Showing 6 items matching "lamp rotator"

-

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumEquipment - Lighthouse Lamp Changers, 23 August 2002

... lamp rotator...-and-the-bellarine-peninsula Lighthouse lamps lamp rotator Point Lonsdale ...Two 120 VAC lighthouse lamp changers, 6 globes on each ex Point Lonsdale Lighthouse and new control unit mechanismLC-300 120 VAC amp changer Part No. 630.1087 Series A Max voltage 130 Lamp size 250Watts US and foreign patents Tideland Signal Ltd, Surrey, England. Identifier No 1: 189486-5/01 Tideland Signal Corp, Houston, Texas USA identifierlighthouse, lamps, lamp rotator, point lonsdale lightouse -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects. 'Philips" electric Shaver, c1977

... is the dynamo-powered bicycle lamp. Its rotating power system inspires... bicycle lamp. Its rotating power system inspires the Philishave ...Established in 1891 in Eindhoven, the Netherlands, Philips & Co. was founded to meet the growing demand for light bulbs following the commercialization of electricity. Science and technology underwent tremendous development in the 1940s and 1950s, with Philips Research inventing the rotary heads that led to the development of the Philishave electric shaver, and laying down the basis for later ground-breaking work in transistors and integrated circuits.Philishave was the brand name for the electric shavers manufactured by the Philips Domestic Appliances and Personal Care unit of Philips They used the Philishave brand name for their shavers from 1939 to 2006. The Philishave shaver was invented by Philips engineer Alexandre Horowitz, who used rotating cutters instead of the reciprocating cutters that had been used in previous electric shavers. The shaver was introduced in 1939, though initial production was limited due to the outbreak of World War II. A more ergonomic egg-shaped single-head model was introduced in 1948 and was designed by US industrial designer Raymond Loewy. Global sales increased markedly after a double-head model was introduced in 1951. As a spin off from the light bulb and research is the dynamo-powered bicycle lamp. Its rotating power system inspires the Philishave triple head electric razor. A triple-head model was test marketed in Australia and New Zealand in 1956, but would not be introduced globally until 1966. The brand name Philishave was phased out in 2006 so shavers now bear only the Philips name. Mr Alfred William ( Bill ) Roper, 1913 - 1996 grew up in Ripponlea, ( East St Kilda ) Victoria. As a child he went with his father Arthur Leopold Roper to purchase vegetables from the Moorabbin Chinese market gardeners at the Hotham St. / Nepean Highway corner. c1920 . Bill served in WW2 in New Guinea and post war was Army Auditor, Victoria Barracks, St Kilda Road Melbourne. His staff presented this 'Philishave upon his retirement and he used it until his death1996. He lived in Carlton, Belgrave, Ascot Vale, South Yarra, East St Kilda and moved to Bentleigh in 1987.A ‘Philishave’ triple head electric razor , with cord, head protector and cleaning brush in a hinged plastic case The case has compartments, for Razor and cord, that are lined with a mustard coloured, soft, synthetic material .Case top PHILIPS ; inside EXCLUSIVE PHILISHAVE Razor Handle front PHILIPS / PHILISHAVE; back Type HP 1121/ 110-130V/ 220-240 V / PHILIPS Shield / ? Shield / BS 3456 / V 75255 / MADE IN HOLLAND Nameplate Presented to / BILL ROPER / On the occasion of his retirement / BY THE STAFF OF / DEFENCE AUDIT BRANCH / May 1977 philishave, royal philips electric company, razors, electric razors, bentleigh, moorabbin, market gardeners, st kilda markets, world war 2 1939-1945, department of defence melbourne, melbourne, roper alfred william, roper arthur leopold, ripponlea, chinese market gardeners -

Bendigo Military Museum

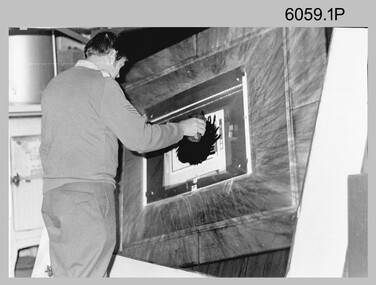

Bendigo Military MuseumPhotograph - Photographic Technicians performing tasks at the Army Survey Regiment, c1960s, c1970s

