Showing 10 items matching "capacitor"

-

Federation University Historical Collection

Federation University Historical CollectionScientific Instument, Capacitor

DEFINITION microfarad Posted by: Margaret Rouse WhatIs.com Contributor(s): Kenda, Jack Clements The microfarad (symbolized µF) is a unit of capacitance, equivalent to 0.000001 (10 to the -6th power) farad. The microfarad is a moderate unit of capacitance. In utility alternating-current (AC) and audio-frequency (AF) circuits, capacitors with values on the order of 1 µF or more are common. At radio frequencies (RF), a smaller unit, the picofarad (pF), is often used. This unit is equal to .000000000001 (10^-12) µF. In RF scenarios, capacitances range from about 1 pF to 1,000 pF in tuned circuits, and from about 0.001 µF to 0.1 µF for blocking and bypassing. At audio frequencies (AF), capacitances range from about 0.1 µF to 100 µF. In power-supply filters, capacitances can be as high as 10,000 µF. Capacitor, 1/3 M.F.D. (microfarad) within wooden insulating box. Two terminal posts set in an insulating box. Maker's name and place 1/3 M.F.D No. 34402scientific instrument, capacitor, electrical engineering, laboratory -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Cyclotron accelerator

Builit in 1950s and used till the mid 1970s within the Physics Department used in Melbourne. John Rouse and David Caro was involved in the construction.Black and white photo of cyclotron (nuclear physics accelerator): R.F. power amplifier - tank coil & tuning capacitors. Sticky typed labels on back from top and left to right: “VIEW INSIDE FINAL AMPLIFIER SHOWING TANK COIL & TUNING CAPACITORS” -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumPhotograph, Cyclotron accelerator

Builit in 1950s and used till the mid 1970s within the Physics Department used in Melbourne. John Rouse and David Caro was involved in the construction.Black and white photo of cyclotron (nuclear physics accelerator): R.F. power amplifier - tank coil & tuning capacitors. Duplicate of 190. Sticky typed labels on back from top and left to right: “VIEW INSIDE FINAL AMPLIFIER SHOWING TANK COIL & TUNING CAPACITORS” Handwritten in pen in bottom right hand corner: “RF Power Amplifier” -

Plutarch Project

Plutarch ProjectMachine - Shortwave Radio Antenna, Active Antenna, circa late 1980's

This antenna was used between 1989 and 1990 to help receive the daily news service in the Greek language directly from Athens, Greece. At the time, news from Greece for the Greek people in Australia were arriving in Melbourne a week late, on newspapers from Athens sent through air-mail. These newspapers were displayed at Salapatas and Carras newsagents at Lonsdale street in Melbourne. One thing that was a problem for this service was that the news came at least 7 days late. Using the Shortwave Antenna we could get the latest news from Athens on shortwave radio directly and within an hour these news were recorded on a cassette tape and taken to the Tricom Group P.L. offices in Melbourne (1155 Malvern Road, Malvern 3144). The tape was loaded onto a system which allowed people to call a local phone number and listen to the latest news with a cost of a local call, or a little bit more. As this was prior to the Internet being established around the globe, it was the fastest news service directly from Greece, in the Greek language. It was used for a span of about 12 months, until Tricom closed down their dial-in services, sometime in 1990. The service was captured and loaded onto the system by Iakovos Garivaldis, then an employee of the Tricom Group which was a subsidiary of Southern Cross TV.The Primary significance of this object is of its historical value, social and informative value for the first generation of Greeks in Victoria"World Tuner AT4 SW" antenna with a 920mm fully extended aerial, a tuned circuit and two transistors to prevent loading of the antenna and boost signal output. It is made of plastic, black in colour with the aerial being made of steel. The signals picked up by the antenna are fed via a 15pF ceramic capacitor to a tuned circuit consisting of either VC1a or VC1b and either L1, L2, L3 or L4. The slider switch S1 selects the band to be tuned. The band range is normally from 3 to 30MHz. When S1 is in position A, L1 and VC1a are selected and the antenna can be tuned from 3-9MHz. Similarly positions B, C, and D select higher frequencies up to 30MHz. It was purchased by Iakovos Garivaldis for this use for $119.WORLD TUNER AT4 SW "Amplituned" Shortwave Antennaantenna, radio, short-wave, language, greek -

Federation University Historical Collection

Federation University Historical CollectionBook - Log Books, G. Beanland, Log-Books of Yarraville Laboratory, 1952-1954, 1952

