Showing 20 items matching " brake cylinders"

-

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Air Gauge, J.A. Floyd Maker Melb for and Horrocks Roxburgh Pty Ltd Melbourne, c1930

... Brake Cylinders... in the brake cylinder. Note the red needle is on the wrong side...Tramways trams Air Compressors Brake Cylinders Brake Valves ...Air Gauge - duplex type for tramcars with self lapping brakes - brass case, and back, with two needles - red and black - glass front, paper pressure indication. The red needle shows the pressure in the air-tank and the black needle, the pressure in the brake cylinder. Note the red needle is on the wrong side of the stop, possibly due to transport. Would have been used on a Melbourne or MMTB tramcar. Has the name "Horrocks Roxburgh Pty Ltd Melbourne" on the base and "J.A. Floyd Maker Melb" in the centre.has "551" scratched onto the rear.tramways, trams, air compressors, brake cylinders, brake valves, air gauges, mmtb -

Ballarat Tramway Museum

Ballarat Tramway MuseumDrawing - R1872 - Air Brake rigging single truck cars, Melbourne and Metropolitan Tramways Board (MMTB), 12/1926

... of the air brake cylinder, rodding, hand brake connection... of the air brake cylinder, rodding, hand brake connection ...Digital image of MMTB Drawing No. R1872 - "Standard Dimensions for single truck air brake rigging" - shows the layout of the air brake cylinder, rodding, hand brake connection, for various cars listed by numbers.Yields information about the layout of the air cylinder and connections to the brake rods of a 21E truck.Digital image of a scanned drawing - R1872drawings, tramcars, brill 21e, braking, air brakes, mmtb -

Melbourne Tram Museum

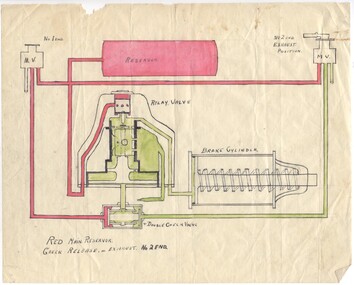

Melbourne Tram MuseumDrawing - air brake system on a Melbourne tram using a self lapping brake and relay valve, Melbourne & Metropolitan Tramways Board (MMTB), 1960's?

... , reservoir, brake cylinder and pipes...., brake cylinder and pipes. Drawing air brake system ...Drawing of the air brake system on a Melbourne tram using a self lapping brake and relay valve - the charging and release positions. 89.1 - shows the relay valve in the exhaust position 89.2 - shows the valve in the applied position. Has been drawn in ink on a piece of paper, and the coloured red or green as necessary to show the various positions and state of the valves, reservoir, brake cylinder and pipes.trams, tramways, mmtb, braking, brake valves -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Westinghouse Brake & Saxby Signal Co. Ltd, "Compressed Air Brakes for Tramways", May. 1929

... , Governors ES16, Brake Valve No. 13, 9, brake cylinder, sand ejectors..., Governors ES16, Brake Valve No. 13, 9, brake cylinder, sand ejectors ...Forty One page book with dark red cover titled "Compressed Air Brakes for Tramways", published by Westinghouse Brake and Saxby Signal Co. May 1929. Cover - cloth texture laminated paper cover, dark red on outside, with embossed title and publishing details and Westinghouse logo embossed on rear cover. Forty printed pages sewn at three points into cover with page 41, tipped onto right hand edge of page 40, with a blind perforated strip to enable the sheet to be used as an Enquiry form to obtain a price regarding tram brake equipment. Covers compressed air brake systems in general for tramways, including layout drawings, straight air brake, braking ratio, brake cylinder sizing, reservoirs, air compressor type E13, DH16, E13, Governors ES16, Brake Valve No. 13, 9, brake cylinder, sand ejectors, reservoirs drain cocks, with an appendix describing the automatic brake system for use with trailers. Manual No. DP12."Colin Rutledge" stamped on top of page 1.trams, tramways, westinghouse, tramcar brakes, compressors, governors, equipment -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Instruction, Melbourne & Metropolitan Tramways Board (MMTB), "Duties of Electrical Mechanics - Runningsheds", May. 1970

