Showing 24 items matching " moulding mill"

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - HARRY BIGGS COLLECTION: COPIES OF VARIOUS PHOTOS

... moulding mill... Yards, and 'a corner of the moulding mill at J.R. Hoskins... moulding mill Document: copy of photos 'J.R. Hoskins' Timber ...Document: copy of photos 'J.R. Hoskins' Timber and Iron Yards, and 'a corner of the moulding mill at J.R. Hoskins' A. Robert & Sons Engineering Works, Winch manufactured by A. Roberts & Sons.place, bendigo, historical items, bendigo, hoskins', j.r. hoskins, moulding mill -

Bendigo Historical Society Inc.

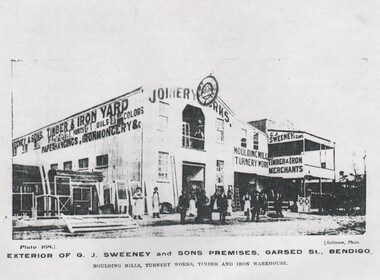

Bendigo Historical Society Inc.Photograph - DILLON-SHALLARD COLLECTION: G.J. SWEENEY AND SONS PREMISES GARSED STREET BENDIGO

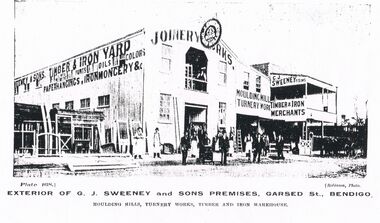

... Premises in Garsed Street, Bendigo. Moulding Mills, Turnery Works..., Bendigo. Moulding Mills, Turnery Works, Timber and Iron ...Photograph, showing the exterior of G.J. Sweeney and Sons Premises in Garsed Street, Bendigo. Moulding Mills, Turnery Works, Timber and Iron Warehouse.Several people standing outside. Photo by Robinson Plate 168.Robinsonphotograph, building, g.j. sweeney & sons -

Ringwood and District Historical Society

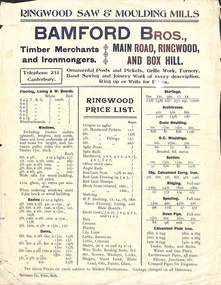

Ringwood and District Historical SocietyDocument, Bamford Bros Main Road, Ringwood and Box Hill - Price List Template plus handwritten accounts notes on reverse. Undated. Probably 1918-1930

... on Price list is "Ringwood Saw & Moulding Mills", "Bamford Bros... on Price list is "Ringwood Saw & Moulding Mills", "Bamford Bros ...Thin sheet of paper. Price List template on one side (no prices), and handwritten accounting notes on reverse. Title on Price list is "Ringwood Saw & Moulding Mills", "Bamford Bros.," Main Road Ringwood and Box Hill. Telephone 231 Canterbury. Price List used as note paper for accounts. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HARRY BIGGS COLLECTION: J R HOSKINS BENDIGO TIMBER & IRON YARDS

... of the moulding mill at J R Hoskins - it shows men working at the mill... - A corner of the moulding mill at J R Hoskins - it shows men working ...Photograph. Harry Biggs Collection. 2 small black & white photos of J R Hoskins Timber & Iron Yards. Photo 1 - A corner of the moulding mill at J R Hoskins - it shows men working at the mill - inside in a large shed. Photo 2 - The front of the business in Hargreaves & Queen Streets, Bendigo. 2 horses & carts with a load of timber on them. There are also 9 men standing at the front.organization, business, commercial, harry biggs collection, j r hoskins timber & iron yards -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CAMBRIDGE PRESS COLLECTION: ACCOUNT - G. J. SWEENEY AND SON

... Limited, Railway Steam Saw, Moulding and Planing Mills. Printed... Steam Saw, Moulding and Planing Mills. Printed letterhead has ...Note/account paper with date line ending 192-. Lined paper with greenish grey printed letterhead G. J. Sweeney & Sons Propriety Limited, Railway Steam Saw, Moulding and Planing Mills. Printed letterhead has a building with two tall chimneys and a horse and lorry at the side on the left and the name and phone number on the right side. Also Mining timber prepared. On the back is a stamped Sample with Cambridge Press and the date 26/4/24. Stamped in blue.business, printers, cambridge press, cambridge press collection, g j sweeney & sons proprietary limited, cambridge press -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Charles Nurse, 1860-1900

