Showing 216 items matching "machine lace"

-

Australian Lace Guild - Victorian Branch

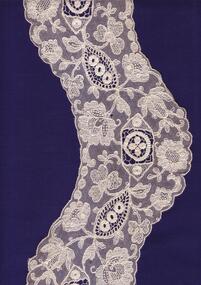

Australian Lace Guild - Victorian BranchTextile - Machine lace

... Machine lace...Machine lace edging...: Household trimming Machine lace edging Textile Machine lace ...Use: Domestic: Household trimmingMachine lace edging -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine lace

... Machine lace...Machine lace motif... lace motif Textile Machine lace ...Use: DomesticMachine lace motif -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine lace

... Machine lace...Machine lace cuff.... Fashion Machine lace cuff Textile Machine lace ...Use: Domestic. FashionMachine lace cuff -

Australian Lace Guild - Victorian Branch

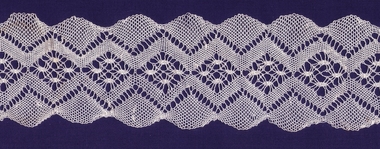

Australian Lace Guild - Victorian BranchTextile - Machine made lace, Late 19th Century

... Machine made lace...This piece of machine made lace was probably made...Pink machine made lace edging.... made lace was probably made on a Levers machine (invented 1813 ...This piece of machine made lace was probably made on a Levers machine (invented 1813)Pink machine made lace edging. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine lace

... Machine lace...Machine-made lace...-made lace Textile Machine lace ...Use: DomesticMachine-made lace -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine Blonde lace, 1800-1900

... Machine Blonde lace...Machine lace bonnet veil.... Fashion Machine lace bonnet veil Textile Machine Blonde lace ...Use: Domestic. FashionMachine lace bonnet veil -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace : Filet, Late 19th Century

... Machine made lace : Filet...Machine made lace. Probably made on a Levers machine using...A length of individual square motifs of machine made Filet... Gardenvale Road Gardenvale Gardenvale melbourne Machine made lace ...Machine made lace. Probably made on a Levers machine using jacquard apparatus to make a series of individual square motifs. These were probably destined to be cut apart and used as applique pieces on some other textile.A length of individual square motifs of machine made Filet lace -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine Embroidered net lace, 1880-1920

... Machine Embroidered net lace...Machine lace... Gardenvale Road Gardenvale Gardenvale melbourne Machine lace Textile ...Machine lace -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Textile - Satin and machine lace bedspread

... Satin and machine lace bedspread...A pink satin and cream machine lace bedspread made from... machine lace bedspread made from alternative 13 to 14cm wide ...A pink satin and cream machine lace bedspread made from alternative 13 to 14cm wide strips in a rectangular pattern with central rectangle set at 45 degrees. Three sides are edged with silk chenille bobbles in pink and cream. The central rectangle and the four corners surrounding the central rectangle have a floral cut work pattern in the silk overlaying the lace which has couched cornelli work.. The third satin rectangle from the outside has a looped and wave pattern in couched cornelli work, missing on one corner.favaloro, bedspread, satin, chenile bobble trim -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine or Bobbin lace, 1900-2000

... Machine or Bobbin lace...Machine lace insertion.... Fashion Machine lace insertion Textile Machine or Bobbin lace ...Use: Domestic. FashionMachine lace insertion -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine Knitted lace

... Machine Knitted lace...Machine knitted lace shawl... Gardenvale Road Gardenvale Gardenvale melbourne Machine knitted lace ...Machine knitted lace shawl -

Australian Lace Guild - Victorian Branch

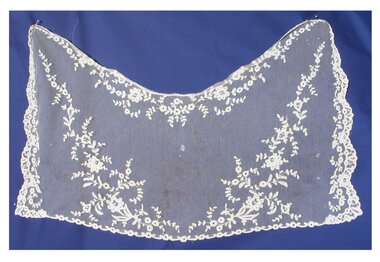

Australian Lace Guild - Victorian BranchTextile - Machine Muslin appliqué lace, 1850-1900

... Machine Muslin appliqué lace...Machine lace bonnet veil.... Fashion Machine lace bonnet veil Textile Machine Muslin appliqué ...Use: Domestic. FashionMachine lace bonnet veil -

Australian Lace Guild - Victorian Branch

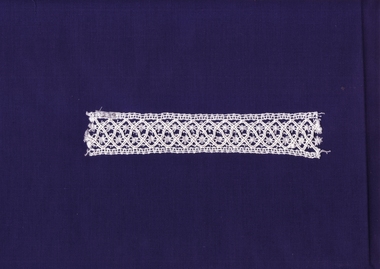

Australian Lace Guild - Victorian BranchTextile - Machine made lace: Torchon, Early 20th Century

... Machine made lace: Torchon...Machine made lace imitating Torchon bobbin lace. Insertion... Gardenvale Road Gardenvale Gardenvale melbourne Machine made lace ...Machine made lace imitating Torchon bobbin lace. Insertion. Costume trimming -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace : Torchon, Early 20th Century

