Showing 3 items matching "amalgam bucket"

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Amalgam bucket

... Amalgam bucket...Amalgam bucket... plates and put into the amalgam bucket ready for retorting too... plates and put into the amalgam bucket ready for retorting too ...Ore bearing rock brought out of the mine was crushed at the battery by heavy metal stampers and the fine material passed over copper pates coated with mercury. Gold particles would combine with the mercury forming an amalgam which was then scrapped off the copper plates and put into the amalgam bucket ready for retorting too extract the gold. The amalgam of mercury and gold was placed into the retort which was heated to evaporate the mercury. The mercury cooled as it ran down the pipe which was recovered to be reused leaving the gold behind. The gold would later be put into a crucible and heated to burn of impurities and the molten pure gold poured into an ingot.A heavy cast iron bucket 20 centimetres high, 16 centimetres in diameter at its base and 22 centimetres diameter at the top. It has a spout five centimetres wide protruding two centimetres. There is a handle which is a semi- circular shape 19 centimetre wide extending 14 centimetres above the bucket The inside of the bucket has an enamel coating. amalgam bucket, bendigo gold, gold retort -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - MERCURY BUCKET

Cast iron mercury bucket, used to hold mercury, potentially in the process of recovering minute pieces of gold mixed in soil and sediments. See research page for description of one process of using mercury to extract gold.gold mines, mining equipment, mercury bucket, miners used mercury in a number of ways to amalgamate gold, with each mill or battery operator having their preferred method depending on the nature of the ore. by the late 1850s the most common way of crushing goldbearing quartz ores or consolidated alluvial cements was in a stamp battery. the battery featured heavy iron stamp heads held in a frame, with each head often weighing up to 500 pounds (226 kg) or more (see msv 1880, page 45) (birrell 2005). stamp heads were lifted and dropped by a rotating overhead cam shaft driven by a steam engine or water wheel. ore was fed into a large cast-iron battery box, mixed with a steady stream of water, and pulverised by the stamp heads. in some batteries, mercury was placed in the base of the boxes to amalgamate with freed gold. the violent agitation of the mercury in the mortar box, however, could cause the mercury to break into myriad tiny globules that were carried away by the water with the tailings, thus losing a certain amount of gold in the process (thompson 1867; ritchie & hooker 1997). the water and sand slurry was splashed by the falling stamps from the box through fine mesh screens and onto inclined wooden tables below the mortar box (figure 2). the tables were covered with copper sheets or plates coated with mercury, which caught and amalgamated with a portion of the gold. the grey putty-like amalgam was periodically scraped off the sheets and retorted in a furnace to collect the gold and recover the mercury for reuse. mercury was inevitably lost from the plates, while poor maintenance resulted in further losses of gold and mercury in the tailings. mercury use and loss from gold mining in 19th century victoria. peter davies1, susan lawrence, and jodi turnbull, department of archaeology and history, la trobe university. -

Rutherglen Historical Society

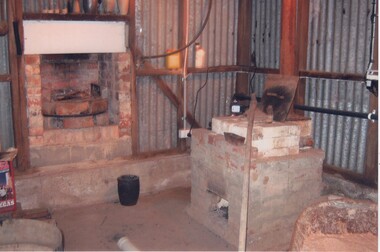

Rutherglen Historical SocietyImage, c1990

This photograph shows the pre-heater on the left and the furnace on the right. After clean up of stamper table, amalgam is placed in a retort, then placed in the furnace where mercury is condensed and runs down the small pipe into an enamel bucket and can be reused. This is one of a series of photographs of the Rutherglen Gold Battery. The battery's purpose was to crush quartz from nearby quartz reefs and extract gold from within. The battery was erected in 1908 and consists of a five-head battery, Wilfrey table, Bergin pan, portable steam engine and shed. The battery was restored in 2011/12 and can be viewed daily between 9.00am and 5.00pm. See website for details.Colour photograph of the interior of a room with corrugated iron walls, with a fireplace on the left and a furnace on the right.gold battery, gold processing