The original Nurse family business began in 1841 in Maidstone Kent until 1861 where they were plane makers, moving to London in 1887 the company became C Nurse & Co. And continued until 1937 under that name at the (Invicta works). The majority of their plane making was done in London but there are Sheffield and Brighton marks on their tools as well. The company was not only wood plane makers but tool makers in general with the Charles Nurse & Co catalogue having 350 pages of tools for sale of varying types for different building trades and over 138 pages dedicated to woodworking tools. Records show that the company was at 182 Walworth Road London from 1887-1949. However, they had several retail outlets before this time and records indicate before 1887 Charles Nurse was at 32 Mill St Maidstone Kent, from 1844 -1860 but were in business before then. Also in Brighton at 135 Queens Road from 1865 -1871 and at 3 Mill Street Maidstone, again from 1872 - 1889 listed on records of the time as “plane and tool makers.”A vintage item made by a significant tool maker and retailer from the middle of the nineteenth century and into the first half of the twentieth century. These items were made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before electric or mechanical routers or spindle moulders came into use. They were used by craftsmen to produce decorative mouldings by hand. These profiled planes came in various shapes and sizes. A significant tool that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Moulding plane Side Bead - Single Box Size 5/16 Maker Charles and Co 1863 Stamped W. Burden (previous owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Eltham District Historical Society Inc

Eltham District Historical Society IncFilm - Video (DVD), H.V. Plowman, Briar Hill Timber & Trading Co. Pty. Ltd, c.1956

Briar Hill Timber was associated with the Olympic Village Project being suppliers of all building materials including Flush Panel Doors, Mouldings and Joinery. Briar Hill Timber owned by F. Squire and the Squire family owned a lot of land around Briar Hill and land for forest at Flowerdale. The 16 mm film photographed by H.V. Plowman (converted to DVD) shows all aspects of the operations of Briar Hill Timber from logging of trees, to milling to manufacture of joinery and housing framesMP4 00:13:12; 247MB Converted from DVD converted from VHS video converted from 16mm colour filmbriar hill timber, f. squire, olympic village, 1956 olympic games, timber mill, flowerdale, cinematography, briar hill, h.v. plowman, logging, video recording -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . Stamped HB on one end and 8 on otherflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower with a symbol "M"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower Size 9/16"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Charles Nurse, 1860-1900

The original Nurse family business began in 1841 in Maidstone Kent until 1861 where they were plane makers, moving to London in 1887 the company became C Nurse & Co. And continued until 1937 under that name at the (Invicta works). The majority of their plane making was done in London but there are Sheffield and Brighton marks on their tools as well. The company was not only wood plane makers but tool makers in general with the Charles Nurse & Co catalogue having 350 pages of tools for sale of varying types for different building trades and over 138 pages dedicated to woodworking tools. Records show that the company was at 182 Walworth Road London from 1887-1949. However, they had several retail outlets before this time and records indicate before 1887 Charles Nurse was at 32 Mill St Maidstone Kent, from 1844 -1860 but were in business before then. Also in Brighton at 135 Queens Road from 1865 -1871 and at 3 Mill Street Maidstone, again from 1872 - 1889 listed on records of the time as “plane and tool makers.”A vintage item made by a significant tool maker and retailer from the middle of the nineteenth century and into the first half of the twentieth century. These items were made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before electric or mechanical routers or spindle moulders came into use. They were used by craftsmen to produce decorative mouldings by hand. These profiled planes came in various shapes and sizes. A significant tool that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Moulding Plane a Casing Moulding Plane with two Scotia profiles Maker C Nurse and Co London. Owner A. E. NunnMaker C Nurse & Co & A E Nunn (previous owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Charles Nurse, 1860-1900

