Showing 58 items

matching machine driven

-

Churchill Island Heritage Farm

Churchill Island Heritage FarmFunctional object - Lister stationary engine

... machine driven... machine driven belt driven Green Lister Stationary Petrol Engine ...Robert Ashton Lister was born in England in 1845 into an industrial family. After attending the Paris Exhibition in 1867, Robert argued with his father and formed the R.A. Lister Company to produce agricultural machinery at his factory in Dursley, England. In 1889 he linked his machine with Pederson’s cream separator which now ran at a consistent speed due to a spinning centrifugal separator thus producing consistency of cream. It was marketed through the Commonwealth and Robert himself drove right across Alberta in Canada with horse and buggy to promote the machine. He also expanded the use of his machine to sheep shearing. In 1909 the Company acquired the rights to manufacture petrol driven engines. When World War 1 began in 1914 the Company focused on producing petrol engines, lighting plants and munitions for the War Department, the workforce was mainly female as the men enlisted and left for the Front. After the War, Robert Lister retired, and the Company was taken over by his grandsons Robert, Frank, George and Percy with A.E.Mellerup. Their father Charles represented the Company in North America and Europe. Foreign competition and over supply of second-hand ex-military engines and lighting sets saw profits drop but the Company managed to recover under the leadership of Managing Director Percy. In 1929 the Company designed the CS (cold start) diesel engine producing 6-7kW which became known as the Lister 9-1. The engines were all painted the same shade of Brunswick green. By 1936 Lister was producing a wide range of petrol and diesel engines most of which were small at 1.5 to 3 horsepower. These could be bought ‘stand-alone’ or powering a complementary range of pumps, churns, cream separators, auto-trucks, generating plant and sheep shearing equipment. The most successful was the D Type Lister introduced in 1937 most of which were rated at 1.5hp at 700rpm. More than 250,000 were sold up to 1964 and although RA Lister ceased production many years ago, hundreds of these engines are still in use today.Green Lister Stationary Petrol Engine Serial No. 16268. It is the smaller of two Lister engines in collection. It was made in 1924, Dursley, UK. The two engines in the collection are petrol engines from the 1920s predating the more numerous diesel engines manufactured from 1920 on.farm machinery, stationary engine, machine driven, belt driven -

Churchill Island Heritage Farm

Churchill Island Heritage FarmFunctional object - Butter worker

... machine driven... machinery dairy equipment butter butter worker machine driven ...Belt driven wheel, timber, blue metal trims and circumference bandThe Alexandra. Maker T.Robinson & Co Ltd, Spotiswoodefarm machinery, dairy equipment, butter, butter worker, machine driven -

Puffing Billy Railway

Puffing Billy RailwayKBW Belt Driven Slotting Machine

... KBW Belt Driven Slotting Machine... - Industrial - Slotting Machine belt driven puffing billy slotter kbw ...KBW Slotting MachineHistoric - Industrial - Slotting MachineLarge metal KBW Slotting Machine KBWbelt driven, puffing billy, slotter, kbw, slotting machine -

