Showing 53 items matching "beanie"

-

National Wool Museum

National Wool MuseumBeanie

Worn as part of the Mens opening ceremony uniform for the Winter Olympics,2002Mens beanieAUSfashion, costume, hats, sport, salt lake city -

National Wool Museum

National Wool MuseumBeanie

part of the womens casual "sportwool' uniform for the Winter Olympics, 2002AUSfashion, wool, costume, sport, salt lake city -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchBeanie

Wollen Beanieheadgear, korea, army -

Plutarch Project

Plutarch ProjectBoy's Costume beanie, σκούφο, 1990's

The full costume used traditionally by soldiers in the 16th to 19th century AD. Recently used in parades and plays as a traditional costume. Beanie is an integral part of the costumeHistorical significance used as part of traditional functions by Thessaloniki AssociationRed woollen beanie with black tassel part of the traditional tsolia costume, with tassel stitched to the top of the beanie. Part "E" of a 6 piece costume.cap, beanie, σκούφο, σκούφος, φούντα, tsolia, costume, στολή -

National Wool Museum

National Wool MuseumTextile - Beanie, Tina Knitwear, 1980-2000

Part of a selection of garments knitted by ‘Tina Knitwear’. Tina Knitwear was a successful made to order knitwear business in Brighton from the mid-1960s to around 2010, run by Assunta and Franco Liburti. Daughter Melissa Persi writes: Our parents Assunta (Mum) and Franco (Dad) Liburti ran a successful made to order knitwear business in Brighton from the mid-1960s to around 2010. Assunta was affectionately known to her family as Assuntina, therefore the business was named "Tina Knitwear" after her. Assunta and Franco were born in the beautiful seaside town of Terracina in Italy in 1933 and 1930 respectively. As was so common in Italy in the 1950s, Assunta who was in her late teens and early twenties learnt the intricate skills of machine knitting, dressmaking and pattern making. Franco on the other hand, learnt the building trade with his 2 brothers and specialised in bricklaying and tiling. As was so common after the war, Assunta and Franco yearned for a better life so they decided that they would get engaged and then migrate to Australia to be married and raise their family in Australia, a land of much opportunity which they no longer felt their beloved Italy held for them. Assunta migrated to Australia first in 1957 and later Franco joined her in 1958 where they were married. For the first few years, Franco (also known as Frank) worked as bricklayer /tiler on buildings such as the Robert Menzies building at Monash University in Clayton and various buildings in the Melbourne CBD. Assunta on the other hand put her machine knitting skills to use working in factories doing piece machine knitting for various knitwear companies. The hours were long, the conditions were difficult, and travel was onerous without a car. After their 2 older children were born, it was decided that dad would leave the building trade and they would start their own made to order knitwear business. That way they could work from home and raise their family together. Mum taught dad everything he needed to know so he could operate the knitwear machinery. They purchased COPPO knitting machines from Italy and a Linking machine from Germany. Initially they had a knitwear shopfront in Bay Street Brighton where a store assistant would take the orders and client’s measurements and Assunta would then make the garments from a small workshop in their home. Unfortunately, the assistants were not skilled dressmakers and often measurements and orders were incorrectly taken. Assunta being the perfectionist and highly skilled machinist that she was, decided that she needed to oversee the entire process from meeting the client, to taking their order, right thru to the fittings and completion of the garment. It therefore made sense that they should close the shop front and run their business from their own home in Brighton and hence “Tina Knitwear” was born. Together, for more than 40 years they ran their very respected and successful business and were well known in the Bayside area. They specialised in made to order knitwear for both men and women using mainly pure wool (from Patons, Wangaratta Mills, Japan and Italy) but also lurex and estacel. Over those years, many of their clients became their close friends. It wasn't unusual for clients to come to order garments and then end up in the kitchen chatting over a cup of Italian espresso coffee and homemade biscuits. Some of their clients were especially memorable and became lifelong friends. Mrs Connell was a dear friend of mum’s, each year she would buy tickets for the “Gown of the Year” fashion show. She would insist on taking Assunta and her 2 daughters so that we could see the latest fashions. Then there was their dear friend Ms Griffiths. She had been a Matron nurse at the Queen Victoria Hospital when she met my parents in the 1970s. She returned to live in New Zealand in the 1980s but came back to Melbourne every year to stay for 2 weeks with the sole purpose of visiting my parents (she adored them) and order garments. For those 2 solid weeks, mum and dad would only knit for Ms Griffiths and she would go back to New Zealand with at least 5 or 6 new outfits. I actually think she enjoyed mum’s homemade pasta almost as much as her new clothes! Over the years, my parents learnt to speak English very well given that majority of their clients were not Italian speaking. Their oldest child John born in 1960 learnt to speak English with the help of those clients who were such a big part of our childhood. Mum and dad always went above and beyond to ensure their clients were satisfied. Mum was an absolute perfectionist and it showed in her attention to detail and the quality of their beautiful work. You only need to look at the garments that have stood the test of time or speak to their clients to know that this is true. Their clients would always comment on how well their clothes would last and much of their clients came via word of mouth and recommendations. Occasionally there would be disagreements because mum had found an error in dad's knitting (either a wrong stitch or a sizing mistake mainly) and would ask him to redo a piece, he would argue back saying that it was fine, but we always knew who would win the argument and that the piece would get remade! Similarly, we recall discussions where mum would ask dad to find a particular colour of wool in the garage where the stock was kept. He would try to convince her that they were out of stock of that colour and that the client should choose a different colour. She would insist they had it and then after hours of searching, he would return into the house sheepishly holding the wool! Our childhood is full of beautiful memories of mum and dad always being present, clients coming and going, mum humming her favourite songs as she worked often late into the night and sometimes, we even fell asleep to the hum of the machinery. They put their heart and soul into "Tina Knitwear" and took pride in providing only the best quality garments for their clients. In Italian there is a saying “lei ha le mani d’oro” which literally translated means “she has hands of gold”. Franco enjoyed his work but for Assunta, it was more than just work and there is no better way to describe her skills, passion and dedication to her machine knitting… she truly did have “hands of gold”. We will forever be grateful that our parents’ life journey gave us the opportunity to live in a home filled with creativity, dedication and passion, amazing work ethic and mutual respect, lifelong friendships and a lifetime of love. Teal knitted ribbed beanie with gathered crown.knitwear, clothing, italy, migrants, brighton, knitting machine, linking machine, garments, business, family, community -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesHeadwear - Hats, Burnley Student Association, Burnley Student Association Beanie Hats, <2009