These five photographs were most likely taken in the 1970s in Lithographic Squadron at the Army Survey Regiment, Fortuna, Bendigo. Photos .1P to .3P are annotated with the name of the technicians written on the back. Although Photo .4P is not annotated the technician is positively identified. In these five photos the technician is applying a UV-sensitive pigmented dye emulating one of the print colours to a white opaque polyester sheet mounted on a rotating table in a whirler. The coated sheet was dried before placement in a vacuum light frame beneath a stud registered map negative. They were then exposed to a carbon arc lamp. If there was more than one negative – typical for a type impression or 1st proof, the process was repeated for the other negatives of that print colour. There was a single exposure for composite negatives which was typical for the 2nd and final proof - the pre-press proof. The sheet was removed and washed with water and dried leaving the exposed colour impression. The technician repeated this process using process or spot dyes for remaining publication colours. Type impressions were a combination of the map grid and the topographic features in their correct print colours, forming a base for the cartographer to accurately position map names and symbols on a clear film overlay. The pre-press proof was a cost-effective way of producing a one-off visual copy of the map or chart product. It enabled cartographers to perform a quality inspection and correct any faults before publication. The pre-press proof was deemed authoritative before its release to Print Troop for bulk printing and distribution.This is a set of photographs of lithographic technicians preparing map proofs at the Army Survey Regiment, Bendigo c1960s c1970s. The photographs were printed on photographic paper and are part of the Army Survey Regiment’s Collection. The photographs were scanned at 300 dpi. .1) - Photo, black & white, c1970s, SGT Graham Jeffers, Lithographic Squadron .2) - Photo, black & white, c1970s, SGT Ken Slater Lithographic Squadron .3) - Photo, black & white, c1970s, Ian ‘Loft’ Turner, Lithographic Squadron .4) - Photo, black & white, c1970s, Gary Kerr, Lithographic Squadron .5) - Photo, black & white, c1960s, unidentified, Lithographic Squadron.1 to .3 – personnel names (less rank) annotated on back. .4 to .5P – no annotationroyal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, litho -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Dioptric Apparatus, mid 19th century

Before the introduction of electricity, lighthouses had a clockwork mechanism that caused the lens to rotate with a light source inside that was either powered by Kerosene or Colza oil. The mechanism consisted of a large weight attached by a cable through the centre of the lighthouse to the top where the cable wrapped around a barrel, drum or wheels that controlled the speed of the lights rotation by a clockwork mechanism. The keeper would crank the clockwork mechanism, which would lift the weight ready for the next cycle similar to an old grandfather clock mechanism. Once the weight lifted to its apex at the bottom of the first landing, the keeper would let it fall, which would pull on the cable, which would, in turn, operate a series of gears activating the rotation of the Fresnel optical lens, which would then rotate to create the lighthouse’s unique light speed of rotation characteristic. Creating a specific characteristic required a way to regulate the speed of the rotation, and was important as sailors could identify a particular light by its speed and time between flashes. The weight had to fall at a certain rate to create the proper rotation speed of the lens and a regulator within the mechanism accomplished this. History: From 1851, Chance Brothers became a major lighthouse engineering company, producing optical components, machinery, and other equipment for lighthouses around the world. James Timmins Chance pioneered placing lighthouse lamps inside a cage surrounded by Fresnel lenses to increase the available light output these cages, are known as optics and they revolutionised lighthouse design. Another important innovation from Chance Brothers was the introduction of rotating optics, allowing adjacent lighthouses to be distinguished from each other by the number of times per revolution the light flashes. The noted English physicist and engineer, John Hopkins invented this system while employed at Chance Brothers. Chance Brothers and Company was a glass works and originally based in Spon Lane, Smethwick, West Midlands England. The company became a leading glass manufacturer and a pioneer of British glass making technology. The Chance family originated in Bromsgrove as farmers and craftsmen before setting up a business in Smethwick near Birmingham in 1824. They took advantage of the skilled workers, canals and many other industrial advances taking place in the West Midlands at the time. Robert Lucas Chance (1782–1865), known as 'Lucas', bought the British Crown Glass Company's works in Spon Lane in 1824. The company specialised in making crown window glass, the company ran into difficulty and its survival was guaranteed in 1832 by investment from Chance's brother, William (1788 – 1856). William owned an iron factoring business in Great Charles Street, Birmingham. After a previous partnership that Lucas had dissolved in 1836, Lucas and William Chance became partners in the business which was renamed, Chance Brothers and Company. Chance Brothers invented many innovative processes and became known as the greatest glass manufacturer in Britain. In 1848 under the supervision of Georges Bontemps, a French glass maker from Choosy-le-Roi, a new plant was set up to manufacture crown and flint glass for lighthouse optics, telescopes and cameras. Bontemps agreed to share his processes that up to then had been secret with the Chance Brothers and stayed in England to collaborate with them for six years. In 1900 a baronetcy was created for James Timmins Chance (1814–1902), a grandson of William Chance, who had started the family business in 1771 with his brother Robert. Roberts grandson, James became head of Chance Brothers until his retirement in 1889 when the company became a public company and its name changed to Chance Brothers & Co. Ltd. Additional information: Lighthouses are equipped with unique light characteristic or flashing pattern that sailors can use to identify specific lighthouses during the night. Lighthouses can achieve distinctive light characteristics in a few different ways. A lighthouse can flash, which is when brief periods of light interrupt longer moments of darkness. The light can occult, which is when brief periods of darkness interrupt longer moments of light. The light can be fixed, which is when the light never goes dark. A lighthouse can use a combination of flashing, oscillating, or being fixed in a variety of combinations and intervals to create individual light characteristics. It is a common misconception that a lighthouse's light source changes the intensity to create a light characteristic. The light source remains constant and the rotating Fresnel lens creates the various changes in appearance. Some Fresnel lenses have "bulls-eye" panels create beams of light that, when rotated between the light and the observer, make the light appear to flash. Conversely, some lenses have metal panels that, when rotated between the light and the observer, make the light appear to go dark. This Dioptric clockwork apparatus used to turn a lighthouse optical lens is very significant as it is integral to a lighthouses operation, we can also look at the social aspect of lighthouses as being traditionally rich with symbolism and conceptual meanings. Lighthouses illustrate social concepts such as danger, risk, adversity, challenge and vigilance but they also offers guidance, salvation and safety. The glowing lamp reminds sailors that security and home are well within reach, they also symbolize the way forward and help in navigating our way through rough waters not just on the oceans of the world but in our personal lives be it financial, personal, business or spiritual in nature. Nothing else speaks of safety and security in the face of adversity and challenge quite the way a lighthouse does. Revolving dioptric clockwork apparatus used to turn a Fresnel optical lighthouse lens. A cylindrical cast metal pillar and cabinet painted green with 3 glass doors enclosing the top section. Inside the pillar/cabinet is a large clockwork mechanism used to turn and regulate a lighthouse light by means of weights and a chain attached to same. One door has the name "Adams Mare" in metallic dots similar to "Braille" to the inside edge of door frame.shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, flagstaff hill, maritime-museum, shipwreck-coast, warrnambool, flagstaff-hill-maritime-village, revolving dioptric mechanism, dioptric mechanism for lighthouse, lighthouse clockwork timing mechanism, acetylene lighthouse light mechanism, 19th century lighthouse mechanism, kerosene light, fresnel lenses, colza oil, chance brothers -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: RAILWAY LAMP