Churchill Island Heritage Farm

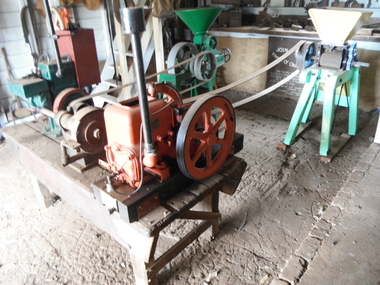

Churchill Island Heritage FarmFunctional object - Stationary engine, red, 1925

... on local farms. Representative farm machinery stationary machine ...“Sundial 2hp engine, open crank, 600rpm, serial number 6420.” These small 4 stroke engines were widely used on Australian farms through the 20th century to power chaffcutters, grinders, saws, lighting plants, pumps, shearing plants, milking machines and cream separators easing much of the drudgery of farm work. They were also used in garages and workshops and by bush fire brigades. The engine was made by H.V.McKay Massey Harris. At one time Hugh Victor McKay’s Sunshine Harvester Works was the largest factory in Australia but in 1930, to ensure survival during the Great Depression, elected to merge with the Australian arm of a Canadian firm, Massey Harris. The Sundial is fitted with twin flywheels, making it a compact and convenient power source as either wheel could double as a drive wheel. Its connecting rod, crankshaft and flywheel spokes are covered, a safety measure that was not standard at the time. These engines were advertised as simple, dependable, low in price and cheap to run. They had the additional advantage that a bolt-on kit was made by the manufacturer to convert them to run on kerosene. ‘The engine's output is two horsepower (1.5 kW) at 600 rpm. The compression ratio is 5:1 and the spark plug is activated by a high tension magneto. The fuel tank holds 3.3 litres and the cooling water hopper holds 6.6 litres. Cylinder bore is 101 mm and piston stroke is 115 mm.’ In a catalogue of HV McKay Massey Harris agricultural machinery published in March 1942, the engine is described as follows: 'The cylinder head is of the hot, turbulent type, giving the finest fuel atomisation and heat distribution. The carburettor, of special design, has an automatic air valve controlling the amount of air. The supersensitive, high speed, flyball-type governor provides an ample range of speed.'Typical of units used on local farms. RepresentativeSundial 2 h.p. engine, open crank 600 rpm Seral number 6420, red. Attached to yellow grain grinderSunshine McKay, 1939 Serial no. 6420farm machinery, stationary, machine operated, belt driven -

Federation University Historical Collection

Federation University Historical CollectionCalculator, Burroughs, Calculator (Adding Machine), c1935

... & Tarrant "Comptometer". The first Burroughs key-driven machine...-driven type machine did not print, and was exceedingly fast... The "Burroughs Calculator" was a non-printing key-driven machine ...The "Burroughs Calculator" was a non-printing key-driven machine introduced in 1912 in response to the success of the Felt & Tarrant "Comptometer". The first Burroughs key-driven machine was very similar to the Comptometer in its external appearance, but was quite different in its internal mechanism, with the register and carry mechanism based on a complex system of planetary gears. It was only about two-thirds of the weight of the Felt & Tarrant machine, and had none of the safety features. In particular, there was no protection against incomplete keystrokes in either direction. The register would simply advance in proportion to the depth of stroke, with no indication of error. However, the price was also about two-thirds of the Comptometer, which made it quite a popular (if dangerous) machine. (http://home.vicnet.net.au/~wolff/calculators/Burroughs/Burroughs.htm) The Burroughs Portable Adding Machine introduced in 1925 became the basic design for the adding machine for many years, until the ten key adder was introduced and started to replace it gradually. The key-driven type machine did not print, and while it was often used as an adding machine, it developed into a special purpose machine in later years. The machine was very fast . The efficient operation of these machines required an experienced operator who often received a high salary. The machine was produced over a very long period because of its unique capabilities and was often used to verify product delivery lists from delivery routes. Later models of the machine, called a duplex design, could hold a running total in a second set of dial wheels while the primary wheels continued to add and subtotal amounts that could be transferred at any time to the running total. A side note, Burroughs copied the Felt design for its first models and was sued for patent infringement by Felt and Tarrant who prevailed in the suit. As a result, Burroughs totally redesigned their machine and went on to compete with the Felt machine for decades. Info from (http://www.burroughsinfo.com/group_d.htm) Black metal low keyboard manual adding machine. The key-driven type machine did not print, and was exceedingly fast and experienced operators could easily outrun an operator on a full keyboard or 10-key adding machine. The adding machine has a brown leather carry case.calculator -

Cheese World Museum

Cheese World MuseumPump, dairy vacuum

... Milking machine chain driven vacuum pump made of cast iron... milking machines Leon Miller 209 Milking machine chain driven ...From the dairy farm of Leon Miller, Swans Lane, AllansfordMilking machine chain driven vacuum pump made of cast iron, marked on the circular cylinder cap with an identification number.209allansford, machinery, dairy machinery, dairying, pumps, milking machines, leon miller -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumGrain Grister, 1925

... are adjustable .Machine driven by flat leather belt on a pulley from... Rollers are adjustable .Machine driven by flat leather belt ...grinding grainWooden delivery /storage box on top of metal Grister with three cogs and flywheel [approx. 30 cm diameter] and metal grinding cylinders [rollers] with horizontal grooved lines all around .This is bolted to a wooden stand [painted green] which has a wooden box to receive the crushed grain Rollers are adjustable .Machine driven by flat leather belt on a pulley from a small stationary engine Metal plaque attached to top of delivery box. J Buncle Parkside Ironworks North Melbournegrain, grister, farming, machinery -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageObject

