Showing 29 items

matching bolt threader

-

Arapiles Historical Society

Arapiles Historical SocietyBolt Threader

... Bolt Threader...bolt threader... bolt threader bolts file Farm equipment, iron hand made ...Farm equipment, iron hand made with file surfacebolt threader, bolts, file -

Bendigo Military Museum

Bendigo Military MuseumSouvenir - NUT & THREAD, BURMA RAILWAY, c.1940 - 1943

... Square steel nut with section of 3/4 inch dia bolt thread... steel nut with section of 3/4 inch dia bolt thread. Rusted ...This item was souvenired by Brian PATTEN on the Burma Railway when visiting as a tourist.Square steel nut with section of 3/4 inch dia bolt thread. Rusted.railway, souvenir, burma -

Friends of Westgarthtown

Friends of WestgarthtownBolt with nut and washer

... Steel bolt with washer and nut. Three quarter of the bolt... melbourne trades metalworking bolt threaded nut washer steel forged ...Steel bolt with washer and nut. Three quarter of the bolt is threaded and one quarter plain shank. Hexagonal head and square nut.No visible markingstrades, metalworking, bolt, threaded, nut, washer, steel, forged. -

National Wool Museum

National Wool MuseumBolt

... Square headed steel tapered screw type thread coach bolt....-and-the-bellarine-peninsula Square headed steel tapered screw type thread ...Square headed steel tapered screw type thread coach bolt. -

Ballarat Tramway Museum

Ballarat Tramway MuseumEquipment - Part of overhead - corroded eye bolt, 2024

... Overhead equipment - galvanised eye bolt with screw thread... of the eye bolt that supports the overhead in Wendouree Parade ...Item show corrosion of part of the eye bolt that supports the overhead in Wendouree Parade that has occurred primarily around the screw thread. Also shows how the span wire is terminated around a thimble that is fitted to the eye bolt. The item was probably erected by the SEC during the mid-1930s and replaced by the BTM 2024. Salvaged from Wendouree Parade during overhead span wire replacement and repair work in March 2024 undertaken by the BTM. See also item 9019 for a corroded section of span wire around insulators.Demonstrates a corroded eye bolt and associated parts.Overhead equipment - galvanised eye bolt with screw thread - partly corroded with left over wire around a galvanised thimbleoverhead, span wires, btm, tramways, poles -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationPropeller

... to be made of brass and has a stainless steel threaded bolt through... a stainless steel threaded bolt through the center. Propeller ...The 4 armed steel propeller is from an unknown yacht of unknown date. The object is fixed to a block of pink granite with bolts and is displayed in front of the lightkeepers’ quarters.The remnants of shipwreck fabric have second level contributory significance for their interpretive and historic value as artefacts that highlight the distinctive history of the Gabo Island Lightstation.Four armed propeller from a boat/yacht. It appears to be made of brass and has a stainless steel threaded bolt through the center. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageG Clamp

... threaded bolt, inscribed - "H B D E C�"...., heavy metal U shaped metal piece with large threaded bolt ...G Clamp, heavy metal U shaped metal piece with large threaded bolt, inscribed - "H B D E C�".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Lakes Entrance Regional Historical Society (operating as Lakes Entrance History Centre & Museum)

Lakes Entrance Regional Historical Society (operating as Lakes Entrance History Centre & Museum)Domestic Object - Flower Press

... 2 x 205 cm wooden plates aligned together by threaded bolts... by threaded bolts in each corner, corners have been rounded, butterfly ...2 x 205 cm wooden plates aligned together by threaded bolts in each corner, corners have been rounded, butterfly nuts on each bolt used to apply pressure between both platesWooden flower press, 2 wooden plates held together with bolt in each corner, used to press flowershandcrafts, equipment -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Bolt, 1870s

... Bronze stud bolt - six-sided bolt head, 16 thread runs, 7...-sided bolt head, 16 thread runs, 7 circular wea marks about 1 mm ...Bronze stud bolt - six-sided bolt head, 16 thread runs, 7 circular wea marks about 1 mm deep on the top surface of the bolt head. -

