Showing 20 items matching "blade shearing"

-

Wodonga & District Historical Society Inc

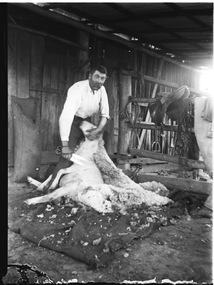

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Harry Schuster blade shearing

... Haeusler Glass Negatives Collection - Harry Schuster blade...Haeusler Glass Negatives Collection - Harry Schuster blade...blade shearing... shear their own sheep or employ blade shearers rather than... collection. Harry Schuster shearing sheep using blade shears. ... shear their own sheep or employ blade shearers rather than ...The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. The Schuster family were also of German migrant background. Johannes Edward Schuster was born in Hoyles Plains, South Australia and with his wife Johanna and young family moved to Victoria circa 1882. He took up farming land in Wodonga West. The St John’s Lutheran Church Sunday school hall was erected from part of the proceeds of the sale of some 41 acres of land at Wodonga West, which had been bequeathed to the Wodonga congregation by the late Johannes Edward Schuster. This land was the original home site of the Schuster family on arrival from South Australia. Shearing - Although the first mechanised sheep shearing machine was created by James Higham, from Melbourne in 1868, the use of blade shears were more common well into the early 20th century. Pastoralists on smaller holdings continued to either shear their own sheep or employ blade shearers rather than outlay the cost of machines. In large sheds, professional shearers worked as they travelled the country. They would earn around 17 to 20 shillings per day in the early days of the wool industry. However mechanisation continued and by 1915 most sheep shearing sheds in Australia contained sheep shearing machines. The original machines were powered by steam and later combustion engines were used. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Harry Schuster shearing sheep using blade shears. wodonga pioneers, haeusler family, glass negatives, dry plate photography, blade shearing, schuster family -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Black and White, Blade Shearing on McCookes' Property at Mount Emu, 1910, 1910

... Blade Shearing on McCookes' Property at Mount Emu, 1910..., woolclasser J. Ringin, C. McCooke, J. Brown. Blade Shearing ...According to the donor these image copies were used in an exhibition, and distributed at the conclusion. The originals are thought to be in the collection of Snake Valley HIstorical Society.Framed black and white photograph of a group of shearers at the Mount Emu property of McCookes. The shearers shear in an open paddock with a rough wool classing table. Shearers from left: A. Corbet, W. Rowler, L. Tanner. Others from left: V. Corbet, the owner A. McCooke, Bert McCooke, A. McCooke, woolclasser J. Ringin, C. McCooke, J. Brown.a. corbet, w. rowler, l. tanner, v. corbet, a. mccooke, bert mccooke, j. ringin, c. mccooke, j. brown, woolclassing, woolclasser, shearing, shearer, mount emu, mt emu, farm, livestock -

National Wool Museum

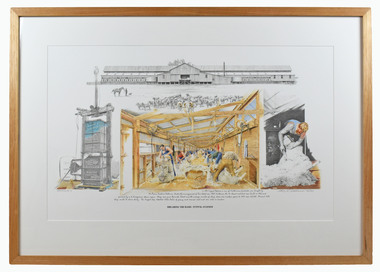

National Wool MuseumPrint, Chris McClelland, Shearing the Rams – Tuppal Station, 210

