Showing 97 items matching "german tool"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Pliers, Henry Boker, late 19th to early 20th century

... german tool... in the 18th century in Remscheid, Germany. Boker tools were known... in Germany by Henry Boker (Heinrich Boker). Boker hand tools were ...This unusual set of pliers was made in Germany by Henry Boker (Heinrich Boker). Boker hand tools were being produced in the 18th century in Remscheid, Germany. Boker tools were known for good quality and value for money. George A. Fox & Co., of 250 Victoria Street North Melbourne, were agents for Boker tools in the 1950s. Museums Victoria has a Boker catalogue in its collection dated circa 1954.These pliers are significant as an example of hand tools used in the early 20th centry or earlier. Pliers like this would typically be used in maritime trades.Pliers, double headed. This hand tool has two sets of jaws on its pair of handles. It was made by Henry Boker, Germany. Impressed into metal "HENRY BOKER / GERMANY"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, pliers, double headed pliers, henry boker, boker hand tool, german tool, german pliers, antique pliers, vintage pliers, victorian pliers, heinrich boker, tradesmen's tools -

Bendigo Historical Society Inc.

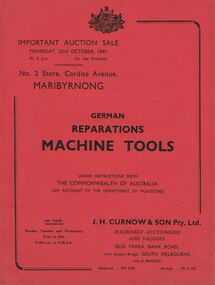

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GERMAN REPARATIONS MACHINE TOOLS

... Red cover, catalogue for a sale of German Reparations... Collection - Auction Catalogue - German Reparations Machine Tools ...Red cover, catalogue for a sale of German Reparations Machine Tools under instruction from The Commonwealth of Australia (on account of the Department of Munitions) at No. 2 Store, Maribyrnong on 23/10/1947. Special Notice and Conditions of Sale printed in catalogue. J. H. Curnow & Son Pty. Ltd. were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - german reparations machine tools, the commonwealth of australia, the department of munitions, j h curnow & son pty ltd, the prahran telegraph printing co -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Souvenir - Holster, c1914-1918

... to secure weapon for German Luger Pistol with tool kit holder... for German Luger Pistol with tool kit holder attached (no Tools) 2 ...Used in World War 1 by German officers. Collected by Charles Honybun during WW1. Part of the Honybun Collection.1. Dark brown leather holster with buckle and strap to secure weapon for German Luger Pistol with tool kit holder attached (no Tools) 2. Belt Leather. 3. belt buckle with inscription Got Mit Uns. 4. Tool in pocket inside top of holster.A P L Hofman Berlinarms, firearms, ww1, charles henry honybun -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Tool Part, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Tool part for a Wertheim sewing machine. Made by Joseph Wertheim, Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, sewing machine foot, seamer foot, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Sewing Tuck Marker, Joseph Wertheim, ca. 1891

The tuck making tool is part of a set of tools and Instructions for a Wertheim New High Arm Sewing Machine as well as the "B' Medium, Cylinder Arm and Titania Machines. This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Tuck marker or creaser for a Wertheim sewing machine. Made by Joseph Wertheim , Germany, and distributed by Hugo Wertheim, William Street Melbourne. Circa 1891flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, sewing machine tool, sewing machine accessory, tucker, tuck maker, creaser, wertheim, joseph wertheim, germany, hugo wertheim, victorian era, sewing machine, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, domestic machines, dressmaking, home industry, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAccessory - Foot tool, Joseph Wertheim, ca. 1891

