Showing 2401 items matching "foundries"

-

Federation University Historical Collection

Federation University Historical CollectionDocument, John Edward Skilbeck, Foundries of Ballarat's Past, c1950

... Foundries of Ballarat's Past...Foundries ...William Edward Skilbeck was a toolmaker with Ronaldson and Tippett, and creator of the Gold Centenary Monument in Sturt Street BallaratPhotocopied notes on Ballarat Foundries. Originals are held by Peter Skilbeck, and have been reproduced with permission.foundries, ballarat, john e. skilbeck -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph, Wright, Win, Front of Charlton Foundry 1963, c.1963

Charlton Foundry established 1885 by C. Munro, owned and operated by the Dabrons 1899 - 1965.Black & white photograph of the front of the Charlton Foundry. Alf and Ted Dabron and a dog sitting outside their business. Parked car on RH side of photo.The Charlton Foundry, Dabron Bros and Terry. Taken by Win Wright 1963munro, charlton, business, industry, foundry -

Puffing Billy Railway

Puffing Billy RailwayPhoenix Foundry Plate

Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112 The Phoenix Foundry (1857-1906) fabricated iron and brass products - including engines and pumping gear for the mining industry, locomotives, steam rollers, water pipes, water gauges and diverse small items. Throughout its operation the business was located at premises on Armstrong Street, Ballarat . Background In 1852, at the age of thirty-three and after a year of operating his own engineering business at Williamstown, Lancashire-born blacksmith and engineer George Threlfall (1819-1897) arrived on the Sebastopol gold plain and immediately undertook blacksmith work repairing picks and tools for the miners. Little did he know that this fledgling business would be the genesis of the most iconic business of nineteenth-century Ballarat. At approximately thirty-nine years of age, English mechanical engineer Richard Carter (c1814-1883) came to Australia on board the Arrogant - arriving in Melbourne on 19 April 1853. He soon travelled to the Ballarat goldfields. Born in the year 1830 in Belfast (Ireland), mechanical engineer William Henry Shaw (1830-1896) arrived in Australia in October 1853. He worked briefly with George Threlfall at Sebastopol, then moved to Geelong to manage the small foundry of Frederick Moore. Twenty-four year old English-born iron moulder Robert Holden (c1831-?) left his home in Belfast (Ireland) in late 1854 and travelled from Liverpool to Melbourne on board the James Baines - arriving in February 1855. Afterwards he joined his brother-in-law William Henry Shaw in Ballarat. History Foundation to Incorporation In March 1857 George Threlfall joined in business with Richard Carter, William Henry Shaw and Robert Holden. They relocated Threlfall's successful engineering enterprise from Sebastopol to new premises in Armstrong Street, Ballarat. This business was then known variously as the Phoenix Iron Works Company, Phoenix Foundry or Messrs Carter and Co. By 15 April 1857 they were advertising that they were open for business as engineers, millwrights, boiler makers, smiths, iron founders and brass founders. In January 1858 George Threlfall left the partnership. Incorporation to 1889 1890 to Closing locomotive Y112 Builder: Phoenix Foundry, Ballarat Builder’s Number & Year: 238 of 1889 Designer: Kitson & Co Wheel Arrangement: 0-6-0 No. in class: 31 Entered Service: 24 July 1889 Taken off Register: 11 May 1961 The origins of the Victorian Railways Y-class lay with the decision by Kitson & Co, Leeds to place a 0-6-0 freight locomotive on display at the Centennial International Exhibition, Melbourne in 1888, together with a 2-4-2T suburban passenger locomotive. This marketing initiative proved successful as the Victorian Railways were clearly impressed with these machines, with both purchased after the exhibition and becoming the patterns for new standard locomotive types. Thirty examples of the 0-6-0 heavy freight design were ordered from the Phoenix Foundry, Ballarat, becoming the Y-class for main line heavy freight duties, while the 2-4-2T design became the E-class for Melbourne suburban passenger duties (represented by preserved locomotive E 236). The Y-class prove successful in service and accrued high mileages. They were inevitably superseded by more modern and powerful steam locomotives and a number cascaded into shunting and yard pilot duties, often with the addition of shunters steps along both locomotive and tender. Y 112 was one of the last in service when withdrawn in 1961. Fortunately it was saved for preservation and plinthed in central Ballarat, ostensibly in commemoration of Phoenix Foundry. I understand it is owned by the Sovereign Hill Museums Association. During the 1980’s, Y 112 was leased to Steamrail Victoria and restored to operation at an industrial site in Ballarat. Y 112 features an attractive lined apple green livery and has performed various rail tours around Victoria since restoration. It is normally based at the Steamrail depot in Ballarat East. Y 112 is the only 19th century design in operational condition in Victoria and as such is one of the oldest working steam locomotive in Victoria . Historic - Phoenix Foundry Plate - replica Made about 2010 cast off original from locomotive Y112Phoenix Foundry Plate Oval shaped plate with an image of a phoenix centered at the top with lettering surrounding it.Phoenix Foundry No 238 Ballarat Company Limited 1889.puffing billy, phoenix foundry, ballarat, locomotive y112, phoenix foundry plate - replica -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph, Clarke Bros Photographers, The Charlton Foundry c. 1890, c.1890