... Machine made lace : Torchon...Machine made lace imitating Torchon bobbin lace. Insertion... Gardenvale Road Gardenvale Gardenvale melbourne Machine made lace ...Machine made lace imitating Torchon bobbin lace. Insertion - costume trimming -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace: Embroidered net

... Machine made lace: Embroidered net...Machine embroidered net lace. Wide band.... net lace. Wide band. Textile Machine made lace: Embroidered ...Machine embroidered net lace. Wide band. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine mixed lace, Late 19th or early 20th Century

... Machine mixed lace...A collar of machine made lace imitating Carrickmacross.... A collar of machine made lace imitating Carrickmacross. Machine ...Fashion accessory.A collar of machine made lace imitating Carrickmacross. Machine muslin applique motifs on the body of the collar with Chemical lace motifs on the points. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace

... Machine made lace...Machine made lace "Chemical" oval lace motif. Cotton thread... Gardenvale Road Gardenvale Gardenvale melbourne Machine made lace ...Machine made lace "Chemical" oval lace motif. Cotton thread embroidered onto a base fabric which is later dissolved away. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace, Late 19th or early 20th Century

... Machine made lace...Machine made "Chemical" lace motif. Cotton thread... which is later dissolved away. Textile Machine made lace ...Machine made "Chemical" lace motif. Cotton thread embroidered onto a base fabric which is later dissolved away. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace

... Machine made lace...Machine made "Chemical" lace edging. Cotton thread... which is later dissolved away. Textile Machine made lace ...Machine made "Chemical" lace edging. Cotton thread embroidered onto a base fabric which is later dissolved away. -

Whitehorse Historical Society Inc.

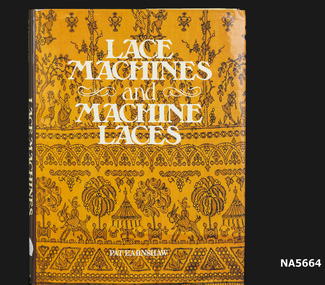

Whitehorse Historical Society Inc.Book - Lace Machines and Machine Laces, B.T. Batsford Ltd London UK, 1986

... Lace Machines and Machine Laces...Lace Machines and Machine Laces...- Documentation of history of lace machines & lace making... machines and machined lace....- Documentation of history of lace machines & lace making ...- Documentation of history of lace machines & lace making - Dates covered 1760's - present day- Bound, hardcover book - Dust jacket - First published 1986 Book provides excellent comprehensive history of lace machines and machined lace.Various - Author Pat Earnshawlace, lace machines -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace, Second half 19th Century

... Machine made lace... machine chain stitch. Textile Machine made lace ...Machine made muslin applique Fichu. Muslin appliqued onto machine made net using machine chain stitch. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace: Chemical lace, Early 20th Century

... Machine made lace: Chemical lace...Chemical lace. The design was machine embroidered onto... Machine made lace: Chemical lace ...Chemical lace. The design was machine embroidered onto a base fabric which was then chemically dissolved away.Collar with standing neck edge. -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine made lace: Embroidered net

... Machine made lace: Embroidered net... net scarf Textile Machine made lace: Embroidered net ...Machine embroidered net scarf -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine Buckinghamshire Point lace

... Machine Buckinghamshire Point lace...: Household trimming Bobbin lace edging Textile Machine ...Use: Domestic: Household trimmingBobbin lace edging -

Australian Lace Guild - Victorian Branch

Australian Lace Guild - Victorian BranchTextile - Machine Embroidered net lace, 1900-1950

... Machine Embroidered net lace...Australian Lace Guild - Victorian Branch Briphil House 80 ...Use: Domestic. FashionMachine made embroidered net -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Petticoat, late 19th century to early 20th century

