Showing 15 items matching "forms of gearing"

-

Federation University Historical Collection

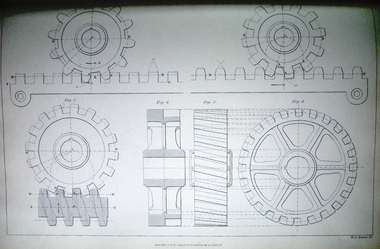

Federation University Historical CollectionBook, The Engineer and Machinist's Drawing-Book: a complete course of instruction for the practical engineer, Possibly c1887

... forms of gearing... projection, eccentric curves, various forms of gearing,tinting... projection, eccentric curves, various forms of gearing,tinting ...A large brown cloth hardcover book with black leather spine and corners. Title is engraved in gold on spine. Illustrated by numerous engravings on wood and steel, including select details, and complete machines. Illustrations in b/w. It includes a list of b/w plates, a table of contents, 116 p. of text and 112 p. of plates. This workwork provids instruction on drawing and illustrating heavy machinery including steam engines. It also contains lessons in drawings and examples of approved construction. non-fictionengineer drawings, drawing instruments, the sector, the lines of numbers, drawing of elementary forms, m le blanc, mm armengaud, linear drawing, projection, eccentric curves, machinery sketching, forms of gearing, projections of shadows, spur gearing -

Bendigo Military Museum

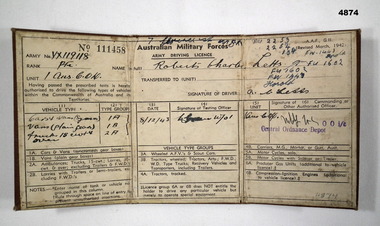

Bendigo Military MuseumAdministrative record - DRIVERS LICENCE, ARMY, Aust Army (AMF), Army Driving Licence

See Cat 4867.2 for dataA Brown buckram document. It is folded 3 ways to make a pocket sized document. Inside is white paper with both printed and written words. It is Army Form AAF G11 No. 111458.It was issued to VX119118 Pte Robert Charles Letts. It states he can drive cars and vans (synchronised gear box) Vans (Plain gear Box) All dated at 8 Dec 1943. Trucks 15 Cut and over.ww2, drivers licence -

Lara RSL Sub Branch

Lara RSL Sub BranchService Gear, Military Police Beret. Red, 1976

The Australian Army Provost Corps,was formed on the 3rd April 1916.It is responsible for battle traffic control, security duties, prisoner of war handling,the investigation of service offences,maintaining discipline and the running of military prisions. The red beret is a military beret worn by many Military police,para military,commando, and police forces.Red Beret with black grosgrain binding with the Royal Australian Corps of Military Police Badge at the front.29936 W02 RICH. BERET MNFRS.PTY.LTD.VICTORIA 1976 DSN 8406 66-089-5429 SIZE59.military police beret,berets,hats,lara r.s.l. -

Federation University Historical Collection

Federation University Historical CollectionBooklet - Booklet - BCAE General Information, ZILLES COLLECTION: Ballarat College of Advanced Education; A Guide including details of courses and requirements, costs and facilities

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Ballarat College of Advanced Education evolved over time with the merger of other sectors of Education in Ballarat. Ballarat College of Victoria and Ballarat Institute of Advanced Education merged in 1976 to form Ballarat College of Advanced Education. It remained as such until 1990 when it became Ballarat University College then in 1994 University of Ballarat. 2014 saw it change again to become Federation University. Booklet outlines details of courses, entry requirements, application procedures, costs and facilities. There is a tear-off section on Back cover that can be filled in and returned to the Information Officer, BCAE, Gear Avenue, Mount Helen.Small booklet with beige coloured cover, brown print and illustration. Sixteen pages stapled together.Symbol of Ballarat College on coverzilles printers, ballarat college of advanced education, course details, entry requirements, application procedures, costs, facilities, information officer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClocks, 1950