... Object steam driven machine attached to base by 4 bolts... steam driven machine attached to base by 4 bolts. 640mmH x ...Object steam driven machine attached to base by 4 bolts. 640mmH x 430mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Kaolin Mining -- mining a fine white clay used for crockery in Stone Street Stawell 1914

... Group of men and women inspecting horse driven puddling... horse driven puddling machine. Kaolin Mining -- mining a fine ...Kaolin Mining (a fine white clay used for crockery) Stone Street Stawell 1914Group of men and women inspecting horse driven puddling machine.stawell -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Kaolin Mining -- mining a fine white clay used for crockery in Stone Street Stawell 1914

... Group of men and women inspecting horse driven puddling... horse driven puddling machine. Kaolin Mining -- mining a fine ...Kaolin Mining (a fine white clay used for crockery) Stone Street Stawell 1914Group of men and women inspecting horse driven puddling machine.stawell -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Craft - Tapestry

... Tapestry has been woven on a electrical driven machine...Tapestry has been woven on a electrical driven machine ...Tapestry has been woven on a electrical driven machine.|Belonged to Mrs. A.E. Hepburn 1933 - 1988. Formerly of Mont Albert.Wall hanging tapestry in brown toning. Scene of an old room with three women sitting at a table sewing with a child standing near them. All women wearing fitted caps. Room heavily detailed - chairs, fireplace, dresser, windows, half open door, lectern, wardrobe, etc. One woman wearing glasses. 3/4 backed in heavy cotton with opening for wooden rod. Long fringing on one end. Wooden rod.handcrafts, tapestry -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, The Homeward Bound Gold Mine in Stawell c1898

... of a steam driven puddling machine. Two horses and carts are in front... and women standing in front of a steam driven puddling machine. Two ...Stawell Alluvial Mining Scene. The Homeward Bound Mine Company puddling machine c1898Four well dressed men and women standing in front of a steam driven puddling machine. Two horses and carts are in front of the puddler and three men standing on the machineEarly Mining Scene Stawell. Mine Believed to be "The Homeward Bound'stawell -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPrinting Machine, John Key, Engineers, Kircaldy et al

... Electrically driven platen machine. Used by Gordon & Gotch... driven platen machine. Used by Gordon & Gotch Publishers ...Electrically driven platen machine. Used by Gordon & Gotch Publishers Australia & New Zealand. Metal with wooden tray for printed sheets. Automatic paper feed pickup.Plate naming it as "Auto Platen Machine" British patent No's 463542, 463617, 480587, 490661, 512459, 513892, 413818. Plate on side "John Key / Engineers / Kircaldy. -

Eltham District Historical Society Inc

Eltham District Historical Society IncNewsletter, Newsletter, No. 19 July 1981

... • Subscriptions • Horse-Driven threshing machines, Kangaroo Ground ... • Subscriptions • Horse-Driven threshing machines, Kangaroo Ground ...Contents: • Next meeting – Discussion evening – Early history of Kangaroo Ground • Former Eltham Police Station • Subscriptions • Horse-Driven threshing machines, Kangaroo Ground The Shire of Eltham Historical Society was formed in October 1967. The first newsletter of the Society was issued May 1978 and has been published continuously ever since on a bi-monthly basis. With the cessation of the Shire of Eltham in late 1994, the Society's name was revised to Eltham District Historical Society and this name first appeared with issue No. 103, July 1995. The collection of the Society's newsletters provides a valuable resource on the history of the Society's activities, office bearers and committee members, guest speakers and subjects of historical interest pertinent to the former Shire of Eltham and the Eltham District.A4 photocopied newsletter distributed to membersnewsletter, eltham district historical society, shire of eltham historical society -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Singer Electric Sewing Machine, The Singer Manufacturing Company, 1950