This sewing machine accessory was donated with our collection's Wertheim sewing machine accessory box. The box contains twelve accessories, the instruction book and the receipt for the purchase of a Wertheim sewing machine. The receipt was written on July 23rd 1891 by the Wertheim distributor in Melbourne, Hugo Wertheim. His business was the Wertheim Sewing Machine and Hapsburg Piano Depot, trading at 173 Williams Street, Melbourne. The purchaser was Mrs Burrowes from Burrumbeet, Victoria, a district northwest of Ballarat. She paid £6-6 (six pounds and six shillings) in cash. The receipt was signed by H. Wertheim and the other signatory looks like John A. Cherry. Hugo Wertheim (1854-1919) was an agent for his father’s cousin Joseph Wertheim, a well-established sewing machine manufacturer in Germany. He was born in Lispenhausen, Germany, and migrated to Melbourne in October 1875, where he opened a merchandising business at 39 Flinders Lane East. He returned to Germany in 1885 to marry Joseph Wertheim's daughter Sophie Emilie. The couple came back to Melbourne, and Hugo quickly established a substantial business selling sewing machines, bicycles, pianos and other mechanical devices, under brands such as Wertheim, Electra, Planet, Griffin and Hapsburg. He exhibited at agricultural shows and in 1901 at the Pan American Exposition, Buffalo, United States of America. One of his staff was O. C. Beale, who later set up his own piano business in New South Wales. Hugo continued to own 25 per cent of one of Beale's companies, which became Wertheim's Queensland business. In 1908 Hugo Wertheim opened a piano factory in Richmond, Melbourne, aiming to produce 2000 pianos and player pianos a year, predominantly using Australian materials. In laying the foundation stone, Prime Minister Alfred Deakin observed that “few men with such opportunities for a life of ease would have embarked on such an enterprise” Hugo died of chronic hepatitis in 1919 at his home in South Yarra. His eldest son, Herbert Joseph (1886-1972), continued the business. The piano factory closed in 1935, becoming a Heinz food processing plant and in 1955, GTV Channel 9 studios and offices. The Wertheim Sewing Machine Company – Joseph Wertheim (1804–1899) founded the company in 1868 in Frankfurt, Germany. At this time Joseph was the Frankfurt city delegate for the Democratic Party. At its height, the Wertheim factory employed approximately 650 workers. The company used a trademark of a dwarf holding a hammer which is known to have been used until at least 1925, however in 1909 a Star of David was also registered. In 1870 a Wertheim subsidiary was formed in Barcelona, Spain. The business imported and sold complete machines, including the English Jones machine. Locals began calling the sewing machines “las rapidas”, and the business became known as “las casa de las rapidas”. In 1915 production began of a totally manufactured Spanish Wertheim machine. Wertheim in Germany continued manufacturing machines until 1932 when the Wertheim family fled to Spain. Despite converting to Christianity from Judaism, they feared the political unrest in Germany during that time. Wertheim Spain became Rapida SA and was then the sole manufacturer of the Wertheim machines. The factory was managed by Karl Wertheim under the alias Carlos Vallin. The sewing machine accessory is part of a donation that connected to domestic life in 1891 during the Victorian era. It is significant for connecting the Melbourne distributor of Wertheim sewing machines, Hugo Wertheim, to Victoria’s northwest district where the purchaser lived. It is also significant for connecting the Melbourne distributor to the importing of goods from the well-known German manufacturer of early domestic sewing machines, Joseph Wertheim. Foot accessory tool for a Wertheim sewing machine. Mane by Joseph Wertheim, Germany, and distributed by Hugo Wertheim William Street Melbourne. Circa 1891.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wertheim, sewing machine, victorian era, sewing machine accessory, wertheim sewing machine and hapsburg piano depot, wertheim sewing machines, domestic machines, dressmaking, home industry, fashion -

Frankston RSL Sub Branch

Frankston RSL Sub BranchTool - Magneto Field Lamp

German World War 1 magneto lamp. It has a carrier rope and a pull down ring. It has a prism lens. -

Shepparton RSL Sub Branch

Shepparton RSL Sub BranchWW1 Trench Tool, German Trench Spade

Came from Tallygaroopna RSL ClubSurface rust. Handle shorten. 5 Rivets holding the back-plate to shovel. 2 Rivets holding the handle. Wood handle scratched with indention . String maybe not original trench tool, tool, ww1, first world war, the great war, world war one, world war 1 -

