Showing 4 items matching "colonial boiler"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

... colonial boiler... called a colonial boiler. Steam boilers were used in factories... called a colonial boiler. Steam boilers were used in factories ...A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Federation University Historical Collection

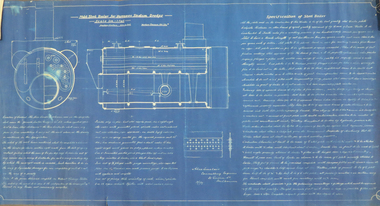

Federation University Historical CollectionPlan, Mild Steel Boiler for Yarrawee Suction Dredge, 16 January 1907

George Milford, a long term staff member of Thompsons Foundry Castlemaine, remembers discussing Alexander Sinclair with this son, Alex Sinclair Jnr. "When Alex Jnr was a boy, his father, a senior design engineer, was sent to Malaya to oversee the erection on site of a suction cutter dredge for Thompsons. This was an adaptation of the idea of a bucket-dredge, where gold is won from alluvial gravels. In the 1915-1920 era, the Thompsons Engineering Department designed a suction-cutter dredge, by which hydraulic suction with a revolving cutter at the end of a long proboscis would collect the alluvial soil and deliver it into the dredge for recovery of the precious metals. Export marketing was then ‘all the go’, and the tin dredges were ordered from Thompsons, using the new cutter design. The dredges were, of course, shipped to Malaya in pieces, ready to be assembled on site. A number of Thompsons employees were selected to travel to Malaya to assemble the dredges. There were fourteen men in the gang. These men sailed on 1st July 1925, their number including Delmenico, McKay and Charles Albert Hauser, an engine driver. C A Hauser died of malaria in Malaya shortly after arrival. Components for a further three of these dredges were in transit or on site when the first suction-cutter dredge was assembled and tested. The designers had failed to take into account the fact that, in the jungle floor in Malaya, many trees grow up, and fall down, in tropical conditions, and become submerged still waterlogged in the floor of the jungle, and in the tin-bearing gravels. The suction-cutter dredge was found to be inefficient in these circumstances, the price of tin had fallen and the Malayan client reneged on the contract. Faced with an outlay of over £4,000 on which no money would be received, the company went bankrupt on 25th August 1925. Alex Sinclair Snr was at that stage in Malaya, and received the news of the bankruptcy by telegram. Upon telegraphing his employers for funds to return home, he received the reply that there were no such funds available. Alex Sinclair Jnr told the story of how his father worked as a labourer in Malaya for two years, while his mother took in washing and ironing during the same period, until together they had assembled enough money to pay for his father’s return Anyone who talks about “the good old days” is talking nonsense!"Large blue printed paper plan outlining the conditions of contract for the making of a steel boiler. The Blueprint includes design drawings and written contract specifying materials, time frame and costs. Signed on front 'Alec Sinclair Consulting Engineer, 31 Queen Street, Melbourne'. Stamped on verso 'Printed by Paterson & Co, Colonial Mutual Chambers, Collins St, Melbourne'. blueprint, designs and plans, yarrawee suction dredge, conditions of contract, thompsons foundry castlemaine, george milford -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water standpipe, Langlands Bros. & Co, 1880-1893

