Showing 1004 items matching "loom"

-

National Wool Museum

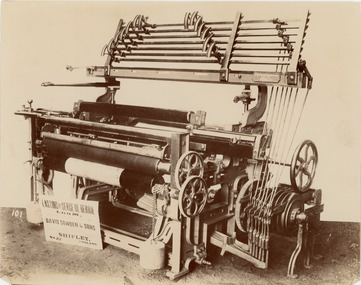

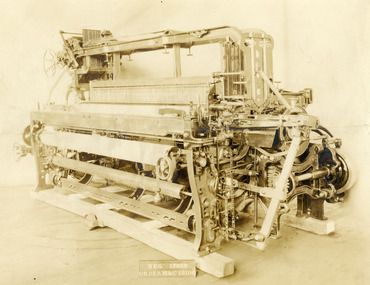

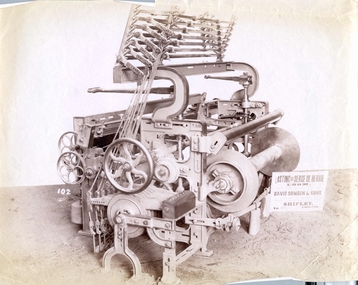

National Wool MuseumPhotograph, Lasting or Serge de Berrie Loom

Photograph probably for promotional purposes, of a "David Sowden & Sons" loom, No101, "Lasting or Serge de Berrie Loom". Photograph was among items from Yarra Falls Mill.Photograph, sepia, of a "David Sowden & Sons" loom, No101, "Lasting or Serge de Berrie Loom".LASTING OR SERGE DE BERRIE/ LOOM/ DAVID SOWDEN & SONS/SHIPLEYtextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumPrice list, Price lists for Loom Accessories

"Price lists for Loom Accessories"-R Gruenhut & Son Pty Ltd"Price lists for Loom Accessories"-R Gruenhut & Son Pty LtdPrice lists for Loom Accessoriestextile machinery textile mills textile mills, r. gruenhut and son pty ltd, weaving machinery, weaving looms, textile machinery, textile mills -

National Wool Museum

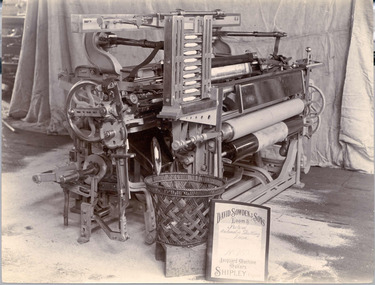

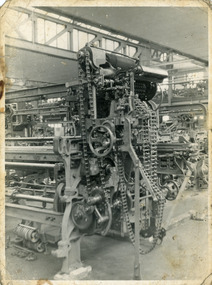

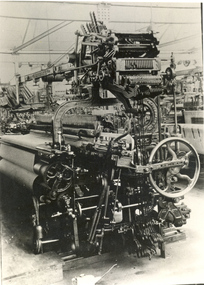

National Wool MuseumPhotograph, Patent Automatic Shuttling Loom

Photograph probably for promotional purposes, of a ""David Sowden & Sons Patent Automatic Shuttling Loom", No 162. Photograph was among items from Yarra Falls Mill.Photograph, black and white, of a "David Sowden & Sons Patent Automatic Shuttling Loom", No 162."David Sowden & Sons/Looms/ Patent /Automatic Shuttling/ Loom"/ No 162/Jacquard Machine Makers/ SHIPLEYtextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

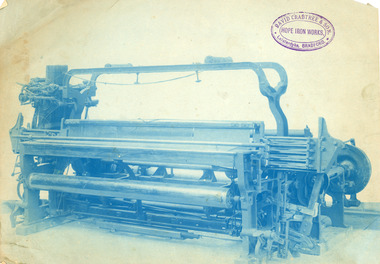

National Wool MuseumPhotograph, Loom, Unknown

Photographs were most likely used for promotional purposes. Loom made by David Crabtree & Son, a loom manufacturer based in Laisterdyke, Bradford.Black and white blue tinged photograph of a loom in landscape format.Stamped top right corner - David Crabtree & Son HOPE IRON WORKS, Laisterdyke, BRADFORDtextile machinery, wool manufacture, wool, loom -

