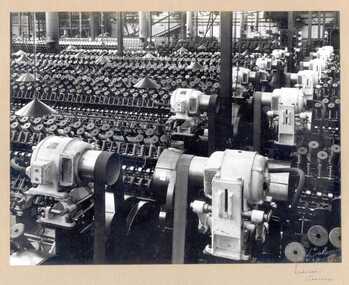

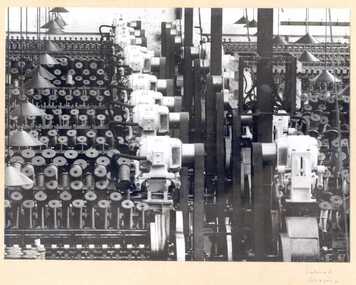

National Wool MuseumPhotograph, Foster Valley Mill

Interior view of machinery at Foster Valley Mill. Shows the winding (or twisting) machinery (where the spun yarn is threaded onto bobbins).Spinning machinery within the Valley Mill.T. Lockwood Lockwood / GEELONGtextile mills operation, valley worsted mill, winding machinery, textile mills - operation -

National Wool Museum

National Wool MuseumPhotograph, Foster Valley Mill

Interior view of machinery at Foster Valley Mill. Shows the winding (or twisting) machinery (where the spun yarn is threaded onto bobbins).Spinning machinery in the Valley Mill.T. Lockwood Lockwood / GEELONGtextile mills operation, valley worsted mill, winding machinery, textile mills - operation -

National Wool Museum

National Wool MuseumSpinner

Hand held wool spinner - distaff spinner made by Ted Fairhurst.handicrafts, spinning - hand, fairhurst, mr ted -

National Wool Museum

National Wool MuseumT-shirt

Australian womens top/t-shirt from the formal uniform for the Sydney 2000 Olympic Games. Manufactured by Blossom Road Pty Ltd from Colana yarn (a wool/cotton blend) from Rocklea Spinning Mills Pty Ltd.fashion, woolmark company blossom road pty ltd, sport, the woolmark company 2000 australian olympic display - exhibition (21/12/2001 - 24/05/2002) -

National Wool Museum

National Wool MuseumPhotograph Album, The Valley Worsted Mills, Geelong

Photograph album containing 15 photographs of the textile processes which took place at the Valley Worsted Mill which was established in 1923.Photograph album contains 15 photographic postcards of textile processes from the Valley Mill, c.1920s. Valley Mill, Geelong, c.1920s. Wool sorting at the Valley Mill, Geelong, c.1920s. Wool scouring at the Valley Mill, Geelong, c.1920s. Woollen carding at the Valley Mill, Geelong, c.1920s. Worsted carding at the Valley Mill, Geelong, c.1920s. Combing and drawing at the Valley Mill, Geelong, c.1920s. Woollen spinning at the Valley Mill, Geelong, c.1920s. Worsted spinning at the Valley Mill, Geelong, c.1920s. Winding at the Valley Mill, Geelong, c.1920s. Warping at the Valley Mill, Geelong, c.1920s. Weaving at the Valley Mill, Geelong, c.1920s. Mending at the Valley Mill, Geelong, c.1920s. Wet finishing at the Valley Mill, Geelong, c.1920s. Dry finishing at the Valley Mill, Geelong, c.1920s. Warehouse at the Valley Mill, Geelong, c.1920s.PHOTOGRAPHS THE / VALLEY WORSTED MILLS / GEELONG WOOL SORTING / WOOL SCOURING / WOOLLEN CARDING / WORSTED CARDING / COMBING & DRAWING / WOOLLEN SPINNING / WORSTED SPINNING / WINDING / WARPING / WEAVING / MENDING / WET FINISHING / DRY FINISHING / WAREHOUSE C.J. Frazer Photographer / Melbournetextile mills warehouses, weaving, textile production, textile mills, valley worsted mill, scouring, carding, combing, drawing, spinning, winding, warping, wet finishing, mending, milling, dry finishing, textile mills - warehouses -

National Wool Museum

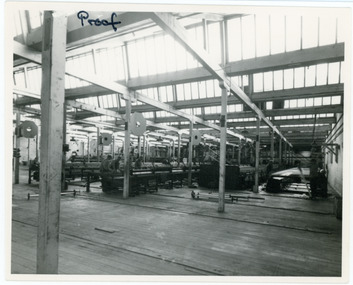

National Wool MuseumPhotograph

Depicts the woollen spinning room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, spinning, spinning machinery -