... , compressor, lighting, buzzers, door engines, wipers, brake cylinders..., wipers, brake cylinders and general body eg handrails. Dated ...Instruction - 5 pages - duplicated foolscap sheets - headed "MMTB Engineering Department - Workshops and Running Shed Branch" - titled "Duties of Electrical Mechanics - Runningsheds" Details electrical work to be done on tramcars at the 100 hours service; trolley pole, electrical equipment, controllers, switches, resistance boxes, line breakers, RC units, motors, governor, compressor, lighting, buzzers, door engines, wipers, brake cylinders and general body eg handrails. Dated May 1970.trams, tramways, depot, safety, workshops, electrical equipment, instructions, procedures -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Instruction, General Electric, "General Electric - Straight Air Brake Equipment Instruction Book 84564A", Sep. 1919

... , motorman valves, brake cylinders, rules for operating, emergency..., cylinders and governors, safety valves, motorman valves, brake ...Instruction - 16 pages + brown covers, centre stapled, cloth binding on left hand side and two punched holes on left hand side, right hand side has rounded corners, titled "General Electric - Straight Air Brake Equipment Instruction Book 84564A", dated Sept. 1919. Includes instructions on compressors, air intakes, valves, cylinders and governors, safety valves, motorman valves, brake cylinders, rules for operating, emergency stops, sanding of rails and general issues. Has a list of company offices on the last page.trams, tramways, electrical engineering, electrical equipment, general electric, air compressors, brakes, instructions, maintenance -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Technical pamphlet/s, Westinghouse Brake & Saxby Signal Co. Ltd, "Combined Guard's Van Valve and Gauge for Vacuum Brakes", 1924 - 1928

... "Prestal Vacuum Brake Cylinders Combined and Separate Types... technical pamphlet, titled "Prestal Vacuum Brake Cylinders Combined ...2287.1 - Four page technical pamphlet, titled "Combined Guard's Van Valve and Gauge for Vacuum Brakes", published by Westinghouse Brake and Saxby Signal Co. Ltd. November 1926. Manual No. D.P. 8. 2287.2 - Eight page technical pamphlet, titled "Brake Control Valve for Automatic Vacuum Brake", published by Westinghouse Brake and Saxby Signal Co. Ltd. January 1928, Manual No. D.P. 15. Saddle Stapled. 2287.3 - Twelve page technical pamphlet, titled "Vacuum Brake Apparatus", published by Westinghouse Brake and Saxby Signal Co. May 1924, Manual No. D.P. 3. Saddle Stapled. 2287.4 - Eight page technical pamphlet, titled "Prestal Vacuum Brake Cylinders Combined and Separate Types", published by Westinghouse Brake and Saxby Signal Co. Ltd. January 1928, Manual No. D.P. 14. Saddle Stapled. Two copies held.Each have "Colin Rutledge" stamped on top of page 1.trams, tramways, westinghouse, railway brakes, vacuum brakes, equipment -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Westinghouse Brake & Saxby Signal Co. Ltd, "Air Brakes for Tramways", 1934

