Showing 7 items matching "feeder cables"

-

Ballarat Tramway Museum

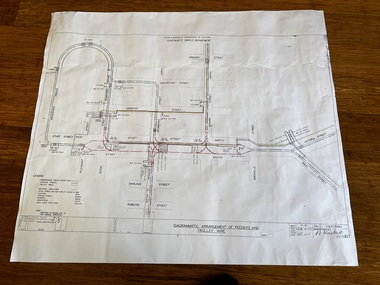

Ballarat Tramway MuseumDrawing - VB4/7184C, State Electricity Commission of Victoria - Ballarat office, "Diagrammatic Arrangement of Feeders and Trolley Wire", 2-9-1958

... Feeder cables... Trolley Wire Feeder cables Overhead Power Station electrical ...Print of drawing number VB4/7184C "Diagrammatic Arrangement of Feeders and Trolley Wire", marked up in colour showing the various feeder and trolley wire arrangements for the central part of Ballarat and the Gardens line. Shows the detailed switch locations that enable the overhead to be isolated or changed when electrical work was being undertaken on the overhead that required it to be isolated. Shows how the various sections were fed from the power station. Revision C issued 2-9-1958.Yields information about the arrangement of the power supply to the trams from the power station and changes made to the system about 13 years prior to closure. Dyeline print on white paper of Drawing - "Diagrammatic Arrangement of Feeders and Trolley Wire" - VB4/7184Ctramways, ballarat, secv, trolley wire, feeder cables, overhead, power station, electrical engineering, electrical switching -

Ballarat Tramway Museum

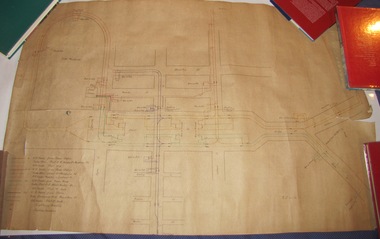

Ballarat Tramway MuseumDrawing, Electric Supply Co. of Vic (ESCo), Tramway Power supply arrangements 1914, Jan. 2014

... 1914, track map, power station, feeder cable, switches, section... station, feeder cable, switches, section insulators, box locations ...Yields information about the electrical power supply and overhead switching for Ballarat in 1914.Rolled drawing showing Tramway Power supply arrangements 1914, track map, power station, feeder cable, switches, section insulators, box locations, lightning arrestors and feeder cables for the various routes in Ballarat. Dated 2/1/1914, with initials GL. The various cables and trolley wire has been drawing in differing colours.ballarat, power station, overhead, section insulators -

Ballarat Tramway Museum

Ballarat Tramway MuseumPhotograph - ESCo cable or switch pillar, Robert Green, c1970

... ". This type of item was used to terminate and interconnect feeder... and interconnect feeder cables in both Ballarat and Bendigo. Yields ...Photograph - Black and white of an Electric Supply Co. pillar or switch box, cast iron, with the company on the side and on the base "The British Insulated Wire Co. Ltd Prescot England". This type of item was used to terminate and interconnect feeder cables in both Ballarat and Bendigo.Yields information about the ESCo switch or cable pillars.Black and white photograph on plain paperIn ink on rear "R Green photo" and "See composite caption" which has been crossed out.tramways, tramcars, esco, electrical switching, electrical equipment, british insulated wire company -

Ballarat Tramway Museum

Ballarat Tramway MuseumSlide - 35mm slide/s - set of 2, Eldon Hogan, Sep. 1971

... . Taken Sept 1971. Note the ESCo feeder cable panel... 1971. Note the ESCo feeder cable panel on the ground in front ...Set of two 35mm Agfa colour blue and white plastic mount slide - photo of Ballarat No. 40 reversing direction in Sturt St at the intersection of Drummond St, Hospital Corner to run out to Sebastopol. Taken Sept 1971. Note the ESCo feeder cable panel on the ground in front of No. 40 in 3025.2 All files transferred from disc to high res files 2/9/2009.tramways, trams, sturt st, drummond st, feeders, hospital corner, tram 40 -

Melbourne Tram Museum

Melbourne Tram MuseumDocument, The Met, "Overhead Appreciation - draft", 2/1995

... wire, pantograph operation and feeder cables. Has notes... operation and feeder cables. Has notes on the SCADA system ...Document - full title "Met Tram Overhead appreciation for Met Tram Officers & Tram Drivers" Gives a detailed inforamation on the structure of the tram overhead, its parts, poles, such as frog pans, crossing pans, points, contactors ,broken trolley wire, pantograph operation and feeder cables. Has notes on the SCADA system and Carlton Electrical control system. Written at the time when trolley poles remained in operation.Yields information about the Melbourne tramway overhead system.Document 47 A4 pages, clear plastic cover, with card covers comb bound along top edge.tramways, tramcars, equipment, overhead, electrical engineering, trolley wire -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Specification, Melbourne & Metropolitan Tramways Board (MMTB), "specifications - MMTB various", 1922 to 1925