In 1865 James Jones Elliott of 156 Cheapside in the City of London, was apprenticed to a clockmaker"Bateman" of 82 St John Street, Smithfield, London., to learn the art of clock making. Initially, J J Elliott specialized in producing pinions and balance shafts for clocks. He eventually progressed to making, and patenting, a weight-driven movement which had chimes on tubes. This clock was very successful and resulted in considerable trade with America. James Elliott's son, Frank Westcombe Elliott, when he was 17 years old, went into business with his father after his father had bought a partnership with a jeweler called “Walden” of Brompton Road, London. In 1904, JJ Elliott died and Frank succeeded his father in clock making business. In 1909 company of JJ Elliott amalgamated with Grimshaw Baxter, and the factory moved to Grays Inn Lane, London, in 1911, followed by a further move, in 1917, to larger premises in St Ann’s Road, Tottenham, London. In 1921 the partnership with Grimshaw Baxter was dissolved and Frank Elliott joined a well-known firm of Bell Founders and Clockmakers, Gillett and Johnson Ltd, in Croydon. In 1923, two years later, he took over their clock factory and formed the famous company of F.W. Elliott Ltd. He was joined by his two sons, Leonard and Horace Elliott, who had served their apprenticeships in the trade. The third son, Ronald, joined the company in 1929. Elliott's started to produce clocks for the armed forces when war was declared in 1939, together with test gear and apparatus for the Rolls Royce engines used in the RAF planes. In 1944, Frank Elliott died at the age of 69 and Horace Elliott assumed the role of Managing Director. Whilst Horace controlled sales from a showroom in Hatton Garden. In 1952, Horace Elliott was elected Chairman of the British Horological Institute in the same year as Tony, one of Horace's sons, joined the company after he had completed training as a cabinet maker. Ronald Elliott died suddenly in 1966, at the age of 54, his son Peter continued to manage the company until 1998 when it ceased trading. An item that is now regarded as vintage, sought by horology collector’s worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by a well-known British clock manufacture. Its provenance is well established as the serial numbers on the clock indicate it was made in 1950. Production by F.W Elliott for this design of ships clock ceased in 1959. Clock has a gold color case with a 150 mm white painted dial and Roman numerals. The movement has a balance wheel escapement and a slow-fast timekeeping adjuster to the top of the dial. The back of the clock is stamped “made by F W Elliott Ltd of Croydon” and a serial number 21B/829, an additional number 994 is also stamped on the back casing. Thsi model clock finished production in 1959. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, f w elliott, maritime clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1920s

In 1902, William E Sessions and other family members purchased a controlling interest in the E.N. Welch Company, a clock manufacturer located in Forestville, Connecticut. Sessions' father owned a foundry located in the town of Bristol, Connecticut that produced cases for E.N Welch Co. On January 9, 1903, the company was reorganized and registered as The “Sessions Clock Company”. Within a few years the Sessions Clock Company was producing clock movements, cases, dials, artwork and castings for their line of mechanical clocks. Between 1903 and 1933 Sessions produced 52 models of mechanical clocks, ranging from Advertisers, large and small clocks with logos of various businesses, to wall, or regulator clocks, and shelf or mantel clocks, designed for the home. Many of the Session clocks from this period are prized by collectors. In 1930, the company expanded to produce electric clocks and timers for radios, while continuing to produce traditional brass mechanical movements. Beginning at the end of World War II Sessions W Model (electric) was widely used by various casting companies for their clocks. The dial of the W Model read Movement by Sessions. In the early 1950s Sessions begin to produce timers for television. In 1956, Sessions was absorbed by a company interested mainly in their timing devices. In 1959, William K. Sessions, grandson of William E. Sessions left the Sessions Clock Company and formed the New England Clock Company. In 1960, one of the Sessions Clock buildings was sold to the Bristol Instrument Gears Company. Kept as the Sessions Company, the new owners ran the operation until 1969 when changes in the market forced the Sessions Company into liquidation. In 1970, the remaining buildings were sold to Dabko Industries, a machine parts manufacturer.The item marks a time when clock production in America was at it’s peak producing clocks for sale in many countries, they were keenly priced, mass produced and available to all. The company had a relatively short life span life regards clock manufacture later diversifying into electric timer mechanisms. Yet it was perhaps inevitable with the advent of electricity along with stiff competition from other clock manufactures that would ultimately herald the end in 1935 of the Sessions company's ability to continue manufacturing mechanical clocks. Clock mantle type face set in a painted black case designed to represent a Greek building with gold decorative pillars. Free standing with decorative feet. No markings or inscriptions on clock case or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sessions, mantel clock, clock, clock industries -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Construction Site, n.d

Port of Portland Authority Archivesport of portland archives, steel girders -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Construction Site, n.d

Port of Portland Authority Archivesport of portland archives -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Equipment - Barbers’ Equipment, hair clippers steel 'Brown & Sharpe", c1940