... - DP27a Westinghouse Air brake cylinders - April 1934 - two... Westinghouse Air brake cylinders - April 1934 - two sheets -DP35 Quick ...28 sheets contained within a folded buff coloured cover secured with folded metal clips and washers, titled "Air Brakes for Tramways". Published by the Westinghouse Brake & Saxby Signal Co. Ltd. of 82 York Road, Kings Cross London in 1933/34. Contains various data sheets for various Westinghouse brake system components. Cover sheet with index. Air brakes for Tramways - June 1934 - fold out sheet and single sheet - DP12. Interconnection of air and magnetic track brakes - June 1934 - fold out sheet and a single sheet - DP12a Motor Driven Air compressor - type DH - March 1933 - four sheets - DP1 Air Compressor type E13 - June 1934 - two sheets - DP18 Electric compressor Governor's - ES16, ES16C and NS16 - April 1934 - six sheets - DP7 Drivers Brake Valve No. 9 - July 1934 - one sheet - DS7 Improved self lapping Driver's Brake Valve - October 1933 - two sheets - DP27a Westinghouse Air brake cylinders - April 1934 - two sheets -DP35 Quick Release Valve - June 1934 - 1 sheet - DS18 Double Check Valve - July 1934 - 1 sheet DS8 Double Check Valve No. 19 - June 1934 - 1 sheet DS8a Conductors Emergency Valves - June 1934 - 2 sheets - DP37 Pneumatic Sanding apparatus - July 1934 - 1 sheet DS11 Safety Valve Type N - June 1934 - 1 sheet DS17. Contents scanned to COTMA Web site 5/2/2011."Colin Rutledge" stamped on top of page 1 and date stamp of "The Westinghouse Brake Co. Ltd. Melbourne 17 Dec 1934" on front cover.trams, tramways, westinghouse, tramcar brakes, compressors, governors, equipment -

Federation University Historical Collection

Federation University Historical CollectionBook, William J. Goudie, Ripper's Steam Engine Theory and Practice, 1932

Formerly part of the Ballarat School of Mines libraryA blue book with the title printed in gold on the spine, and the publisher "Longmans" printed in gold at the base of the spine. It has 503 illustrations throughout. It has two loose pages of plates in a sleeve inside the back cover and some pull out plates throughout. 841 pagesIt is stamped with The School of Mines Ballarat near the front and back pages, as well as some throughout the book.steam engine, properties of steam, flywheels, condensers, thermodynamic principles, energy diagrams, engine cycles and efficiencies, brake horse-power, steam in the cylinder, multiple expansion engines, valve gears, governors, crank, corliss and drop-valve engines, steam turbines, turbine performance, steam -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Folder with papers, State Electricity Commission of Victoria (SECV), 1960's