Pittock coach builder's box: Old railway lamp, marked origin unknown, probably belonging to A. E. Pittock * stored in paper bag as detailed, refer 13000.44a * steel, glass construction * lamp is 310 mm tall, 150 mm round * lamp has three adjustable filters ( red / broken, blue and space for third (clear!) lens, which are set by rotating the handle to fixed loacations * lamp lit by kerosene wick, refer 13000.44e & f, brass container with mirror behind wick to intensify the light Item stored in Pittock coach builkder's box, reference 13000.1. -

Bendigo Military Museum

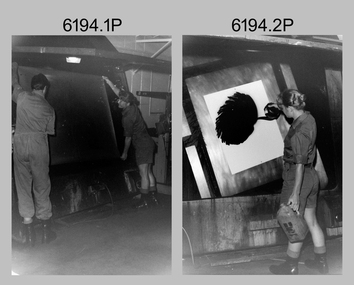

Bendigo Military MuseumPhotograph - Lithographic Technicians and Equipment at the Army Survey Regiment, Fortuna Villa Bendigo, c1990s

These 10 photographs were most likely taken in the 1990s in Lithographic Squadron at the Army Survey Regiment, Fortuna, Bendigo. In photos .1P to .2P the technicians are applying a UV-sensitive pigmented dye emulating one of the print colours to a white opaque polyester sheet mounted on a rotating table in a whirler. The coated sheet was dried before placement in a vacuum light frame beneath a stud registered map negative. They were then exposed to a carbon arc lamp. For more photos and details on the process, see item 6059.5P. In photos .3P to .5P the technician is preparing a orthophotomap film positive. Photo .6P is the rear view of the tri-linear film punch. In photos .7P and .8P the technician is operating a heavy-duty guillotine to trim bulk printed map stock. Cartographers normally provided trim marks to specified map dimensions as guidance to the printer. The trimming stage, like all the other printing processes required high levels of accuracy. These guillotines were extremely powerful to cut through bulk quantities of printed maps. For more photos and details on this process, see item 6069.6P. In photo .9P the technician is operating a daylight film contacting frame. In photo .10P LT Ian Stoddart is taking a well-earned break.This is a set of 10 photographs of lithographic technicians undertaking tasks at the Army Survey Regiment, Bendigo c1990s. Photos .1P to .7P and .9P to .11P are on 35mm negative film and scanned at 96 dpi. Photo .8P is printed on photographic paper and scanned at 300 dpi. They are part of the Army Survey Regiment’s Collection. .1) and .2) - Photo, black & white, c1990s, unidentified printer technician and SPR Janet Murray using the map proof whirler. .3) to .5) - Colour, c1990s, Mick ‘Buddha’ Ellis preparing an orthophotomap film positive. .6) - Photo, Colour, c1990s, rear view of tri-linear film punch. .7) & .8) - Photo, Colour, c1990s, unidentified technician operating a heavy-duty guillotine. .9) - Photo, Colour, c1990s, printer technician SPR Shona Hastie operating a daylight film contacting frame. .10) - Photo, Colour, c1990s, LT Ian Stoddart taking a well-earned break. .1P to .10P– no annotationroyal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr, litho