Showing 17 items matching " hydraulic machines"

-

Glen Eira Historical Society

Glen Eira Historical SocietyDocument - Crotonhurst

... Hydraulic machines... Land Boom and Bust Hydraulic machines Geo. Fincham and Sons ...Five pages of brief notes compiled by the Caulfield Historical Society about Crotonhurst. Provides details on the occupants of the house and the assessments of the house in different years.crotonhurst, langdon william farrar, langdon sophie sarah annie, langdon dottie, webb frank henry, webb george rupert, langdon william webb, langdon violet webb, langdon isobel, warburton-egerton frank, warburton-edgerton frank, crotonhurst avenue, anderson i v, hawthorn road, webb g h f, langdon w f, langdon sophie, mclaughlin j, land boom and bust, hydraulic machines, geo. fincham and sons, webb george henry frederick, supreme court judge, seelenmeyer adolphe dr, brammerton, bramerton, kamesburgh, mansions -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1920

... This photo shows the large mining cavity with a hydraulic...-country This photo shows the large mining cavity with a hydraulic ...This photo shows the large mining cavity with a hydraulic sluicing machine in operation at Baarmutha Three Mile Mine, Beechworth . The Beechworth Mining District was one of six mining districts established by the Governor-in-Council on 4 January 1858 under the provisions of An Act for Amending the Laws Relating to the Goldfields (21 Vic no.32). The District was further divided into seven divisions: Spring Creek, Snake Valley, Three Mile Creek, Buckland, Woolshed, Yackandandah and Omeo. The boundaries of each of these divisions and of the whole district are described in the Governor-in-Council's proclamation printed in the Government Gazette, 5 January 1858, pages 3-5. Hydraulic mining is a form of mining that uses high-pressure jets of water to dislodge rock material or move sediment. In the placer mining of gold or tin, the resulting water-sediment slurry is directed through sluice boxes to remove the gold. It is also used in mining kaolin and coal.This photograph shows the impact the gold rush era had on Australia and the earth.A black and white rectangular photograph printed on photographic paperCopied from original on loan film (WEBB QLD) / Donated 2009 NOV/ Baarmutha Three Mile Mine c1920-1950/ Managed by John Weir Peter Jereen Jack Cox / Owned by Plain Bros then Parkinsons Sluicing.mining, gold fields, beechworth, gold rush, burke museum, photograph, mining cavity, hydraulic mining, hydraulic sluicing, baarmutha -

The Beechworth Burke Museum

The Beechworth Burke MuseumFunctional object - Sluicing Nozzle, c1900

Nozzle was fitted in the end of the director and was used for hydraulic gold miningMining played an important role in the history of Beechworth, for the township was established in the mid-1850s after gold was discovered in the area. The success of goldmining lead to the growth and development of early Beechworth.A sluicing nozzle attachment which is 3 inch diameter inside top. Base area has thread machined inside for attachment to sluice. Casting venturi shaped internally.3 /burke museum, beechworth, gold mining, sluicing -

Kiewa Valley Historical Society

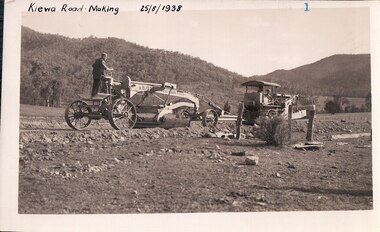

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making, 25/08/1938

Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment . A black and white photograph showing the type of machinery used for road making in the 1930's. It shows a grader being towed by a caterpillar tractor.On the top left hand corner of the photograph , hand written in black ink is the words 'Kiewa Road Making 25/8/1938'. On the right hand side of the photo has been stamped in blue the Number 1. It has been developed on Velox paper (marked on back of photo) with a gloss finish.road making, state electricity commission, caterpillar tractor, kiewa -