This water standpipe is believed to be the only one of its kind in working order. It was originally located in Warrnambool, on the hillside at the corner of Mickle Crescent and Banyan Street, providing water for the Chinese Market Gardens below, on the flats. It was removed from this location on May 2nd, 1979, with the intention to relocate it at the new Flagstaff Hill Maritime Museum & Village. The standpipe lay in storage for years until the Warrnambool Company, Chemblast, offered to restore it for use as a working display. The display was officially opened on March 31, 2014. The water from the adjacent lake is drawn out with a hand operated water pump, and goes up into the standpipe, where flows through the canvas hose and into the top of the Furphy Farm Water Cart. The display is a visual acknowledgement of the years served by Flagstaff Hill volunteer and Friends of Flagstaff Hill Chairperson, Bob Crossman. Warrnambool’s early settlers had no water supply prior to the mid-1850s. They relied on rain water tanks, domestic wells and springs. The town experienced a huge, destructive fire in William Bateman Jnr. & Co.’s large produce store in November 1856, which highlighted the need for both a fire brigade and a good supply of water. In 1863 a volunteer fire brigade was established. In August 1880 the town celebrated the installation of its first water standpipe on the corner of Liebig and Timor streets. The water was pumped from springs at Cannon Hill through the connected pipeline to the standpipe, then distributed to households via horse and cart. Each of the licenced cart drivers were compelled by Council regulations to keep their carts full from sunset to sunrise, ready to cart water to outbreaks of fire. They received a fee for this service. In 1893 the town installed a water supply, sourced from the Merri River, stored in a reservoir basin and tower in north Liebig Street, and distributed throughout the town in a system of pipes. By late 1939 a reticulated supply was installed, with the water piped in under the Otway Scheme. Standpipes are still used in modern times in rural and remote areas for homes, farms, stock, agriculture and firefighting. Many commercial or government owned standpipes are metered, charging a fee for the quantities of water supplied. This water standpipe was made by Langlands Foundry Co. Limited, Melbourne, which was establish in 1842. It was Melbourne’s first foundry and iron shipbuilder, and one of the largest employers in Victoria at the time. Langlands was known for its high quality workmanship and wide range of goods for mining, engineering, marine, railway and other industrial uses. The company made the first cast bell, the first lamp posts in the colony, and the boiler for the first Australian train. In the 1860s it produced cast iron pipes for the Board of Works, which laid the pipes for Melbourne’s first reticulated water supply. The firm was bought by Austral Otis Co. in 1897.This water standpipe is significant historically as it is believed to be the only one of its type in working condition. The standpipe is significant for being manufactured by early colonial firm Langlands Foundry of Melbourne, which was known for high quality, cast iron products. The firm made the boiler for the first Australian train, assembled the first Australian paddle steamer and made the first Australian cast bell and lamp posts. Langlands was one of the largest employers in Victoria at the time. The standpipe is significant historically as it represents the evolution of water supply services in Australia. Standpipe; vertical cast iron water pipe, painted crimson, fixed in position, tapering inward from the round base to the rectangular joint near the finial on top. A hexagonal pipe extends at right angles from the joint, with an outlet fitting and flow-controlling wheel on the end. A length of canvas hose hangs from the outlet fitting. Inscriptions are on one face of the joint. The standpipe was made by Langlands Foundry Company of Melbourne. Embossed “LANGLANDS FOUNDRY CO. / LIMITED / ENGINEERS / MELBOURNE”warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, flagstaff hill, standpipe, stand-pipe, water standpipe, fire standpipe, firefighting equipment, water supply equipment, chinese market gardens, banyan street, liebig street, water tower, bateman’s fire, working display, water supply, town water, rural water, reticulated water, cannon hill spring, merri river, otway water, water carters, horse and cart water supply, volunteer fire brigade, langlands foundry, early melbourne, iron works, bob crossman, late 19th century water supply -

Clunes Museum

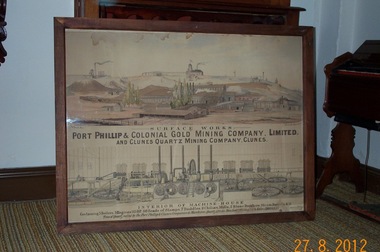

Clunes MuseumArtwork, other - FRAMED LITHOGRAPH

PORT PHILLIP & COLONIAL MINING COMPANY LIMITED AND CLUNES QUARTZ MINING COMPANY, THE MACHINE CONTAINED 5 BOILERS, 3 ENGINES 145 HP, 80 HEADS OF STAMPS, 7 BUDDLES, 2 CHILIAN MILLS & 2 STONE BREAKERS, STEAM VALVES. TONS OF QUARTZ RAISED BY THE PORT MINING & CLUNES COMPANIES TO MARCH 1880 1123365 TONS & GOLD 465,168 OUNCES, 7 DWTS, VALUE 1860, 925,54 POUNDS. EXHIBITED BY R.H. BLAND, CLUNES.LITHOGRAPH DEPICTING SURFACE WORKS OF THE PORT PHILLIP & COLONIAL MINING CO. LIMITED AND INTERIOR OF MACHINE HOUSE.local history, illustrations, lithograph, mining.