National Wool Museum

National Wool MuseumPhotograph, Loom, Unknown

Photograph of a Hutchinson, Hollingworth and Co. Limited Loom gears and mechanisms. Hutchinson, Hollingworth and Co. was an Oldham-based loom manufacturer estalished in 1860 by Messrs. John Hutchinson (c.1816-1888) of Cawthorne and James Hollingworth(c.1834-1895) of Holmfirth.Three black and white photographs in portrait format of a looms gear mechanisms.8052.1 - front on machine mid left quadrant - Hutchinson, Hollingworth and Co 8052.2 - front on machine mid left quadrant - Hutchinson, Hollingworth and Cotextile machinery, wool manufacture, wool, loom -

National Wool Museum

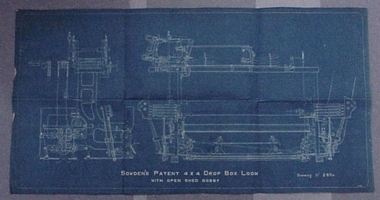

National Wool MuseumBlueprint, Sowden's Patent 4x4 Drop Box Loom with open shed dobby

Blueprint of part of a "David Sowden and Sons" 4x4 Drop Box Loom. It was among items from Yarra Falls Mill.Blueprint of part of a "David Sowden and Sons" 4x4 Drop Box Loom.SOWDEN'S PATENT 4X4 DROP BOX LOOM/WITH OPEN SHED DOLBY T & I H /Kent GWNtextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

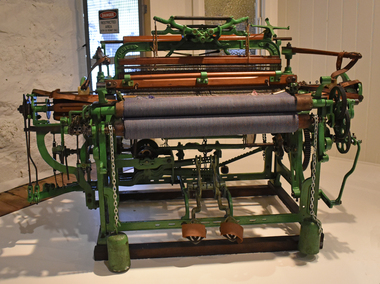

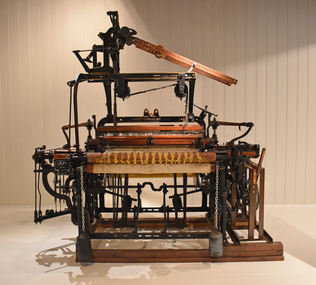

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1925

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley treadle loom (revolving box hand loom). Beam of loom was removed and sent to Foster Valley Mill in 1989 to be returned via Tom Crocker. The National Wool Museum gratefully acknowledges the contribution of Mr Fred Murgatroyd & Mr Bernard Tolan in making this Hattersley Loom Operational. Green painted Hattersley treadle loom (revolving box hand loom).weaving, george hattersley and sons ltd, weaving machinery, wool processing, loom, restoration -

National Wool Museum

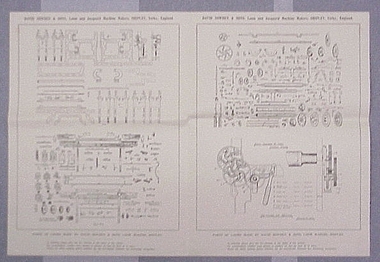

National Wool MuseumChart, Parts of looms made by David Sowden & Sons, loom makers, Shipley

Chart: "Parts of looms made by David Sowden & Sons, loom makers, Shipley ", among items from Yarra Falls MillChart: "Parts of looms made by David Sowden & Sons, loom makers, Shipley ".textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumPhotograph, Loom, Unknown

Photographs were most likely used for promotional purposes.Sepia photograph of a loom in landscape format.Bottom mid edge - NEG. 17689 ORDER M&C 12106textile machinery, wool manufacture, wool, loom -