... of the station rams by 72 blade shearers. Over a single weekend in 2010... of the station rams by 72 blade shearers. Over a single weekend in 2010 ...Chris was invited to be artist in resident for the historic re-enactment of “Shearing the Rams” at the North Tuppal Station woolshed held on the 4th and 5th June 2010. The celebration attracted record crowds to witness the shearing of the station rams by 72 blade shearers. Over a single weekend in 2010, thousands of people queued for hours to see a piece of Australian history recreated at North Tuppal Station near Tocumwal, NSW. In 1900, Francis Faulkner invested a staggering £4000 to extend his shearing shed on Tuppal Station, making it the biggest in the country. Over the next decade more than three million sheep trod its pine boards and were shorn in its 72 stands. After years of drought and the Great Depression, the property fell into disrepair and the station was split up. When North Tuppal Station was sold to the Atkinson family in 1928, just five of the 72 stands were in operation. In 2010, Sport Shear Australia approached the Atkinson family about holding an event in the historic shearing shed to raise money for a team of Australian shearers to go to the world shearing title in Wales. An army of volunteers restored the T-shaped shed and yards and organised a weekend of events. Over two days, 6,000 sheep were shorn and all 72 stands of the restored North Tuppal shed were brought back to life. A total of 117 shearers shared the boards with 90 wool handlers who skirted 19 fleeces every minute. For a period on each day of this historic weekend, the machines were then silenced, and 72 shearers picked up their old blade shears to recreate past shearing methods. “When they fired up and got the blades out there was deathly silence on the board - you could hear a pin drop because normal shearing you have all the machines and it is quite noisy. Here you could just hear the click, like in the song Click Go the Shears Boys. People had tears in their eyes. It was quite an emotional thing to see that and very proud to be here.” George Falkiner, grandson of Francis FalkinerColoured framed print of shearing scene in the Tuppal station, Ferrrier’s wool press on the left-hand side and station on the top. Print in framed in a light-coloured wooden frame with white coloured matte.Under artwork - In 1891 Tuppal Station, a sum of 176,000 acres threshold, was bought by Mr Fiane Sadlies Falkines, Under the management of his eldest son F.B.S. Falkines, the 72 stand woolshed was build in 1900 and powered by a 16 horsepower steam engine. Sheep were pure Boonoke blood and the average numbers of sheep shorn over nineteen years to 1909 was 152,780. Around 7200 sheep could be shorn daily. The largest clip totalled 3326 baled of greasy and scoured wool and was sold in London. Bottom right corner - Chris McClelland 181/720 Shearing The Rams – Tuppal Station -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Artefact, Lister, Shearing heads, Early 20th century

The woollen industry has always been of the utmost importance in Australia. Although exports have declined over the past decades the production of fine wool still remains important in our economy. The great increase in wool production in the mid to late 19th century in Australia led to the need to replace the hand shears with some mechanized form of shearing. The first sheep shearing machine in Australia was patented in 1867 and improvements to this early model were made over the ensuing years. The early 1890s saw the introduction of flexible drive shafts. The two items here described show this innovation. These two items are of interest as examples of handpieces used early in the 20th century in the mechanized shearing of sheep. They would be typical of the pieces used in the wool industry in the early 20th century in Western Victoria. There are today many local shearers living in Warrnambool and nearby towns and working in the district. .1 This is a metal handpiece for a sheep shearing mechanism. It has a toothed blade attached with metal screws at one end and a jointed metal pipe at the other end for attachment to the shearing machine. The middle section has been covered with black leather for easier gripping. .2 This is a metal handpiece for a sheep shearing mechanism. It has a toothed blade at one end and a flexible metal attachment at the other end to connect it to the shearing machine. Both items are rusted and stained. ‘Sunbeam Flight Lister’sheep shearing in the western district, warrnambool -

Orbost & District Historical Society

Orbost & District Historical Societyhand shears, early 20th century

These hand shears were used for sheep shearing. They appear to be dual purpose sheep or topiary shears. They would have been used on a rural property in early Orbost. This item is an example of a hand tool used commonly before the widespread use of power tools.A pair of metal hand shears with a circular loop handle. On blade - Red Reaper Hand Shears 219 Ward & Payne 303 SHEFFIELD ENGLANDtool hand-shears -

Federation University Historical Collection

Federation University Historical CollectionTool, Handshears

Hand shears needed to be very sharp and often had a leather strap or ‘driver’ which passed over the hand. Others had sheepskin bound around the grip. Blades had to be regularly sharpened on a grinding stone. Most hand shears were made in Sheffield, England, with various models produced offering wide or narrow blades, sharp or rounded points, and various grips and bows. The technique of Australian hand shearing gradually developed from the 1830s using the old English method of cutting the flank with hand shears in a series of circular cuts from the sheep’s neck to the tail. In the early 1930s the Ballarat School of Mines introduced a wide-ranging Wool Classing Course as jobs were in extremely short supply during the Great Depression. Metal handshears used for shearing sheep.ballarat school of mines, shearing, woolclassing, sheep -