Bendigo Military Museum

Bendigo Military MuseumTool - SHIPS BELL, c.1900

This bell was apparently salvaged from a Freighter by Syd Storrie a Merchany Navy Sailor. The Freighter had been torpedoed by a German Submarine in WW1.Ship's bell, rough cast bronze? Clapper is rough cast steel. There is an old steel mounting bracket at the top, painted green. maritime technology, ship relics, military history - navy, ships fittings, souvenirs -

Bendigo Military Museum

Bendigo Military MuseumTool - RADAR COUNTERMEASURE - WINDOW TAPE, c.WWII

Window tape or chaff was released by the British in WWII from aircraft to confuse radar into thinking it was observing multiple primary targets. Separately developed by the Germans who called it Duppel. Item re Frederick Gardner DAVEY DFC No 410533 RAAF. Refer Reg No 3536P for his service details. Consists of strips of card covered with aluminium.anti radar, aluminium, raaf -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wrench, Late 19th Century

... Germany. Tool Wrench Johann Heinrich August Bleckmann ...Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Dusseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Bleckmanns a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to the First World War.Drop hand forged steel wrench with unusual locking mechanism to size jaw opening made by J E Bleckmann, Solingen Germany.Machine stamped on handle of wrench LOTUS L R GEBRAUCHS under has MUNSTER, J E BLECKMANN, SOLINGEN Germany. [ Translated: LR Gebrauchs= use,usage, or custom application] [Lotos] Translated: Lotus ie flower] [Solingen =town in Rhine valley]manufactures, tools, engineering, blacksmith, workshop tool, dropforged, handmade, wrench, adjustable wrench, phoenix steel, j e bleckmann, solingen, murzzuschlag, steel mill, cutlery, steel foundery -

Flagstaff Hill Maritime Museum and Village

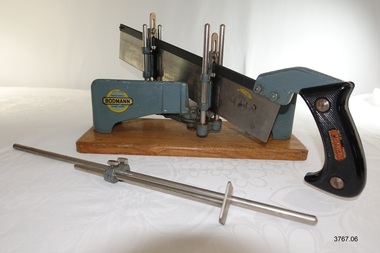

Flagstaff Hill Maritime Museum and VillageTool - Mitre Saw Set, 1930-1955's

This Bodmann mitre saw set was used in the making of components for the ship model Sovereign of the Seas. It is part of a collection of objects used by Jim Williams, maker of fine ship models from about 1930-1955. Most of the components for the models, as well as many of the tools, were handmade by Jim Williams. Jim’s family has donated the ship model “Sovereign of the Seas” and many tools, accessories and documents used in the making of this and other ship models have been donated to Flagstaff Hill Maritime Village. ABOUT the BRAND NAME ON THE SAW - BODMANN and CO, Germany In 1927 the Brisbane Courier Mail described Bodmann and Co of Reinscheid, Germany as "manufacturers of guaranteed tools and hardware. It appears that at least the saw has been re-badges and sold by Bodmann because (1) there are remnants of a label on the saw blade similar in shape to the Bodmann label on the mitre set (2) the removed label reveals the name and logo of "ULMIA Schutz OTT Marke" (3) one of the "Bodmann" labels on the saw handle has been applied in a crooked manner, almost leaving off the last "N". ULMIA is a German manufacturer of high quality woodworking tools. A drawing of a very similar mitre bset with saw can be seen on the ULMIA website. In 2002 the long established company ANKE of Swabian Alb, Germany (makers of cut timber, workbenches and countertops) bought out the name and trademark rights of ULMIA. HISTORY OF SOVEREIGN OF THE SEA (brief) Ship model of HMS Sovereign of the Seas, scale model of 17th Century English war ship, was handmade and carved from plans, enclosed in airtight glass case. All components of that model, including even the smallest pulleys, were hand crafted using tools designed and made by Jim. Outstanding details include functional rigging and moving cannons. Please see our record 3732 of the mode Sovereign of the Seas for further details of the ship and the Jim Williams. This mitre saw set is connected with the hobby and skill of ship model making that has been crafted as a leisure activity for many generations. The hobby is often chosen by serving and retired mariners who appreciate the connection with maritime history. This mitre saw set was used by local Warrnambool man, Jim Williams, who was employed at Cramond and Dickson clothing store, and then at Fletcher Jones menswear for 27 years. It was used in making components for the model of the historic ship, the Sovereign of the Seas. The Sovereign of the Seas was a historic 17th century English war ship with important maritime heritage. Bodmann Mitre Saw set model 348, comprising metal, adjustable mitre saw on timber stand, and metal hand saw with Bakelite handle. The mitre saw is labelled with the trademark of Bodmann, Germany, and stamped with the model number 348. The saw has Bodmann trademark badges on each side of the handle; the text on one of these badges is not quite aligned. The saw blade has remnants of a label under which the stamped logo of ULMIA Schutz OTT Marke is clearly visible. Saw is fitted with two metal guides that slide onto vertical posts on the mitre saw. Metal measuring guide holds the wood job to the correct length. Saw has a protective brown paper wrapper. This mitre saw set is part of a collection of tools and accessories once used by Jim Williams, maker of a series of ship models 1930-1955 including “HMS Sovereign of the Seas”.On mitre saw- 2x logos "REGISTERED / BODMANN / TRADE MARK" and embedded stamp “348”. On saw - Remnant of logo on blade “ULMIA Schutz OTT Marke” with image of a church-like tall building, and 2x , "BEST QUALITY / BODMANN / MADE IN GERMANY” flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jim williams, james bernard williams, ship model hobby, ship model tools, ship model making equipment, ship model making accessories, wood working tool, model making tool, mitre box set, mitre saw, bodmann and co reinscheid, germany, ulna ott of of swabian alb, germany, anke of swabian alb, germany, sovereign of the sea, ship model, hobby, ship model tool, mitre saw set -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, Mid 19th to late 19th Century