The original Nurse family business began in 1841 in Maidstone Kent until 1861 where they were plane makers, moving to London in 1887 the company became C Nurse & Co. And continued until 1937 under that name at the (Invicta works). The majority of their plane making was done in London but there are Sheffield and Brighton marks on their tools as well. The company was not only wood plane makers but tool makers in general with the Charles Nurse & Co catalogue having 350 pages of tools for sale of varying types for different building trades and over 138 pages dedicated to woodworking tools. Records show that the company was at 182 Walworth Road London from 1887-1949. However, they had several retail outlets before this time and records indicate before 1887 Charles Nurse was at 32 Mill St Maidstone Kent, from 1844 -1860 but were in business before then. Also in Brighton at 135 Queens Road from 1865 -1871 and at 3 Mill Street Maidstone, again from 1872 - 1889 listed on records of the time as “plane and tool makers.”A vintage item made by a significant tool maker and retailer from the middle of the nineteenth century and into the first half of the twentieth century. These items were made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before electric or mechanical routers or spindle moulders came into use. They were used by craftsmen to produce decorative mouldings by hand. These profiled planes came in various shapes and sizes. A significant tool that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Cornice Moulding plane type Maker C Nurse and Co. Has A E Nunn stamped on end (Owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing wood Plane, Mid to Late 19th Century

A smoothing plane is a wood plane used for making a smooth surface to wood surfaces traditionally, these planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape or size required. The blade, or iron was likewise formed to the intended flat or level profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Large crown mouldings or smoothing plane surfaces required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by an unknown maker, that was made commercially for firms and individuals who worked in wood and needed a tool that could produce a flat or level finish to timber. These types of planes came in various shapes and sizes to achieve the required finish to timber surfaces used in cabinet making. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Smoothing Plane Coffin typeMaker J Moseley & Son London and 2¼" also has OS stamped on side (probably an owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Eltham District Historical Society Inc

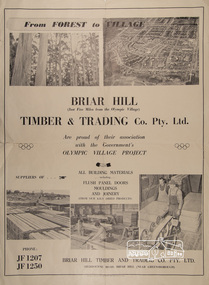

Eltham District Historical Society IncPoster, Briar Hill Timber & Trading Co. Pty. Ltd, c.1956

Advertisement insert in The Age newspaper around the opening of the 1956 Olympic Games promoting Briar Hill Timber's association with the Olympic Village Project being suppliers of all building materials including Flush Panel Doors, Mouldings and Joinery. Briar Hill Timber owned by F. Squire and the Squire family owned a lot of land around Briar Hill and land for forest at Flowerdale. Operations ranged from logging of trees, to milling to manufacture of joinery and housing frames.Poster approximately A2 in sizebriar hill timber, f. squire, olympic village, 1956 olympic games, timber mill, flowerdale, briar hill, h.v. plowman, logging, advertisement -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Plane, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will named his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard's estate when he died in 1856. From John's will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool-making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield.A vintage tool made by a well-known company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could remove large amounts of timber. These jack or dressing planes came in various shapes and sizes to achieve a flat and even finish to timber surfaces and came in many sizes. A significant tool from the mid to late 19th century that is still in use today with early models sought after by collectors. It gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting-edged hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items.Jack Plane metal body with rose wood filler.Mosley & Sons London No 2flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, john moseley & son, jack plane, woodworking tool, carpenders tools, cabinet makers tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - HARRY BIGGS COLLECTION: G. J. SWEENEY

... moulding mills commercial business Document: copy of photo exterior ...Document: copy of photo exterior of G.J. Sweeney and Sons premises, Garsed Street, Bendigo.place, bendigo, business premises, bendigo, f.j. sweeney and sons, moulding mills, commercial business -

Wodonga & District Historical Society Inc

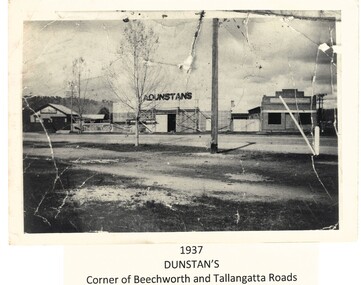

Wodonga & District Historical Society IncPhotograph - Mann Collection Album - Dunstan's Corner, Wodonga, C. 1970s