National Wool Museum

National Wool MuseumDagging Shears, 1900-1980

Dagging shears belonged to donor's father Maurice Dalton who was foreman of the show floor of the Dennys Lascekkes building until his retirement after 34 years with the company. Maurice used the shears in his work as a wool classer in rural Victoria and New South Wales. The shears are SUCCESS 11" Ball Bros. & Co. Dagging Shear, made in Sheffield, England.A pair of metal blade shears. The blade is engraved with 'SUCCESS / BALL BROS & CO / SHEFFIELD ENGLAND'. The ends of the two symmetrical grips loop around on themselves where they are riveted together to form a spring action.Mirrored. Image: Sword Mirrored. Lettering: SUCCESS / BALL BROS & CO / SHEFFIELD ENGLAND -

National Wool Museum

National Wool MuseumTool - Shearing Handpiece, c.1890

Ford and McFarlane shearing handpiece c.1890. This shearing handpiece is from ‘Wellington Lodge” in Tailem Bend, South Australia. Wellington Lodge today is an Angus beef farm; however, the property has a long history which includes wool farming. Wellington Lodge has been in the McFarlane family since the 1840’s and was originally around 19000 acres. The donor, Brian Licence, assembled this handpiece out of spare parts he found while classing wool on the property in the 1960s. Brian showed the finished handpiece to the owners once his classing work was completed and was told he could keep the handpiece as a souvenir. Brian also classed wool at “Jockwar” and “Pleasant Park” in Penola for members of the McFarlane family during the 1960s. The handpiece is named after Ford, the name of the engineer who designed the handpiece and McFarlane, the owners of Wellington Lodge Station and employers of Ford. This handpiece was developed as a prototype for use on the property. The handpiece which is made of solid brass is in a “used condition” and has been patched with solder. The handpiece is stamped with the number 10. Internally, the handpiece is powered from a drive mechanism of compressed air, this compressed air was typically produced by burning mutton fat. The handpiece comes from the pre-electrical– steam engine era of shearing. Brass metal shearing handpiece. A three-pronged fitting to hold both the comb and the blade protrudes from one end. A cylindrical stem extends vertically from the other. This is likely where a connecting rod to the shearing plant would be found. Below this vertical stem, the handpiece has an additional threaded hose fitting. This is likely where compressed air was delivered into the handpiece. The inscriptions can be found on the rear, near the previously mentioned vertical stem. Around this stem is also where the repairs of solder can be found. These repairs are unique to this handpiece and are not common practise.Etched. Base of handle. “FORD & McFARLANE . SHEEP SHEARER . Etched. Base of handle. “10”sheep shearing, shearing equipment, ford & mcfarlane, wellington lodge, tailem bend, south australia, shearing handpiece, shearing -

National Wool Museum

National Wool MuseumShears

Blade shears owned by Mr R.W. Pettitt, a breeder and judge of corriedale sheep.Detail of makers inscription on blade shears. Blade shears, with leather keeper.COMBINATION / U / T / S / No. 1 / SHEFFIELDshearing, pettitt, mr r. w. -

National Wool Museum

National Wool MuseumShears

Used from mid 1920s to late 1960s. Shears were used by Mr Embling and with leather scabbard. Made by Mr Embling in his first year at Dookie Agriculture College and were entered in R.A.S in Melbourne 1927 and won first prize in its class. Mr Embling used the set on properties such as "Nap Nap", "Wallah", "Narabri", "Bangool", "Skipton", "Lang Kal Kal", "Beaufort", "Nareen" in Western District (Fraser property). These artefacts were generally carried by stockmen or horsemen when crutching sheep.Metal blade shears dressed with appropriate leather and string strapping to suit user and with leather keeper. Handles have been painted blackCOMBINATION/ UTS No 1/SHEFFIELD/ MADE IN ENGLANDshearing, sheep stations management, animal health, embling, mr ken, sheep stations - management -