Friends of Kurth Kiln

Friends of Kurth KilnShackle

... internal depth and 3cm clearance. 3cm threaded bolt with square.... 3cm threaded bolt with square head. Short section of torn ...Heavy Steel Shackle made from 3cm round steel. 10cm internal depth and 3cm clearance. 3cm threaded bolt with square head. Short section of torn 1.5cm wire rope still attached -

Bendigo Military Museum

Bendigo Military MuseumBadge - AIRFORCE INSIGNIA, RAAF

... and connected each by 3 threaded small bolts. ... each by 3 threaded small bolts. Badge AIRFORCE INSIGNIA, RAAF ...Insignias worn as part of the uniform to indicative. Division of Service. In this case the RAAF. Belongs to Peter T. Stoklahsa who joined in 1966. Refer Cat No. 7674P.Two identical RAAF Airforce Insignia's uplifted eagle wings and a crown bolted on to wing shaped plate. All gold in colour and connected each by 3 threaded small bolts. raaf, uniform -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Tramcar component, Hand brake pawl, c1900

... or forged pawl with a forged, turned and threaded bolt, steel washer... pawl with a forged, turned and threaded bolt, steel washer ...Hand brake pawl, possibly from a cable or horse tram, smaller than an electric tram version consisting of a cast or forged pawl with a forged, turned and threaded bolt, steel washer and nut. Components have been removed from very rotten wooden floor. Possibly c1900tramcars, brakes, handbrakes -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumSecurable hook

... by means of holes long metal bolts with screw-threaded tips..., at either end of which by means of holes long metal bolts with screw ...8431.1 - A metal hook which has one end curved around a moderately large single metal chain link, which is itself secured by an encircling metal band to a metal strip, at either end of which by means of holes long metal bolts with screw-threaded tips, screwed onto which are square metal nuts, protrude. -

Bendigo Military Museum

Bendigo Military MuseumWeapon - TRIGGER PARTS

Various parts of weapon trigger system and trigger guards, Items in the collection of Sgt P.L.James, refer Cat No 7446 for his service details.1. Container - brown rusted metal box with sliding lid. Items 2 - 6 all contained within box. 2. Trigger mechanism - hard curled metal part with curved trigger at one end and swinging lever attached by small screw at other end. 3. Lever tripping - silver metal part of the trigger mechanism of the weapon, highly machined and gear attached to one side. 4. Post spring gear - extended black metal pipe (hollow) with gear mechanism attached to end. 5. Container - various parts of threads, screws, springs etc. 6. Bag and small parts - various screws, bolts and other metal parts.trigger mechanism, ww2 -

Bendigo Military Museum

Bendigo Military MuseumHeadwear - HELMET, STEEL - BRITISH PATTERN, c. WW2

British pattern steel army helmet as used in both WW1 and WW2. This example dates from the WW2 era.British pattern steel helmet, dark olive in colour. Outside of the helmet is covered in dark olive green mesh which is secured with olive green cotton cord. A bolt head is prominent on the crown of the helmet and corresponds to a nut and thread on the inside. This nut and bolt secures a black rubber pad. A sweat band in black synthetic material is secured to the inside rim of the helmet. An adjustable webbing chin strap with brass buckle is attached with clips to each side.Niluniform - army, costume - male, protective headgear -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBolt with Nut

Used for fastening two materials (eg. wood, steel) together.Used in the Kiewa Valley4 inches steel bolt with a nut. The bolt consists of a head and a cylindrical body with screw threads along a portion of its length. The nut is the female member of the pair, having internal threads to match those of the bolt. -

Orbost & District Historical Society

Orbost & District Historical Societyrope machine, Continental Trading Corporation, 1911

Metal rope making machine, "The New Era Rope Machine". It has three claws through which roping material is threaded. The internal wheels have cogs around the perimeter and it is bolted together in two pieces.rope-making-machine handcraft -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Steering Gear, 1889