1833 Brown & Sharpe was founded in Providence, Rhode Island by David Brown and his son Joseph R. Brown. David Brown retired in 1841 and Joseph Brown formed a partnership with Lucian Sharpe in 1853. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators ) and helped establish: The American wire gauge (AWG) standards for wire; The Brown & Sharpe taper in machine tool spindle tapers; and The Brown & Sharpe worm threadform for worm gears. .Like most machine tool builders, Brown & Sharpe rode a business cycle roller coaster during 1920- 40. After being kept very busy during World War I, builders suffered a slump in the post–World War I recession and depression of 1920–21. The Roaring Twenties brought renewed sales, but then the Great Depression slashed them. The armament-build-up period of 1936 to 1940 again renewed machine tool activity, and then the World War II materiel effort exploded demand, pushing it to record heights and employed 11,000 workers. Brown and Sharpe machine tools were a mainstay of American metal manufacturing until the late 20th Century and could be found in most machine shops and factories that worked with metal. Brown and Sharpe made callipers and micrometers that were essential to products built to fine tolerances. Shortly after World War II, Henry D. Sharpe, Jr. succeeded his father as president of Brown & Sharpe Manufacturing Company, at which point it evolved into a new and modern company built, or at least designed, to last. The firm stopped producing its old stalwarts: sewing machines, hair clippers, and certain categories of machine tools and employment dropped to 3,500 in 1976. Due to industrial disputes in the 1980’s B&S started focusing more on developing Coordinate-Measuring Machines. The company began to lose money as it shifted production away from machine tools and toward advanced metrology equipment, losing $14.6 million in 1990 and employed only 700. In 1994 Brown & Sharpe acquired DEA of Italy, an established manufacturer of CMMs. In 2001, substantially all of the assets of the Brown & Sharpe Manufacturing Company, including the intellectual property, designs, trademarks, facilities and inventory, were acquired by Hexagon AB, Switzerland, without the acquisition of the Brown & Sharpe Manufacturing Company itself. A set of manual barbers’ hair clippers with an adjustable wing screw, from Brown and Sharpe, Manufacturing Company Ltd., Providence, Rhode Island, USA. Chrome plated, in fair condition, c1940on Right handle; MADE BY BROWN & SHARPE MFG. CO. POV. R.I. / PAT'D IN GREAT BRITAIN, EN FRANCE, S.G.D.G. / U.S.A. PATENTS JULY 1-79, JUNE 3-84, AUG 23- 92 on top blade ; BRESSANT / TRADEMARK on base of lower blade ; No. 2* barbers, hairdressers, hair clippers, brown and sharpe manufacturing company, providence rhode island, hexagon ab, switzerland, great britain, france, ww1 1914-1918, ww11 1939-1945, great depression 1930, micrometers, tools, precision instruments, brown david, brown joseph r , sharpe lucian, sharpe henry d jnr, american wire gauge standard, sewing machines, metrological tools, worm gears, spindle tapers, screw machines, moorabbin, bentleigh, cheltenham, city of moorabbin industries, -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Article, 25th Year Celebrations, 1993

25 Year Celebration of Mitcham based Maroondah Singers, established 1968, in the form of a Concert at Nunawading Arts Centre.25 Year Celebration of Mitcham based Maroondah Singers, established 1968, in the form of a Concert at Nunawading Arts Centre. The Choir commenced through the interest of Mervyn and May Vagg and George Irvine. Guest artists include recipients of the Maroondah Singers Memorial Scholarship (established 1990).25 Year Celebration of Mitcham based Maroondah Singers, established 1968, in the form of a Concert at Nunawading Arts Centre. choirs, maroondah singers, vagg, mervyn, vagg, may, irvine, george, horner, viviene, barnfather, jenny, wishart, claire, morgan, joy, gearing, john, thomson, max -

Parks Victoria - Maldon State Battery

Parks Victoria - Maldon State BatteryConcentrating table

The table was used to separate gold from crushed quartz through vibration movement The Phoenix Foundry, part of James Martin and Company, was established by James Martin, MLC, often referred to as the “Father of Gawler”. The Phoenix Foundry was significant, historically, because it formed part of the leading engineering works in the state in the late nineteenth century when Gawler was one of Australia's most important industrial centres. The company was established in 1848 and ceased operation: in1907 Large Phoenix-Weir concentrating table. Rectangular green and pink painted table, inscription on one side with decorative motives, comprises of slatted table top which creates ridges, wooden channel which is bolted on table top, box with holes in base sitting loosely next to channel, table is joined to gear/s which in turn runs belt wheel, gear/s sits on unpainted concrete block, whole table sits on 2 concrete pillars which are raised, table top is tilted on an angle, wooden trough is on lower side of table and sits underneath which is sitting on rusty tins."the phoenix-weir jas martin & co/concentrating table sole makers/gawler. S.A" -

Melbourne Tram Museum

Melbourne Tram MuseumDocument, General Electric, GE 264 motor scheduled speeds data sheet

