Showing 23 items matching "combustion of fuel"

-

Federation University Historical Collection

Federation University Historical CollectionBook, William Ripper, Steam, 1897

... combustion of fuel... condensers heat horse-power transfer of heat combustion of fuel ...This book was owned by Alf Gresham Johnston who was a former SMB mining student from the Ballarat School of Mines. He died at the age of 29 during military service in South Africa. The following is from the Federation Uni Honour Roll at http://federation.edu.au/about-us/our-university/history/geoffrey-blainey-research-centre/honour-roll/j/alfred-gresham-johnston-1872-1901 The October 1901 Ballarat School of Mines (SMB) Students Magazine reported 'Alf. Johnston's gone. The news came as a shock to all of us at the school. He who was with us a few short months ago, in all strength of sturdy manhood, has met a soldier's death in South Africa, and we sincerely mourn his loss…. His heart was in the school, and he did his best to further its interests … His last act on leaving Australian shores was to send a telegram from Albany to Prof. Mica Smith, to whom he was warmly attached, wishing the School and all connected with it "Good-bye". In his short, all to short, life of 29 years, he had more adventure than falls the lot of most men, and possibly the spirit of adventure, and also, of duty, prompted him to throw in his lot with the "colors," and leave for the front. The news of his death comes to us with added weight of sadness when we remember that he was one of the organisers of the School entertainment last year to help swell the fund for the erection of a statue to fallen Victorian soldiers.'A small red book with a double black line bordering the front cover, with the text Longmans Elementary Science Manuals on the bottom of the cover. On the back cover is an L&Co logoOn the title page is the inscription of the original owner of the book Alf G Johnston School of Mines Ballarat 1899. Inside the front cover and on page 19 is the stamp of the School of Mines Ballaratalfred johnston, steam engine, compound engines, condensers, heat, horse-power, transfer of heat, combustion of fuel, saturated steam, cranks and crank shafts, watt governor, boilers, alf johnston, william ripper, boer war -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Lights, paraffin lamp c1950, c1950

... . A flat-wick lamp has a fuel tank (fount), with the lamp burner... lamp has a fuel tank (fount), with the lamp burner attached ...A flat-wick lamp is a simple type of kerosene lamp, which burns kerosene drawn up through a wick by capillary action. A flat-wick lamp has a fuel tank (fount), with the lamp burner attached. Four prongs hold the glass chimney, which acts to prevent the flame from being blown out and enhances a thermally induced draft. The glass chimney needs a "throat," or slight constriction, to create the proper draft for complete combustion of the fuel; the draft carries more air (oxygen) past the flame, helping to produce a smokeless light which is brighter than that produced by an open flame. The lamp burner has a flat wick, usually made of cotton. The lower part of the wick dips into the fount and absorbs the kerosene; the top part of the wick extends out of the wick tube of the lamp burner, which includes a wick-adjustment mechanism. Adjusting how much of the wick extends above the wick tube controls the flame. The wick tube surrounds the wick, and ensures that the correct amount of air reaches the lamp burner. Adjustment is usually done by means of a small knob operating a toothed, metal sprocket bearing against the wick. A paraffin lamp with a green metal base to hold fuel with a side screw to adjust wick length. An opaque white glass shield sits in a metal frame attached to base* moorabbin, bentleigh, cheltenham, pioneers, early settlers, market gardeners, lights, lamps, paraffin, oil lamps -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRelative Humidity Meter

... for combustion. The amount of fine fuel available can increase rapidly... the availability of fuel for combustion. The amount of fine fuel available ...Bushfire behaviour is influenced by many factors including temperature, relative humidity (RH), forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), as well as fire size, shape and direction. Temperature and relative humidity have major impacts on fuel dryness and therefore upon the availability of fuel for combustion. The amount of fine fuel available can increase rapidly from nearly zero when fuel moisture content is more than 16% after rain or a heavy morning dew, to many tonnes per hectare as fuel dries out later in the day and the moisture content drops below 9%. This explosive escalation in the amount of available fuel can happen over a few hours on hot and windy days. This device is used for determining air temperature and relative humidity. It contains two thermometers, one of which is covered with a wick saturated with ambient temperature liquid water. These two thermometers are called dry bulb and wet bulb. Once the thermometers to reach equilibrium temperatures the two thermometers are quickly read. The figures are then used to convert the dry bulb temperature TDB and the wet bulb temperature TWB into humidity information. The wet bulb temperature is approximately equal to the adiabatic saturation temperature. Relative humidity meter in wooden box two stainless steel tubes contain wet and dry thermometers A small clock drives a fan motor in the base to circulate airforests commission victoria (fcv), weather, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionSling Psychrometer

