Showing 3 items matching "fusee mechanism"

-

Flagstaff Hill Maritime Museum and Village

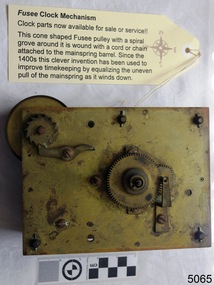

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

... Fusee Clock Mechanism...fusee mechanism... mechanisms. The earliest existing clock with a fusee, also... Vinci also show fusee mechanisms. The earliest existing clock ...The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, c. 1860s

... winds a fusee chain mechanism, attached to the brass mainspring...” embossed on the back of the fusee mechanism behind the clock. ... on the back of the fusee mechanism behind the clock. This 1864 hall ...The clock was either made or sold by T. Gaunt & Co. of Melbourne, a manufacturer, importer and retailer of a wide variety of goods including jewellery, clocks and watches, navigational and measuring instruments, dinnerware, glassware and ornaments. Thomas Gaunt photograph was included in an album of security identity portraits of members of the Victorian Court, Centennial International Exhibition, Melbourne, 1888. Thomas Gaunt History: Thomas Gaunt established Melbourne's leading watchmaking, optical and jewellery business during the second half of the 19th century. Gaunt arrived in Melbourne in 1852, and by 1858 had established his own business at 14 Little Bourke Street. Around 1869 he moved to new premises in Bourke Street on the corner of Royal Arcade, Gaunt's shop quickly became a Melbourne institution. Gaunt proudly advertised that he was 'The only watch manufacturer in the Australian colonies'. While many watches and clocks may have had Gaunt's name on the dial, few would have been made locally. Gaunt did make some watches for exhibitions, and perhaps a few expensive watches for wealthy individuals. Gaunt's received a telegraph signal from Melbourne Observatory each day to correct his main clock and used this signal to rate and repair ship's chronometers and good quality watches. His main horological manufacturing was directed at turret clocks for town halls, churches and post offices. These tended to be specific commissions requiring individualised design and construction. He made the clock for the Melbourne Post Office lobby, to a design by Government Astronomer Robert Ellery, and won an award at the 1880-81 Melbourne International Exhibition for his turret clock for the Emerald Hill Town Hall. He became well known for his installation of a chronograph at Flemington Racecourse in 1876, which showed the time for the race, accurate to a quarter of a second. The firm also installed the clockwork and figures for Gog and Magog in the Royal Arcade. Thomas Gaunt also developed a department that focused on scientific instrumentation, making thermometers and barometers (from imported glass tubes), telescopes, surveying instruments and microscopes. Another department specialised in electroplating for trophies, awards and silverware, and the firm manufactured large amounts of ecclesiastical gold ware and silverware, for the church including St Patrick's Cathedral. There are no records that disclose the number of employees in the firm, but it was large enough for Gaunt to hold an annual picnic for the watchmakers and apprentices at Mordialloc from 1876; two years previously they had successfully lobbied Gaunt to win the eight hour day. Gaunt's workforce was reportedly very stable, with many workers remaining in the business for 15 to 30 years. Gaunt's wife Jane died on September 1894, aged 64. They had one son and six daughters, but only three daughters survived to adulthood. Two became nuns at the Abbotsford Convent and one daughter, Cecelia Mary Gaunt (died 28 July 1941), married William Stanislaus Spillane on 22 September 1886 and had a large family. Gaunt died at his home in Coburg, Victoria, leaving an estate valued at ₤41,453. The business continued as T. Gaunt & Co. after his death. Post Office and Clock History: Warrnambool’s Post Office has been in existence since 1857, when it was originally situated on the corner of Timor and Gilles Street. In March 1864 the Warrnambool Borough Council purchased this clock from Henry Walsh Jnr. for the sum of £25, “to be put up in front of the Post Office”. Henry Walsh Jnr was the eldest son of Melbourne’s Henry Walsh, maker and retailer of clocks, watches, thermometers and jewellery. In 1854 Henry Walsh Jnr. began business in Warrnambool as a watchmaker and jeweller later becoming a Councillor with now a local street named after him. The Post Office was extensively remodelled in 1875-76. Early photographs of this building show that the clock was installed on the northern outside wall, Timor Street, under the arches and between the 2 centre windows, where it could be seen by passers-by. Although spring loaded clocks date back to the 15th century, and fob and pocket watches evolving from these date to the 17th century, personal pocket watches were only affordable to the very fortunate. Public clocks such as this Post Office clock provided opportunity for all to know the time, and for those in possession of a personal watch to check and set their own timepieces to the correct time. During post office reservations during the 1970s the clock was removed and was eventually donated to the Flagstaff Collection. The Clock’s maker Thomas Gaunt, is historically significant and was an established and well renowned scientific instrument and clock maker in Melbourne during the 1860s. He was at that time the only watchmaker in the Australian colonies. In the 1870’s and 1880’s he won many awards for his clocks and was responsible for sending time signals to other clocks in the city and rural areas, enabling many businesses and organisations to accurate set their clocks each day. Warrnambool Borough Council purchased this clock from Henry Walsh Jnr. for the sum of £25 and the clock used to stand in front of the Warrnambool post office to allow ordinary citizens to set their time pieces as they walked by. The item is not only important because it was made by a significant early colonial clock maker and retailed by a locally known clock maker and jeweler but also that it was installed in the Warrnambool Post Office a significantly historical building in it's own right. Built in 1857 and regarded as one of the oldest postal facilities in Australia, with a listing on the National Heritage Database, (ID 15656). This 1864 hall clock originates from the Warrnambool Post Office. The clock glass is hinged to the top of the clock face and has a catch at the bottom. The metal rim of the glass is painted black. The clock face is metal, painted white, with black Roman numerals and markings for minutes and five minutes. The tip of the small hour hand is shaped like a leaf. "T. GAUNT / MELBOURNE" is printed in black on the clock face. The winding key hole is just below the centre of the clock face. The key winds a fusee chain mechanism, attached to the brass mainspring barrel that powers the pendulum with an 8-day movement. The speed of the clock can be adjusted by changing the position of the weight on the pendulum, lengthening or shortening the swing; raising the pendulum shortens its swing and speeds up the clock. The metal fusee mechanism has an inscription on it. The rectangular wooden casing is with a convex curve at the bottom that has a hinged door with a swivel latch. The original stained surface has been painted over with a matte black. There are two other doors that also allow access to the clock’s workings. The case fits over the pendulum and workings at the rear and attaches to the clock by inserting four wooden pegs into holes in the sides of the case then into the back of the clock. A flat metal plate has been secured by five screws onto the top of the case and a hole has been cut into it for the purpose of hanging up the clock. There is a nail inside the case, possibly used for a place to the key."T. GAUNT MELBOURNE" is printed on the clock face. “6 1 3” embossed on the back of the fusee mechanism behind the clock. warrnambool, shipwrecked coast, flagstaff hill, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, shipwrecked artefact, clock, warrnambool post office, fusee, henry walsh jnr, thomas gaunt, t gaunt & co, post office clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Clock, 1900's