Document gives the data about scheduled speeds in miles per hour for General Electric GE-264 motors for stops per miles, gear ratios, and wheel sizes for form A and B motors. Has a table for truck or bogie data and weights. Enabled street car or tramway operators to select their equipment and motors. Demonstrates a GE data sheet to assist tramway engineers in their equipment selection.Data sheet typed on foolscap paper.tramways, tramcars, ge, general electric, motors, specifications -

Melbourne Tram Museum

Melbourne Tram MuseumLetter - Correspondence, Melbourne & Metropolitan Tramways Board (MMTB), "Trolley Buses", 1922-36

File containing correspondence between the MMTB Chief Engineer Mr. Strickland and various companies, including Railless Ltd, Australian General Electric, English Electric / Dick Kerr and its UK consultants Heap and Digby (H&D) between the period August 1922 and August 1936. Includes drawings, technical specifications, some of which are duplicated in the Reg Item 535 file. For a listing of the contents of this file and of Reg Item 535, see Related Documents - htd535-536list.pdf Item 536 - Trolley Buses Listed from top of file, in order found. Letters generally to/from MMTB Chief Engineer. Date Type Notes 7/8/1936 Letter from TE Barnes – re Bremen Germany Steam Omnibus. Three pages. On foolscap paper – rest quarto. Has been damaged. 3/2/1926 Letter from Bruce Henderson re transport in the Glen Eira Rd area – poor private bus. 25/10/1925 Letter to G. Higgins, regarding a paper he had presented and printed in Australian Municipal Journal about transport around Melbourne, predicted the demise of trams, trains. Notes Spencer St bridge. Copy of paper is pinned with letters. 28/819/22 Copy of letter to H&D from AEC (see above) Includes the Mexborough test gradient drawing. Undated Pamphlet from Railless Limited about Birmingham’s new trolley buses. 16/3/1923 Extract from Electric Railway and Tramway Journal – wages of trolleybus drivers not getting paid extra in Bradford. Two copies pinned together. 9/4/1923 Letter from H&D re pamphlet exchange You should have had it! 23/2/1923 Letter to H&D asking for information. Has a note re the Board’s attitude towards motor buses. 28/8/1922 to 24/23 Series of letters pinned together with L. de Koenneritz regard trolley buses and Paris. Noted that the MMTB did not have the legislative power to run trolley buses. 15/2/1922 to 10/4/23 Series of letters pinned together with the Aust. GE regarding trolley buses and references to their operation in journals. 10/1/1923 Letter from H&D re request for information on driving gear of Railless Ltd. vehicles 23/2/1923 Letter to H&D re above. 23/2/1923 Sheet of paper on “Steads Review” paper – pamphlet not yet to hand. 8/11/1922 to 10/1/1923 Series of letters with H&D pinned together asking for Railless driving gear – reluctant to provide. 26/9/1922 Letter from H&D, with copy of letter from English Electric enclosing materials regarding Trolley Bus equipment. Note much of this material is the same as that in Reg Item 535 contained within the green cloth tape. Performance curves for DK 26B motor Blueprint – 4449 – outline of controller DK, Type D, form B. Specification for DK 26B trolley motor. Blueprint – drawing 2810 – DK 26 Motor Blueprint – No. 1312D – controller diagram Pamphlet – EE – tramcar Type D automatic circuit Breakers. Publication No. 230, dated 9/1920. Ditto, Form A, drawings No 3565, 1/1/19. Performance curves for DK85A motor Blueprint – P2002M034 – DK85 Motor. EE specification for Traction Motor DK85 Modified from a tram motor. Blueprint – EE drawing – P2002M036 – DK85 motor with ball bearings. EE blueprint P2102F021, traction control wiring for form D controller. EE blueprint P2103F033 – outline of controller type SE1, form C and D. EE blueprint P2102Z011 – wiring diagram for type SE1 form controller. EE blueprint – P2102F025 – diagram of connections (wiring) for Type SE1, form D controller.trams, tramways, trolley buses, melbourne, mmtb, aec, heap and digby, english electric, railless, dick kerr, general electric -

Hymettus Cottage & Garden Ballarat

Hymettus Cottage & Garden BallaratWork on paper - Bookmark, Calendar Bookmark

A 1954 Australian Calendar Bookmark advertising a range of local businesses headed with the Victoria Lending Library and Gears Pharmacy. The preponderance of circulating lending libraries on bookmarks with general advertising of this era is significant in that this was probably the high point of a form of lending library that was popuar from the Victorian era until government supported municipal libraries took over the role by the 1960s.Nilballarat, gears pharmacy, victoria lending library