Steering Gear Operation: All steering was done from the stern of the ship and a steering mechanism was used to connect the rudder to the ship's wheel, often housed in a box-like construction behind the helm. The rudder was, in turn, mounted on a pintle or stern-post held in place by gudgeon's (sockets). The steering was activated with lines attached to the blocks on the two threads (half left hand, half right hand) of the steering gear. As the helmsman turned the helm in the direction in which he wished the ship to travel, the central screw of the steering gear, which was attached to the back of the helm, turned horizontally. This caused the rods on either side of the gear to move backwards or forwards at the same time, which then turned the pintle and rudder to port or starboard. A brief history of the Newfield (1889-1892): - The Newfield was an iron and steel sailing barque of 1306 tons, built in 1889 by Alexander Stephen & Sons Dundee (Yard No 89) for Brownelles & Co., Liverpool. The Newfield was on a voyage from Sharpness to Brisbane on 29 August 1892, with a cargo of 1850 tons of fine rock salt. The Cape Otway light had been sighted in squally, bumpy weather, but the captain was under the impression it was the King Island light. The ship’s chronometers were wrong, and orders were given to tack the ship away from the light, which headed it straight for the cliffs of the Victorian coast. The vessel struck rocks about 100 yards from shore, and five feet of water immediately filled the holds. The captain gave orders to lower the boats which caused a disorganised scramble for safety among the crew. The panic resulted in the deaths of nine men, including the captain when they drowned after the boats capsized in heavy seas. The seventeen men who regained the ship decided to wait until daylight and rowed to Peterborough in the ship’s jolly boat and gig after locals had failed to secure a rocket apparatus line to the ship. The Marine Board inquiry found the wreck was caused by a "one-man style of navigation" and that the captain had not heeded the advice of his crew.The Newfield wreck and its collection of recovered items are heritage listed and are regarded as historically significant. They represent aspects of Victoria’s shipping history and their potential for us today to interpret the maritime history and social themes of the time. The assemblage of various Newfield artefacts held in the Flagstaff Hill Museum is not only significant for its association with the shipwreck but helps archaeologists when examining the relationship between the objects to better understand our colonial marine past.Ship’s steering gear, cast iron, consists of a long round metal rod into which gears have been machined. The thread of the gear from one end to almost the centre winds in a left hand direction while the thread of the gear from the other end to almost the centre winds in the right hand direction. Each end of the rod has a metal coupler attached and two narrower round rods are also attached to the coupling, one each side of the gear rod, the same length as it and parallel to it. Two more ‘S’ shaped couplers are joined to the gear rod. Each of these have an opening through which the gear rod is threaded and can move along. There is another opening in these couplers through which one of the narrower rods is threaded. The other end of this coupler has half length metal rod attached to it by a bolt through the ring at the end of the rod. One end of the steering gear still has the brass hub of the ship’s wheel solidly attached. The hub no longer has its wooden spokes but the ten holes for the spokes can be easily recognised.Noneflagstaff hill, maritime museum, shipwreck coast, warrnambool, peter carmody, carmody, newfield, shipwreck, peterborough, south west victoria, rocket, rocket crew, shipwreck artefact, flagstaff hil maritime museum, steering, steering gear, screw steering gear, sailing ship -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSteam-engine coupling, On or before 1889

This Steam Engine Coupling was recovered from the wreck of the Newfield and is thought to be part of a Donkey Engine (or steam donkey, or donkey winch), which is a small secondary steam engine with a cylindrical shaped boiler. In 19th century merchant sailing, a steam donkey was often used in marine applications such as to help raise and lower larger sails, loading and unloading cargo or for powering pumps. The barque Newfield left Liverpool on 1st June 1892 with a cargo of 1850 tons of fine rock salt for Brisbane. About six weeks later the ship ran into very heavy weather approaching the Australian coast. On 28th August at about 9pm her master, Captain George Scott, observed between the heavy squalls the Cape Otway light on the mainland of Victoria, but due apparently to a navigational error (the chronometers were incorrect), he mistook it for Cape Wickham on King Island, some 40 miles south. He altered course to the north expecting to run through the western entrance of Bass Strait, but instead, at about 1:30am, the ship ran aground about about 100 yards from shore, one mile east of Curdies River. The vessel struck heavily three times before grounding on an inner shoal with six feet of water in the holds. The Newfield remained upright on the reef with sails set for a considerable time as the wind slowly ripped the canvas to shreds and the sea battered the hull to pieces. Seventeen men survived the shipwreck but the captain and eight of his crew perished.Flagstaff Hill’s collection of artefacts from the Newfield is significant for its association with the shipwreck Newfield, which is listed on the Victorian Heritage Registry. The collection is significant because of the relationship between the objects. The Newfield collection is archaeologically significant as the remains of an international cargo ship. The Newfield collection is historically significant for representing aspects of Victoria’s shipping history and its association with the shipwreckCoupling is believed to be part of the Donkey winch's steam-engine. Threaded brass collar (with side outlet) attached to a copper pipe via a locking nut, and a four holed flange with bolts and coupling plate the other end.warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, shipwrecked artefact, 1892, 1893, 28 august 1892, 29 august 1892, barque, curdie's river, donkey engine, newfield, nineteenth century, peter ronald, peterborough, port campbell, shipwrecks, steam engine coupling, steam donkey, victorian shipwrecks -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Plumbing Fitting, Late 19th to early 20th century