National Wool Museum

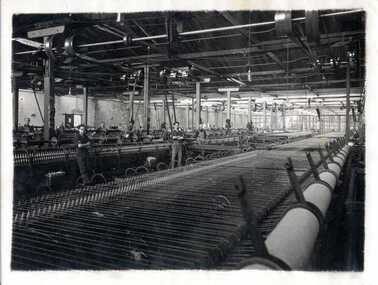

National Wool MuseumPhotograph

Depicts spinning/twisting machinery within a mill, c.1930s.textile mills - staff, spinning machinery, twisting machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the winding / spinning operations within a mill, c.1950s. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, winding, spinning -

National Wool Museum

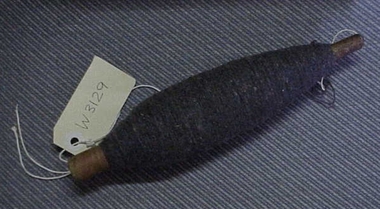

National Wool MuseumBobbin, Mule spinning bobbin

Spool of grey yarn used in the process of mule spinning.weaving mills -

National Wool Museum

National Wool MuseumSpool

Spool used for spinning.weaving mills -

National Wool Museum

National Wool MuseumSpindle

Spindle originally from Collins Bros Mill.collins bros mill pty ltd deakin university, spinning machinery -

National Wool Museum

National Wool MuseumPirn

Wood and metal pirn. Companion part to a shuttle, used in a loom. Shuttle looms disappeared in the 1960's.spinning -

National Wool Museum

National Wool MuseumFunctional object - Spinning Wheel

-

National Wool Museum

National Wool MuseumSpool, Roving bobbin

Spool used for spinning.spinning -

Whitehorse Historical Society Inc.

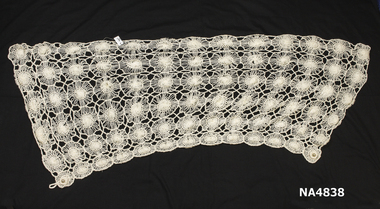

Whitehorse Historical Society Inc.Clothing - Cape, 1997

I have lived in Box Hill now City of Whitehorse since 1970 I have belonged to Box Hill Spinners and Weavers Inc. since 1990.During the 90s' Box Hill Spinners and Weavers participated in the Annual Sheep and Woolcraft Show, at that time held in the Melbourne Showground. As well as submitting individual entries we always entered the Group Competition, known as the '5 articles' the entry had to have 5 separate articles made by a group and displaying different woolcraft techniques . In 1997 our Box Hill entry focused on 'The Planets' featuring five capes. The red one representing Mars the red planet. It was woven. The dark cape represented Jupiter. It was also woven. the Neptune cape was felted in blue and greens. The Earth cape featured knitting and crochet. My contribution was the Venus cape featuring spinning from raw merino fleece and silk. Once completed this wool/silk yarn was fashioned using hairpin lace. I was adept at spinning by this time but knew nothing about the old technique of hairpin lace. Box Hill Spinners and Weavers won First Prize. Margaret Dimelow.Cream coloured cape spun from raw merino fleece and silk, technique is hairpin lacecostume, female -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - WOOL WINDER

Wooden instrument for winding wool with circular base, a detachable top section which spins with four concertina arms.handcrafts, wool work equipment, wool winder -

Bendigo Historical Society Inc.

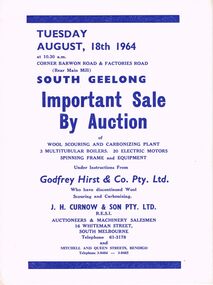

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GODFREY HIRST & CO PTY LTD

Two white covered catalogues with blue printing. Sale of wool scouring and carbonizing plant, 3 multi tubular boilers, 20 electric motors, spinning frame and equipment. J. H. Curnow & Son Pty. Ltd. Were the auctioneers for Godfrey Hirst & Co. Pty. Ltd. Catalogue contains Memorandum of Purchase at Auction, Special Note to Buyers, Location, Description of 183 lots and Conditions of Sale. Sale was on the 18/8/1964.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - godfrey hirst & co pty ltd, j h curnow & son pty ltd, f c dyett, l c osborne, r w e hammill -

Bendigo Historical Society Inc.