... 195 Supply of Low tension feeder cable Not dated 194 Supply... jacks 6/12/1922 195 Supply of Low tension feeder cable Not dated ...See image 2085i4 for tender re brake blocks detailing the type of cast iron and the Brinell hardness.Demonstrates MMTB tender documents of 1923.Manila colour file marked "Specifications" containing 25 different specifications of the MMTB 1922 to 1925. Not all dated, generally foolscap sheets either pinned or stapled. Dated Tender No. For supply of: 30/6/1925 157 Steel castings Not dated Ballast Hopper trucks 1923 Steelwork for electric and cable tramway crossings Pamphlet Monier Pipes and box culverts Pamphlet Monier – septic tanks and aerators Not dated 229 Purchase of removal of cottages 101 to 107 Bouverie St Carlton Not dated Side tipping ballast trucks 18/7/1923 226 Brake shoes - see pdf file for a full scan 18/7/1923 222 Steel tramway tyres 18/7/1923 220 Concrete Mixing Plants Not dated 219 Dressed wooden poles 9/5/1923 215 Bricks 19/4/1923 214 Reinforced Concrete fencing posts 20/3/1923 213 Tramway steel wire ropes 28/3/1923 212 Painting exterior of 673 Bourke St Melbourne Not dated 210 Alterations to offices at Rathdowne St depot Not dated 202 80lb steel rails and fishplates 5/1/1923 198 GE201 Motors 6/12/1922 197 Hydraulic pit jacks 6/12/1922 195 Supply of Low tension feeder cable Not dated 194 Supply of high tension cable 4/12/1922 188 Supply of hard drawn trolley wire 6/11/1922 186 Dressed wooden poles 20/11/1922 182 Steel Poles 20/12/1922 171 Erection and completion of new car depot Glen Huntly Roadtrams, tramways, mmtb, tenders, specification, trackwork, motors, cables, poles, ballast wagons, glenhuntly tram depot, brake blocks -

National Wool Museum

National Wool MuseumPicker

Wool picking machine designed to separate locks of wool before it is carded and spun. The picker opens the wool’s locks which makes it easier to send the fleece through a carding machine. It does this by teasing the fibres (which can also be done by hand just by pulling the lock structure apart), but a picker does this in bulk and much quicker than what can be done by hand. It is possible to spin fibres directly after the picking stage; however, it is usually more desirable to card and blend them with other fibres. Typically, at a textile mill, a picking machine can separate enough lengths of fibre for a full day’s work after just a single hour. It will also help to remove any vegetation matter or other any unwanted elements that may be present in the wool. The quality of the casting on this machine suggest that it was made locally, either in Australia or New Zealand. Mike Leggett, the donor of the machine, acquired it from New Zealand where the seller said it had been used by his father to pick wool to make hand stuffed horse saddles. Mike attempted to used it a couple of times to pick alpaca hair, but the speed of the attached motor caused damage to the fibres. The motor is thought to be an added attachment, sometime around the 1960s judging by its age, while the machine itself is thought to be dated around the 1920s. The machine works by inserting wool through the rollers. Initially there was a conveyor belt feeder system which was powered by the handle on the side. This conveyor belt has been removed however, most likely due to age and deterioration. Wool is now fed through the initial teeth and is met by a spiked rotating drum which works to separate the fibres. The separated fibres would then complete a loop of the drum before being dispatched somewhere below, around where the motor presently sits, at a rapid rate of speed. Typically this wool will be collected in a closet or large catchment area, as can be seen from the 8:47 minute marker in the linked video (link - https://www.youtube.com/watch?v=kMjx-t3tH3A). It is not apparent how the wool is collected with this machine. Red and green machine with four green legs currently attached to a wooden pallet with wheels for easy movement. The green legs lead up to a red central circular barrel from which many attachments are present. Also present on the wooden pallet is a small black motor which is attached by a rubber belt to the central drum inside the red barrel. The belt spins the wooden drum via a dark red circular plate attached to the side of the drum. On the other side of the red barrel, a green handle extends for turning the picker’s conveyor belt feeder system. Two green walls extend forward from the central red barrel, guarding either side of where the conveyor belt would have been. At the start of these walls is a wooden cylinder, which the conveyor belt would have wrapped around, followed by two interlocking gears which rotate and accept the fed wool. The red roof extends over the central cylinder from here, securing the wool inside and protecting hands from the heavily spiked internal wooden cylinder which rotates and separates (picks) the wool. Extending over the top of this red roof is a green handle which reaches to the back of the machine (not pictured). Here it accepts a weight to ensure pressure is always present for the initial feeder interlocked gear teeth. There are two large gear cogs on the rubber belt side of the machine and 3 small gear cogs on the handle side of the machine, all coloured green. A green handle is also present at the rear of the machine, below the location from which the weight is hanging. A power cable extends from the motor and there are two adjustable metal rods on the top of the machine, the purpose of these rods is presently unknown. Black texter. On top of drum. Wording: HG3707 Wording. Imprint: BRACEWIND BLYN On motor. Wording AEIwool picking, textile manufacturing, wool processing