Kiewa Valley Historical Society

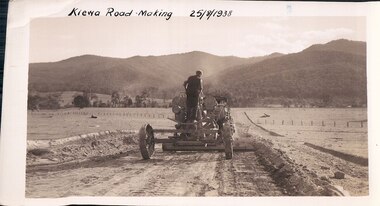

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/08/1938 No. 2, 25/08/1938

Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trailbuilders (angle dozers). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer ( Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route let immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939, the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km.) had been surfaced. (see KVHS 0328)The purchase of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commissions engineers in purchasing such innovative equipment.A black and white photograph of road making near Mt. Beauty in 1938. Mount Beauty hills can be seen in the background with cleared land for grazing in the fore ground.Hand printed in black ink at the top of the photograph is 'Kiewa Road Making 25/8/1938'. On the right hand corner has been printed the number 2. It has been printed on gloss Velox paper.road making, state electricity commission, caterpillar tractor, kiewa, secv -

Kiewa Valley Historical Society

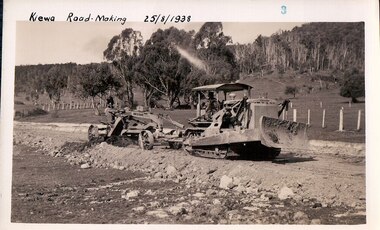

Kiewa Valley Historical SocietyBlack and White photograph of Road Making Machinery, Kiewa Road Making 25/8/1938(No. 3 in a series of 8), 25/08/1938

Construction of the main road from South Tawonga to the Bogong High Plains, to provide access to the construction sites for the new Kiewa Hydro Electric Scheme, was commenced early in 1938, the work being undertaken on behalf of the Commission by the Country Roads Board. For the construction work, the Commission purchased three Caterpillar - model R07 - diesel crawler tractors equipped with Kay Brunerei (Brunner) hydraulically operated trail builders (angle dozers)). This acquisition resulted from a visit to the United States of America in May, 1937 by the Construction Engineer ( Mr. C.H. Kernot) and Assistant Civil Engineer (Mr. J.F. Douglas) where they saw this relatively new type of equipment in use. With the co-operation of the CRB, the Commission demonstrated the operation of these machines at Fishermen's Bend on 6th April, 1938. They were then sent to Kiewa where they commenced operation towards the end of the month. From South Tawonga, the route led immediately across the Western Branch of the Kiewa River necessitating the construction of a bridge 100 feet long. By the end of 1939,the excavation had been 'opened up' for a distance of 19 1/2 miles (approx. 31 km.) and of this length, 10 miles (approx. 16 km) had been surfaced.The purchase and use of this type of mechanical equipment in road making was a huge investment, as prior to this most of the work would have been done manually with the use of picks and shovels. Not only were many months of hard manual labour saved, but a very significant amount of time in providing access to the proposed work sites for the new Kiewa Hydro Scheme. This photo is an excellent reminder of how primitive the early machinery was compared to the present but also represents the forward thinking of the State Electricity Commission's Engineers in purchasing such new and innovative equipment.A black and white photograph of a Caterpillar diesel crawler tractor and a hydraulically operated trailbuilder (angle dozer) making a road in the Mt. Beauty area.Hand written in black ink in the top left hand corner are the words "Kiewa Road Making 25/8/1938". On the upper right hand of the photograph has been stamped the number 3. On the back is stamped the word 'Velox' severaly times, which is the make of the photograhic paper. roadmaking, caterpillar tractor, kiewa, state electricity commission -

Federation University Historical Collection

Federation University Historical CollectionMinutes, Victoria Institute of Colleges Minutes (selected), 1967-1969