Graham Beanland's logbooks for the Electrical Branch Hydro-Design Section. Beanland was later the Principal of the Ballarat School of Mines. Four foolscap books with handwritten notes. .1) includes Richmond Power Station, Midworth Statino Load Indicator Transmitter, Thomastown Experimental Line (220v), The story of Richmond, Power factor curves, dryout of 6.6. KV motor, etc .2) Pressure Tests at Mt Waverly Pump Station, Shunt capacitor Bank for Bendigo, Shepparton Main Substation, Boronia Level Crossing - Supply continuity. commissioning Warragul Main Sunstatin, Tests carried out on Sedgewick installation, Bendigo Main Substation, MMBW Instalation at McVeighs, The South-Western Story, etc .3) History of Kiewa Hydro Scheme, Kiewa Scheme Layout Plan, Kiewa No. 4 Main Transformers, Motor operatied Power-Station lift, etc (included flyers "Power From Kiewa" and "White Coal", etc .4) Newport B and C Power Station, Yarraville Maintenance Workshops, Richmond and Brusnwick Terminal Stations, Rubicon-Eildon Area, Kiewa No.3 Power Station, etc.graham beanland, electricity, kiewa power station, newport power station, yarraville, richmond terminal station, brunswick terminal station, white coal, coal, boronia level crossing lights -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Federation University Historical Collection

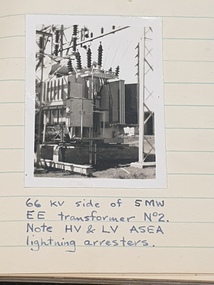

Federation University Historical CollectionMagazine, ASEA magazines, 1953/58, 1953 to 1958

collected by Ballarat School of Mines Principal G.H.BeanlandMagazines bound in ASEA folder, blue spine and black cloth boardselectrical engineering, generators, graham beanland, power stations, voltage control, electrohydraulic governor for water turbines, high voltage dc transmission, oil-minimum contraction circuit-breakers, lightening arresters, air-blast circuit breakers, testing circuit breakers, closing mechanisms for high voltage circuit-breakers, outdoor isolators, series capacitors, capacitor voltage transformers, guide to current transformers, routine testing of power tranformers, generator -

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumStandard Capacitor Nalder Bros & Co

No. of pieces: one object recessed into wooden box with detachable parts. Handmade wooden box enclosing a machine molded solid metal object. Plastic machine molded attachment. Gold electroplated metal, wax-matte hand polished wooden box, plastic has either been polished or had a varnish polish added to the surface. Detachable brass elliptical stopper, two brass butterfly screws, two hook latches attached to outside of box to secure object for transport. Polished wood surface, possibly wax coated. Brass metal coated with gold patina/electroplating. Plastic component either polished or coated with gloss varnish. Inscribed on top of the object, in the wooden box: “MICROFARAD/NALDER BROS & CO/WESTMINSTER/No 1509” Paint dot approx. 1.0cm in diameter on top face of wooden box, back edge, towards the right. -

Moorabbin Air Museum

Moorabbin Air MuseumAdministrative record (item) - ASTA Systems; Category 1 Approved Suppliers; Category 2 Approved Suppliers; Category 3 Approved Suppliers; Category 4 Approved Suppliers; Category 5 Approved Suppliers; Category 6 Approved Suppliers;Category 7 Approved Suppliers; Category 8 Approved Suppliers; Jindivik; Aerials; Alternators; Air Conditioners; Aluminium Extrusions; Batteries; Bonding Leads; Brass; Boxes & Racks; Cable Ties; Capacitors; Conduits & Fittings; Connectors; Connector Accessories; Copy Services; Specifiations; Bob Nash, ASTA Systems; Category 1 Approved Suppliers; Category 2 Approved Suppliers; Category 3 Approved Suppliers; Category 4 Approved Suppliers; Category 5 Approved Suppliers; Category 6 Approved Suppliers;Category 7 Approved Suppliers; Category 8 Approved Suppliers; Jindivik; Aerials; Alternators; Air Conditioners; Aluminium Extrusions; Batteries; Bonding Leads; Brass; Boxes & Racks; Cable Ties; Capacitors; Conduits & Fittings; Connectors; Connector Accessories; Copy Services; Specifications; Bob Nash

-

The Ed Muirhead Physics Museum

The Ed Muirhead Physics MuseumCapacitor Bridge H.W. Sullivan

Wood cut and dove tailed, screwed and adhered; plastic moulded, screwed and adhered. Metals cast, forged, machine cut, screwed and adhered. Wood coated (painted varnish). Inscribed on upper face along right edge: H.W. SULLIVAN/LONDON; painted on upper face along front edge: UNIT 10-9 F; painted on front face: PART III and “F” carved into the wood below “Part III”; [Stamped] upper face along left edge: NAT.PHIL.LAB./NO 55/UNIV. OF MELB; adhered label on left side face: PA 4.