These town photos are part of a collection donated by Elaine Mann. Elaine was married to David Mann, a successful Wodonga businessman and community leader who passed away in Wodonga in June 2012. David was a member of the Mann family who began their business in Wodonga in 1920. Elaine was a teacher in Wodonga for many years and an active member of the community. Arthur Dunstan Hardware Arthur Dunstan established mills at Red Bluff on the Mitta and a timber yard at Wodonga. He also built a sawmill at Glen Wills in 1931 which operated for about 16 years. A larger and more modern sawmill with drying kilns was erected at Eskdale in 1947. He was contracted to build Wodonga’s Municipal sale yards in 1935, followed by the Wangaratta sale yards. This created so many forward orders that he bought a large block of land on the corner of Beechworth and Tallangatta Roads and opened a timber mill and hardware store. The business stood on this corner for about 40 years. A large proportion of the company's timber output was processed at the Wodonga yards into flooring, weatherboards, mouldings etc. and practically the whole output was distributed locally and throughout the Riverina and eastern areas of New South Wales, and Canberra. At its peak Dunstan’s was one of the biggest sawmilling businesses in Victoria and in Wodonga employed 150 people and milled l6,000,000 super feet of timber annually. A super foot is a measurement for timber, equal to one foot square by one inch thick. Arthur Dunstan also built Tower Place in High Street. He died in Wodonga in 1963 and the business was continued on by his sons. Dunstan’s timber yards in Wodonga were sold to Ezerd Industries in 1987 with the retail section being bought by BBC Hardware.This photo collection is of significance as it documents how the businesses and buildings in Wodonga have evolved and contributed to community throughout the late 20th century. A. Dunstan & Sons Hardware was located at the roundabout on the corner of High Street and Thomas Mitchell Drive (Formerly Tallangatta Road). "Southside Terrace" now occupies this site.wodonga businesses, high st wodonga, dunstan's hardware wodonga -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Codling Collection 01 - Dunstan’s Corner - Thomas Mitchell Drive, c1987

These Wodonga photos are part of a collection donated by Miss Olive Codling. Arthur Dunstan Arthur Dunstan established mills at Red Bluff on the Mitta and a timber yard at Wodonga. He also built a sawmill at Glen Wills in 1931 which operated for about 16 years. A larger and more modern sawmill with drying kilns was erected at Eskdale in 1947. He was contracted to build Wodonga’s Municipal sale yards in 1935, followed by the Wangaratta sale yards. This created so many forward orders that he bought a large block of land on the corner of Beechworth and Tallangatta Roads and opened a timber mill and hardware store. The business stood on this corner for about 40 years. A large proportion of the company's timber output was processed at the Wodonga yards into flooring, weatherboards, mouldings etc. and practically the whole output was distributed locally and throughout the Riverina and eastern areas of New South Wales, and Canberra. At its peak Dunstan’s was one of the biggest sawmilling businesses in Victoria and in Wodonga employed 150 people and milled l6,000,000 super feet of timber annually. A super foot is a measurement for timber, equal to one foot square by one inch thick. Arthur Dunstan also built Tower Place in High Street. He died in Wodonga in 1963 and the business was continued on by his sons. Dunstan’s timber yards in Wodonga were sold to Ezerd Industries in 1987 with the retail section being bought by BBC Hardware.This photo collection is significant as it documents how the businesses and buildings in Wodonga have evolved and contributed to community throughout the 20th century.The first business at this location was a timber will and hardware store established by Arthur Dunstan in 1935. It operated there for about 40 years. Businesses from left to right: Dry Cleaner, Delicatessen, Twin Cities Fruit & Vege Market, Ollies Family Restaurant, Victoria Star Hot Bread Kitchen, Trophies and Gifts, and Horseland. This area is not referred to as Southside and the former Horseland premises are not occupied by an Italian restaurant.wodonga businesses, dunstan's corner wodonga, thomas mitchell drive -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Codling Collection 01 - Dunstan’s Corner and Beechworth Road Roundabout, Mid 1980s