... attaches to the centre of the bowl and to a threaded fitting at its... of the threaded fitting and a bolt joined to the bar's centre. Functional ...The plumbing fitting has been recovered from the sea, as shown by the encrustations on its surface. The source of the fitting is unknown but i is likely to have been part of the fittings of a shipwreck, probably a urinal.The plumbing fitting is an example of a fitting from a ship, late 19th to early 20th century.Plumbing fitting, metal, from an unknown shipwreck. Top of fitting is bowl-shaped with a narrow inlet pipe. Wide pipe attaches to the centre of the bowl and to a threaded fitting at its base. There is a bar across the inside of the threaded fitting and a bolt joined to the bar's centre.flagstaff hill maritime museum and village, shipwreck artefact, great ocean road, flagstaff maritime museum, plumbing, ship's plumbing, urinal -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Rope machine, Continental Trading Corporation Ltd, ca. 1911

This rope-making machine, called The New Era Rope Machine, was patented in the USA on July 18th 1911. It was made by the Continental Trading Corporation Ltd. in Chicago, USA. The ends of the rope would be threaded through the matching and hooked onto the machine's claws on the other side. The machine's handle would be rotated manually, which would twist the rope ends together, entwining them to make one thick rope.This manually operated rope-making machine is a labour saving devise used particularly by sailmakers in their rigging and ropework tasks. Rope-making machine, metal. The model is "The New Era Rope Machine". The manually operated machine has three claws through which roping material is threaded. Internal wheels have cogs around their perimeter. The two pieces that make up the machine's case are bolted together. Made by Continental Trading corporation Ltd Chicago USA. The machine was patented on 18th July 1911."The New Era Rope Machine" " Continental Trading Corporation Ltd Chicago USA" "Patd july 18 1911" "Made in USA" "Keep oiled"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ropework, the new era rope machine, patented, 1911, textile machine, continental trading corporation ltd., chicago, rope-making machine, textile industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageNail, circa 1810