... provided some room for storage. The machine is driven by a small... some room for storage. The machine is driven by a small ...Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. According to its serial number, this machine was manufactured in 1950 and was one of the new models designed to be more portable as it only weighed about 10 KG.This sewing machine is of local, national and international significance as it represents developments in technology and the impact this had upon the work of women.The Singer 99 was a sturdy and reliable machine that was easy to use. Lighter than other machines of its time, this machine weighed only 10 Kgs. It is mounted on a wooden base with a small compartment under the balance wheel to store accessories and bobbins. It has a 'Bentwood' (polished plywood) cover which also provided some room for storage. The machine is driven by a small electric motor and a light to illuminate the work area. It is decorated with gold decals and a filigree pattern. It includes a knee control which is inserted in a hole at the front of the machine. The serial number EG045782 indicates it was manufactured in 1950.Across the top in gold script: "The Singer Manufacturing Co. / Made in Great Britain" On light cover: "SINGER" Plate with specifications also attached. On front of machine in oval badge: A CENTURY OF SEWING SERVICE/ THE SINGER MANFG. CO. 1851 - 1951singer sewing macnine, domestic appliances, women's work, technology -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAddressograph Machine

... into the middle section. The electric machine is belt driven.... The electric machine is belt driven and controlled by three 52 cm long ...This metal plate machine used plates that contained names, addresses and classifications of each State Electricity Commission of Victoria employee working on the Kiewa Hydro Electric Scheme. The plates were put through the machine onto pay envelopes.See also: KVHS 1046, KVHS 1233The S.E.C.V. employed many people on the Kiewa Hydro Electric Scheme and used the latest technology of the time to pay each of them including providing each one with a pay slip. Metal table with the addressograph machine set into the middle section. The electric machine is belt driven and controlled by three 52 cm long metal pedals. The operator uses 5 stops, 2 knobs and 1 winder while sitting at the machine. There are 5 extra metal parts (or pieces) which belong to this machine. Ref. KVHS 1046 - Ink Rolls - Labelling Cartridges for Addressograph MachineMetal plate attached to front of machine which reads "Class 22000 Serial No. B-01547. Addressograph regd. Addressing machine. Patents Pending Made in England Addressograph Multigraph Limited London.addressograph machine. state electricity commission of victoria. kiewa hydro electric scheme. payroll. office work. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, early to mid-20th century

... Post type drill press machine with gear driven flywheel... machine drill with gear driven flywheel forging tool metal working ...This post drill press has been made by Melbourne business, Dawn Manufacturing Company. It can be operated manually or by a pulley driven flywheel, with the aid of an engine connected to a power supply. In the late 1800s early 1900s a drill press like this would have been driven by steam from a boiler, the main power source for manufacturer’s power at that time. Dawn’s Golden Anniversary 1917-1967 Catalogue describes this model 611 drill as … “Ruggedly constructed with accurately reamed bearings. The coupling between the main spindle and feed screw engages the full circumference of the spindle, and embraces a ball-bearing thrust race. The pillar, as in all “Dawn Drilling Machines” is a solid bright steel bar, in place of the usual light tubing. Adjustable automatic feed.” And “F. & l. Pulleys extra, if required”. DAWN MANUFACTURING CO. The Dawn Manufacturing Co. was founded in Coburg, Melbourne, in 1917 by the four Blake brothers, who were all engineers. After World War I Dawn was supplying drills Australia wide and the company was growing at a healthy rate. During the depression they remained busy, with employees working 60-80 hour weeks. Dawn was contracted to supply vices and clamps to the Australian Defence Department and munitions factory during the World War II. - 1959 the company was taken over by G.N. Raymond Group. - 1967 the Dawn Manufacturing Co. had distributors in Australia and overseas, including USA, Canada, New Zealand, Asia and the Middle East. - 1973 the Siddons Ramset Limited acquired Dawn. - December 1991, Dawn became a unit of the United States owned Stanley Works Pty. Ltd. - November 1998 Dawn became 100 per cent Australian owned. The drill is a typical tool of a blacksmith, cart wright, wheelwright and garage business. It is an example of the tools of the blacksmiths’ trade in Victoria in the early to mid-20th century.Post type drill press machine with gear driven flywheel. Drill press is attached to a post and is fitted with a pulley belt and will run at a speed of maxim 200 r.p.m. The machine can also be manually operated. It has an aperture in the centre, a chuck, for the drill bit and has two metal handles at the centre, on the right hand side. Gear ratio 2:1 main drive, 6" diam, 3:1 reduction gear. Made by Dawn of Melbourne, Australia. Model No. 611, Code No. 9157"DAWN MFG COY”, “MELB. AUSTRALIA", " 611"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, blacksmiths, blacksmith’s drill, blacksmith tools, dawn drill model no. 611, dawn drill code no. 9157, dawn manufacturing coy melbourne, dawn manufacturing coy coburg, dawn post drill, drilling machine, drill with gear driven flywheel, forging tool, metal working tool, post drill, steam powered drill, trade tool, warrnambool district 1900s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