Charlton Foundry building est 1885 corner of Learmonth and High Sts. Residence next door. Later Dabron's Foundry.Sepia photograph, mounted unframed of The Charlton Foundry Company, Late C.Munro, Engineers, Agricultural Implements Makers, Wheelwrights etc.. Ten people standing outside, seven men, a boy with a bicycle and two young girls. Long timber building with large chimney at the rear of the building, Machinery, wheels and horse drawn vehicles on display. Clark Bros Photographers 25 Thomas St Windsor. Charlton Foundry 1890munro's, charlton, industry, business, foundry -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Certificate, Castlemaine Health, C2010

Certificate Presented to Thompsons Foundry Band Inc. Castlemaine Health Certificate of Appreciation awarded to Thompsons Foundry Band In grateful acknowledgement for service provided to Castlemaine Healthcertificate -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Certificate, Castlemaine Health, C2010

Certificate Presented to Thompsons Foundry Band Inc. Castlemaine Health Certificate of Appreciation awarded to Thompsons Foundry Band In grateful acknowledgement for service provided to Castlemaine Healthcertificate -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Certificate, Castlemaine Health, C2010

Certificate Presented to Thompsons Foundry Band Inc. Castlemaine Health Certificate of Appreciation awarded to Thompsons Foundry Band In grateful acknowledgement for service provided to Castlemaine Healthcertificate -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionBellows

Used in FCV foundryFoundry Bellows -

Seaworks Maritime Museum

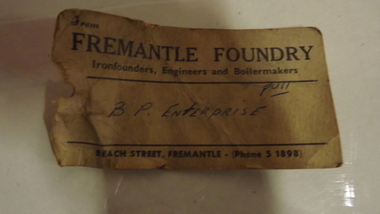

Seaworks Maritime MuseumMaker's tag for apparatus

Tag from Fremantle Foundry with pen annotationsFrom/Freemantle Foundry/Ironfounders, Engineers and Boilermakers/Beach Street, Freemantle - (Phone 5 1898)"/ Annotation; Full/B. P. Enterpriseport melbourne authority (pma) -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Certificate, Mount Alexander Hospital Castlemaine, C2010

Certificate Presented to Thompsons Foundry Band Inc. Mt Alexander Hospital Castlemaine Quality, Care and Commitment Certificate of Appreciation awarded to Thompsons Foundry Band In grateful acknowledgement for service provided to Mt Alexander Hospitalcertificate -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Certificate, Mount Alexander Hospital Castlemaine, 2006-10-02

Certificate Presented to Thompsons Foundry Band Inc. Mt Alexander Hospital Castlemaine Quality, Care and Commitment Certificate of Appreciation awarded to Thompsons Foundry Band In grateful acknowledgement for service provided to Mt Alexander Hospitalcertificate -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Certificate, Mount Alexander Hospital Castlemaine, 2007-10-29

Certificate Presented to Thompsons Foundry Band Inc. Mt Alexander Hospital Castlemaine Quality, Care and Commitment Certificate of Appreciation awarded to Thompsons Foundry Band In grateful acknowledgement for service provided to Mt Alexander Hospitalcertificate -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Water standpipe, Langlands Bros. & Co, 1880-1893