... -round' bench tool and for rougher work depending on how... be used as an 'all-round' bench tool and for rougher work ...A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the coffin pattern made by Henry Boker the item is a rare and significant example of vintage woodworking tools used in the manufacture of wooden items.Smoothing Plane Coffin design. Blade marked Henry Bokerflagstaff hill, warrnambool, maritime-museum, shipwreck-coast, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Screwdriver large, c1900

A screwdriver is a tool, manual or powered, for turning (driving or removing) screws. A typical simple screwdriver has a handle and a shaft, and a tip that the user inserts into the screw head to turn it. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handle are typically wood, metal, or plastic and usually hexagonal, square, or oval in cross-section to improve grip and prevent the tool from rolling when set down. The handle and shaft of screwdrivers have changed considerably over time. The "Perfect Pattern Handle’ screwdriver was first manufactured by HD Smith & Company, which operated from 1850 to 1900. Screwdrivers were probably invented in the late 15th century, either in Germany or France when Screws were used to construct screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. The jaws that hold the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The screwdriver depended entirely on the screw, and it took several advances to make the screw easy enough to produce to become popular and widespread Canadian P.L. Robertson, though he was not the first person to patent the idea of socket-head screws, was the first to successfully commercialize them, starting in 1908. In Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his screw to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which was not possible with the Robertson Screw. A large steel screwdriver with worn wooden handlepioneers, early settlers, market gardeners, moorabbin, bentleigh, cheltenham, brighton, tools, craftsman, carpenters, , blacksmiths, builders, farmers, metalwork, woodwork, screws, philllips head screwdrivers, h.d.smith & co usa, p.l. robertson, henry f.phillips , oregon, canada, american screw company, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyWoodworking Tool - Jack Plane

... "The Burgham Tools Company / Solingen Germany"... Tools Company / Solingen Germany" A Jack Plane is a general ...Very Old. Until the end of the 19th century the bodies of jack planes were predominantly wooden, typically made out of beech (wood). Wooden planes were largely superseded by iron-bodied planes.Used by carpenters and cabinet makers in the Kiewa Valley from the late 1800s and the early 1900s.A Jack Plane is a general purpose woodworking bench plane, used for dressing timber down to size in preparation for truing and/or edge jointing. It is usually the first plane used on rough stock, but for rougher work it can be preceded by the scrub plane. German Pattern Jack Plane. The smallest - 1.5 inches. Ref. Page 21 - Tools for all Trades Catalogue 1930s?"The Burgham Tools Company / Solingen Germany"woodworking tool, jack plane, plane -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPlane Wood, 1890 -1900