Found in former bookshop when it closed in 2009.9 polyester hats with, "Burnley Student Association" and logo embroidered (green and blue) . Various shades of black and textures. 1 acrylic knitted hat, black. 1 acrylic knitted hat, blue. Burnley Student Association with a leaf logo.burnley students, uniform, student association, artifact -

Melbourne Tram Museum

Melbourne Tram MuseumUniform - Beanie, Control by Kaos, c2005

Beanie - dark blue heavy polyester cloth formed and sewn to provide a head covering with the Yarra Trams logo (1st version) sewn into the front of the item with blue and green thread. Made by "Control by Kaos", www.kaossnow.com, of China.trams, tramways, uniforms, cap, clothing, yarra trams -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaPainting, Lisa Carman, S.O.S, 2019

The painting explores the mental health issues often faced by those who work at sea as a result of loneliness, isolation and illness, amongst other things. This seafarer’s face is made up of thousands of SOS Morse code symbols: dot,dot,dot dash,dash,dash dot,dot,dot. Morse code was used to signal to land that a ship or crew was in trouble. This seafarer is in trouble- his face says it all and speaks volumes. Mental health issues are often hidden when we look from afar but when we take the time to look closer and listen, the signs are often there.Lisa Carman entered this painting to the Maritime Art Prize 2019 and donated the artwork after the exhibition.Naive, Marine artLisa Carman, MTSV Collection Squared shape painting depicting a portrait in blue and dark tones of a sailor with a beard wearing a beanie. His face is made of dots using the SOS Morse code.sos, seafarers welfare, maritime art prize, 2019, lisa carman, morse code, seafarers, sailors, beanie, blue -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchBeanie

Green Woolheadgear, c1970, army -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchBeanie

Green (use on UC009)headgear, c1970, army -

Bendigo Military Museum

Bendigo Military MuseumHeadwear - BEANIE HAT, C.1939 -45

Belonged to Thomas Henry ISER V24933 and VX102660 2nd AIF. Refer Cat No 383.2 for his service history.Headwear, Military issue, Beanie woollen, khaki colourhats woolen, beanie military -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionHeadwear - Beanie - WestVic Work Force, n.d

Navy knitted beanie (acrylic), embroidered logo in yellow 'WESTVIC WORK FORCE Rewarding Employment'headwear, warmth beanie, advertising -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO PEOPLE

Photo of 2 people One tall with reed/Brown Beard wearing a white beanie , blue jumper and blue pants, the second older wearing a blue beanie , blue jumper and blue pants both are holding polystyrene cups - Location and Date UnknownPolaroidorganisation, industry, gas and fuel -

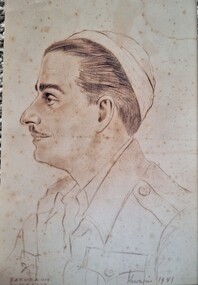

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph, Marco Gazzi

The sketch is of Marco Gazzi and internee during WW2, an Italian Dunera boy and drawn by Kurt Winkler (Kurwin) in 1943.Sepia photograph (x 2) of a mans head and shoulders, facing to the left of the photograph. Wearing a beanie and uniform.marco gazzi, italian internee, dunera boy, kurt winkler, kurwin -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Jim Connor, Alan Marshall by Marcus Skipper (1995) outside Eltham Library, Panther Place, Eltham, July 2020