Yields information about the drawings that were used by the depot or workshop staff as reference drawings. Has a strong association with the depot workshop staff. Yields information about equipment on Ballarat tramcars and Signalling.Folder containing 46 blueprints or Dyeline prints of SEC tram equipment drawings. Front of folder made from a cloth back sheet of paper extended to secure to a thick cardboard runner. Rear of folder made from an old tram advertising panel or cardboard sheet, cut to size and secured to a thick cardboard runner with a cloth backing on both sides. Sheets secured with three brass screwed clips. Front cover damaged in bottom right hand corner. Rear cover breaking apart on outside around cloth binding. Heavy dirt marks from “grease” on bottom half of rear cover. Contains 46 drawings which have been individually catalogued and numbered on the rear of each drawing within the folder. Some of the drawings have been folded. Reg Item Micro Film No. Old BTPS No. SEC Drawing No Title 4807 42/4 1 VB4/8103C Westinghouse T1F Controller Main Cylinder Segments. 4867 47/2 2 BA-T8-8128 Westinghouse 225N Motor Case Bolt 4830 22/3 B 3 BA-T7-7666 Half Ball Brake Hanger Link, Driving Wheel, Brill Maximum Traction Truck 22E 4868 44/3A 4 BA-T8-8113 Split Suspension Bearing for Type W225 Motor (Westinghouse) 4869 52/2 5 BA-T8-8158 Contact Tips for G.E. Compressor Controller 4818 52/3 6 BA-T8-8159 GE B-23 Contact Finger Tips for G.E. Type ‘B’ Main Cylinder 4870 6/1 7A BA-T3-6734 Brass Nut for Switch Mechanism 4829 6/2 7B BA-T3-6735 Tongue Clip Link for Switch Mechanism 4871 6/3 7C BA-T3-6736 Fulcrum for Switch Mechanism 4872 6/4 7D BA-T3-6737 Plunger for Switch Mechanism 4832 7/6 8 BA-T3-6754 Pivot for Switch Mechanism No numbers 9 or 10 4873 17/5 11 BA-T7-7639 Detail of Motor Pinion for Brill Cars 4831.2 21/4 B 12 BA-T7-7661A Half Ball Hanger Links – single bogie trucks 4874 21/6 13A BA-T7-7663 Axle Box Inner Spring Driving Wheels Maximum Traction Truck 22E 4875 22/1 13B BA-T7-7664 Axle Box Outer Spring Driving Wheels Maximum Traction Truck 22E 4876 22/2 14 BA-T7-7665 Body Spring Brill Maximum Traction Truck 22E 4830.2 22/3B 15 BA-T7-7666A Half Ball Brake Hanger Link Driving Wheel Brill Maximum Traction Truck 22E 4877 22/4 16 BA-T7-7667 Body Spring, Brush Maximum Traction Truck 22E 4820.2 22/6 A 17 BA-T7-7669 Wear cups for Half Ball Brake Hanger Links, Single & Double Bogie Trucks 4878 50/5 18 BA-T8-8149 Connections of Line Breaker and Ratchet Switch for use with Drum Controller 4879 74/6 19 BA-T13-8757/9 Signal boxes, Back of Panel Wiring and External Connections 4880 45/1 20 BA-T8-8116 Trolley Harp 4806 15/3 21 BA-T7-7625 Equalizing Lever, Fulcrum, Brill 21 E truck 4881 15/5 22 BA-T7-7626A Brake Beam Fulcrum Brill 21E truck 4808 16/1 23 BA-T7-7628 Pinion Remover, GE 201G and GE 202 motors 4882 16/3 24 BA-T7-7630 Spring Posts, Brill 21E Truck 4883 21/3 25 BA-T7-7660 Brake Shoe Holder, Driving Wheel, Maximum Traction Truck Brill 22E 4884 21/5 26 BA-T7-7662 Brake Rod Guide, Single Bogie Trucks 4885 22/5 27 BA-T7-7668 Brake Shoe Holder, Pony Wheel, Maximum Traction Truck Brill 22E 4809 42/2 B 28 BA-T8-8101 Trolley Wheel and Axle 4815 42/1 B 29 BA-T8-8102A Motor Suspension Bearing, GE 202 Motor 4796.2 42/5 30 BA-T8-8104 Connection Diagram WH 225N Motor 4886 42/6 B 31 BA-T8-8105B Motor Suspension Bearing, GE 201 Motor 4797.2 48/6 32 BA-T8-8137 WH T1F Controllers 4816 49/2 33 BA-T8-8138 Connection Diagram GE 202 Motor 4887 49/3 34 BA-T8-8139 Connection Diagram K-36-J Controller 4888 50/3 35 BA-T8-8146 GE K-36-JR Controllers, with line breaker (Connection diagram) 4889 50/6 36 BA-T8-8150 Commutator for Westinghouse 225N Motor 4846 51/1 37 BA-T8-8151A Armature Bearing Lining, Commutator End, Type GE 201G Motor 4813 51/2 38 BA-T8-8152 Armature Winding Diagram Westinghouse 225 Motor 4840.2 51/40 39 BA-T8-8154A Armature Bearing Lining, Pinion End, Type GE201G Motor 4890 51/6 40 BA-T8-8156 Armature Bearing Lining, Pinion End, Type GE202A Motor 4891 52/1 41 BA-T8-8157A Armature Bearing Lining, Commutator End, Type GE202A Motor 4892 64/5 42A BA-T9-8392A Step Hangers, Single and Double Bogie Trucks, Hinged Type 4785.2 64/6B 42B BA-T9-8392/1A Step Hangers, Single and Maximum Traction Trucks, Fixed Type 4812.2 43/1 43 BA-T8-8106B GE K36J Controller, Main Cylinder Segments 4893 50/2 44 BA-T8-8145A GE B23E Controller, Main Cylinder Segments 4816 65/2 45 BA-T9-8394B Door Lock for Motorman’ Cabin Maximum Traction Trucks. 4810 73/3 46 BA-T13-8757 Ballarat Electric Tramways Signalling System, Arrangements & Details of Box.On front cover of folder, "1 - 46"trams, tramways, drawings, ballarat, sec, depot, workshops -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook - Instruction, Westinghouse Traction Brake Co, "Westinghouse - T5001-1 Straight-Air Brake Equipment", March 1923