National Wool Museum

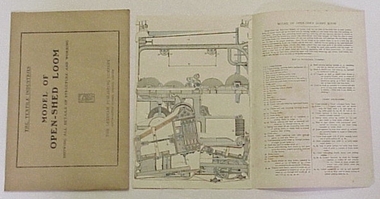

National Wool MuseumModel, Model of Open-Shed Loom

This paper model of an open-shed loom was produced by the Gresham Publishing Company and was part of the eight volume set of books titled: "The Textile Industries" by William S. Murphy and first published by Gresham in 1911. (The NWM holds two sets of these books; one donated in 2001 and the other donated in 1989 by Godfrey Hirst. This model was not part of the set donated in 2001, but may possibly have come into the collection with the 1989 donation. It may also have come seperately via another, unknown donor.)This paper model of an open-shed loom was produced by the Gresham Publishing Company and was part of the eight volume set of books titled: "The Textile Industries" by William S. Murphy and first published by Gresham in 1911.THE TEXTILE INDUSTRIES / MODEL OF / OPEN-SHED LOOM / SHOWING ALL DETAILS OF STRUCTURE AND WORKING / THE GRESHAM PUBLISHING COMPANY / SOUTHAMPTON STREET, STRAND, LONDONweaving looms -

National Wool Museum

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

Vision Australia

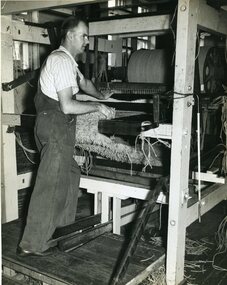

Vision AustraliaPhotograph - Image, Mannix O'Reagan operating a loom

QIIB worker Manix O'Reagan demonstrating a matting loom.1 x B/W photograph of man operating a loom10. C7146 Manix O'Reagan (bdod)queensland industrial institute for the blind, manix o'reagan, employment -

National Wool Museum

National Wool MuseumBook, Practical tackling of the plain and fancy loom

"Practical tackling of the plain and fancy loom" James Culpan, 1920."Practical tackling of the plain and fancy loom" James Culpan, 1920.textile industry - history textile machinery weaving textile industry - education, weaving looms, weaving machinery, textile industry - history, textile machinery, weaving, textile industry - education -

National Wool Museum

National Wool MuseumCatalogue, Detached piece catalogue of the Hattersley "Standard Model" Fancy Woollen and Worsted Loom

Catalogue of woollen and worsted loom produced by George Hattersley & Sons Ltd.Catalogue of woollen and worsted loom produced by George Hattersley & Sons Ltd.textile machinery, george hattersley and sons ltd -

National Wool Museum

National Wool MuseumBook, Instruction Paper No.490: Woolen and worsted loom fixing, 1st ed

Instruction Paper No.490: Woolen and worsted loom fixing, 1st ed, 1925Instruction Paper No.490: Woolen and worsted loom fixing, 1st ed, 1925weaving textile machinery textile industry - history textile industry - education, international correspondence schools ltd, cloth - woollen, cloth - worsted, weaving looms, weaving, textile machinery, textile industry - history, textile industry - education -

National Wool Museum

National Wool MuseumPhotograph, Tweedside 1920: Northrope loom

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroyd Tweedside/ 1920/ Northrope /Loomstextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, weaving looms, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

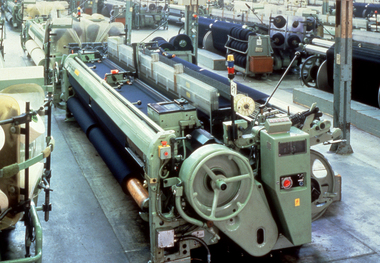

National Wool MuseumPhotograph - Slide, Stuart Ascough, Loom, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training and technical advice at mills in China, India, Russia and Australia. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing a factory interior with loom machinery.wool, industry, australia, australian wool board international wool secretariat, factory, training, loom -

National Wool Museum

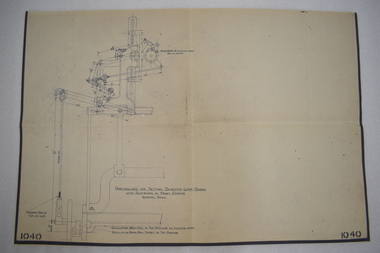

National Wool MuseumBlueprint, Particulars for Setting Domestic Loom Dobby with Slayboard at Front Centre

Blueprint / diagram for a Hattersley loom: "Partculars for Setting Domestic Loom Dobby with Slayboard at Front Centre".Blueprint; detailed diagram printed in black on buff coloured paper. "Partculars for Setting Domestic Loom Dobby with Slayboard at Front Centre".weaving, george hattersley and sons ltd, weaving machinery -