J.E. Bleckmann were German Blade makers, registry shows Bleckmann (1899, No. 37190):J.E.Bleckmann, Solingen, registry class 9b). As well as blades for wood working tools they were also sword makers (used in American Civil War), Bayonet makers 1871-1918 and also pocket cutlery (pocket knives) as per advertisement 1907.This wood plane holds historical importance as carpentry tools such as this would have been used in the construction of local homes, outbuildings, furniture. It represents an era before power tools. Investigation is ongoing as to ownership and specific use in the area. Hand made wooden hand plane with metal blade. Carpentry tool from 19th century1/38 / 34 mm stamped into wood on front edge of plane. Metal Blade inscribed "J.E. BLECKMANN/ WARRANTED / CAST STEEL / SOLINGEN/GERMANY"tool, blade makers, hand plane, woodworking. -

Orbost & District Historical Society

Orbost & District Historical Societyhand drill

The invention of a hand drill is credited to Arthur James Arnot and William Blanch Brain of Melbourne, Australia who patented the electric drill in 1889. In 1895, the first portable handheld drill was created by brothers Wilhem & Carl Fein of Stuttgart, Germany. Hand-powered devices have been used for millennia. However, during the last quarter of the 19th century a radically improved generation of tools appeared. These tools took advantage of modern mass production machinery and processes (like interchangeable parts) and an increased availability in superior material (metal instead of wood). One of the outcomes included an array of new drilling machines. These human-powered tools were a vast improvement over earlier tools.This item is an example of a commonly used domestic tool - pre power tools.A Stanley hand drill with two wooden handles. The red wheel is painted metal. On red wheel - STANLEY ENGLANDwoodwork tool hand-drill -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Knife Sharpener, Johann Friedrich Dick, 1873 to 1900

Johann Friedrich Dick founded the company in 1778 to manufacture files, the company continued in the manufacture of files as its main product line until 1873, when Paul Friedrich Dick took over the company and began the production of sharpening steels, with the logo of “F Dick” on their products. One hundred years after the founding of the company, a factory in Esslingen began construction. At that time the company had 20 employees. In 1881, company commissioned Germany's first file production machine. In 1889, Friedrich Dick built a new factory in Kollwitz/Fleischmannstrasse in Esslingen, employing 100 people and expanding the product line to include knives for butchers and chefs, cleavers and other specialized tools. Files manufactured ranged from the smallest watchmaker's file to the largest (over 45 cm in length) square file. In 1997, the F Dick company moved to a new headquarters in Deizisau, Germany. The old factory in Esslingen is now a class listed monument and the town's landmark.An item made by a world class manufacture of cutlery for chefs, the subject item is significant as its manufacture was probably early in the firms beginnings when Friedrich Dick took over in1873 when he specialised in making sharpening steels. The company is still producing these items today as well as other specialised knives for professionals. Early manufactured steels such as the subject item are sought after today by collectors and quite rare. Sharpening Steel or Knife sharpener with bone handle with ribbed pattern, brass knobs and ring at end of handleMarked F Dick Esslingenflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, sharpening steel, knife sharpener, kitchen tool, carving, kitchen utensil, cooking, f dick -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Colander, Late 19th or early 20th Century

The colander is an extremely useful tool in the kitchen, as it allows food to be fully drained of liquids such as water or oil. Enamelware dates back to 1760 in Germany.This object is significant as an example of a type of item in common use in the 19th Century and that is still in use today.Mottled blue enamel colander with draining holes in the base and sides. Two thin handles on lip of bowl.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, colander, food preparation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Tatting Shuttle, Aero Needles Group Ltd, Mid to late 20th century