... . The 1870 US Census reported the firm had 21 machines, driven.... The 1870 US Census reported the firm had 21 machines, driven ...Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyElectric Megger (Insulation Tester) and its case

... . The optimal megger for large Generating machines was motor driven.... The optimal megger for large Generating machines was motor driven ...Megger as the device was called, is in fact its brand name. It is a device that supplies a DC (direct current as per car batteries) voltage to enable testing of electrical apparatus. This particular device produces 250volts DC when the handle is turned vigorously. If an electrical device, such as a kettle or toaster, blew a fuse or tripped a circuit breaker, when switched on, then it must be checked electrically before any more use. Following the repair of the faulty item a megger would be used to check if either of the AC 240volt plugs leads were touching the metal case (earth). The output leads of the megger would be connected with one to the earth (metal case) and the other to each of the power connections in turn. A good megger reading of 50,000 ohms (resistance) would enable the device to be returned to service. A reading of zero ohms resistance would mean that it would again blow a fuse, and was therefore unsafe to use. In the electrical industry e.g. the former State Electricity Commission, a megger would be used to test lots of similar item in sequence. Because of the vigorous job of winding the handle, two persons were often used to save time. One would crank madly whilst the other shifted the leads. This particular megger is of a small voltage, but other meggers are bigger and have a few ranges of DC voltages able to be selected. The optimal megger for large Generating machines was motor driven megger. This was applied to the device being tested for a duration of approximately 30 minutes with reading of the resistance taken at regular intervals.All equipment belonging to the State Electricity Commission of Victoria was labelled with a metal plaque attached to it. The SECV constructed the Kiewa Hydro Electric Scheme in the Upper Kiewa Valley and on the Bogong High Plains. The scheme began in 1938 and finished in 1961 when this megger was used and also possibly later as the SECV remained to maintain and operate the Scheme. This megger is of significance in relation to the advancement of technology.A rectangular box in dark brown bakerlite casing. It has an agent's plaque fixed to the left of the face and on the right is the marker's recessed stamp. In the middle in a transparent window so the level of ohms can be read. The front also has two recessed fixing knobs in black. On one side is a crank handle with a knob that lifts up and is turned vigorously to create the voltage. The back has four recessed screws and four small leather pads. There is a hole on each side to insert wires. There are two copper insulated wires. The SECV Plaque states: State/Electricity Commission/of/Victoria/ Electrical Engineer's Section/ No.1747 The Agent's Plaque states: H. Rowe & Co. Pty Ltd/Melbourne & Sydney/Sole Agents/in Australia for/Evershed & Vignoles Ltd Maker's states: 500 volts/Megger/Regd Trade Mark/Made in England/Patent No/400728electrical meters, electrical equipment, fuses, safety, state electricity commission of victoria, mt beauty, bogong village -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionDocument - Military Submission, John Ferres, Government Printer, Defences of the Colony, 1864

... a steam-driven printing machine was imported and installed.... On his advice a steam-driven printing machine was imported ...1864 group of 4 submissions bound in to one document. Heavy paper sewn together with twine, black print on white.portland battery, military, major scratchley, commodore wiseman, governor, john ferres -