... for combustion. The amount of fine fuel available can increase rapidly... the availability of fuel for combustion. The amount of fine fuel available ...Bushfire behaviour is influenced by many factors including temperature, relative humidity (RH), forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), as well as fire size, shape and direction. Temperature and relative humidity have major impacts on fuel dryness and therefore upon the availability of fuel for combustion. The amount of fine fuel available can increase rapidly from nearly zero when fuel moisture content is more than 16% after rain or a heavy morning dew, to many tonnes per hectare as fuel dries out later in the day and the moisture content drops below 9%. This explosive escalation in the amount of available fuel can happen over a few hours on hot and windy days. A sling psychrometer is a simple device for determining air temperature and relative humidity. It contains two thermometers, one of which is covered with a wick saturated with ambient temperature liquid water. These two thermometers are called dry bulb and wet bulb. When the sling psychrometer is spun rapidly in the air, the evaporation of the water from the wick causes the wet bulb thermometer to read lower than the dry bulb thermometer. After the psychrometer has been spun long enough for the thermometers to reach equilibrium temperatures, the unit is stopped, and the two thermometers are quickly read. A psychrometric scale on the side of the instrument is then used to convert the dry bulb temperature TDB and the wet bulb temperature TWB into humidity information. The wet bulb temperature is approximately equal to the adiabatic saturation temperature. The thermometers fold back into the plastic handle when not in use. Used to measure temperature and relative humiditySling PsychrometerBACHARACH INSTRUMENTS - Pittsburg PAbushfire, forests commission victoria (fcv) -

Greensborough Historical Society

Greensborough Historical SocietyBooklet - Recipe Book, State Electricity Commission of Victoria, Handy hints on cooking; issued by the State Electricity Commission of Victoria, Briquette Advisory Service. 1950s, 1950s

... Handy hints on cooking using a fuel or slow combustion... Plenty Lower Plenty melbourne Handy hints on cooking using a fuel ...Handy hints on cooking using a fuel or slow combustion cooker. In this booklet, briquettes are named as the fuel of choice; issued by the State Electricity Commission of Victoria. Briquette Advisory Service. Includes a variety of recipes and handy hints.Part of a collection of recipe books from Laurence N. Lewis37p. illus. Metal spiral binding.non-fictioncookbooks, recipe books, combustion ovens -

Greensborough Historical Society

Greensborough Historical SocietyBooklet - Recipe Book, State Electricity Commission of Victoria, Handy hints on cooking; from the State Electricity Commission of Victoria, Briquette Advisory Service. 1970s, 1970s

... Handy hints on cooking using a fuel or slow combustion... Plenty Lower Plenty melbourne Handy hints on cooking using a fuel ...Handy hints on cooking using a fuel or slow combustion cooker. In this booklet, briquettes are named as the fuel of choice; issued by the State Electricity Commission of Victoria. Briquette Advisory Service. Includes a variety of recipes, menu ideas and handy hints.Part of a collection of recipe books from Laurence N. Lewis49p. illus. (some col.) Plastic spiral binding.non-fictioncookbooks, recipe books, combustion ovens -

Greensborough Historical Society

Greensborough Historical SocietyBrick, Wooden road block, 1880s

... wood yards to be sold as fuel for open fires and combustion... and combustion heaters. As most of these blocks were sold for fuel ...Accompanied by article by Kevin Patterson (Nillumbik Historical Society) which explains the use of these blocks as a road surface in the City of Melbourne from the 1880s. The final wood blocks were dismantled in the 1950s and blocks sent to suburban wood yards to be sold as fuel for open fires and combustion heaters.As most of these blocks were sold for fuel, it is unusual to find one surviving. Block of timber cut to size and dipped in tar for use a a road block. wood blocks, paving, melbourne, road surfaces, tar -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Bay Steamers Maritime Museum