Alan Marshall fully protected from the weather and COVID-19 virus with beanie and maskBorn Digitalalan marshall, art in public places, covid-19, eltham library, marcus skipper, pandemic, sculptures, statue -

Greensborough Historical Society

Greensborough Historical SocietyNewspaper clipping, Beanies on display in exhibition, 03/12/2014

Discusses the 2014 craft exhibition at Bundoora Homestead, showing beanies from the Alice Springs Beanie Festival.News clipping, black text, colour image.bundoora homestead, alice springs beanie festival, colours of the country -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumSandstone Rock, 1940

This rock was found by a Year 3 boy, Beanie Cockram-Russell, in the Dhurringile Primary School garden bed.Piece of sandstone which has a, 1940, a map of Australia, a Rosella and the word Tatura Vic. carved into it.Australia, Rosella and Taturadhurringile primary school, carved sandstone rock -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BENDIGO ADVERTISER COLLECTION: BOXING

Black and white photograph, boxing, photograph of a man wearing a beanie, a jacket, along with some overalls standing in a boxing ring. Bendigo Advertiser description, back of photo is unmarked:recreations, sports, boxing -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph, A. Beilharz, 1940's

Made in Camp 3, possibly originally part of the 4 x 4 red gum which supported the shed.Colour photograph of wooden carpenter planes, wooden jewel cases and on left a table on which is a portion of a beanie or tea cosy. Coloured red with a black and brown circle and brown/faune lining.camp 3, hand made objects, wooden objects, camp 3 hand crafts, camp 3 carpenter planes, a. beilharz, templer society -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Loading cargo, n.d

Port of Portland Authority archives.Front: (no inscriptions) Back: (no inscriptions)port of portland archives -

Halls Gap & Grampians Historical Society

Halls Gap & Grampians Historical SocietyPhotograph - Coloured, 27/09/1985

A display at the Wildflower Show.The photo shows a stage display with a tent, fireplace with billy hanging on a tripod and a dummy dressed as a camper. There is a man wearing jeans, a jumper, gum-boots and a beanie posing with the dummy. A large painting of rock banded peaks forms the backdrop of the stage. "85 9 27" photo date on lower right side of photo.events, wildflower show -

National Wool Museum

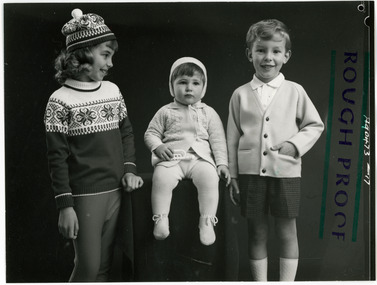

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

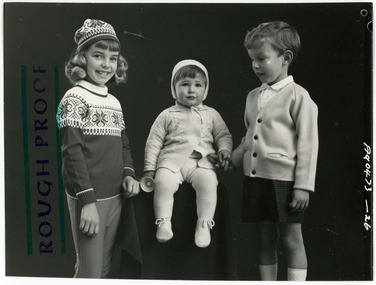

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it.From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - LEGGO'S TIN CAN BAND 1915

Copy of black and white image : four rows of men dressed in jackets, beanie type hats with tins attached on top. Two men back LH row wearing army coats and hats. Two men RH side back are wearing army uniform.organisation, band, leggo's tin can band, bendigo, leggo, leggo's tin can band, jam tin band. -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-28[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink)business, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-17 From a promotional shoot for Kathryn Knitwear[Obverse] (stamped in blue ink with green ink lines above and below) ROUGH PROOF (White ink) A90473-17 [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the left edge with white ink is an index code A90473-23 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-23 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-14 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-14 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the right edge with white ink is an index code A90473-26 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-26 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the left edge with white ink is an index code A90473-2 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-2 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing -

National Wool Museum

National Wool MuseumPhotograph, LaTrobe Studios, c.1972

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black and white photograph of three children Child on left has light chin-length curly hair and wears a beanie and turtleneck jumper with a Nordic motif. Toddler in the middle wears a three piece knit set of a beanie, cardigan and bootee leggings. It features a textured patterned stitch and is very similar to NWM-08913. The Child on the right wears a collared shirt and checked shorts with a pale V-neck cardigan with two front pockets and four buttons. Stamped with ROUGH PROOF in blue ink with green lines above and below it. Written along the left edge with white ink is an index code A90473-2 From a promotional shoot for Kathryn Knitwear[Obverse] (White ink) A90473-2 (stamped in blue ink with green ink lines above and below) ROUGH PROOF [Reverse] LATROBE STUDIOSbusiness, business history, manufacturing, knitting machine, fashion textile production, business archives, manufacturing documents, textile industry - history wool marketing, wool marketing fashion textile industry, children's knitwear, children's clothing, knitwear marketing