Has a table of contents, outlines the rules of operating brake equipment fitted to tramcars, the SM3, SX2 brake valve, locomotive straight air, installation piping, wiring, maintenance - piston travel, lubrication, car tests, hints to Motormen and Conductors and General Hints. Schedule for SM-1 and featherweight equipment. Includes instructions on compressors, air intakes, valves, cylinders and governors.Provides instructions about Westinghouse air brake equipment used on tramcars around the world.Instruction - 48 pages + light brown card cover centre stapled with cloth binding on outer edge + 13 fold out drawings inside the rear cover, titled "Westinghouse - T5001-1 Straight-Air Brake Equipment". Dated March 1923. On first page a signature in ink - "W. Armstrong"?brakes, electrical engineering, •electrical equipment, •westinghouse, •air compressors, •instructions, •maintenance -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, 1877

Restored by Maldon Flywheelers Association. Originally owned and used by Zemster Brothers of "Brook Mount" Shellbourne.Known as "Aunty Jack"Large 4 wheeled 9 HP single cylinder (horizontal) steam engine, designed to be towed. Front wheels smaller than rear. Folding smoke stack with spark arrestor. Fire box and smoke stack painted black, boiler and steam cylinder green, wheels grey. In working order but engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Timber front turntable and back brake pad assembly. Brass water drain tap on firebox. Also other brass fittings on firebox.On brass ring near top of firebox:- "Serial No. 5672, Marshal Sons & Co. / Limited / Engineers / Gainsborough England". Metal plate on front turntable:- "Restoration of the Front Undercarriage / and retubing of the boiler by / Castlemaine Technical School / 1979". Cast in relief on wheel hubs:- "Marshal Sons & Co. Gainsborough".machinery - engines - steam -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - L-30 Chain saw, Lombard, 1962 - 1964

This chainsaw was one of the earliest models sold in Australia. It was manufactured by the Lombard company which was established in 1894 when Nathaniel Lombard developed the first practical water wheel governor in Roxbury, Massachusetts, USA. In 1904, the company moved to Ashland, Massachusetts. During the first World War, Lombard Governor produced hydraulic lathes for the manufacture of artillery shells At the conclusion of the war, Lombard expanded into the areas of chain saws and plastic molding injection machines. This model, the L-30 was only produced for 2 years from 1962 - 1964, primarily due to safety concerns and the fact that it did not have any way to sharpen or tighten the chain. This chainsaw was sold by Mann of Wodonga and donated to the Wodonga and District Historical society by David Mann, owner and manager of Mann Wodonga.This item is significant as it was produced for a limited time. It was also sold by a prominent Wodonga business.A single operator chain saw from Lombard, Ashland, Massachusetts, USA. The chainsaw was relatively lightweight but had no safety features such as a chain brake. It was made primarily of sand cast magnesium. The main cylinder was constructed of aluminium with a cast iron sleeve. It had a manual oil pump, the crankshaft operated on ball bearings and it had a maximum rpm of 4,500. See the Model profile in the accompanying Media item for details.On side of fuel tank: "ONE HALF PINT/SAE-30 OIL/ FOR EACH/ GALLON GASOLINE/ MIX WELL IN SEPARATE CONTAINER/BEFORE FILLING" On opposite side: "STARTING INSTRUCTIONS 1: FILL FUEL TANK WITH PROPER FUEL MIXTURE ( AS NOTED ON TANK) 2. FILL OIL RESERVOIR WITH #30 MOTOR OIL 3. CLOSE CHOKE, MOVE LEVER BACK TOWARDS AIR FILTER 4. HOLD THROTTLE WIDE OPEN 5. PULL STARTER HANDLE SLOWLY UNTIL STARTER ENGAGES, THEN GIVE IT A SHARP YANK 6. AS ENGINE WARMS UP, EASE CHOKE LEVER TO OPEN POSITION"hand tools, vintage chainsaws, david mann, mann wodonga -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - Holden FE special sedan, July 1956