Bay Steamers Maritime MuseumBook, John Lamb, Questions & Answers on Diesel, Semi-Diesel and other Internal Combustion Engines, Air Compressors etc, 1940

Black cloth hardcover book of 365 pagesnon-fiction, heat, diesel engine, engineering, fuel -

Moorabbin Air Museum

Moorabbin Air MuseumManual - CAC Commonwealth Aircraft Corporation, rolls royce derby jet pipe combustion nene 3 engine fuel system tools

... rolls royce derby jet pipe combustion nene 3 engine fuel... Moorabbin melbourne rolls royce derby jet pipe combustion nene 3 ... -

Puffing Billy Railway

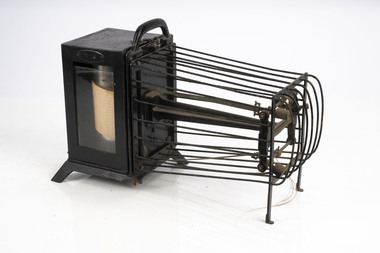

Puffing Billy RailwayBlackstone Oil Engine, 6 November 1908

8HP Blackstone Lamps Start Oil Engine engine number 71076 Engine Details Maximum operating RPM of 240. Fitted with a 3'9" Flywheel Tested on the 6th of November 1908. Shipped to Cluter buck South Australia for installation on concrete base. Recovered and restored during the 80's in South Australia Purchased privately in 2013 in Tailem Bend South Australia and transported to Victoria. Currently on loan to the Puffing Billy Museum at Menzies Creek as an operating exhibit. Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom. In 1896 they built lamp start oil engines. The Lamp or hot-bulb engine (also hotbulb or heavy-oil engine) is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine. Most hot-bulb engines were produced as one-cylinder, low-speed two-stroke crankcase scavenged units Historic - Industrial - single cylinder, horizontal, 4 stroke, hot-bulb ignition oil engine Blackstone 8HP Oil Engine made from steel, wrought iron and brassOval Plate with Black Stones and Clutter Buck Brass Plaque engine number 71076blackstone, oil engine, clutter buck, black stone, puffing billy, hit and miss, engine, blackstone & co -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