This water standpipe is believed to be the only one of its kind in working order. It was originally located in Warrnambool, on the hillside at the corner of Mickle Crescent and Banyan Street, providing water for the Chinese Market Gardens below, on the flats. It was removed from this location on May 2nd, 1979, with the intention to relocate it at the new Flagstaff Hill Maritime Museum & Village. The standpipe lay in storage for years until the Warrnambool Company, Chemblast, offered to restore it for use as a working display. The display was officially opened on March 31, 2014. The water from the adjacent lake is drawn out with a hand operated water pump, and goes up into the standpipe, where flows through the canvas hose and into the top of the Furphy Farm Water Cart. The display is a visual acknowledgement of the years served by Flagstaff Hill volunteer and Friends of Flagstaff Hill Chairperson, Bob Crossman. Warrnambool’s early settlers had no water supply prior to the mid-1850s. They relied on rain water tanks, domestic wells and springs. The town experienced a huge, destructive fire in William Bateman Jnr. & Co.’s large produce store in November 1856, which highlighted the need for both a fire brigade and a good supply of water. In 1863 a volunteer fire brigade was established. In August 1880 the town celebrated the installation of its first water standpipe on the corner of Liebig and Timor streets. The water was pumped from springs at Cannon Hill through the connected pipeline to the standpipe, then distributed to households via horse and cart. Each of the licenced cart drivers were compelled by Council regulations to keep their carts full from sunset to sunrise, ready to cart water to outbreaks of fire. They received a fee for this service. In 1893 the town installed a water supply, sourced from the Merri River, stored in a reservoir basin and tower in north Liebig Street, and distributed throughout the town in a system of pipes. By late 1939 a reticulated supply was installed, with the water piped in under the Otway Scheme. Standpipes are still used in modern times in rural and remote areas for homes, farms, stock, agriculture and firefighting. Many commercial or government owned standpipes are metered, charging a fee for the quantities of water supplied. This water standpipe was made by Langlands Foundry Co. Limited, Melbourne, which was establish in 1842. It was Melbourne’s first foundry and iron shipbuilder, and one of the largest employers in Victoria at the time. Langlands was known for its high quality workmanship and wide range of goods for mining, engineering, marine, railway and other industrial uses. The company made the first cast bell, the first lamp posts in the colony, and the boiler for the first Australian train. In the 1860s it produced cast iron pipes for the Board of Works, which laid the pipes for Melbourne’s first reticulated water supply. The firm was bought by Austral Otis Co. in 1897.This water standpipe is significant historically as it is believed to be the only one of its type in working condition. The standpipe is significant for being manufactured by early colonial firm Langlands Foundry of Melbourne, which was known for high quality, cast iron products. The firm made the boiler for the first Australian train, assembled the first Australian paddle steamer and made the first Australian cast bell and lamp posts. Langlands was one of the largest employers in Victoria at the time. The standpipe is significant historically as it represents the evolution of water supply services in Australia. Standpipe; vertical cast iron water pipe, painted crimson, fixed in position, tapering inward from the round base to the rectangular joint near the finial on top. A hexagonal pipe extends at right angles from the joint, with an outlet fitting and flow-controlling wheel on the end. A length of canvas hose hangs from the outlet fitting. Inscriptions are on one face of the joint. The standpipe was made by Langlands Foundry Company of Melbourne. Embossed “LANGLANDS FOUNDRY CO. / LIMITED / ENGINEERS / MELBOURNE”warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, flagstaff hill, standpipe, stand-pipe, water standpipe, fire standpipe, firefighting equipment, water supply equipment, chinese market gardens, banyan street, liebig street, water tower, bateman’s fire, working display, water supply, town water, rural water, reticulated water, cannon hill spring, merri river, otway water, water carters, horse and cart water supply, volunteer fire brigade, langlands foundry, early melbourne, iron works, bob crossman, late 19th century water supply -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Balance Scale, Henry Crane (Crane Foundry), 1870-1900

The Crane foundry opened some time before 1827 and was known as Atherton’s Foundry, run by James Atherton and Henry Crane. Initially it was a brass foundry, but by 1827 iron castings were also produced on the site. The main products were castings for the building industry, ironmongery and brassware. In the 1830s castings for the hand tool and lock industries were added to the product range and by 1836 Henry Crane had taken control of the business. The company became known as the Crane Foundry in 1847 with its own registered trademark. By the 1850s iron weights were produced, and a design was registered in 1872 with roundels decorating the edge. Brass weights were also produced, mainly after the regulation of 1890 that required weights of 2oz. or less to be made of brass. In the early 1900s the foundry began to produce castings for electric motors and continued to do so throughout its life. The Crane family continued to control the company until 1917 when William Cyril Parkes of lock makers Josiah Parkes & Sons Limited, Willenhall became a majority shareholder. Things were going well until the company’s liabilities spiraled out of control with the rise in electricity and gas prices along with the loss of two of the company’s largest customers. The factory went into liquidation and then closed in 2006 an end to one of Wolverhampton’s oldest companies.An item made by one of England's foundry’s based in Wolverhampton that exported items all over the world for many years. The scale gives a snapshot into the commercial life not only of England by Australian colonial life before Federation.Beam scale with three weights (4lb, 2lb, 1lb), metal tray, corrodedMarked on 2lb weight "Wolverhampton Crane Foundry" flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, scale, beam scale, pounds and ounces, imperial weight, grocers scale, domestic scale, henry crane, crane foundry -