... of an early mechanism “Fusee” that was originally invented around 1525 ...In August 1884, Alfred Hirst who had started his trade as a watch repairer and was described as a watchmaker extraordinaire established Hirst Brothers and Company, on Union Street in Oldham Manchester. He took his two stepbrothers into the business and the company was set up to produce timepieces and jewellery as well as importing “Limit company” Swiss watches and precision machine tools for the watch and clock trade. By 1902 Hirst Brothers. had become a limited company and was still growing, adding other businesses in Manchester in 1904 and at Birmingham in 1907. The quality of the clocks and watches was such that Alfred Hirst realised his greatest ambition in 1912 with a range of watches which carried the "Limit" trademark. These watch movements had originally been made in Switzerland and shipped to Hirst Bros. to be put into British made “Dennison” cases. This trade brought even more growth with additional sales offices opening in London and Glasgow. At the outbreak of the First World War in 1914 found them manufacturing aircraft parts including revolution counters and optical instruments. The firm had been tasked by the Ministry of Munitions to solve the problem of pilots dropping bombs by hand and as a result, they effectively created the first bomb rack. After the war, the company once again began to prosper and with the demand for their products increasing they looked to build a new purpose-built factory to manufacture their products. In 1917 they purchased a seven-acre field site at Tame Side Dobcross, the designing of the new factory was passed onto local architect AJ Howcroft. His brief for the design of the clockworks would have been prompted by Alfred Hirst who having visited modern factories in the United States was inspired by the latest factory designs providing as much daylight as possible during working hours. The factory was eventually completed in 1920, by the mid-1920s there were cheap clock imports from Germany and production turned to radio sets and other components as well as counter and gas meters for the "Parkinson and Cowan" company who was later to take over the business. In 1926 came the cotton crash and the District Bank who had loans with the company foreclosed on the Hirst loan. The company did survive and throughout the second World, War II were involved in munitions work at the factory as well as making instruments for various aircraft. In the 1950’s they were producing meters and high grade measuring equipment but by the 1970's the business had closed and the factory was demolished in the mid-1980 "s The item is a good example of the later use of an early mechanism “Fusee” that was originally invented around 1525 in Prague. This type of clock mechanism was replaced as watchmakers looked for mechanisms that could reduce the size of clocks and watches, it appears England was the only country to continue making clocks with a Fusee device until around 1900,s of which our clock is an example. The use of a Fusee movement eventually became obsolete in 1970,s. The item is significant for the collection as it is a clock with a movement that has long since been made obsolete. Fusee type gallery wall clock made by Tame Side with an 8-day mechanical fusee movement. The white enamel dial is a little crazed and some of the Roman Numeral numbers are fading due to over-cleaning. The movement has a hexagonal iron pendulum bob hooking onto a pendulum rod with a spring-wound anchor escapement.Only mark is stamped on the movement believed to be a production number "13490" and made in Tame Side. (If the clock had been made after 1912 it would have had a trade mark "Limit")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, wall clock, fusee, gallery clock, alfred hirst, tame side