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots.The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century.Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic (as is item 8535.1). The second type has a post in the center where the thread is wound (e.g. item 8535.2). The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace. One type of tatting shuttle produced by "Aero" from the 1930's to the late 1960's was an anodized grey coated aluminium shuttle with a sharp pick at one end. In the 1970's it was superseded by the grey plastic "Aero" which has a removeable bobbin which you can put on the end of the shuttle to make thread winding easier and an embedded crochet hook for joining picots. The "Aero" company developed in Redditch, England - a town renowned as a centre for manufacturing needles. Firms run by Henry Milward and Abel Morrall were based in Redditch and by the 18th century Redditch was manufacturing one million sewing needles per year. Abel Morrall Ltd launched the "Aero" brand in 1936 and greatly expanded the firm's product line to include tatting shuttles and knitting needles. The classic plastic "Aero" tatting shuttle was manufactured in England from the early 1970's until the 1990's. These items are significant as examples of easily accessible handiwork tools that enabled women in the 1930s -1960s to be able to decorate and personalize their household linen and clothing.Shuttle no. 8535.1 is a beige, boat shaped plastic shuttle with enclosed ends, small round central indentations on both sides and an enclosed black removeable bobbin. The shuttle has a grooved point at one end to hold a bobbin and a small metal crochet hook at the other end. Shuttle no. 8535.2 is a beige, boat shaped metal shuttle with pointed ends that are open but snug, small round central indentations and two smaller circular markings (on both sides) and two internal posts with cream thread wound around.Shuttle no. 8535.1 - "AERO" / "ENGLAND" Shuttle no. 8535.2 - "AERO' / "ENGLAND" "39c" (written in ball point pen)flagstaff hill maritime museum and village, flagstaff hill, warrnambool, shipwreck coast, great ocean road, tatting shuttle, aero company, handwork, handwork tool, craft, handcraft, needlework, tatting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Fob Watch, 1940-60s

Fob (or pocket) watches were developed in Europe in the 16th century and gained wide usage during the mid 18th century until World War 1 when the wristwatch was invented. These watches were designed to be carried in a small pocket and attached through the means of a 'fob' which could be a chain or made from a variety of materials such as leather. Their popularity peaked in the nineteenth century where they were an important part of middle and lower class society as well.This item is of social significance as fob / pocket watches were valued as an essential object in all levels of society. For some occupations, such as the railroads, it was a necessary tool of the job. Steel York Lever open face pocket / fob watch dated between 1940-1960. The dial has an inner pewter circle, outer minute divisions and a circular insert and hand to show the seconds. The numbers are finely edged with a black line and the hands are two coloured. The back of the watch is patterned with fine lines and three rectangle shapes. The words 'ANTIMAGNETIC' are on the front of the watch. Anti-magnetic watches began to be made at the beginning of the 20th century as mechanical watches were affected by magnetic fields. The 'lever' set on watches was a requirement for railroad watches. It required a two step process for the hands to be adjusted. The front dial of the watch has the words 'YORK LEVER', 'ANTIMAGNETIC' and 'MADE IN GERMANY'. flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, fob watch, pocket watch, watch, horology, time keeper, york lever, anti-magnetic, made in germany -

Flagstaff Hill Maritime Museum and Village

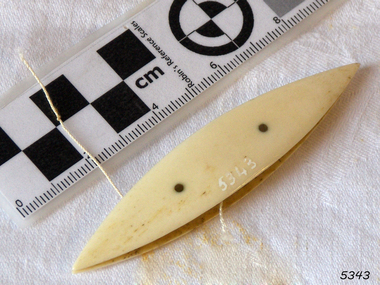

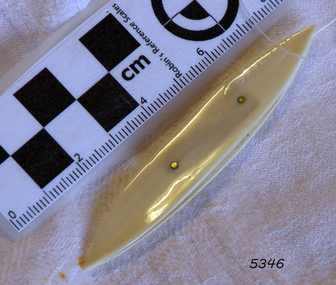

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, Ivoryflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

