Showing 7 items matching "clock components"

-

Melbourne Tram Museum

Melbourne Tram MuseumFunctional object - Clock components, c1930

... Clock components...Clock components - clock face - white background, black... Trams tramways Bundy clock Clock components - clock face - white ...Clock components - clock face - white background, black markings for each minute, and black numerals 1 to 12 - from a Bundy clock. Has number "26" in the middle of the number 6 indicating the clock it came from. Made from a circular sheet of metal, with four screw holes on the outer edges and three holes, one for the hands and two for the keys.trams, tramways, bundy clock -

Melbourne Tram Museum

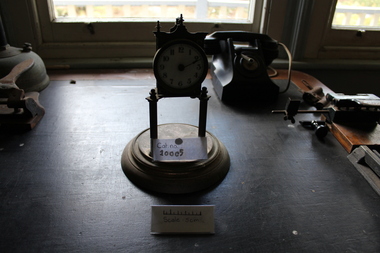

Melbourne Tram MuseumFunctional object - Clock components, Graeme Coates, 2019

... Clock components...Clock components - comprising two springs and part... Trams tramways Bundy clock Clock components - comprising two ...Clock components - comprising two springs and part of the pendulum of the Bundy Clock in the Training Room during the refurbishment of the clock by Graeme Coates during 2019. Returned to the depot 4/9/2019. Found that the springs were too strong for the mechanism - they have been secured with plastic cable ties - do not undo they could cause serious injury. The pendulum was too long - shortened by 72mm, consists of an oval shaped piece of wood and sealed. Notes from Graeme: 1 - wind both springs at the same time 2 - always wind the hands forward to adjust the time 3 - the timing mechanism can be set by hand, the time is on the opposite side to that shown on the case.trams, tramways, bundy clock -

Mont De Lancey

Mont De LanceyDomestic object - Mantel Clock

... clock components... by Harold and Jean Parker. clocks timepieces clock components clock ...The mantel clock has a rich history that dates back to the 18th century. These smaller clocks were designed during an age when people wanted elegant timepieces that fit on mantels or shelves. Their compact size and decorative designs made them a popular choice for homes of the time. They graced the mantelpieces or tables in homes, serving as both functional timepieces and sophisticated decorations. These clocks often feature ornate wooden carvings and intricate designs, with their gentle ticking and chimes adding a cozy ambiance to living spaces. It was used by Harold and Jean Parker.An antique wooden mantel clock made in USA with an Australian made Duff brand oak case with a plain angled top with round shaped pillar styled sides. It has a white ceramic dial face with black digits and black metal hands. The dial is covered by a glass and gold trimmed covering that may be opened on the right side. Inside the case is a Waterbury Clock Co of USA key and the internal workings are visible. It is not in working order.'Duff' brand brass plaque on back of cover. The key has 'Waterbury Clock Co USA' stamped on it.clocks, timepieces, clock components, clock keys, mantel clocks -

Mont De Lancey

Mont De LanceyDomestic object - Mantel Clock, 1880's - 1920's

... Clock components... components Timepieces Clocks Mantel clocks A small vintage ...The mantel clock has a rich history that dates back to the 18th century. These smaller clocks were designed during an age when people wanted elegant timepieces that fit on mantels or shelves. Their compact size and decorative designs made them a popular choice for homes of the time. They graced the mantelpieces or tables in homes, serving as both functional timepieces and sophisticated decorations. These clocks often feature ornate wooden carvings and intricate designs, with their gentle ticking and chimes adding a cozy ambiance to living spaces.A small vintage decoratively carved dark timber steeple mantel pendulum clock with a white cardboard face, black roman numerals and black metal hands. There is a brass trim around the face. The turned wooden frame at the front has has It is in working order. The very ornately white painted pattern on the glass door has a leaf and floral pattern. The door opens with a small decorative brass catch to reveal the inner workings. It has an ornate hanging brass pendulum and the internal workings are visible.There are two spirit plumb levels inside, one is aluminium metal and is attached to the wall. There is a brass key which does not wind the mechanism. clock keys, clock components, timepieces, clocks, mantel clocks -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side -

Learmonth and District Historical Society Inc.

Learmonth and District Historical Society Inc.Mantle Clock, "circa 1910"

... the firm produced all components of their clocks including... to succeed an older private firm who made clocks under the name ...Founded in1903 when William E.Sessions and some of his family took over E.N.Welch Co. in Forestville. E.N.Welch Manufacturing Company used a local foundry to produce their castings. The foundry owner's son,William E.Sessions, took an interest in horology and ,along with other Sessions family members, bought controlling interest in the E.N.Welch Company., which was a joint stock corporation formed July 6th 1864 to succeed an older private firm who made clocks under the name of E.N.Welch. Elisha N. Welch (1809-1887),had been making clocks at a factory on East Main Street Forestville Conneticut after taking over J.C.Browns bankrupt business around 1856.Under William Sessions management the firm produced all components of their clocks including movements,cases,dials,artworks and castings.In 1930 the company expanded to produce electric clocks,timers for radios,televisions and other devices as well as their traditional brass mechanicial movements.In 1956 Sessions was absorbed by another company while retaining the name and in 1969 the business went into liquidation.Clock is made of black wood with Corinthian style columns,three set on each front corner. These are black metal, and show remains of gilt paint on top of columns.On the base of the clock is carved decoration with similar carvings on each of the four corners of square around clock face.Dial is cream with Roman numerals. the hands are set in gilt centre piece.Below the 12 is the name WELCH.The glass dial cover is edged in gilt. It is spring wound and has settings-day/night,1/2 hour strike(hour on gong -1/2 0n bell), Cathederal Gong, turn back hands. THE SESSIONS CLOCK COMPANY. Successors to the E.N.WELCH MANUFACTURING COMPANY.Forestville.Conneticut.United States of America.mantle clock, the sessions clock company, forestville conneticut united states of america -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumClock

... Korumburra gippsland Missing 1 hand, Seized Missing Components (Gears ...Missing 1 hand, Seized Missing Components (Gears) Slight Rust