This copper nail, sometimes known as a ‘Dumpy Bolt’ or spike, was salvaged from the hull of the wreck of the “George III”. It dates back to at least 1810. It was found by an abalone diver on the south east coast of Tasmania. The nail would have been used to hold the layers of the ship’s keel frame and the planking together. The nail has been passed from the abalone diver to an interested business man on a trip to the south of Hobart, on again to the business man’s close friend who then donated it to Flagstaff Hill Maritime Village. The metal of nails such as this one, after being in the sea for a long time, become affected by the natural reaction of the sea water, causing it to degenerate and thin, and the stress from the force of the sea over the years alters its shape. Iron nails had been used on ships previously, but they quickly corroded in the salt; ships needed regular, costly and time-consuming maintenance to replace the iron nails. Towards the end of the 18th century the British Navy trialled the use of copper nails, finding them to be very successful. Merchant ships began to adopt this process in the early 19th century, although it made ship building very expensive and was more often used for ships such as the “George III” that sailed on long voyages. The three masted sailing ship “George III” was a convict transport ship built in Deptford, England, in 1810. On 14th December 1834 she left Woolwich, England, bound for Hobart Town, Van Diemen’s Land (Tasmania), under Captain William Hall Moxey. She was carrying 220 male convicts plus crew, guards and their families, totalling 294 persons (another 2 were during the voyage). Amongst the cargo were military stores including several copper drums of gun powder. On 27th January 1835 the “George III” was near the Equator, about half way into her journey. A fire broke out and the gun powder was in danger of explosion, threatening the whole ship. Two convicts braved the heat and smoke, entered the store and seized the gun powder drums, suffering burns for their efforts but saving a probable disaster. The fire destroyed some of the provisions and food was scarce. Many became ill with scurvy and some died during the journey. Nearing the end of their journey on 10th April 1835 the “George III” was headed through the D'Entrecasteaux Channel, south east Tasmania, between the mainland and Bruny Island. She was sailing in the moonlit night to hasten her arrival in port due to the great number of sick on board. She struck uncharted rocks, known only to the local whalers, between Actaeon Reef and Southport Lagoon and within hours began to break up. The ship’s boats were used to first rescue the women and children. Firearms were used to help quell the panic of the convicts below decks and some were killed by the shots. Many convicts, including the sick, were drowned. In all, 133 lives were lost including 5 of the crew, guards and their families. It was the third worst shipping disaster in Tasmanian waters. A monument in honour of the prisoners who perished in the “George III” has been erected, noting the date of the wreck as “Friday 10th April 1835.” (NOTE: there are a few differences between sources regarding dates of the shipwreck, some saying March and others April 1835. There are also differences in the figures of those on board and the number of lives lost.) The copper nail is significant as an example of sailing ship construction; fasteners used in the early 19th century on ships carrying convicts to Australia. The nail is also significant for its association with the ship “George III”. The “George III” is registered on the Australian National Shipwreck Database, ID 7195 as an Historic Shipwreck. She is the third worst shipwreck in Tasmanian waters. She is also associated with Early Australian History and the transportation of convicts to Australia. The incident of the fire on board and the bravery of the convicts in making the gun powder safe is an example of the social character of the people in early Tasmanian colonisation. Copper nail (also called a Dumpy bolt or spike) from the convict ship George III, wrecked in 1835. Nail is long, bent in an ‘L’ shape about 3/5ths along, tapering from both ends to the bend. Both ends are flat and do not taper to a point, nor have a thread. The shorter end has been polished, showing bright copper. There is pitting along the nail and virdigris is evident on the longer, unpolished end. The nail is displayed with the longer section resting on a wooden board between two ‘U’ shaped uprights, the shorter section upright. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, george iii, ship construction, ship nail, 1835 shipwreck, 19th century shipwreck, william moxey, d'entrecasteaux channel, convict transportation, copper nail, dumpy bolt, spike, keel nail -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NORTH DEBORAH G. M. CO. N. L. - STATEMENT TO NORTH DEBORAH G. M. CO. N. L

Statement from F. W. Milne & Son, Merchants and General Engineers, Vine Street, Bendigo to North Deborah G. M. Co. N. L. Copy of statement for the month of July, 1958. Top of the page is printed with the name and types of goods and services. Statement is for repair to boiler feed pump, turn taper on end of rock drills to suit sample, make a mild steel cross head wedge to suit samle, supply of bolts, make dies and remove dent from tube of telescopic drill bar, make mild steel split clamp nut to suit sample, make 2 mild steel screws 2 1/2'' x 5/8'' with hexagon head 1'' across flats 1/2'' long and thread to suit sample. Statement is a typed, carbon copy. It has copy written in pencil under the typing.document, gold, north deborah g. m. co. n. l., north deborah g. m. co. n. l., statement to north deborah g. m. co. n. l., f w milne & son -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Brace and auger bit for fencing

Brace and eyed auger bits were used for boring deep holes into timber, providing space for mechanical fasteners, such as bolts or spikes. Made of iron, the pictured tool comprises a Jennings type, double twist auger bit with a threaded point to draw the bit into the wood. The other end of the shank is shaped as an eye and fitted to a hand brace. Sometimes simple cross-bars were used instead of a brace. The eye design provides greater strength than a standard auger bit. This tool’s cradle further secures the bit, preventing unwanted twisting during use. Since the late 1800’s, brace and eyed auger bits such as this were used for boring holes in fence posts, bridge building and other heavy construction.Bit bolted on and held with hook. Brace probably blacksmith made. Bit commercially made. May have been used vertically. Surface pitted.auger, fencing, brace, blacksmith, tool, tools, farm, farming, churchill island -