These Wodonga photos are part of a collection donated by Miss Olive Codling. Arthur Dunstan Arthur Dunstan established mills at Red Bluff on the Mitta and a timber yard at Wodonga. He also built a sawmill at Glen Wills in 1931 which operated for about 16 years. A larger and more modern sawmill with drying kilns was erected at Eskdale in 1947. He was contracted to build Wodonga’s Municipal sale yards in 1935, followed by the Wangaratta sale yards. This created so many forward orders that he bought a large block of land on the corner of Beechworth and Tallangatta Roads and opened a timber mill and hardware store. The business stood on this corner for about 40 years. A large proportion of the company's timber output was processed at the Wodonga yards into flooring, weatherboards, mouldings etc. and practically the whole output was distributed locally and throughout the Riverina and eastern areas of New South Wales, and Canberra. At its peak Dunstan’s was one of the biggest sawmilling businesses in Victoria and in Wodonga employed 150 people and milled l6,000,000 super feet of timber annually. A super foot is a measurement for timber, equal to one foot square by one inch thick. Arthur Dunstan also built Tower Place in High Street. He died in Wodonga in 1963 and the business was continued on by his sons. Dunstan’s timber yards in Wodonga were sold to Ezerd Industries in 1987 with the retail section being bought by BBC Hardware.This photo collection is significant as it documents how the businesses and buildings in Wodonga have evolved and contributed to community throughout the 20th century.The first business at this location was a timber will and hardware store established by Arthur Dunstan in 1935. It operated there for about 40 years. In this photo Horseland occupies the corner premises including a video outlet. On the left is the Victoria Star Hot Bread Kitchen. This area is now know as Southside.wodonga businesses, dunstan's corner wodonga, thomas mitchell drive -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Dunstan & Son, Wodonga

Mr Arthur Dunstan established a sawmill at Glen Wills in 1931 which operated for about 16 years. A larger and more modern sawmill with drying kilns was erected at Eskdale in 1947. He was contracted to build Wodonga’s municipal saleyards in 1935, followed by the Wangaratta saleyards which created so many forward orders that he bought a large block of land on the corner of Beechworth and Tallangatta Roads and opened a timber mill and hardware store. In 1974 other sawmills opened in Tallangatta Road near Chapple Street to cope with the expanding business. A large proportion of the company’s timber output was processed at the Wodonga yards into flooring, weatherboards, mouldings, and practically the whole output was distributed locally and throughout the Riverina and eastern freeboard of New South Wales, and Canberra. At its peak Dunstan’s was one of the biggest sawmilling businesses in Victoria and in Wodonga employed 150 people and milled 16,000,000 super feet of timber annually. Arthur Dunstan died in 1963 and the business was carried on by his sons Arthur Jr, Jack and Les, together with Reg McDermott and Neil Carr. Dunstan’s timber yards in Wodonga were sold to Ezard Industries in 1987 with the retail section being bought by BBC Hardware. Hardy’s took over the timber yard in 1989 and staff was gradually reduced to 51 by 1991. Processing fell to 1000-1200 tonnes of pine a month by 1992 and Hardy’s, by then part of Pacific Dunlop, finally closed operations in that year with the loss of the remaining 27 jobs. The area where Dunstan’s was located is now known as Southside.A black and white photo of a retail buildinga and workshopOn shopfront: DUNSTAN A & SONS HARDWARE JOINERY & TIMBER MERCHANTS RICKSHAW MAGICOLOR We stock and recommend HARDIES FIBROLITE SHERWIN WILLIAMS PAINT FINISHESdunstan's hardware wodonga, wodonga businesses, dunstan's timber -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Folder, Stevenson, Joseph