... testing machine and an Hydraulic Flow Channel for Yallourn... testing machine and an Hydraulic Flow Channel for Yallourn ...In 1966 E.J.T. Tippett, President of the Ballarat School of Mines Council was on the interim council and committee member of the Victorian Institute of Colleges.Foolscap typed Victorian Institute of Colleges (VIC) minutes .1) Minutes of the inaugural meeting of the Victorian Institute of College held at the State Electricity Commission of Victoria, 15-23 William Street, Melbourne on 26 June 1967. This meeting followed 25 meetings of the Interim Council. The Council included E.J. Barker of the Ballarat School of Mines, representing principals of affiliated colleges outside the metropolitan area. .2) Building Committee minutes of the Victoria Institute of Colleges, 11 April 1969. These minutes mention Ballarat Institute of Advanced Education including the request for approval to purchase recording double beam spectrophotometer, Logic panel for Hitachi 505 analog computer and Nuclear-magneto-resonance gaussmeter system). The also requested approval to appoint L.H. Vernon and Associates and G.J. Harrison as joint campus planners, and outlined how water would be supplied to the Mount Helen site. The minutes outline a request for State.Commonwealth approval to purchase a concrete testing machine and an Hydraulic Flow Channel for Yallourn Technical College. The request was moved by E.J. Barker of the Ballarat School of Mines. .3) 'Colleges of Advanced Education - The Vision and the Reality' an address delivered at the Diploma Conferring Ceremony, Yallourn Technical College by R.E. Parry, registrar of the Victoria Institute of Colleges on Friday 18 April 1960. .4) Minutes of the Victoria Institute of Colleges Buildings Committee minutes, 8 November 1968. These minutes include information on the transfer of Yallourn Technical College to the new site at Churchill. .5) Minutes of the Victoria Institute of Colleges Council , 17 September 1969.victoria institute of colleges, victoria institute of colleges at ballarat, vic, vicb, jack barker, barker, e.j. tippett, tippett, victoria institute of colleges council, ll.h. vernon and associates, vernon, harrison, g.j. harrison, mount helen campus, campus development, master plan, campus master plan, water supply, mt helen campus water supply, ballarat school of mines, yallourn technical school, churchill campus, churchill, colleges of advanced education, ballarat college of advanced education, gippsland college of advanced education, parry, r.e. parry -

Federation University Historical Collection

Federation University Historical CollectionBook, New York Post, The School of Mine Quarterly: A Journal of Applied Science, 1889-1809

The School of Mines Quarterly was a jpournal of Applied Science from Columbia College, New York City.The Index to the School of Mines Quarterlu Volumes X1-XX (1900) and 32 green covered journals school of mines, new york, columbia college, schools of mines, columbia school of mines, witwatersrand goldfield, inter-continental railway, mine ropes, harbor improvememnts on the pacific coast, glycerine and artificial butter industry, transit factors for teh columbia college observatory, tables for the reducation of transit observations, ancienct methods for dividing and recoording time in japan, assay of tin, john strong newberry, standards of linnear measure, comparison of costs of electric lighting, huanchaca mine bolivia, el callao gold mine venezuela, john magnus adams, ores in saxony, hartz and rhenish prussia, hofmann apparatus, adjustment of trangulation, determination of carbonic acid in white lead, lower coals in western clearfield county pennsylvania, old telegraph mine ningham canon utah, mechanical preparation of ores, modern waterworks construction, curdling of milk, french regenerative gas furnace, irrication canals, peruvian salt mine, collection of metallurgic dust and fume, permeability of iron and steel, assay of silver, explosion in a zinc fume condenser, teaching archtectural history, liquid air, between the mine and the smelter, ballistic galvonometer, assay of telluride ores, analytical chemistry, theory and design of the masonry arch, silver pick mine wilson colorado, telegraphy and telephoney, mineralogy, morse code, michigan mining practices, titaniferous magnetites, paradox of the pantheon, rocks from wyoming, witwatersrand goldfields, gaseous sun, alternating current distribution, engineering tests on direct current electrical machinery, thomas egleston, ore dressing, frederick morgan watson, camp bird gold mine and mills, magnetic properties of iron and steel, morphology of organic compounds, antimony, structure of the starch molecule, cerrillos hills new mexico, geology, rossie lead veins, practical electrochemistry, lines of graphic statics, anistic acid by the ozidation of anniseed oil, bromate method for antimony, john krom rees, trust company of america building, helion lamp, frederick arthur goetze, mine surveying, pine wood oils, malleable cast iron, electrolytic treatment of galena, turpentine and pine oils, bluestone, ashokan dam bluestone, road resistances, oxy-gas blowtorch, mine dumps, segregation of steel ingots, masonry dam formulas, putnam county magnetic belts, gases, continuity of education, hydraulic diagrams, standardistion of potassium permanganate, sewerage discharge into sea water, modern waterworks, true column formula, slags from lead furnaces, missouri river, tempreture of gases, rocks, architectural history, modern dome, oil machine, undulations in railway tracks, irrigation engineering, cleps-tachymeters, electrical engineering, new york shales, fan pump, sucrose, isaac newton, french school of anstronomers, electrolytic polarization, benjamin bowden lawrence, diamond drilling, new york ciy water front, engineering profession ethics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Tilting Saw Bench, W F & John Barnes, 1874 to 1880