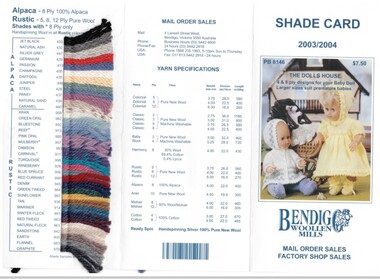

Bendigo Historical Society Inc.Document - Shade Card, 2003

The Bendigo Woollen Mills were initially designed as a mail order company that sold its wool both domestically and internationally. The mill uses first cross merino wool from Australia that is then sent to China for scouring before returning to Bendigo for grading, dying and spinning. It now includes factory shop sales to the public.Bendigo Woolen Mills Shade Card (With samples of different coloured wool, pattern selections which were available at the Factory Shop Order Form.history, bendigo, merle lummis collection, bendigo woolen mills -

Kew Historical Society Inc

Kew Historical Society IncEquipment - Hand drum carder, Ertoel Wheels, 1980s

... carders, and spinning and weaving accessories. wool carding drum ...Ertoel Wheels made a wide range of looms, chairs, drum and hand carders, and spinning and weaving accessories. Small drum carder, designed to be used on a table and operated by hand to card wool and or other fibres in preparing them for spinning or felting. This wooden carder has two cylindrical drums covered with coarse or fine metal “tines” designed to rake through and comb the natural fibre. The manufacturer's name 'Ertoel Wheels' is glued at one end"Ertoel Wheels"wool carding, drum carders, carding equipment -

National Wool Museum

National Wool MuseumBobbin

Bobbin, used on a spinning frame (See also Reg No 140)handicrafts weaving, spinning, handicrafts, weaving -

National Wool Museum

National Wool MuseumBobbin

Wooden bobbin, used on a spinning framehandicrafts weaving, spinning, handicrafts, weaving -

National Wool Museum

National Wool MuseumBook, Worsted Machinery Catalogue

"Worsted Machinery Catalogue (French Section)" - Prince-Smith & Stells Limited, Keighley, England, c.1920. The catalogue is very comprehensive and describes in detail many types of combing, drawing, spinning and twisting machinery (French System).Book/catalogue - "Worsted Machinery Catalogue", Prince-Smith and Stells Limited, c.1920.textile machinery, prince-smith and stells limited jackson, mr george - mount gambier spinning mills limited, combing, drawing, spinning machinery, twisting, yarn - worsted, cloth - worsted -

National Wool Museum

National Wool MuseumFunctional object - Yarn Spinner and Accessories, John Nesbitt, 19th Century

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design.Custom made wooden hinged box with a hook latch. Brass yarn spinner, attached to a mahogany wood plinth base, which spins fibre into cord/yarn/thread. It has dials to set the rate that it spins. Metal plaque with black inlaid enamel lettering. Small cork inlay. Brass rod with hinge and wingnut, and ball at end. Ball at end has an adjustment mechanism. Rod also has an adjustable circular collar. Pair of curved tweezers. Circular magnifying glass on long thin handle. Glass has two concave lenses. Weaving sample in shades of blue, green and brown. Twill weave. Alternate pattern samples separated by red thread.Brass plaque on base of spinner: 42 MARKET St / John Nesbitt / REGd TRADE MARK / LIMd / MANCHESTER Underside of wooden plinth: 4976apparatus, textile, testing, spinning, nino corda, magnifyer, tools, brass, mahogany, tweezers, yarn, spinner, design, john nesbitt, manchester, england, 19th century, engineering, manufacturing -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Spinning, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior of a factory depicting spinning machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

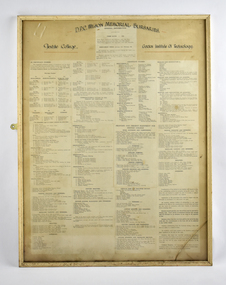

National Wool MuseumPhotograph - Framed Printed Coursework, Gordon Institute of Technology, Textile College, 1950

Framed papers outlining the courses and coursework for the Textile College at the Gordon Institute of Technology in 1950. The courses include Woolcombing, Worsted Spinning, Woollen Yarn Manufacture, Designing, Weaving and Turning and Finishing. A digital copy of this item was made for the National Wool Museum Collection, with the original remaining with the donor. Digital TIFF file, 100 MB, showing image of framed printed paper.D.P.C. WILSON MEMORIAL BURSARIES. / Textile College / Gordon Institute of Technology. / GENERAL INFORMATION / TERM DATES 1950 ...courses, gordon institute of technology, textile college, geelong, woolclassing, weaving, spinning, coursework, 1950 -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Spinning Machinery, 1990s

... Executive, Early Stage Wool Processing at the International Wool ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a person working inside a factory with spinning machinery.wool, industry, australia, australian wool board international wool secretariat, factory, training, spinning -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Spinning Machinery, 1990s

... Executive, Early Stage Wool Processing at the International Wool ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a factory interior with spinning machinery.wool, industry, australia, australian wool board international wool secretariat, factory, training, spinning