Joseph Stevenson came to Australia in 1837, eventually settling near Kangaroo Ground. He was active in local affairs.. Contents Handwritten and typed notes by Winifred Joy Ness, 1985, "Joseph Stevenson of Kangaroo Ground". Handwritten extracts from "Pioneers and Painters" by Alan Marshall, relevant to Joseph Stevenson. Handwritten extracts from "Pastoral Pioneers of Port Phillip"by R V Bills and A S Kenyon, relevant to Joseph Stevenson. Photocopy of photographs: Stevenson daughters; a stevenson daughter with baby; Joseph Stevenson. Handwritten Stevenson family tree (on 2 sheets). Photocopy of photograph: Robert Stevenson and family, "Bankhead", Kangaroo Ground (ref 423). Photocopy of two prints/paintings, annotated on reverse (information from R B Ness: Punt over Yarra River at Melbourne which Joseph Stevenson helped build, from "History of South Melbourne", published 1930s; First bridge over Yarra at Melbourne which Joseph Stevenson helped build. Photocopy of Death Certificate: Joseph Stevenson, 1 November 1878. Photocopy of Death Certificate: Ruth Sevenson, 1 November 1868. Photocopy of Marriage Certificate: names illegible 16 November 1868 Photocopy of extract of Marriage Certificate: Joseph Stephenson and Ruth Boyd, 14 June 1837. Newspaper article: "Resting in peace", Diamond Valley News, 23 March 1982. Judith Furphy and early Kangaroo Ground families buried in Kangaroo Ground Cemetery. Newspaper article: "Grounds for celebration", Diamond Valley Leader, 23 November 2005. Lynette Beale traced her ancestor Joseph Stevenson to Kangaroo Ground. Letter Diana Bassett-Smith to EDHS, 10 August 2005. Donation of a moulding plane marked Joseph Stephenson, property of descendants.Newspaper clippings, A4 photocopies, etcjoseph stevenson, ship willington 1837, ruth stevenson nee boyd, david stevenson, jane stevenson, kirk's bazaar, first punt across yarra river, princes bridge melbourne, stevenson street melbourne, saltwater creek, river plenty, christmas hills, david christmas, diamond creek, isabella stevenson, robert stevenson, five mill creek, watson's creek, "bankhead" kangaroo ground, ellen stevenson, yarra glen road, yarra glen cemetery, stevenson's corner kangaroo ground, stevenson's creek, presbyterian church kangaroo ground, eltham district road board, margaret stevenson, ruth stevenson, emma stevenson nee peers, margaret hargreaves nee stephenson, robert peers, cyrus peers, charlotte peers, jane mess nee stevenson, robert mess, pearl mess nee mills, james mess, george mess, janet mess, joseph mess, william mess, alexander mess, barbara mess, isabella mess, ruth gosling nee mess, john gosling, jessie gosling, evelyn sinclair nee gosling, william gosling, vera rowland nee gosling, florrie rawland, ethel rawland, john rawland, isobel gilson nee mess, bruce mess, joy mess nee masefield, janet crook nee mess, rodney crook, judith rodgers nee mess, ray rodgers, dean crook, jenine crooks, carolyn rodgers, merryn rodgers, beryl nansen nee mess, robert nansen, gerry oliming, roberta oliming nee nansen, bernard nansen, michele nansen nee blackie, rohan nansen, janet nansen nee britton, vera cope nee mess, cliff cope, graeme cope, louise cope nee thimpton, shannon cope, lucas cope, peter cope, marilyn cope nee turnley, oliver cope, sarah cope, kelvin cope, donald mess, joan mess, geoffrey mess, peter mess, rosemary mess, kerrie mess, isobel gibson nee mess, ellen stevenson nee armstrong, james stevenson, john stevenson, elizabeth stevenson, joanna stevenson, ellen little nee stevenson, william little, francis little, janet little nee armstrong, ruth lorimer nee little, david lorimer, ruth cameron nee lorimer, francis lorimer, val wade, elizabeth lorimer, david kelso, willaim lorimer, jean lorimer nee hewitt, nancy mitson nee lorimer, stan mitson, john hewitt, alison hewitt, john cameron, beryl ryan nee cameron, robert cameron, maryann ryan, peter ryan, margaret ryan, steven wade, andrew wade, jonathan wade, jennifer wade, ruth sadlernee stevenson, thomas sadler, alexander sadler, isabella booth nee sadler, angus sadler, heather sadler, ruth sadler, andrew sadler, nancy sadler, benjamin sadler, robert sadler, alice sadler nee smith, margaret smith, david sadler, anne mcclusky nee sadler, hope sadler, anne carson nee sadler, ruth edwards nee carson, david carson, joseph sadler, isabella bond nee sadler, ian bond, ruth bond, isabella bond, john sadler, thoas sadler, mary sadler nee stewart, stewart sadler, keith sadler, glen sadler, peter sadler, terry sadler, pamela sadler, armstrong family kangaroo ground, bell family kangaroo ground, rogerson family kangaroo ground, barr family kangaroo ground, harkness family kangaroo ground, jardin family kangaroo ground, thompson family kangaroo ground, johnson family kangaroo ground, walters family kangaroo ground, sir ewen camerson, flora margaret cameron, ewen cameron, sir ewan camerson, sir herbert gepp, "garden hill" yarra glen road, andrew moss museum kangaroo ground, lynette beale, noel beale, mick woiwod, diana bassett-smith