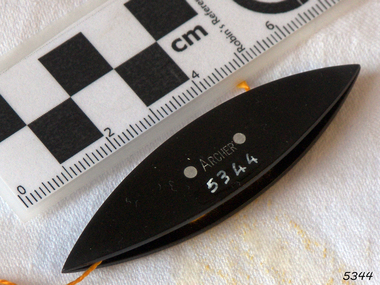

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, Black plastic, "ARCHER" inscribed. "ARCHER" inscribed.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, tortoise-shellflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, ivory, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTatting Shuttle

Tatting is a form of knotted lace making using thread and a small shuttle. Twisted threads are tied around or through small, pointed shuttles that can be made of bone, mother of pearl, tortoise shell, steel or plastic. This produces a stable, strong lace using simple knots of two half hitches to make rings and chains embellished with picots. The origins of tatting are not clear but early versions of decorative knotting were used by the Egyptians on their ceremonial dress. Tatting also has elements of fishermen's net making techniques and the decorative knotting that was practiced by aristocratic women from the 15th century. Tatting, as we know it today, emerged in the first half of the 19th century. The new availability of mercerised thread from 1835 encouraged a burgeoning of lace crafts of all sorts. It was known in Italy as "occhi" and in France as "la frivolite". Tatting looks fragile but is both strong and durable. An article in a column named "Wives and Daughters" published in the Star newspaper in May 1910 describes the durability of tatting lace - "there is edging and insertion still in existence that have outworn two sets of pillow slips." In the 19th century and well into the 20th century, tatting was used like crochet and knitted lace for decorative edgings, collars, doylies, tray cloths etc. At first, different tatting patterns were passed along by word of mouth from person to person, however in time, patterns regularly appeared in newspapers and magazines well into the 1950's. A shuttle is a small tool that looks like a small boat "sailing" in and out of the thread. Tatting is called "schiffchenarbeit" in German, which means "the work of a little boat". There are two popular types of shuttles. The first has closed ends and a removable bobbin where the thread is wound around - often made from metal or plastic. The second type has a post in the center where the thread is wound. The ends of this bobbin are open but snug. Because it is constructed in two pieces, it can be made from materials like bone, ivory or mother of pearl. Shuttles hold a larger amount of thread (as compared with needles) which means fewer ends to weave in. Fishermen in the past are thought to have used large shuttles to weave cord into certain knots whilst making their fishing nets. Their methods were copied by weavers, who innovated by using threads and smaller shuttles to make lace.Tatting Shuttle, black plastic flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, tatting shuttle, handcraft, needlework -

Flagstaff Hill Maritime Museum and Village

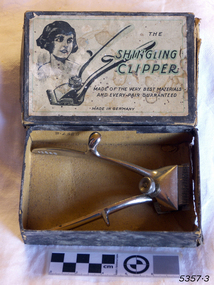

Flagstaff Hill Maritime Museum and VillageTool - Hair Clippers, 1920s

... is made in Germany. Tool Hair Clippers ...Hair clippers in an original rectangular grey cardboard box. The black and white label on the top of the box has green highlights. It shows a portrait of a female, printed description and brand name. This pair of size 0000 Shingling Clippers is made in Germany."The Shingling Clipper" "MADE OF THE VERY BEST MATERIALS / AND EVERY PAIR GUARANTEED" "MADE IN GERMANY"flagstaff-hill-maritime-museum, shipwreck-coast, hair clippers, hair care, personal care, personal grooming, hairdresser, barber, shingling clipper, germany -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Johann Heinrich August Bleckmann, 1870 to 1920