Coal Creek Community Park & Museum

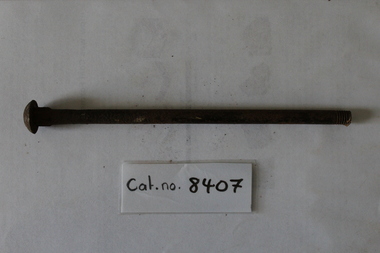

Coal Creek Community Park & MuseumLarge bolt

8407.1 - The bolt has a roughly cubic base beneath the head and a screw-thread at the other end. -

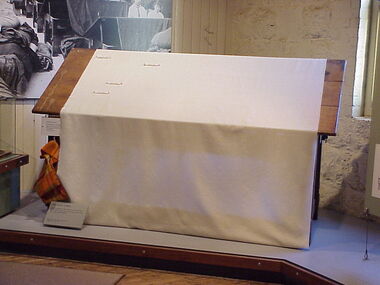

National Wool Museum

National Wool MuseumFunctional object - Mending Table, c1930

Any faults in the final product can be repaired by mending. Prior to more advanced machinery, fabric was draped over a mending table and carefully inspected for faults. Quick eyes and nimble fingers were needed. Repairing faults was a highly skilled manual operation. Any knot or thickness had to be removed without affecting the quality of the fabric and mending had to be invisible. In the 1930s to make the day pass faster, popular records were played to the factory workers in the mending room. The top of the table is propped up to make it a well-lit surface over which bolts of fabric were unrolled to check for faults. Menders repaired them with invisible hand stitching. Each weaver stitched a coloured thread in the selvage to show the start of their shift, therefore if mistakes were found the company could easily find who was responsible. This table was used by Gail Morris in teh 1960s. Large wooden table with tilted top. mending table, wool processing, fabric, textile industry -

Ballarat Tramway Museum

Ballarat Tramway MuseumFunctional Object - Trolley Ear hanger, c1900

Trolley ear hanger assembly that would screw into an trolley ear - internal insulation or cap and cone type - hanger - comprising 1 - cast steel hanger shaped in a cone with a mechanism to clip to the overhead span wires thread on the top. 2 - cast steel cap internally threaded 3 - Insulated shaft with a mica type appearance where damaged and a steel bolt with a steel nut at the lower end.overhead, trolley wire, fittings -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryBox, tool

Used to store tools and other assorted items associated with Maldon State Battery..1 storage box with compartments and lid, painted green, made from wood, leather and are chains attatched from box to lid, trapeze shape, .3 grooves on top of box parallel to wooden supports on lid, latch, nails and bolts attatching wood and inner compartments, leather straps on innner lid and inside main compartment for holding tools, main compartment contains torn newspapers, severed cloths, pieces of rock, pipe peices made of metal and plastic, assortment of metal pieces, paint lids, green bucket with grease, food packaging, tap/valve, metal mesh, leather and plastic pieces, 2 keys/padlocks, nails, nuts, assortment of tools, wooden pieces, wooden handle for screwdriver, broken chair, chalk, pieces of ceramic (Bendigo pottery) , pocket handle with inscription, bottle lids, plastic container, rope/belt for machines, piece of belt, broken canvas strap, peices of broken dark brown glazed textured pottery, large circular threaded joins, large elboiw threaded elbow joins .2 upper left compartment containing brush head, sandpaper and assorted rusty metal objects .3 upper middle compartment containing rusty weighing hook, rusty bolt and scrap metal .4 upper right compartment containing broken tan pottery, rusty threaded T join, unknown green paper with inscription .5 lower left compartment containing white cotton waste, assorted circular rusty metal objects, assorted rusty nails and washers, orange lid with insciption, nut and bolt .6 lower left middle compartment containing unknown assorted metal objects, peice of broken clamp and felt .7 lower right middle compartment containing large rusty nuts and unknown rusty metal objects .8 lower right compartment containing assorted threaded rusty circular metal objects, rusty nut and bolt, metal pump part, rusty mobil oil tin 20litres, old newspaper scraps, -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet - CAC Aircraft assembly, Unified Black Hexagon Bolts, Screws , Nuts ( UNC & UNF Threads ) Heavy Series

Overview of standards for unified screw threads, circa 1950snon-fictionOverview of standards for unified screw threads, circa 1950sblack hexagon bolts