Geelong Naval and Maritime Museum

Geelong Naval and Maritime MuseumTeacup

The Orungal was originally built in Glasgow in 1923 for the Khedival Mail Steamship & Graving Dock Company of Egypt and named the S.S. Fezara. Due to the effects on steamship companies of the Great Depression including the steep costs of building new ships and increases in running costs and port charges, no new passenger ships had been ordered in Australia since before World War One. To meet demand for passenger berths, the Fezara (5826 tons) along with its sister ship the Famaka (5856 tons, renamed Ormiston), were chartered by the Australasian United Steam Navigation Company Ltd (A.U.S.N.Co.) in 1927. Both the A.U.S.N.Co and the Khedival Mail Steamship Co. were part of the P&O Group. The Orungal operated in this role as an interstate passenger and mail steamer between 1927 and 1940, being used mainly on the Melbourne to Queensland and Western Australian runs, with 240 single class berths. Following the outbreak of World War Two six of the nine large passenger liners servicing mainland Australian passenger and mail trades were requisitioned by the Government to ferry equipment, troops and supplies. Some of them were converted to armed merchant cruisers and used for patrol work and escort duties in the Indian and Pacific Oceans. The Orungal had originally been requisitioned by the government along with the Zealandia on 25 June 1940, to transport troops to Darwin, but was returned to commercial service because "of her unsuitability", perhaps too slow for the demands of the work. Despite being rejected for patrol and convoy duties the Orungal still had a vital role as one of only three passenger liners left to service the mainland Australian trade. Following its requisitioning by the Government shortly after war broke out, it had been fitted out with defensive armament. On its final voyage arriving at Port Phillip Heads from Sydney, Captain Gilling was attempting to enter the Heads ahead of a worsening south-westerly storm and, with a minefield known to have been laid in the area, had been warned by the Navy not to deviate from the swept channel. The captain and crew held fears that in the stormy seas a mine may have been carried away. In the worsening weather a blur of lights at Barwon Heads was mistaken for Port Lonsdale, and the Orungal steamed ashore onto Formby Reef, just east of the entrance of the Barwon River - instead of passing safely through the middle of the Rip. At the Marine Board Inquiry Capt. Gilling - who had been master of the Orungal since 1926 - stated that after becoming uneasy about his position and changing course to starboard one point: " At 10.21 pm I ordered the engine room to stand by and gave instructions for the patent log to be hauled in and for the sounding-gear to be got ready. Approximately two minutes later, in a flash of lightning, I saw land off the port beam. I immediately recognised it as Barwon Heads, and ordered the helm to be put hard to starboard, but the vessel struck before she had time to answer the helm" Barwon Heads and Ocean Grove residents were startled to hear the shrill blast of the ship's whistle, followed by the bright flares and explosions of signal rockets. The Queenscliff lifeboat crew, who had responded to the tragic collision between the Goorangai and another passenger liner the Duntroon in Port Phillip Bay less than 24 hours earlier, were later praised for their efforts in safely taking off all the passengers and crew. Most of the passengers were asleep at the time of the wreck, and were woken up by the commotion, the ship shaking "from stem to stern" and stewards ordering them to lifeboat stations in driving rain. It was a dramatic time with the ship siren wailing and distress rockets being fired. It was reported that "When it was found the ship was safe, the passengers all went to the music room. There they sang and danced for several hours. The ship's orchestra played merrily, and amateur performers among the passengers clowned, danced and sang to keep the laughter going. In the early hours of the morning passengers went to their cabins, most of them to sleep soundly while the keel grated on the rocks". At dawn the Queenscliff lifeboat arrived at the scene having been launched at 2.30am, and cautiously approached the ship which was being "battered by mountainous seas". By 5am oil from a burst oil line was helping to calm seas around the Orungal sufficiently enough for the lifeboat to approach, and all the passengers and crew were taken off in several trips by the lifeboat. A Court of Inquiry later found that the wreck was caused by an abnormal set of current to the north-west and cleared the officers and crew of neglect of duty. The sight of a huge liner almost on the beach saw an unprecedented amount of traffic as people drove an estimated 10,000 cars, using some 60,000 gallons of fuel in a time of strict petrol rationing, to see the spectacle. Salvage operations began in an attempt to refloat the vessel, scheduled for the high tide on 15 December 1940. However, during these operations, at 2.30 am on 13 December 1940, a major fire broke out, believed to have been caused by spontaneous combustion in the boiler room. The ship was soon ablaze, with smoke pouring from its hatches and ventilators, and at mid-morning the magazine exploded fiercely. Of the 60 men working aboard the vessel two were severely burned and had to be taken to Geelong Hospital. The gathered spectators witnessed the eerie sight of the ship's hull glowing red when night fell. The well-known building demolition contractor Whelan the Wrecker bought the salvage rights, and methodically proceeded to dismantle the ship and its fittings. The drama was not yet over for the wreckers when - without warning - the burnt-out hulk was 'attacked' by RAAF for strafing practice. Salvage rights were transferred to another private owner in 1963. By 1945 the combined effects of the exposed location, fire and salvage had seen what was left of the wreck disappear beneath the waves. The site today is marked by two of the four Scotch type boilers sitting upright and exposed at low tide, just north-east of the small boats channel at the entrance to Barwon Heads. Large sections of steel hull plating and framing, and impressively large pieces of ships structure and machinery including masts, booms, deck winches, propeller shaft, flywheel, and a thrust block lie scattered about and make the site an interesting shallow dive. It is interesting to compare the site of the Orungal with the intact remains of similar large passenger ships scuttled in deep water in the Ships' Graveyard, such as the Milora and Malaita. The site is subject to waves and surge, and is best dived on flat calm days The teacup originated from the SS Orungal and was likely used heavily in the ship's life as a passenger, mail and cargo carrier around Australia. The teacup is significant for its connections to SS Orungal and of this ships connected story of being sunk in extraordinary circumstances in the local region. A.U.S.N. Co. Ltd. Teacup salvaged from SS Orungal ss orungal, fezara, world war two, barwon heads, ocean grove -