... machine made lace... of Edwardian petticoats - when the lace at the bottom became worn... machine made lace hand sewn machine sewn draper's shop Susan Henry ...This petticoat was one of several items donated from the estate of Susan Henry OAM nee Vedmore (1944 - 2021). It is in very good condition and appears to be from the Edwardian era - early 20th century. A petticoat is a lady's undergarment - worn under a skirt or dress. They provided warmth, modesty and shape to the dress. In the middle of the 19th century, petticoats were worn over hoops, bustles or in layers. Petticoats varied according to the style of the outside skirt or dress. Plain petticoats tended to be worn with everyday wear whilst better dresses (party dresses or silk gowns) were worn with petticoats that often had more trim and embellishments. Edwardian petticoats had less volume than Victorian era petticoats and they had a "dust ruffle" or lining under a lace flounce. The "dust ruffle" protected the lace flounce and gave the petticoat more flare at the bottom, greater freedom when walking as well as saving the flounce (which was often made of finer material) from everyday wear and tear. Tucks are another feature of Edwardian petticoats - when the lace at the bottom became worn, it could be cut off and the tucks released. This extended the life of the petticoat. This petticoat features an intricate trim of broderie anglaise. Although broderie anglaise was a lace that could be made by hand, it was very time consuming to make. St Gallen was a city in Switzerland that had become known for producing quality textiles. At the beginning of the 19th century, the first embroidery machines were developed in St Gallen. Factories used embroidery machines but people also had them in their homes. They were able to produce broderie anglaise for export. By the early 20th century, machine made lace, fabric, ribbons etc. were being sold in drapers shops all over England and Wales to women who were making clothes and furnishings for their families. It is highly likely that the lady who made this petticoat brought the lengths of broderie anglaise already made to embellish and personalise her petticoat. Susan's family (Harold and Gladys Vedmore) immigrated to Australia from Wales in 1955 and settled in Warrnambool. Susan was well known in the Warrnambool community for her work supporting children and families across the district - particular those with disabilities, or those who were homeless, unemployed or isolated. Susan was the founding trustee of the "Vedmore Foundation" - a Warrnambool philanthropic trust set up in 2010 to support a range of charitable and not-for-profit causes by providing grant assistance. In 2021, she was awarded a Medal of the Order of Australia for services to the community.This item is an example of the needlework skills of women in the late 19th century - creating pintucks and adding lace to personalise and embellish a practical item of clothing. It is also significant as an example of a practical solution to the difficulties that women of this era faced with regard to the washing of clothes and household linens.A white lawn petticoat with a 22.5 cm opening that fastens with 2 small buttons and a drawstring tie. It is decorated with two wide pintucks followed by two gathered frills (or flounces) - one decorated with three rows of narrow pintucks and a single row of broderie anglaise and the bottom frilled hem finished with 3 rows of broderie anglaise in a flower design. The two bottom frills are lined with plain white cotton fabric.flagstaff hill maritime museum and village, great ocean road, petticoat, lady's petticoat, undergarment, lady's undergarment, lingerie, edwardian petticoat, broderie anglaise, lace, machine made lace, hand sewn, machine sewn, draper's shop, susan henry oam, vedmore foundation -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Accessory - Lace collar ties

... Cream machine lace Irish crochet collar with long ties.... McNamaa family collection Cream machine lace Irish crochet collar ...From the McNamara collection.Cream machine lace Irish crochet collar with long ties.collar, lace, mcnamaa family collection -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's silk nightgown c1930, c1930

... machine lace... was declared in 1934. silk machine lace lingerie clothing moorabbin ...After surviving the Depression Years many market gardeners changed to poultry farming and egg supply to build a multi million dollar industry . Women were able to follow the fashion trends even if they still made the clothes themselves. The City of Moorabbin was declared in 1934. A lady's beige silk nightgown with a lace bodice and long waist ties c1930. Bias cutsilk, machine lace, lingerie, clothing, moorabbin, cheltenham, bentleigh, early settlers, market gardeners, blackburn nance, city of moorabbin, poultry farmers, dairy farmers, -

National Wool Museum

National Wool MuseumTextile - Children's Lace Jumper, Kathryn Knitwear, c.1970

... Machine lace... manufacturing Fashion Textile Production Machine Knitting Machine lace ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Cream short sleeved jumper with overall open lace design, front yoke with accent lacework and applied lace ruffle edging .2 is a retail tag with style code and size, reverse has washing instructions for acrylic and cotton.1) [white tag back neck, printed blue letters] KATHRYN REGD POLYESTER/VISCOSE MADE IN AUSTRALIA .2 [retail swing tag, numbers handwritten in blue ink] KATHRYN Children’s Knitwear STYLE [handwritten] 363 PRICE SIZE [handwritten] 6children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, machine knitting, machine lace -

National Wool Museum

National Wool MuseumTextile - Baby Romper Suit, Kathryn Knitwear, c.1970

... Machine lace... Production machine knitting Machine lace baby clothes .2 [Retail ...Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Orlon was developed by DuPont in the 1940s and became the first commercially successful acrylic fibre in the 1950s and 1960s. The development of Orlon coincided with an increase in availability of washing machines in everyday Australian homes. The great appeal of Orlon was that while wool garments still had to be hand-washed, Orlon’s shrink-resistant nature made it machine washable and dryable. This was a very appealing prospect, especially for the seemingly unending task of cleaning active children’s clothing. Machine washable wool would not be available until the development of the ‘Superwash’ treatment by the Australian Wool Board and CSIRO in 1970. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White lacework baby romper suit with long sleeves and legs, and enclosed feet. Closes at centre back with two plastic buttons. Zips open around leg inseam. Size 00 .2 is a retail tag marked with the price and size, and refers to the label sewn into the garment for washing instructions..2 [Retail Swing Tag] [Obverse] KATHRYN Children’s Knitwear STYLE PRICE [handwritten] $18 SIZE [handwritten] 00 [Reverse] WASHING INSTRUCTIONS Refer to label sewn in Garment Designed and manufactured by ROBERT BLAKE PTY. LTD., Melb., Aust.children's knitwear, children's clothing, baby clothing, baby knitwear, clothing, knitwear, romper, jumpsuit, manufacturing, fashion textile production, machine knitting, machine lace, baby clothes