National Wool Museum

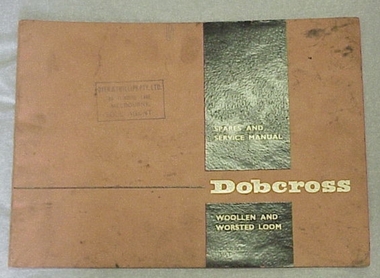

National Wool MuseumCatalogue, Dobcross spares and service manual woollen and worsted loom

"Dobcross spares and service manual woollen and worsted loom" -Hutchinson, Hollingworth and Co. Limited"Dobcross spares and service manual woollen and worsted loom" -Hutchinson, Hollingworth and Co. LimitedDYER AND PHILLIPS PTY LTD/ 89 FLINDERS LANE/ MELBOURNEtextile machinery, hutchinson, hollingworth and co. limited, weaving looms, weaving machinery -

Vision Australia

Vision AustraliaPhotograph (item) - Image, Elderly woman weaving on loom

Weaving is a craft activity that has been a part of many day centres. In this image, a blind woman sit in front of a loom, holding the threads, her lips slightly pursed, as if in conversation. Another woman stands beside her and looks down at the work, her hand holding the weaving slightly forward as she looks at the stitches.royal victorian institute for the blind, day centres -

National Wool Museum

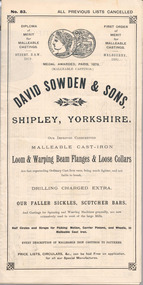

National Wool MuseumCatalogue, Loom and warping beam flanges

Catalogue, "Loom and warping beam flanges and loose collars" - David Sowden & Sons, Shipley. Among items from Yarra Falls Mill.Catalogue, "Loom and warping beam flanges and loose collars" - David Sowden & Sons, Shipley.textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumLoom

The loom was made by John Charles Mann in the late 1920s-early 1930s for Lilian Joyce Mann. Mr Mann enjoyed woodwork. He died in 1945. Ms Mann was very interested in crafts and owned a shop in Jacob Street which sold handmade soft toys and items woven from the loom, for example table mats. The shop was later bought out by Henry Jacobs and later became Myer. Ms Mann died on the 17th July 2007. Ms Mann was a founding and life member of the Geelong Handweavers and Spinners Guild.W7219 (Mann loom) Lilian Joyce Mann's loom in house Lilian Joyce Mann's loom in houseOxy & Electric Welding Motor & Gehandicrafts, geelong handweavers and spinners guild inc., weaving looms, weaving, mann, mr john charles mann, ms lilian joyce, geelong, victoria -

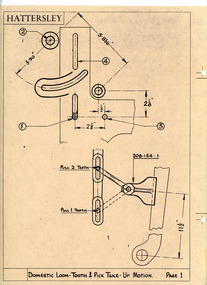

National Wool Museum

National Wool MuseumBooklet, Hattersley Domestic Loom: Tooth and Pick Take-Up Motion

Instructions: "Hattersley Domestic Loom: Tooth and Pick Take-Up Motion"Booklet, 3pp. loose leaf. Printed with text and diagrams on one side only. "Hattersley Domestic Loom: Tooth and Pick Take-Up Motion"weaving, george hattersley and sons ltd, weaving machinery -

![Manual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ed29821f50e3cc9ea4b/item-media/601344e16061d010347e22d5/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumManual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions

This handbook contains the setting instructions for a Standard Hattersley Loom developed by George Hattersley and Sons Ltd. The Hattersley loom was developed by George Hattersley and Sons of Keighley, West Yorkshire, England. The company had been started by Richard Hattersley after 1784, with his son, George Hattersley, later entering the business alongside him. The company developed several innovative looms, of which the Hattersley Standard Loom – developed in 1921 – was a great success. The Hattersley Standard Loom was designed and built in 1921. Thousands of models were expected to be sold, which would bring considerable financial success to the company. After the recapitalisation boom of 1919, cotton yarn production peaked in 1926 and further investment was sparse. Rayon, an artificial silk, was invented in the 1930s in nearby Silsden, and the Hattersley Silk Loom was adapted to weave this new fabric. An example of this type of loom can be seen on Vic Collections here ( https://victoriancollections.net.au/items/54065d0f9821f50e3cc9c122 ) and is also on display within the National Wool Museum in Geelong, Victoria. A copy of this manual may be available by contacting the National Wool Museum Collection Team. Book, 64pp. Red and black loose leaf, soft cover, printed black ink. "[Hattersley] Standard Loom Tuners Handbook: Setting instructions " - George Hattersley and Sons LtdTHE BRUCE WOOLLEN MANUFACTURING CO LTDtextile industry - history textile machinery weaving textile industry - education, george hattersley and sons ltd, weaving looms, weaving machinery, textile industry - history, textile machinery, weaving, textile industry - education -