Johann Elias Bleckmann (1784-1856) founded a steel goods shop in Ronsdorf near Düsseldorf Germany. After completing a business education in his father's business, his son Johann Heinrich August Bleckmann (1826-1891) gained further experience through travel in North and South America. When his father died, he took over the steel goods store and moved it to Solingen. He bought a hammer mill in Mürzzuschlag Styria (Austria) in 1862 and converted it into a modern crucible casting steel smelter. His "Phoenix Steel", which he produced himself, achieved worldwide renown. He then went on to establish a file and tool factory and later founded a steel and plate rolling mill. Apart from cutlery blades, the company's self-produced steel was also processed into tools, scythes, rifle parts, etc. His sons Eugen and Walter continued after his death in 1891 at the Phoenix steelworks. However, by the end of the First World War, the two brothers fell into economic difficulties as a result of eliminating a large part of their foreign trade. In 1921, the company was converted into a public limited company and merged three years later with the company Schoeller & Stahlwerke. Made by Johann Heinrich August Bleckmann a significant Austrian manufacture of cutlery and tools in a recognized area of Germany famous for the production of steel items. The item is giving a snapshot of early colonial and European trades persons tools and gives an interesting insight into the development and progression of European tool and steel development and innervation prior to and just after the First World War.Plane Smoothing type with flat base. Has wooden wedge and iron missing. Knob handle is set on top and at the front. Iron 1 3/5 inches wide. Marked "Bleckmann (symbol) Safingen" "GN".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lamp, Kosmos Brenner, First half of the 20th century

The Kosmos burner is probably the most popular burner used in European lamps. A patent for the design was first lodged in the UK in 1865 by Wild & Wessel from Berlin. In 1875 they began using the trade mark 'Kosmos' on winder knobs. The mark was taken over in 1899 by Brokelman, Jager & Co. who changed it to 'Kosmos Brenner', (literally 'Kosmos burner'), they continued to manufacture right up to the 1970's when the factory closed and most tooling was destroyed. A very popular burner in Germany and still manufactured today in France it has been used in all sizes of lamps from small hand lamps up to large table and hanging lamps.The subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item is believed to have been produced in the first half of the 20th century. Many different lamp manufactures used Kosmos Burners in their lamps up until the 1970s, therefore exact provenance and age is difficult to determine.Lamp, copper, handle on top and one beneath attached to a reservoir made of copper. No glass and painted green.Marked "Kosmos Brenner" to winder flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lamp, kosmos burner, kerosene lamp, lighting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Kerosene Lamp, Perko Inc, 1922 -1930

The company was originally founded by Frederick Perkins a Russian immigrant schooled in Germany as a machinist and tool and die, maker. Frederick came to the United States in the early 1890s and soon became employed as a machinist for E.W. Bliss & Company in Brooklyn, New York. In the early 1900s, he and a partner began operating a business, F. Persky & Company, Lantern Manufacturer, out of the basement of his house. In 1907, Frederick's son Louis joined him in the business, and together they enlarged both the product line and the manufacturing facilities. By 1912, they had seventeen employees and made a wide range of marine lanterns and products. The business continued operating until 1913 when Frederick became president of National Marine Lamp Company, based out of Forestville, Connecticut. Frederick and Louis left that company in 1916 and moved back to Brooklyn, New York, where they started Perkins Marine Lamp Corporation. Five generations later, PERKO is still a privately owned, family-operated corporation. Perkins Marine Corporation was initially known as Perkins Marine Lamp, Inc. The original focus was on the manufacture of hand-formed sheet metal products for the marine market. The first “Perko” catalogue was published in 1916. It included a full range of kerosene and electric lanterns for small and large boats, ventilators, chart cases, signalling devices, mooring buoys, pumps and a variety of spare parts. These products, fabricated from brass, copper and galvanized sheet metal, began a reputation for producing high-quality products. In 1922, the "PERKO" trademark was instituted with each new product utilising the latest, sophisticated metal manufacturing technology.A significant item from an American manufacturer that specialises in making marine products and is still in business today under the same trade name. The subject item is significant as it was made not long after the trade name of PERKO was registered in 1922 and began to be used on the company's various products.Kerosene lamp with circular fuel tank and chrome plated reflector shield. "PERKO" stamped on base.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kerosene lamp, marine lamp, perko inc, lighting, marine accessories manufacturer