... the only ones to also make professional-grade workshop machines... to also make professional-grade workshop machines. From ...he subject item is a pedal-powered rip saw with a tilting table made in the USA by W.F. & John Barnes Co. of Rockford, Illinois, between 1874 and 1890. The saw's blade moves rapidly in a circular motion and is driven by a pedal that spins a heavy flywheel with a leather belt attached to a gear drive that in turn drives the circular saw blade. The operator holds a wood workpiece on the table and moves it forward so the blade cuts it to the desired width and length. Company History: WF & John Barnes Co. was established in 1869, by making a formal partnership between William F. Barnes and John Barnes in 1872, and then incorporating in 1884. This company was an early manufacturer of pedal-powered equipment. By 1881 they were also making powered machinery such as lathes and pedestal drills. Many companies were making lightweight foot-powered equipment, but Barnes and the Seneca Falls Co. were the only ones to also make professional-grade workshop machines. From the beginning of their existence, they focused on pedal-powered machinery and specialised in making scroll saws. By 1937 the company focus had completely shifted to automotive assembly machinery, and custom-built machinery, machine tools, electrical, hydraulic, and mechanical controls and systems, including nuclear hardware. their production of foot-powered machinery had ceased. In the intervening years, they have got out of manufacturing completely. After a series of ownership changes, their equipment parts and stock were purchased in 1998 by LeBlond Ltd. of Amelia, Ohio. An item that although incomplete gives a snapshot into the manufacture and use of early woodworking machinery before the introduction of electricity or electric motors to power machines.A Treadle powered tilting table saw benchWF & J Barnes, Rockford Ill USA flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Puffing Billy Railway

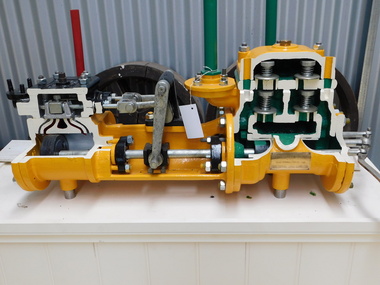

Puffing Billy RailwaySectioned Tangye Steam Operated Water Pump, 1900s

Sectioned steam pump so that the pump workings can be seen. Inscriptions & Markings: Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque) The Colonial Gas Association was originally formed in London on 2 February 1888, as The Australasian Gas Association Limited. The primary objective of the company was to provide investment capital to help finance the construction and management of gasworks being established by the London engineering firm John Coates & Co in metropolitan cities and regional towns throughout Australia and New Zealand. By 1890, the Australasian Gas Association had acquired gasworks at Benalla, Shepparton, Wangaratta, Warragul, Maldon and Seymour, and had constructed a large gasworks at Box Hill to supply the eastern suburbs of Melbourne. In 1893, the company's name was changed to the Colonial Gas Association Limited. During the 1890s, the company acquired regional gasworks in Queensland, Western Australia and South Australia, followed by its first gasworks in New South Wales, in 1911. In 1914, the company consolidated its metropolitan supply area by purchasing the Oakleigh and Footscray gasworks. Further expansion occurred in the 1920s with the purchase of established gasworks at Williamstown, Frankston and Dandenong and the acquisition of ten further gas undertakings in Queensland and New South Wales, making the firm the fifth largest gas producer in Australia. info from The Colonial Gas Association Limited, circa 1893 https://collections.museumvictoria.com.au/items/1553322 Originally formed by the five Tangye brothers from Cornwall as James Tangye & Brothers in 1857, this Birmingham engineering firm grew to become one of the largest suppliers of jacks, pumps, steam and oil engines, hydraulic presses, gas producers and machine tools in the late 19th and early 20th centuries. The successful sideways launching of I.K. Brunel's 'Great Eastern' from the mud of the Thames in 1857 using Tangyes hydraulic jacks gave the firm much needed publicity and new orders flowed in. To finance expansion, George Price provided additional capital and the company name became Tangye Brothers & Price in 1859. A new factory known as the 'Cornwall Works' was built in Clement Street, Birmingham. In 1872, the firm became Tangye Brothers and in about 1879- 1880 began production of internal combustion stationary engines based on Horace Robinson's patents, later using the Otto four-stroke design for its Soho range of gas engines. Examples of the Soho engine were exhibited by the firm at the 1880 Melbourne International Exhibition. Petrol and oil engines were made from the 1890s onward, and by 1910 had developed into the Model B, BR and AA series engines. Tangyes supplied custom-built pumps and presses for particular applications, becoming a major exporter of engineering equipment. In 1884, Tangye Brothers opened a custom-built branch office, showroom and warehouse in Melbourne at Cornwall House in Collins Street West, advertising the full range of engineering products. These lantern slides images are taken from Tangyes product catalogues from the 1910-1925 period and are believed to have been used as sales promotional aids in Australia by the Tangye Brothers. info from https://collections.museumvictoria.com.au/articles/4670 Historic - Industrial Steam Operated Water Pump built by Tangye Bros and used by the Colonial Gas Company - Melbourne, Victoria, AustraliaSectioned steam pump so that the pump workings can be seen. Tangye Birmingham, This steam pump was presented by the colonial gas Assn Ltd (brass plaque)puffing billy, steam pump, sectioned, tangye bros -