Flagstaff Hill Maritime Museum and Village

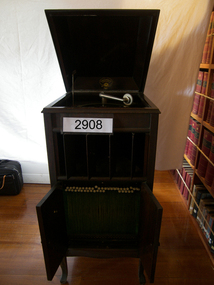

Flagstaff Hill Maritime Museum and VillageGramophone, 1911

Until late 1925, all record players reproduced sound by purely mechanical means and relied on a so-called "amplifying" horn to efficiently couple the vibrations of the stylus and diaphragm to the space occupied by the listeners. In 1906, the Victor Talking Machine Company, Columbia's arch competitor, introduced a line of models in which the horn and other hardware were concealed within a cabinet, made to look like fine furniture rather than a mechanical device. They named the new style a "Victrola". It quickly proved to be very popular and successful. Other makers, adopting the distinctive suffix, introduced their own "-ola" internal horn machines, such as Edison's Amberolas and Columbia's Grafonolas. They were soon outselling the external horn models. At first, like nearly all other early record players, all Grafonolas were driven by a spring motor that the user had to wind up with a crank before playing a record. In 1915, Columbia began to introduce electric-motor-driven models, as a majority of urban areas had been wired to electrical grids. The electrified Grafonolas supported both alternating and direct currents from 110 to 220 volts. Electrified Grafonolas never gained the popularity enjoyed by the spring motor-driven versions due to substantially higher prices and a lack of electrical service in rural areas. Grafonolas were manufactured under the 1886 United States Letters Patent No. 341,214 which Columbia Graphophone company acquired through its predecessor American Graphophone Company. Two models were available; a portable table model and bigger stationary floor model, offering limited mobility through the application of casters. The most notable table models included Grafonola Favorite introduced in 1911 and Grafonola Savoy introduced in 1915. The most notable floor models included Grafonola Symphony Grand introduced in 1907, Grafonola Regent introduced in 1909, Columbia Mignon introduced in 1910, Grafonola Princess introduced in 1911, Columbia Colonial introduced in 1913. Various period Grafonolas were introduced in 1917 to cater to an increasingly prosperous clientele. Columbia Phonograph Company began to manufacture a series of ornate, limited edition period machines. These were highly priced (some as high as US$2,100 ) special orders that provided consumers with options to choose styles which matched their interior décor. Although the Gramophone does not have a large monetary value, it is of social significance as it demonstrates the progress made in audio reproduction from the first Edison cylinder machines to improvements that allowed ordinary people to be able to buy music discs and enjoy music in their own homes. Gramophone with internal horn, floor model, mechanically operated by a crank handle. Colombian Grafonola Princess (Type F2) brand. Gramophone is in a wooden display cabinet with room for record storage underneath and is complete with handle. Manufactured in 1911 by Columbia, USA."Columbia Grafonola Type 2 Made in USA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, record player, gramophone, mechanical gramophone, floor model gramophone, gramophone record, columbia graphophone company, american graphophone company, columbia, grafonola, grafonola princess, music, playing music, audio reproduction, sound equipment, domestic entertainment, 1911 gramophone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, possibly 1918

... of equipment used for a steam driven machine. flagstaff hill ...This type of steam boiler is called a Scotch Marine boiler. It was manufactured in Dordrecht, Netherlands, possibly in 1918 by 'DeMan & Teveldhuis'. The only history that we have was that the boiler was found in an unknown paddock. It had an attached tag labelled "Melbourne Steam Club" but never collected by them. It was eventually brought to Flagstaff Hill Maritime Village for display.This boiler is an example of equipment used for a steam driven machine.Boiler, Scotch Marine Boiler design, cylindrical shape with rivets on the enclosed end, pipe fittings on top and apertures and open pipe ends on the other end.. Possibly manufactured by 'DeMan & Teveldhuis' in 1918 in Dordrecht, Netherlands. Inscription embossed on outside of boiler. "19 DE MANS & TEVEL-(D?)HUIS DORDRECHT 18"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, boiler, scotch marine boiler, steam boiler, ship's boiler, dordrecht netherlands, 1918 boiler, melbourne steam club -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document, Albion woollen mills, C 1926

