Showing 6 items matching "electrical pole maintenance"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBelt Linesman Pole, circa mid to late 1900's

... electrical pole maintenance... generators electrical pole maintenance This thick leather linesman ...This linesman belt was used under the 1947 Electricity Regulations and before tighter Occupation and Health regulations (late 1990's early 2000's) were introduced that mechanical lifting platforms(wherever possible) replaced the belt up the pole method.The safety concern was that it required that tools needed by the linesman had to be placed in a large canvas bag and attached to the belt (extra weight) then the linesman had to climb the ladder. Ladders had to be at the correct angle and not able to "slip" from their initial footings. A full harness and a secondary fall belt is now mandatory for pole linesmen. The safety of fellow workers could be compromised if they were required to assist or recover the first linesman if needed. In 2006 an additional 269 registered lineworkers were employed. Please note that the terminology of linesman has become unisex. The linesman's belt enabled the linesman to place his feet against the pole adjust the belt (if needed) and lean back securely allowing both hands to be free to work with. This linesman belt is very significant to the Kiewa Valley due to the numerous poles and high voltage overhead power structures that needed maintenance for the extensive "mushroom" installation of electrical power polls(wood and metal). On high poles (steel) climbing pegs were welded on, however in the Alpine areas snow in winter caused an OH&S problem which were hard to overcome. The safety of a linesman when maintenance of electricity line on poles can be highlighted by the New Zealand linesman who survived an 11,000 volt shock when carrying out maintenance. For the record 11,000 volts is four times more powerful than execution by "the electric chair". The maintenance of the linesman's belt was his responsibility (keeping it clean and in "good" condition). Labour laws change this initial responsibility, from the linesman, to the employer. Climbing pegs were installed on higher poles that extended beyond the reach of ladders.This thick leather linesman belt is made from two lengths of heavy lengths of leather straps sewn together to make up 80% of the belt. The remaining 20% is "the belt tonge" which has eleven holes for three (solid steel tang) buckle connections.kiewa hydro electricity scheme, victorian state electricity commission, relays, generators, electrical pole maintenance -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWrench Coleman, circa 1950

The 1950's saw a revolution in small appliances for use in the average household. This hand held wrench was provided exclusively for the Coleman self heating kerosene (KVHS 0347A) iron and used for the regular changing the kerosene used in it. The iron was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation. Kerosene supplies were cheaper than electricity but also more inconvenient than electric. Electrical appliances become cheaper to buy and maintain in the later part of the 1900's and the now older kerosene iron was faded out.This wrench was required to open the fuel container which stored kerosene in the Coleman hand iron(see KVHS 0347A). This item was part of the maintenance requirement of this particular hand iron. In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival(use of this wrench was a part of rural life). The ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This item is a flat cast iron wrench, which has been specifically made for KVHS 0347A (kerosene iron). The wrench has four specific forms cut into the steel which fit firmly around their targeted nut and other fixtures. Also see See KVHS 0347B- Instruction sheet; and KVHS 0347D Fuel can.ironing, iron maintenance tool, domestic appliances, household -

Ballarat Tramway Museum

Ballarat Tramway MuseumEquipment - Taillight switch and fuse board, State Electricity Commission of Victoria (SECV), c1950

Item used to switch on or off the red tail lights circuit on a tram. Made by the SECV. The board was located next to the 6V battery that was used to power the tram tail lights when the trolley pole was being reversed under a passenger seat.. Demonstrates an item fitted to a tramcar to switch an external lighting circuit.Softwood wood board with a bakelite two pole switch marked "on" and "off" and a Federal 250V 15A rewireable ceramic fuse attached. Has remnants of cloth covered copper wire on the rear. See item 9024 for an associated drawing."12" in blue pencil.fuse, tram 14, tramcars, tramcar maintenance, electrical switching -

Ballarat Tramway Museum

Ballarat Tramway MuseumEquipment - Taillight relay and box, State Electricity Commission of Victoria (SECV), c1950

Item used to switch the power for the red tail lights circuit from the trolley pole to the battery circuit when the trolley pole was being reversed and not able to provide power to the internal and external lights. Made by the SECV. Salvaged from tram 14 during the project to renew the wiring and electrical arrangements of the tram. The box was located adjacent to the driver's windows and would click when the trolley pole was placed back on the overhead.Demonstrates an item fitted to a tramcar to switch an external battery tail lighting circuit.Wooden box made from softwood with bevelled corners, plywood top painted green containing an 8 Ohm "Post Office" type relay (see reference) fitted with two "break" contacts and associated insulated wiring soldered to the relevant contacts. See item 9024 for an associated drawing. Two examples held.fuse, tram 14, tramcars, tramcar maintenance, electrical switching -

Melbourne Tram Museum

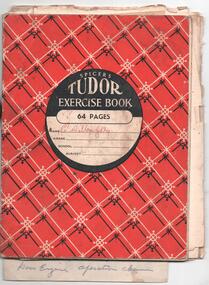

Melbourne Tram MuseumDocument - Notebook, Charlie Willoughby, personal notes on tramcar maintenance, operations, recovery etc of C. Willoughby, late 1950's to early 1960's

Exercise book with personal notes on tramcar maintenance, operations, recovery etc of C. Willoughby in a Spicers Tudor Exercise book - 64 pages with arithmetical tables on the rear cover. Topics covered: Rail Grinder - details on how to operate and maintain it North Fitzroy Dick Kerr, Clyde, K35 and RC2 Controller sequences and diagrams - notes on testing and faults Buzzer wiring diagrams Maintenance of trams interiors and rooves - items to be checked for Line Breakers Lighting Circuits Compressors Trolley poles etc Air operated doors Re-railing of Maximum Traction trams - 22E ditto for equal wheel bogies ditto when split points Use of false trucks Derailments on the Royal Park line Electrical equipment faults Adjusting Trolley Poles heights and tension Notes on truck types and braking Brake diagram summary, giving specifications and a list of relevant drawings Forms for the insulation testing of the Rail Grinders Checking motor leads and electrical equipment - written on the rear of a St Patrick's Day Procession notice for 1962. Advice from Neil Elfick, 23/6/2018 knew him when the Running Shed Foreman at Kew Depot.trams, tramways, tramcars, faults, controllers, 22e trucks, derailments, accidents, royal park, grinder, notices and information, st patricks day -

Ballarat Tramway Museum

Ballarat Tramway MuseumDocument - Training, "Safety First - Section 1", c1974

Document retyped from possibly an SECV training document titled "Safety First" outlining tram driving safety practices, awareness for motormen, electrical aspects, tram circuits, line breakers, insulated trams, trolley poles, light bulbs, broken trolley wires and fallen wires around trams. Section 2 - "instructions to be Observed by members and workers working on track maintenance". Possibly prepared for use by the BTPS, c1974.Demonstrates a Safety document for use by tramway crews and workers.Document - typed 6 Quarto pages - original.tramways, tramcars, operations, passenger services, ballarat, training