![Photograph, [Fred's loom]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ff99821f50e3cc9fb11/item-media/54065ff99821f50e3cc9fb12/item-fit-380x285.jpg) National Wool Museum

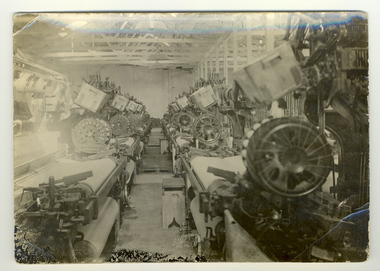

National Wool MuseumPhotograph, [Fred's loom]

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd This is Fred's loom /You can't see much of it /though. He took this/ inside the shed. KODAK PRINTtextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph - Aunde Album 29, Setting the Jacquard Loom, 2002

Aunde / Norwellan Textiles North Western Woollen Mills became Norwellan Textiles then AUNDEColour landscape photo: Two male employees setting up the Jacquard Loom.industry, aunde -

National Wool Museum

National Wool MuseumPhotograph, Federal Mill: Hattersley Loom

James Murgatroyd worked in the textile industry in England and in Victoria and New South Wales.The Murgatroyd CollectionHATTERSLEY LOOM/FEDERAL MILL - 1918/1920 FILM No10textile machinery textile mills weaving mills textile mills, federal woollen mills ltd collins bros mill pty ltd, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

National Wool Museum

National Wool MuseumPhotograph

Photograph probably for promotional purposes, of a "David Sowden & Sons" loom, No102, "Lasting or Serge de Berrie Loom". Photograph was among items from Yarra Falls Mill.Photograph, sepia, of a "David Sowden & Sons" loom, No102, "Lasting or Serge de Berrie Loom".LASTING OR SERGE DE BERRIE/ LOOM/ DAVID SOWDEN & SONS/SHIPLEYtextile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

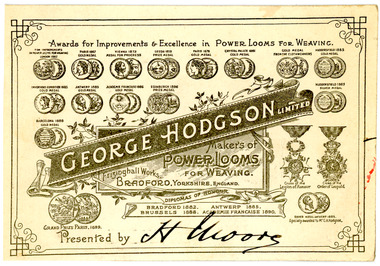

National Wool MuseumAdministrative record - Business Card, George Hodgson Limited Business Card, Unknown

George Hodgson Limited Business Card, a British loom manufacture based in Bradford England. The card showcases the awards the company as won as well as a description of one of their looms.Cream business card printed with the black ink. The front of the card lists the awards and medals the company had one in the background with an image of each award. The company logo is placed in the center. The back of the card has a drawing of a loom with a decorative border.Front top edge - Awards for Improvements & Excellence in Power Looms for Weaving. Front middle - George Hodgson Limited Makers of Power Looms for Weaving. Bradford, Yorkshire, England Front bottom edge - Presented by J T Elioors (?) Back bottom edge - One shaft heavy underpick worsted and woollen cloth loom, with 4 holed drop box on each side, fitted with positive wheel dobby.textile machinery, wool manufacture, wool, loom, george hodgson limited -

National Wool Museum

National Wool MuseumLoom

Used by Ted Fairhurst, an Industrial Chemist from Bradford who came to Australia in 1951 for Bradford Dyers A. He later established the dyeing section for Davos Coop who made Exacto garments. Mrs Fairhurst (donor) made bookmarks, bell hangings and belts. Inkle weaving is for producing narrow braids.Inkle loom.weaving - inkle, fairhurst, mr ted