Showing 10 items matching "ironing machines"

-

Mont De Lancey

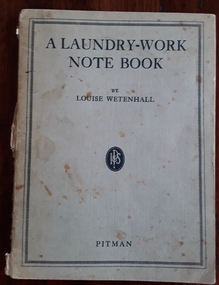

Mont De LanceyBook, Louise Wetenhall, A Laundry-Work Note Book, 1925

... Ironing machines... by Lillie (Scott) Tulloch 1997' Ironing machines Domestic equipment ...A thin paperback work-book intended as a general guide and ready reminder for those taking a course in laundry work.A damaged faded grey paperback book titled A Laundry-Work Note Book by Louise Wetenhall printed in dark blue letters at the top of the front cover, with the Sir Isaac Pitman emblem below and Pitman printed at the bottom. There are 49p. with black and white photographs and diagrams throughout with blank pages for the student or teacher to write notes. It is intended as a general guide and ready reminder for those taking a course in laundry work. Some pencil notes are written on p 50 and on the last inside endpaper is a small pencil drawing. Included in the book is a beige paper sheet decorated with coloured leaves around the edges with the inscription as to it's history as written below. A small white card has the donation facts written by the owner.A thin paperback work-book intended as a general guide and ready reminder for those taking a course in laundry work. ironing machines, domestic equipment, laundry equipment, laundry irons -

Mont De Lancey

Mont De LanceyCrimping Iron

... Ironing machines... and heated before use. Ironing machines Goffering irons Crimping ...This model 1880. The lower roller was removed and heated before use.Crimping or pleating iron with wooden handle."Crown." "Pat. Nov. 2 1875 July 3, 1877. Reissued Mar 23, 1880"ironing machines, goffering irons, crimping irons -

Orbost & District Historical Society

Orbost & District Historical Societypleating machine, late 19th century - early 20th century

Pleated ruffles were a fashionable trimming for ladies’ clothing in the late 19th century - early 20th century. Dressmakers and classy laundries offering “fancy” ironing services both had plenty of use for a pleating machine. Pleating machines were sold for home use too.This item is an example of a machine not commonly used today.Metal and wood pleating machine, still in working order. Handles are carved wood.textile-machinery sewing pleating-machine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Ironing board, 1910-1930

Ironing is the use of a machine, usually a heated tool (an iron), to remove wrinkles from fabric. The heating is around 180–220 °Celsius, depending on the fabric type. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibres of the material. While the molecules are hot, the fibres are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics developed in or after the mid-twentieth century require little or no ironing. Permanent press clothing was developed to reduce the ironing necessary by combining Wrinkle resistant polymers with cotton. The first known use of the iron for removing wrinkles in clothes is known to have occurred in China, and the electric iron was invented in 1882, by Henry W. Seeley. Seeley patented his "electric flat iron" on June 6, 1882 (U.S. Patent no. 259,054). On 15 February 1858 W. Vandenburg and J. Harvey patented an ironing table that facilitated pressing sleeves and pants legs. A truly portable folding ironing board was first patented in Canada in 1875 by John B. Porter. The invention also included a removable press board used for sleeves. In 1892 Sarah Boone obtained a patent in the United States for improvements to the ironing board, allowing for better quality ironing of shirt sleeves.A domestic item with an interesting history of development, significant as it shows the progress and the evolution of a domestic item designed to make housework more efficient.Wooden Ironing board with press board for sleeves, board is folding.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, domestic item, ironing board, ironing, clothes, wrinkles in clothes, henry w. seeley, w. vandenburg and j. harvey -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing, Baby Nylon pale blue dress size 1, 1962

Nylon became a popular, easy care material for clothing in City of Moorabbin in 1950's Flowers, shapes and patterns could be pressed into the material during manufacture and it required no ironing.This Nylon baby dress is typical of the widespread use of this popular synthetic material in the City of Moorabbin c1960 due to the its easy care and prettiness A Maude Wilson Style Baby nylon pale blue dress size 1 with press stud fasteners, lace trim, puff sleeves with blue ribbon and pale blue pink appliqued flowers clothing, baby, nylon, machine pressed designs, layette, knitting,craftwork, wool, early settlers, city of moorabbin, bentleigh, ormond, moorabbin, post war settlers, world war 11 1939-40 sharp valma, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing, Baby's white nylon dress size 1 c1960, c1960

Nylon was a new synthetic material that became very popular c 1960 because it was easy care, had machine embossed decoration and required no ironing. Women in City of Moorabbin made clothes for their families while settling in the new estates opened in Ormond, Bentleigh and Moorabbin post World War 11.Nylon was a new synthetic material that became very popular c 1960 because it was easy care, had machine embossed decoration and required no ironing. A Baby's white nylon dress size 1 with machine embossed flowers, short sleeves, lace trim, plastic buttons and appliqued nylon flowers. Size 1clothing, baby clothes, nylon, dressmaking, layette, knitting,craftwork, wool, early settlers, city of moorabbin, bentleigh, ormond, moorabbin, post war settlers, world war 11 1939-40 sharp valma, -