National Wool Museum

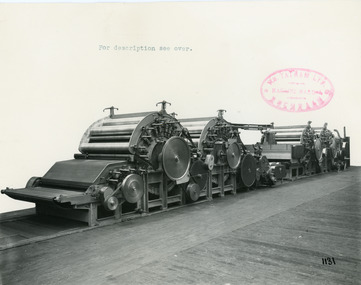

National Wool MuseumPhotograph - Product Photograph, Semi-Continental Card Set

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. A carding machine disentangles and cleans wool fibres and then aligns the individual fibres so that they are parallel with each other.The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866 Tatham developed innovative textile machinery and send their products to Australia and other countries around the world.Two black and white photos of an Semi-Continental Card Set in a landscape format. The first photo is of the whole machine, the second is a close up of the mid section of the machine.8038.1 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1131 Rear - Semi-Continental Card Set arranged to receive latest pattern Automatic Feed fitted with Peralta, improved type Parallel Fiber Feed permitting of passageway between Scribbler and Carder. Four-tier Continuous Tape Condenser. 8038.2 - Front - top margin: For description see over. Front mid right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1132 Rear - Showing Peralta with hydraulic pressure to rollers and working with improved pattern Parallel Fibre Feed arranged with passage between the two main sections.textile machinery, tatham, carding machine, wool manufacture -

Parks Victoria - Wilsons Promontory Lightstation

Parks Victoria - Wilsons Promontory LightstationPart, machine

The rusted metal machine part has an inscription discernible on an attached plate. It is part of the hydraulic system used in the East landing crane between 1971 and 1978.Meets second level threshold.Rusted metal machine part with plate with inscription. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - L-30 Chain saw, Lombard, 1962 - 1964

This chainsaw was one of the earliest models sold in Australia. It was manufactured by the Lombard company which was established in 1894 when Nathaniel Lombard developed the first practical water wheel governor in Roxbury, Massachusetts, USA. In 1904, the company moved to Ashland, Massachusetts. During the first World War, Lombard Governor produced hydraulic lathes for the manufacture of artillery shells At the conclusion of the war, Lombard expanded into the areas of chain saws and plastic molding injection machines. This model, the L-30 was only produced for 2 years from 1962 - 1964, primarily due to safety concerns and the fact that it did not have any way to sharpen or tighten the chain. This chainsaw was sold by Mann of Wodonga and donated to the Wodonga and District Historical society by David Mann, owner and manager of Mann Wodonga.This item is significant as it was produced for a limited time. It was also sold by a prominent Wodonga business.A single operator chain saw from Lombard, Ashland, Massachusetts, USA. The chainsaw was relatively lightweight but had no safety features such as a chain brake. It was made primarily of sand cast magnesium. The main cylinder was constructed of aluminium with a cast iron sleeve. It had a manual oil pump, the crankshaft operated on ball bearings and it had a maximum rpm of 4,500. See the Model profile in the accompanying Media item for details.On side of fuel tank: "ONE HALF PINT/SAE-30 OIL/ FOR EACH/ GALLON GASOLINE/ MIX WELL IN SEPARATE CONTAINER/BEFORE FILLING" On opposite side: "STARTING INSTRUCTIONS 1: FILL FUEL TANK WITH PROPER FUEL MIXTURE ( AS NOTED ON TANK) 2. FILL OIL RESERVOIR WITH #30 MOTOR OIL 3. CLOSE CHOKE, MOVE LEVER BACK TOWARDS AIR FILTER 4. HOLD THROTTLE WIDE OPEN 5. PULL STARTER HANDLE SLOWLY UNTIL STARTER ENGAGES, THEN GIVE IT A SHARP YANK 6. AS ENGINE WARMS UP, EASE CHOKE LEVER TO OPEN POSITION"hand tools, vintage chainsaws, david mann, mann wodonga -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Phillip's Water Wheel, Diamond Hill, Bendigo, 1876