Thomas Broadbent $ sons Ltd was established in 1864 in Huddersfield England. They are an engineering firm , specialists in heavy duty engineering products. By 1893 Broadbent had progressed to steam powered engines for the textile industry. Some of these machines operated for upwards of 50 years Today Broadbent is a leading world designer in the manufacture and maintenance of advanced centrifuges. This document is a manual for a suspended direct steam driven hydro extractor. It shows the various parts , maintenance instructions and erection and working instructions. While it is stamped as Albion Woollen mills which were situated at Geelong, it is likely to have connections to the Warrnambool Woollen Mills.This document is a good example of machinery manual. It is possibly linked to the Warrnambool Woollen Mill. The fact that the company which manufactured these items is still in existence today after 150 years is testament to the quality of the items produced.Cream coloured document with mainly black text with some red text for headings contained in the document. It is printed front and back and is folded in three sections.Stamp at top "Albion Woollen mills Pty Ltd" .4H x 4 in red pencil in top RHC. Printed on front page. Thomas Broadbent & Sons Ltd Central Iron Works Huddersfield. warrnambool, warrnambool woollen mill, broadbent direct steam driven hydo extractors,, broadbent centrifuge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Lawn Mower, Alex Shanks & Sons Ltd Engineers Arbroth London, 1903-1925

The firm of Alexander Shanks & Sons Ltd of Arbroath, were engineers, founders and boiler makers the company was incorporated in the year 1893. At the Dens Iron Works, purchased by the firm in the same year, a wide variety of products was manufactured including cranes, hoists, pumps and lawnmowers. In the 1960s the firm was taken over by Alexander Shanks (1801-1845) was an Inventor of the modern lawnmower, who lived in Arbroath Scotland. While credit is usually given to the Englishman Edwin Budding (1795-1846) for the invention of the lawnmower, it is Shanks' machine which was the direct predecessor of the modern mower. Shanks' innovation was a machine which rolled the grass as well as mowing it. Although Shanks himself died at a young age, his son showed the mowers at the Great Exhibition in 1851 which led to a successful business that continued into the 20th century, supplying mowers to cut the tennis courts of Wimbledon, the cricket grounds at Lords and the Old golf course at St Andrews. The firm was also well known for the manufacture of portable steam engines and steam cranes. In 1968, the company was taken over by Giddings & Lewis Fraser Ltd, Engineers of Arbroath. The subject item is a good example of an early lawn mower made by the company that is credited with being the first to patent and manufacture such a machine. The company Alexander Shanks founded was known throughout the world as significant manufactures of large steam machines used from the middle of the 19th century to the first quarter of the 20th century. The subject item is now regarded as a collector's item.Lawnmower, cast iron handles has two wooden ends and two wooden rollers at front. Blades driven by chain fixed to metal roller. Shanks's Standard Chain. Shanks's Standard Chain Arbroth London. Alex Shanks & Sons Ltd Engineers Arbroth Londonflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, hand mower, lawn mower, mower, shanks, arboth -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wringer/Mangle, Melvin Newton Lovell, 1898 -1900

Melvin Newton Lovell was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family removed to Kerrtown, a village located in the vicinity of Titusville, PA. There Melvin served an apprenticeship at the carpenter's trade, and his natural mechanical talent enabled him to become a skilled workman. He followed his trade during the major portion of his term of residence in Kerrtown. In 1861, at seventeen years of age, Melvin Lovell left his home and, without parental authority, and entered the Union army soon after the outbreak of the Civil war. In August 1862, he was enlisted as a private in the 127th Pennsylvania Volunteer Infantry and saw active service until receiving his discharge at the end of May 1863. In 1865 he took up his residence in Erie, where he worked at the carpenter's trade for several years thereafter. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing of certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. Among the principal products of the original factory were washing machines and step-ladders. In 1881 Lovell individually began manufacturing other of his patents, including spring beds, and from modest inception, his Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country and was recognized as being the most extensive manufacture of clothes-wringers in the entire world. In connection with his manufacture of domestic items, Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan and after his business had already been established becoming a substantial concern Lovell invented and patented the famous wringer which bears his name under the “Anchor” brand, and in later years he confined his operations largely to the manufacture of this very superior household invention. Lovell was also one of the organizers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents, with headquarters in New York and a factory at Bloomfield, New Jersey.A significant household item used in the process of washing clothes by a man who had started in 1869, as a young carpenter and later he became a successful businessman and manufacturer of household items. Lovell was granted numerous patents for various devices during his career including several patents for adding machines (cash registers).Wringer (or mangle); portable wooden washing wringer with rubber rollers, manually driven by iron set of gears and handle. Includes iron clamps and adjusting screws for attaching. Marked on frame "382", "12 x 1 3/4" Anchor Brand "Made in USA" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, mangle, clothes wringer, washing equipment, laundry, wringer, domestic, washing mangle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, ca 1880