Falls Creek Historical Society

Falls Creek Historical SocietyFunctional object - Peacock Hand Warmers

These mid-1960s Peacock and Gold brand lighter fuel hand warmers were used in Falls Creek to keep out the cold. The concept behind the hand warmer is that through combustion (ignition) of lighter fluid (light petrol distillate) it becomes a catalytic heater, relying on a catalysed chemical reaction to break down molecules and create heat. The devices could get quite hot, not hot enough to set paper on fire, but hot enough to give a nasty burn if sustained contact against your skin occurred. The construction of the device is very simple. There is very fine rolled wire mesh which fits on top of the reservoir body. After you fill the reservoir with lighter fluid, vapor pressure builds up. The device ignites by heating the grill with a match or lighter until it glows red. There is no open flame. The hand warmer also had a velvet bag to place it in after igniting to prevent direct skin contact. They were able to generate heat for up to a whole day. The Japanese company Yamato Shokai Ltd was founded in 1923 in the city of Osaka. Destroyed during air raids in 1945, the factory was rebuilt in 1946. They manufactured the Peacock brand pocket-warmer and sold it internationally.These items are significant because they were commonly used at Falls Creek.The pocket warmer is a small, relatively flat device with a tank at the bottom and a burner mechanism a t the top. "PEACOCK/MADE IN JAPAN" is engraved near the burner. The warmer fits into a metal case which features a series of ventilation holes in the shape of a peacock's tail. JAPANESE PAT. 237413.483177 MADE IN JAPANhand warmers, ski equipment 1960s -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Domestic object - Lantern - household

... for complete combustion of the fuel; the draft carries more air (oxygen ...This is a typical example of a flat wick domestic paraffin lamp used in households prior to the introduction of electricity.A flat-wick lamp is a simple type of paraffin lamp, which burns paraffin drawn up through a wick by capillary action. A flat-wick lamp has a fuel tank (fount), with the lamp burner attached. Attached to the fuel tank, four prongs hold the glass chimney, which acts to prevent the flame from being blown out and enhances a thermally induced draft. The glass chimney needs a "throat", or slight constriction, to create the proper draft for complete combustion of the fuel; the draft carries more air (oxygen) past the flame, helping to produce a smokeless light, which is brighter than an open flame would produce. The wick holder has holes around the outer edges. When the lantern is lit and a chimney is attached, the thermally induced draft draws air through these holes and passes over the top of the wick. This has a cooling effect and keeps the wick from over heating. The lamp burner has a flat wick, made of cotton. The lower part of the wick dips into the fount and absorbs the paraffin; the top part of the wick extends out of the wick tube of the lamp burner, which includes a wick-adjustment mechanism. Adjusting how much of the wick extends above the wick tube controls the flame. The wick tube surrounds the wick and ensures that the correct amount of air reaches the lamp burner. Adjustment is usually done by means of a small knob operating a cric, which is a toothed metal sprocket bearing against the wick. If the wick is too high, and extends beyond the burner cone at the top of the wick tube, the lamp will produce smoke and soot (unburned carbon). When the lamp is lit, the paraffin that the wick has absorbed burns and produces a clear, bright, yellow flame. As the paraffin burns, capillary action in the wick draws more kerosene up from the fuel tank. All paraffin flat-wick lamps use the dead-flame burner design, where the flame is fed cold air from below, and hot air exits above. (Source: Wikipedia accessed 24 Nov 2023) This lantern has a circular heavy green glass base for holding the paraffin. The base has a 12mm green glass handle. There is a small clear glass chimney with a fluted upper edge and some bubbles in the glass. The metal burner and wick holder has four metal prongs to hold the glass chimney in place. The round metal wick winder is functioning. There is a small amount of residual paraffin in the base. The flat wick is made of cotton.There are no markings to indicate the manufacturer.paraffin lamp, flat wick lamp, domestic lantern -