National Wool Museum

National Wool MuseumShears

Long narrow double bladed shears. Used in display from 12 April 1989 till early May 1989.COMBINATION/ UTS No 1/SHEFFIELDshearing, sheep stations management, animal health, sheep stations - management -

National Wool Museum

National Wool MuseumShears

... -and-the-bellarine-peninsula Blade shears shearing sheep stations management ...Blade shearsSUCCESS M.L. Bros Sheffield Englandshearing, sheep stations management, sheep stations - management -

Rutherglen Historical Society

Rutherglen Historical SocietyPair of hand shears, 1920 (Approximate)

Used for shearing sheep before shears were electrifiedHand shears for shearing sheep, sprung handle, has leather blade shield"Combination / T / U / S No.1 / Sheffield"shearing, farm work, agriculture, farm tools -

Rutherglen Historical Society

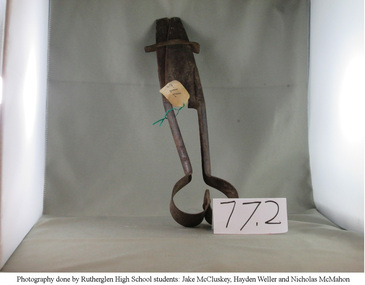

Rutherglen Historical SocietyTool - Pair of hand shears, 1920 (Approximate)

Used for shearing sheep before shears were electrifiedHand shears for shearing sheep, sprung handle, has points missing on blades"Combination / T / U / S No.1 / Sheffield"shearing, farm work, agriculture, farm tools -

National Wool Museum

National Wool MuseumShearing blades

... -and-the-bellarine-peninsula Shearing blades ... -

Trafalgar Holden Museum

Trafalgar Holden MuseumTool - Shearing shears

Shearing tool used in the late 1800's and early 1900'sRetailed by Holden and FrostSteel heart shaped handled shearing shearsMade in England by Ward and Payne LTD 202 Sheffield England, Sheppard and sheep stamped on blade shears, tools -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - Shearing Hand Set

... A metal handpiece for a sheep shearing. A toothed blade... for a sheep shearing. A toothed blade is held in place with metal ...The wool industry has been critical to the Australian economy from the early days of European settlement. The increase in wool production in the mid to late 19th century led to the need to replace the hand shears with some mechanized forms of shearing.The first commercially successful sheep shearing machinery by Frederick York Wolseley in New South Wales who was granted a patent for his machine on 28 March 1877. Many of the early settlers to North East Victoria droved sheep overland from both Sydney and South Australia and established large pastoral runs in the district. Wodonga became a major service centre for the industry and established major saleyards for the pastoral and cattle industries. The handset has the company name "Heiniger" on the side. Heiniger is a Swiss company with subsidiaries in Australia and New Zealand. It was originally established in 1946.This item is connected to a major rural industry in North East Victoria.A metal handpiece for a sheep shearing. A toothed blade is held in place with metal adjustable screws at one end. A jointed metal pipe at the other end allows attachment to the shearing machine. The hinge has been covered with leather.On adjustment knob "Heinger"shearing industry, shearing equipment, shearing handset -

Linton and District Historical Society Inc

Linton and District Historical Society IncShears, Hand Shears

Used in shearing shed near Linton.Metal blade hand shears used for shearing sheep. String-bound handles and leather strap.sheep shearing, hand shears, rural activity -

National Wool Museum

National Wool MuseumTool - Shears, 1928-1932

Hand shearing shears made in England.Twin-bladed shears bolted twice in centre of the handle which is shaped in the form of an incomplete figure 8.[Stamped] Combination UTS Sheffieldshearing, hand shears, tools, wool, shears -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Shears, Clippers

Shears or clippers for shearing sheep or other livestock. Two blades with handle which forms the spring tension. Could also be used in gardening.rural industry, livestock, domestic items, gardening