'Messrs. George Phillips and Richard Williams erected a water wheel crushing machine near the site of the Old Albert shaft at Diamond Hill'. ( Bendigo Advertiser 4th June, 1890). The lack of water available for the venture from the water race caused much controversy in the following years. There was only enough water available in July 1890, to allow the company to operate three head of a ten head stamper. The site of the water wheel is still visible on the side of the water race at Diamond Hill. Mr. Geo Phillips held 1000 shares in the float of the Kangaroo Hydraulic Crushing & Gold Mining Company. He was one of the largest shareholders. (Victorian Government Gazette 72 Page 2260, 1893) Black and white photocopy. Image shows the Phillip's Water Wheel on Diamond Hill, Bendigo. Weatherboard building on right hand side of image, brick chimney on side of building. Large water wheel in cutting directly alongside building. Two men standing in between water wheel and building, one man standing on landing of waterwheel.mining, sandhurst, phillip's hydraulic waterwheel, stafford gold mine, diamond hill, george phillips, richard williams -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Phillip's Water Wheel, Diamond Hill, Bendigo, 1876

'Messrs. George Phillips and Richard Williams erected a water wheel crushing machine near the site of the Old Albert shaft at Diamond Hill'. ( Bendigo Advertiser 4th June, 1890). The lack of water available for the venture from the water race caused much controversy in the following years. There was only enough water available in July 1890, to allow the company to operate three head of a ten head stamper. The site of the water wheel is still visible on the side of the water race at Diamond Hill. Mr. Geo Phillips held 1000 shares in the float of the Kangaroo Hydraulic Crushing & Gold Mining Company. He was one of the largest shareholders. (Victorian Government Gazette 72 Page 2260, 1893) Black and white photocopy. Image shows the Phillip's Water Wheel on Diamond Hill, Bendigo, date unknown but must be in 1890's. Three men and a dog standing in front of a weatherboard shed, brick chimney on side. Large water wheel on left hand side of image. Three images, 2008, showing former site of water wheel on channel, after heavy rain in district caused dry channel to run. mining, sandhurst, phillip's hydraulic waterwheel, stafford gold mine, diamond hill, george phillips, richard williams -

Bendigo Historical Society Inc.

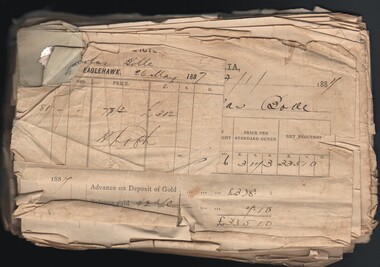

Bendigo Historical Society Inc.Document - GOLD SALE NOTES FOR NICHOLAS BOLLE, 1868 - 1887