BY THE time the FJ Holden was replaced with the FE in July 1956, Australia’s own had taken many steps forward. The six-volt electrics were replaced with a 12-volt set-up, the two-piece windscreen was replaced with a single curved item and the skinny 15in rims were replaced with 13x4.5 steelies. Unlike the FX-FJ, the FE was designed locally by an Australian team. The resulting car was much sleeker than the earlier models, being two inches longer in the wheelbase, four inches longer overall and slightly heavier than its predecessor. To compensate, the 132ci grey motor was blessed with another small dose of horsepower thanks to larger valves and improved cylinder heads. Other mechanical improvements included pendulum-style brake and clutch pedals, hydraulic clutch actuation, larger brake drums and recirculating ball (rather than worm and sector) steering. Other great leaps forward included optional heater, indicators, reversing lights, windscreen washers and demister. In knocked down form was the first model to be exported to New ZealandBlack painted special sedan. Added accessories include exterior sun visor, headlight protectors, and on the interior grab handle mounted across the back of the front seatDiecast special sedan badge on rear quarters. Number plate club permit 63450 Hfe special, holden, sedan, car -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - Holden FC Sedan, 1956

Although the FC series was substantially the same as the FE, it featured revisions to the radiator grille, body trim and interior. Minor mechanical improvements were also made, with changes to the engine, suspension, brakes, gearchange linkages and the steering box The Utility now featured painted rather than chromed grille and headlight rims, as did the Panel Van. All FC models were powered by a 132-cubic-inch (2.2 L) six-cylinder engine producing 72 bhp (54 kW). This engine was carried over from the FE series, although the camshaft was altered, the compression ratio was increased and torque was improved.[ the FC was replaced by the Holden FB series in January 1960 The FC was the first Holden to be regularly available in Indonesia.two tone green body 4 door sedan. Single piece windscreenHolden Registration number 63451-Hautomobile, holden, vintage july 1956, car -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - VN Commodore, 1988

The VN Commodore was available in Executive, S, SS, Berlina and Calais specification levels, although a more basic SL model (opt. code A9K) was supposedly offered to government and fleet buyers, as it was not officially listed as part of the Commodore range. Changes in the relative values of the Australian dollar, the Japanese yen, and the US dollar made it impractical to continue with the well-regarded Nissan engine of the VL. Instead, Holden manufactured their own 90-degree V6 based on an old Buick design from the US, although initially it was imported. The 5.0-litre V8 remained optional and received a power boost to 165 kW (221 hp). Both these engines used multi point GM EFI and the V6 using 3 coil-packs for ignition. Holden and HSV developed this car as the basis for racing in Group A Confederation of Australian Motor Sport events. While the minimum number of cars built to qualify in Australian Touring car Championships, with modified body kit, brakes or engine is 500, only 302 VN were built but CAMS granted an exemption allowing them to compete.Holden and HSV had worked hard to develop this car to be a serious competitor to the Skyline, Ford Sierra and the BMW which had dominated in the previous years. This was to be the Holden’s answer and coincided with the return of Peter Brock back to the Holden team from 1987.Mechanically the cars were fitted with reworked version of Holden’s 4.9 litre V8. The engine block was cast for additional strength, modified cylinder heads roller rockers and high fuel flow fuel injection was applied. Output was 215 kw at 5200revs and, though at today’s standard, that is not that much it was very impressive at that time. The drive was through a six speed ZF gearbox with a heavy duty racing clutch and a limited slip differential.Under the Hawke government's Button car plan, which saw a reduction in the number of models manufactured locally, and the introduction of model sharing, the VN Commodore was rebadged as the Toyota Lexcen, named after the late America's Cup yacht designer, Ben Lexcen. Subsequently, the Toyota Corolla and Camry were, similarly, badged as the Holden Nova and Holden Apollo.Red executive 4 door sedanHolden Lion and stone emblem grille centre, Commodore boot LHS, Lion and stone emblem boot RHS.vehicle, vn commodore, holden, car -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - HD Holden sedan, 1965