Melbourne Legacy

Melbourne LegacySlide, Laundry at Blamey House, 1970

A colour slide of young men in the laundry of Blamey House, Burke Road Kew, in 1970. One slide shows a young man doing ironing. There are two washing machines visible. There 10 slides from the same roll of film, some are marked 'Blamey 1970'. Legacy ran residences to take care of children whose fathers were deceased servicemen, and who may have been left orphans, or whose mother may have been unable to care for them herself, or they needed to stay in Melbourne for education. Was with many other slides taken in the 1950s and 1960s. The slides have been photographed to make digital images and moved to archive quality sleeves. In many cases the original images were not well focussed and the digital image the best available.A record of a Legacy residence supporting children of deceased servicemen.Colour slide x 2 of the laundry room of Blamey House in Kodachrome off-white cardboard mount with yellow and red print.Printed on front 'Made in Australia' in yellow ink. Printed with slide date 'Feb70M3' and slide number '15' or '16' in black ink. Handwritten '8' or '9' in blue ink. Printed on reverse "Kodachrome Transparency / Processed by Kodak" in red ink.residences, blamey house -

Bendigo Military Museum

Bendigo Military MuseumUniform - SLACKS, SERVICE DRESS, ARMY, Australian Government Clothing Factory, 1980

... headings "HAND WASH, MACHINE WASH IRONING", Followed by "NAME... headings "HAND WASH, MACHINE WASH IRONING", Followed by "NAME ...Slacks - garment is part of a Women's Service Dress uniform. Possibly issued to "BALAAM", Service No. "F380519" Refer also Cat No. 9616.1. Slacks - dark green colour wool and polyester, full length slacks with belt loops. Front nylon zipper fly, brown colour plastic button at waist - no pockets. Manufacturers labels - two, inside back of waistband, exterior back of waistband - (to be removed when worn). White colour polyester fabric. 2. Belt - fabric as above with keeper and metal press stud closer.Manufacturers label - black ink print. Inside back "A.G.C.F. VICTORIA 1980 ^/ 8410-66-096-5182 size 10, AVE HGT/ FULL HIP/ WAIST 60 CM HIP 90 CM" Garment care instructions under headings "HAND WASH, MACHINE WASH IRONING", Followed by "NAME/ Service No.". Outside back "THE TAG IS FOR IDENTIFICATION ONLY/ PLEASE REMOVE BEFORE WEARING" with printed and handwritten information.uniform, womens trousers, army, balaam, passchendaele barracks trust -

Mont De Lancey

Mont De LanceyDomestic object - Cookie Press and Icing Set, Unknown

Women in early settler days and 1900's managed the household and had to be self sufficient and were skilful cooks providing meals for their families. Normal daily life involved washing clothes, ironing, cooking meals and baking cakes, scones, bread, and pastries whilst caring for the children and making and mending the family's clothes. This was the precursor to the current hand held machine for making forcer biscuits. The metal cylinder was filled with biscuit dough and the wooden piece pushed down inside the cylinder to force the dough through different shaped, detachable, apertures to produce various shaped biscuits. The wooden forcer is missing from this set. The tin base has a movable end for cleaning the wooden press. An incomplete rusted long tubular tin cookie or icing press with four pattern attachments. There is no handle or forcer. There are four original shaped profiles which can be interchanged tied together with brown string. The tube was to be filled with biscuit/pastry mixture and a wooden press was used to force the mixture out of it. biscuit cutters, kitchenware, kitchen equipment, pastry cutters -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1962-1966

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. The colourwork dogs from this design are a very popular motif, and were available in both wool and Orlon in multiple styles from at least 1961-1972, including a cardigan and a pullover, selling 4346 of these in winter 1961. This example most likely dates from 1962-1966. An Illustration depicting this style is catalogued under NWM-09026. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children’s machine-knit jumper with white dog motif and green grass colourwork, closes with three red plastic buttons at left shoulder .2 and .3 are sample tags with manufacturing information, including sizes and colours available .4 is a swing tag with manufacturer care instructions.1) [label stitched at back neck] KATHRYN REGD. / 100% ORLON / 24 .2) STYLE: 44/OP – ORLON PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. WHITE. / 20” – 24” SKY BLUE. LEMON. WHITE. REDCOAT. BOTANY BLUE. SULTRY GREEN. NUTTY BROWN. OATMEAL .3) STYLE: 44/PW – WOOL PULLOVER – ANIMAL MOTIF / SIZE: 18” 20” 22” 24”/ PRICE: 18/6 21/3 25/- 27/6 / COLOR: 18” PALE BLUE. LEMON. / 20” – 24” SKY BLUE. LEMON. REDCOAT. BOTANY BLUE. / SULTRY GREEN. NUTTY BROWN. NED KELLY GREEN. / .4) Obverse: [handwritten] 5/10 (unintelligible) Kathryn / ORLON KNITWEAR / Style : 44/OP / DESIGNED & MANUFACTURED BY / Robert Blake / MELBOURNE Reverse: STANDARD MEASUREMENTS / FIT EXACTLY / LAUNDER PERFECTLY / HOT WATER WILL DAMAGE / THIS GARMENT / WASHING INSTRUCTIONS / 1. Use lukewarm water and mild soap. / 2. Squeeze water out by hand – DO / NOT WRING. / 3. DO NOT ROLL. Hang on / Clothes hanger to dry. / To keep brushed garments like / new, brush frequently with / Nylon brush. / IRONING [m (handwritten)] ORLON garments require little / or no ironing if drip-dried. If / ironing is necessary, it may be done damp or dry, using / a warm iron. / DO NOT USE / STEAM IRON /knitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, dog motif, animal motif, colourwork