... steam driven engine boiler steam machine firebox steam engine ...This little steam boiler has been beautifully built. It could have been used to drive an engine in a small workshop, a boat or launch, or even farming equipment. It is an example of the steam technology and mechanisation of the 19th century. William Cook introduced steam heating in England in the 18th century. Steam combined with pressure was used for powering transport, such as steam engines for trains, and manufacturing, such as steam engines driving manufacturing machines. Steam boilers are still used today as an energy-efficient means of power.This steam boiler would have been suitable to drive a small engine, possibly that of a small boat. Coal was added to the firebox for fuel to heat water in the boiler. It is an example of the power used to drive machinery and equipment in the mid-to-late 19th century. Steam boilers like this one have played a part in the evolution of steam power. Steam engine boiler; vertical cylindrical coal-fired boiler with a black firebox at its base and a dome top. The cylinder's sides and top have brass fittings, inlet and outlet taps. A round opening near the base is covered by an adjustable metal plate that controls the boiler's temperature. The front door of the firebox has two hinges at the base and when the side clips are opened. A shiny brass collar tops the tall chimney. Oak wood planks around the sides of the boiler, and held in place by brass bands with nut and screw fixtures. The boiler stands on a metal and wood frame with a looped handle at the back. An inscription has been noted. Circa 1880. "1948 D/430" flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, boiler, steam engine, steam boiler, coal fired boiler, vertical boiler, boat boiler, power source, steam driven, engine boiler, steam machine, firebox, steam engine boiler -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDrill Press, Champion Blower & Forge Co

Bench drill belt driven with stand. Pat no 767.282.Aug.9.1804. Champion Blower & Forge Co USA. Painted red and green. Machine number No.201. large bench type. Circa 1900flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bench drill, champion blower & forge co -

Flagstaff Hill Maritime Museum and Village

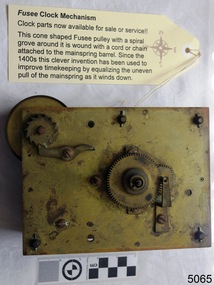

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Flagstaff Hill Maritime Museum and Village

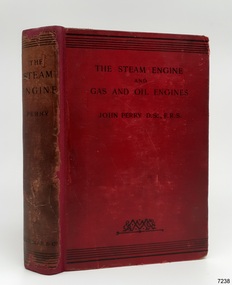

Flagstaff Hill Maritime Museum and VillageBook - Reference, John Perry, The Steam Engine and Gas and Oil Engines, 1899

... , understanding and evolution of power driven machines. The principles ...This is the first edition of the book, printed in 1899. It has since been reprinted with slight corrections in January 1900 and with correction in 1902. It is a text book and reference book based on the study of steam, gas and oil driven machinery of the late 19th and early 20th century. The author, John Perry D. Sc., F.R.S., was born in 1850 and passed away in 1920. He was a Professor of Mechanics and Mathematics in the Royal College of Science, Vice-President of the Institution of Electrical Engineers, and Vice-President of the Physical Society. This book has significance as the First Edition of the book, published in 1899. The book is significant to the history, understanding and evolution of power driven machines. The principles apply to the machinery of the late 19th to early 20th centuries. The Steam Engine and Gas and Oil Engines: a book for the use of students who have time to make experiments and calculations Author: John Perry D.Sc., F.R.S. Publisher: Macmillan & Co Ltd, London Printed by Richard Clay and Sons, Limited, London and Bungay This is the First Edition of the book, printed in 1899 A hard cover book, red linen with black print. The Preface is written by the aughor on 22nd February 1899. The book contains many diagrams and tables as well as having reference numbers on many paragraphs in the chapters.Pencil on front endsheets "SJ 9""Rec. 371 a" Stamped in purple , front endsheet "F. ST. G. D. HOLYMAN" "L.4." Handwritten in ink "Richard G ---- / Liverpool --- P---ye"warrnambool, shipwrecked-coast, flagstaff-hill, maritime-museum, shipwreck-coast, book, the steam engine and gas and oil engines, john perry, reference book, scientific book, steam engines, gas engines, oil engines, combustion engines