The HD range replaced the Holden EH series which had been in production since 1963. The HD had a completely new body, which was wider and longer than that of the EH and offered significant increases in passenger space, load space and equipment level. Body styling exhibited strong similarities to Vauxhall's FC Victor of the previous year, including that car's unusual concave rear window. Disc brakes were offered for the first time on a Holden mode and the optional Hydramatic three–speed automatic transmission as used in the EH was replaced by a Powerglide two– speed unit. Three versions of the inline six cylinder Holden Red motor were available. The 100 bhp 149 cu in (2.4 L) six was standard in all models except the Premiers and a 115 bhp 179 cu in (2.9 L) six was standard on Premiers and optional on all other models.[Blue body with white roof , 4 door HD sedan. 63457-H179 Badge on boot Holden across boot lidvehicle, holden, 1965, car -

Melbourne Tram Museum

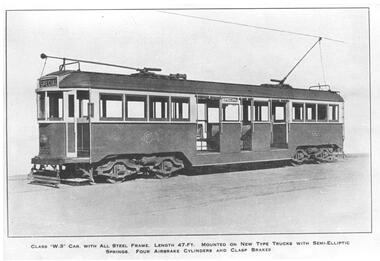

Melbourne Tram MuseumPhotograph - Black & White Photograph/s, c1931

... -elliptical springs. Four airbrake cylinders and clasp brakes... airbrake cylinders and clasp brakes" Destination displayed ...Black and white photograph from an illustration of class W3 tram No 655. The photo is titled: "Class 'W-3' Car, with all steel frame. Length 47 ft. Mounted on new type trucks with semi-elliptical springs. Four airbrake cylinders and clasp brakes" Destination displayed as "Special".trams, tramways, w3 class, new trams, tram 655 -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Instruction, Westinghouse Traction Brake Co, "Westinghouse - T5001-1 SM3 Straight-Air Brake Equipment", Mar. 1927

Instruction - 64 pages + light brown card cover centre stapled with cloth binding on outer edge + fold out drawing inside the rear cover, titled "Westinghouse - T5001-1 SM3 Straight-Air Brake Equipment". Dated March 1927. Has a table of contents, outlines the rules of operating brake equipment fitted to tramcars, the SM3 and PV brake valves, SX2 brake valve, locomotive straight air, installation piping, wiring, maintenance - piston travel, lubrication, car tests, hints to Motormen and Conductors and General Hints. Includes instructions on compressors, air intakes, valves, cylinders and governors.On inside cover "Bob Prentice 13 High Street Prahran Vic 3181" and on top of first page "W. Armstrong"trams, tramways, electrical engineering, electrical equipment, westinghouse, air compressors, brakes, instructions, maintenance -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Instruction, Westinghouse Traction Brake Co, "Westinghouse - T5001-Straight-Air Brake Equipment", Mar. 1923

Instruction - 48 pages + light brown card cover centre stapled with cloth binding on outer edge + 13 fold out drawings inside the rear cover, titled "Westinghouse - T5001-1 Straight-Air Brake Equipment". Dated March 1923. Has a table of contents, outlines the rules of operating brake equipment fitted to tramcars, the SM3, SX2 brake valve, locomotive straight air, installation piping, wiring, maintenance - piston travel, lubrication, car tests, hints to Motormen and Conductors and General Hints. Schedule for SM-1 and featherweight equipment. Includes instructions on compressors, air intakes, valves, cylinders and governors.On front cover in ink "Mr McLaren"trams, tramways, electrical engineering, electrical equipment, westinghouse, air compressors, brakes, instructions, maintenance