Mont De Lancey

Mont De LanceyDomestic object - Kitchen Stove, C. Andrews, c1900's

The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously, cooking was mostly carried out in the outdoors on open fires, and later in fireplaces indoors. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. A vintage cast iron kitchen stove set in the back wall of the Mont De Lancey Slab Kitchen. It has two steel decorative hinged doors with a handle to open and close. There is one pull out metal shelf in each compartment. Between the two doors is a round door which opens to reveal the wood box with a slatted base. This allows the ash and small coals from the fire to fall though to a pull-out tray below to be emptied outside when cooled. There is another lift-out kid to clean the ash and coals underneath.On the chimney plate 'Andrews, Patent Non Pariel' On the front of the stove below the round wood box 'C Andrews Geelong'cooking equipment, cooking stoves, fuel cooking stoves, domestic ovens -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Gas turbine engines, Gas Turbines for Aircraft

... turbine types Turbojets Turboprops Fuels Combustion Lubrication ...Technical history of the gas turbine engine for aircraft, circa 1958non-fictionTechnical history of the gas turbine engine for aircraft, circa 1958history & development, aircraft gas turbine types, turbojets, turboprops, fuels, combustion, lubrication, failures, maintenance, materials -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Gas turbine engines, Gas Turbines and Jet Propulsion

... components Combustion & fuels Metalliurgy Technical history of gas ...Technical history of gas turbine engines for aircraft & jet propulsion, circa 1955non-fictionTechnical history of gas turbine engines for aircraft & jet propulsion, circa 1955jet propulstion, thrust, gas turbine components, combustion & fuels, metalliurgy -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionThermo-hygrograph

... temperature, relative humidity (RH), forest type, fuel quantity... the availability of fuel for combustion. A thermo-hygrograph measures ...Bushfire behaviour is influenced by many factors including temperature, relative humidity (RH), forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), as well as fire size, shape and direction. Temperature and relative humidity have major impacts on fuel dryness and therefore upon the availability of fuel for combustion. A thermo-hygrograph measures and records both temperature and humidity. It produces a continuous record by drawing ink traces on a paper chart held in revolving cylinder. Humidity is measured by shortening or lengthening of specially treated horse hair. Temperature is measured by means of a bi-metallic strip. This particular instrument is a seven day recorder. The instrument is driven by clockwork. Thermo-hygrographNegretti & Zambra -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionThermo-hygrograph

... temperature, relative humidity (RH), forest type, fuel quantity... the availability of fuel for combustion. A thermo-hygrograph measures ...Bushfire behaviour is influenced by many factors including temperature, relative humidity (RH), forest type, fuel quantity and fuel dryness, topography and even slope. Wind has a dominant effect on the Rate of Spread (ROS), as well as fire size, shape and direction. Temperature and relative humidity have major impacts on fuel dryness and therefore upon the availability of fuel for combustion. A thermo-hygrograph measures and records both temperature and humidity. It produces a continuous record by drawing ink traces on a paper chart held in revolving cylinder. Humidity is measured by shortening or lengthening of a bundle of specially treated human hair. Temperature is measured by means of a laminated bi-metal strip of temperature-sensitive metals which bend differentially with temperature change. The recording drum is driven by clockwork which may be geared for rotation intervals of daily, weekly or monthly periods. This particular instrument is a seven-day recorder. Serial number 10186 which probably dates from about 1960. The chart indicates it was last used in March 1979.Used for bushfire research.Clockwork Thermo-hygrographCasella London 10186 Made in England Research Branch. Forests Commission Orbostbushfire, forests commission victoria (fcv), forest measurement -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Aircraft engines

... Aircraft engines Petrol engine peformance The combustion ...Overview of principles & results of research on internal combustion engines for aircraft engineers, circa 1941non-fictionOverview of principles & results of research on internal combustion engines for aircraft engineers, circa 1941petrol engine peformance, the combustion process, aircraft engine fuels, carburettors & fuel systems, superchargers, cooling of engines, altitude effect on engine power, engine temperatures, atmospheric pressures, radiators -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Rolls Royce Jet Engines, The Jet Engine

Description of working & underlying principles of aero gas turbine engines, circa 1966non-fictionDescription of working & underlying principles of aero gas turbine engines, circa 1966basic mechanics, working cycle & airflow, compressors, combustion chambers, turbines, exhaust system, noise suppression, thrust reversal, afterburning, fuel systems, water injection, lubrication, air cooling & sealing, starting and ignition, ice protection, fire protection, controls & instrumentation, powerplant installation, manufacture & overhaul, ground operation, v/stol, thrust redistribution, performance