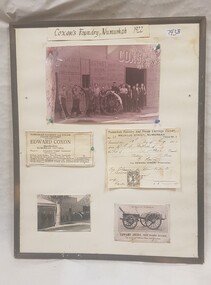

Numurkah & District Historical Society

Numurkah & District Historical SocietyPoster - Poster / displays x 4 of the Coxon Foundry

Purchased by Gary Allert from the estate of E.J. Lee Berrigan. Overview of the Coxon Foundry, Numurkah 4 x framed display boards with photos and photocopies (documents) of the Coxon Foundrysee photocoxon, foundry, wagons, cars -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Colour, Street Lamp at the Ballarat School of Mines, 2011

Billmans Foundry was established in Castlemaine in 1980.Three photographs showing a street lamp in Lydiard Street South. The lamp was made by Billmans Foundry, Castlemaine.lamp, gas lamp, ballarat school of mines, castlemaine, bilmans foundry, lydiard street -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Mr Robert Gray at Kays Foundry in Wimmera Street

Robert Gray at Kays Foundry Wimmera Street Stawell standing beside Crusher built for Bulola Goldfields New Guinea. Robert (Bob) Gray born Stawell in 1879 to Edmond and Susan Gray. Robert worked for 20 years at the George Kay Foundry Wimmera Street as a fitter and turner manufacturing and repairing steam engines and boilers. The foundry burnt down in 1924. George Kay gave Bob this reference. He them worked at the sandstone quarry out beyond Mt Dryden (Heatherlie) The stone of which was used to build the Elizabeth Street Commonwealth Bank in Melbourne. Roberts job was that of black smith tempering and sharpening rock drills.Black and white photograph of a man standing beside a circular structure in a large workshop.Robert Grey at Kays Foundry Stawell. Built for Bulola Goldfields New Guinea.stawell industry mining -

Stawell Historical Society Inc

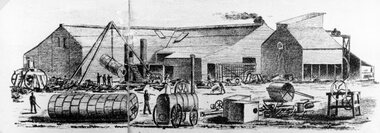

Stawell Historical Society IncDrawing, Wayman & Kay Foundry in Wimmera Street from P.C. News Supplement 1888 -- 2 Sketches -- 1 Newspaper Advert

Wayman & Kay Foundry Wimmera Street from P.C. News Supplement 1888. Wimmera StreetLarge wooden foundry with boiler Steam traction engine, water tanks road roller and machinery in foreground. stawell businesses -

Federation University Historical Collection

Federation University Historical CollectionArticle - Article - Metal plate, ZILLES COLLECTION: Metal plate stamped with Soho Foundry Sovereign Hill Ballarat with symbol

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Small metal plate with the name stamped into it. It is Soho Foundry, Sovereign Hill Ballarat.Small square silver colour metal plate. Corners cut and two sections show residue of sticking tape.Symbol with writing around it - SOHO FOUNDRY SOVEREIGN HILL BALLARATzilles, foundry, soho, ballarat, metal plate -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Set of Oval iron boilers, Cauldron, T & C Clark Co

Oval iron boiler with lid and handle, capacity four gallons (15 litres). Made by T. & C. Clark & Co., Wolverhampton, England. T. & C. Clark & Company Limited was founded in 1795 by Thomas and Charles Clark. Based at Shakespeare Foundry, Wolverhampton, it became one of the largest foundries in the area.These cooking pots were used by the local pioneers to cook their meals over an open fire. The flames from the fire turned the pots black.Oval iron boilers with lid and handle of various capacity : 2½ gallon, 3 gallon, 5 gallon and 6 gallon. Made by T. & C. Clark & Co., Wolverhampton, England. T. & C. Clark & Company Limited was founded in 1795 by Thomas and Charles Clark. Based at Shakespeare Foundry, Wolverhampton, it became one of the largest foundries in the area.T. and C. Clark with their makers markcooking, iron pots, moorabbin pioneers, cast iron, t & c clark & company -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - National Trust Collection: Golden City Implements Foundry, Ironbark, Bendigo, 1960-1980s