Nicholas John Bolle was born in Dorstadt, Germany in 1836 to parents Heinrich (Johannes Heinrich Wilhelm) and Friederike Hartmann (Anne Marie Friedericke). Around the age of 20 he immigrated to Australia and made his way, most likely on foot, 150km in a northerly direction to the Bendigo goldfields. In March 1863 Nicholas registered his first mining claim, naming it Bolle’s Reef. Having worked this reef until it no longer paid, he went on a prospecting tour of the area and found another gold reef towards Elysian Flat, staked a claim and registered it under the name of his beloved wife ‘Rosanna’. Sadly, as was often the case, the cost of hiring men to get the gold out of the ground, and removing it from the clay and quartz, outweighed the amount of profit he was making from his discoveries. In November 1863 while living and working at Old Tom Gully, Nicholas appeared in the Government Gazette as insolvent. Nicholas continued to struggle on, scoping out the surrounding area in the Whipstick Forest, and having some little success and by 1869 he was given a government reward of 25 pounds for discovering a new area of gold in the Whipstick. The Government Gazette records this reward – 'for the discovery of the Whipstick, 25 pounds' (Government Gazette 1869) By 1872 Nicholas had established a quartz crushing plant at his mine in Old Tom Gully, (the Old Tom mine) a remote place in the middle of the Whipstick. Mining was a dangerous business, and in 1875 Nicholas was called as a witness in a coroner’s inquest into the death of a John Bashton who was accidentally killed in a mining accident at nearby Easter Claim in December. In 1881, he was again called to give evidence when one of his employees Mr Thomas Garrett was killed while working at his claim at Old Tom Reef. So we are fortunate to have Nicholas describing his day’s work in his own words. Reference: Michelle Dennis Family History http://www.michelledennis.com.au/?page_id=1067) The Old Tom Mine site is situated between Old Tom Road, Scotsman Road, Eaglehawk-Neilborough Road and an unnamed road, Whipstick VIC 3556. The Marong Heritage Study, Mining Sites ( City of Greater Bendigo) describes the former mine site as follows: '40 metre-long mullock heap with one dumping line running north from a filled shaft. The heap has been partially quarried. 20 metres south is a scatter of red hand-made bricks and rough concrete rubble. Further south there are smaller mullock dumps and a line of shallow reef workings Surface workings 30 metres west of the mullock dump, running north, is a line of small mullock paddocks, terminating in a shallow open cut. On the same line to the south, in an area north and west of the most southerly section of reef workings there is an area of hydraulic sluicing. West of the cyanide works and along Scotchman Gully there are patches of shallow alluvial workings. Battery site On the eastern side of the open-cut is a small mullock paddock, below which is a spread of hand-made red bricks and fire bricks. Near this rubble is a dry dam, with traces of battery sand nearby. Puddling machine site 10 metres north of the water race is the outline of a 20 foot diameter puddling machine. The central mound retains its wooden post and fragments of timber side-boarding are still present in the puddling trench. Water was fed to the puddling machine from the race by a pipe, now largely buried. The dumps are weathered and partially quarried, but the puddling machine is in good con 40 metre-long mullock heap with one dumping line running north from a filled shaft. The heap has been partially quarried. 20 metres south is a scatter of red hand-made bricks and rough concrete rubble. Further south there are smaller mullock dumps and a line of shallow reef workings Surface workings 30 metres west of the mullock dump, running north, is a line of small mullock paddocks, terminating in a shallow open cut. On the same line to the south, in an area north and west of the most southerly section of reef workings there is an area of hydraulic sluicing. West of the cyanide works and along Scotchman Gully there are patches of shallow alluvial workings'. Reference: https://www.goldfieldsguide.com.au/explore-location/553/old-tom-mine/ Document. Gold Sale notes for Nicholas Bolle. Papers pinned together covering the years 1868 - 1887 being statement of gold melted and assayed for Nicholas Bolle from the Eaglehawk branch of the Bank of Victoria. A few of the papers are from the Bank of New South Wales - Eaglehawk Branch, Bank of Australasia, Bank of Australasia Gold Office. The earliest statement dated 3 Jul 1868 is for Messrs Harrison & Bashton. Other early ones are for Derbyshire Reef. The Bank of Victoria cards mention R. H. Andrews, Agent on the back. The Bank of Australasia Gold Office statement contains an ink picture of the building on the back.gold sale notes for nicholas bolle, bank of victoria - eaglehawk branch, bank of new south wales, bank of australasia, bank of australasia gold office, messrs harrison & bashton, derbyshire reef, r. h. andrews