This foundry had been a landmark in Mt Korong Road for many years. It began with an Osborne and Mitchell. After 1914 when mining declined, it became the Golden City Implement boundary and the name can still be seen painted on on the façade which faces the intersection of Marong Road (Calder highway) and Eaglehawk Road. The interior is a mass of used and un-used machinery scattered amongst modern lathes and more modern apparatus. The yard was a fascinating graveyard of past times, with old mining and agricultural scrap everywhere mixed up with coke and slag from the smelting sheds at the rear. A feature of the foundry was the manufacturer of cast iron lace. National Trust Survey Data Sheet and article from the Bendigo Advertiser November 4th 1981. Osbornes Ironbark Foundryhistory, national trust bendigo collection, bendigo, foundary, iron bark bendigo -

Charlton Golden Grains Museum Inc

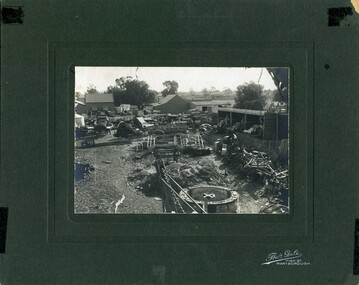

Charlton Golden Grains Museum IncPhotograph, Gale, Thomas, Charlton Foundry yard c. 1910, c.1910

Charlton Foundry established in 1885 by Munros. Taken over by Dabron and Forbes in 1899. Taken over by Dabrons in 1905 to 1965 when it closed.Black & white photograph, mounted, unframed. Taken by Thos Gale Photographer Maryborough. Foundry backyard showing farm machinery and implements. Three workmen in the yard. Thos Gale High St Maryboroughmunro, dabron, forbes, charlton, foundry, business, industry -

Bendigo Historical Society Inc.

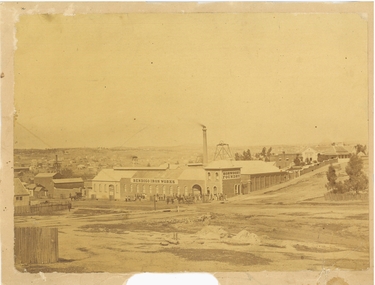

Bendigo Historical Society Inc.Photograph - Horwood's Foundry / Bendigo Iron Works

Joel Horwood established the foundry in the late 19th Century in Vine Street Bendigo. The Foundry manufactured mining machinery, agricultural castings, and bells.Sepia coloured photograph of Bendigo Iron Works / Horwood's Foundry. There is a large single storey building with a group of people standing in front of the side with the Bendigo Iron Works sign. Behind the building there is a chimney and a poppet head. The building is fronted by unmade roads.poppethead, horwood's foundry, bendigo iron works -

Charlton Golden Grains Museum Inc

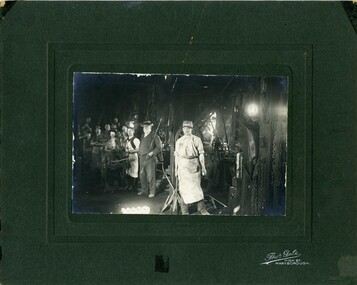

Charlton Golden Grains Museum IncPhotograph, Gale, Thomas, Charlton Foundry c. 1910, c.1980

Foundry established in 1885. Bought by Dabron and Forbes in 1899. Taken over by Alfred Dabron in 1905 to 1965 when it closed. Mounted unframed black & white photo showing a group of workers inside the foundry. One man in suit, waist coat and hat, other men in aprons and rolled up shirtsleeves.Thos Gale High St Maryboroughdabron, forbes, charlton, foundry, business, industry -

Charlton Golden Grains Museum Inc

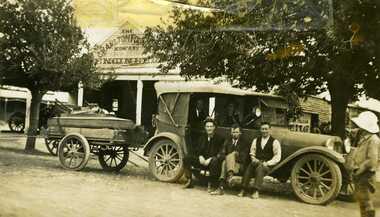

Charlton Golden Grains Museum IncPhotograph, Charlton Foundry Frontage c. 1930, c.1930

Charlton Foundry established 1885 and closed 1965.Black & white photograph showing the front of the Charlton Foundry. A Car and trailer are parked in front. Three men are sitting on the car running board and two men are inside the car. A boy is standing at the right of the photo. Cricket Club Hotel in the background on left.charlton, foundry, business, industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912