Showing 48 items matching "machinery room"

-

Ballaarat Mechanics' Institute (BMI Ballarat)

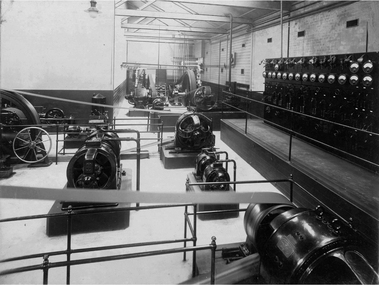

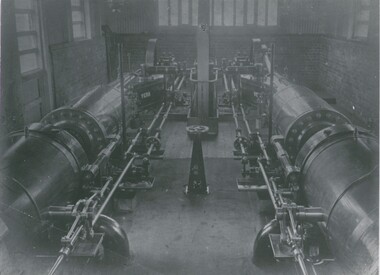

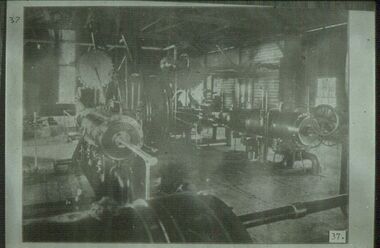

Ballaarat Mechanics' Institute (BMI Ballarat)Machinery Room View 1

... Machinery Room View 1...Machinery Room... BMI for all print and usage inquiries. Ballarat Machinery Room ...This photograph is from the Max Harris Collection held by the Ballaraat Mechanics' Institute. Please contact BMI for all print and usage inquiries.ballarat, machinery room, george farmer, eureka st, ballarat east, factory, 1910 -

Ballaarat Mechanics' Institute (BMI Ballarat)

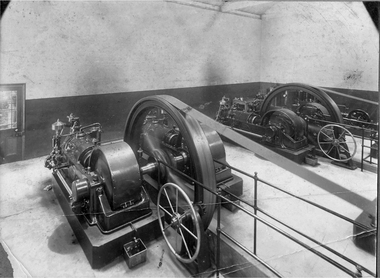

Ballaarat Mechanics' Institute (BMI Ballarat)Machinery Room View 2

... Machinery Room View 2...Machinery Room... BMI for all print and usage inquiries. Ballarat Machinery Room ...This photograph is from the Max Harris Collection held by the Ballaraat Mechanics' Institute. Please contact BMI for all print and usage inquiries.ballarat, machinery room, george farmer, eureka st, ballarat east, factory, 1910 -

Bendigo Historical Society Inc.

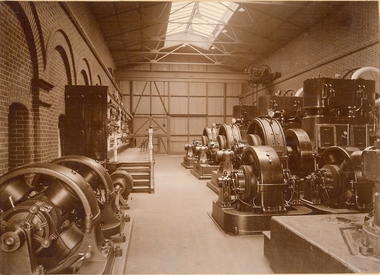

Bendigo Historical Society Inc.Photograph - BASIL MILLER COLLECTION: TRAMS - MACHINERY ROOM WITH POWER SWITCH PANEL

... BASIL MILLER COLLECTION: TRAMS - MACHINERY ROOM WITH POWER... on green cardboard, of machinery room and power switch panel..., mounted on green cardboard, of machinery room and power switch ...Sepia colour photograph, with buff border, mounted on green cardboard, of machinery room and power switch panel. Reverse: Stamped in blue W. H. Robinson Photographer Mundy Street Bendigo. Written in black biro 5'' x J'' 86% Page6y.W. H. Robinson Photographer Mundy Street Bendigo Vic 3550person, individual, basil miller -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BASIL MILLER COLLECTION: TRAMS - ROOM WITH MACHINERY

... BASIL MILLER COLLECTION: TRAMS - ROOM WITH MACHINERY...Sepia colour photograph of room with machinery, buff border..., Mundy St. Bendigo Sepia colour photograph of room with machinery ...Sepia colour photograph of room with machinery, buff border, mounted on green cardboard. Reverse: stamped in blue W. H. Robinson, Photographer, Mundy St. Bendigo.W. H. Robinson, Photographer, Mundy St. Bendigoperson, individual, basil miller -

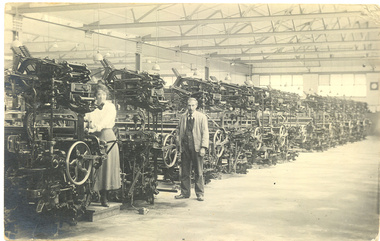

Stawell Historical Society Inc

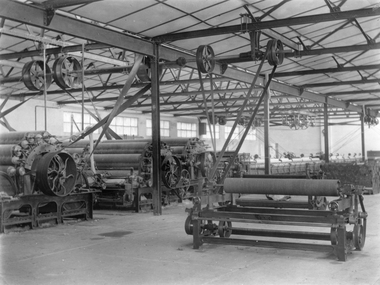

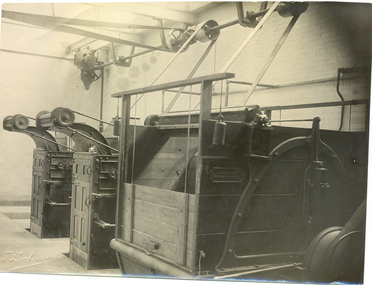

Stawell Historical Society IncPhotograph, North Western Woollen Mills in the Work Room with machinery

... North Western Woollen Mills in the Work Room with machinery...North Western Woollen Mills Work Room with machinery...North Western Woollen Mills Work Room with machinery ...North Western Woollen Mills Work Room with machinery, Stawell Victoria. Initially there were moves to start the woollen mill in1919. Eventually opening in 1923 but closed in 1925 as unsuccessful. Mr. J. Bennett formed a company North Western Woollen Mills Pty Ltd. and restarted the mill on 1st August 1926.Black and white photograph of a work room with large complex roller type machinery attached to belts and rollers in formwork on ceiling..stawell -

Clunes Museum

Clunes MuseumDrawing - Plans, J BARTRAM, CIRCA 1894

... .3 1 PAGE DRAWING OF THE MACHINERY ROOM AT CLUNES DISTRICT... MACHINERY ROOM AT CLUNES DISTRICT BUTTER FACTORY CO .LIMITED .5... MELBOURN .3 MACHINERY ROOM AT CLUNES DISTRICT BUTTER FACTORY CO ...PLANS FOR THE ESTABLISHMENT OF CLUNES BUTTER FACTORY.1 2 PAGE LETTER, TYPED IN PURPLE INK .2 4 PAGES OF PAPER STAPLED TOGETHER WITH HAND HANDWRITTEN MATHEMATICAL CALCULATIONS OF THE QUANTITY OF SAWDUST OR CHARCOAL REQUIRED FOR REFRIGERATION CHAMBER .3 1 PAGE DRAWING OF THE MACHINERY ROOM AT CLUNES DISTRICT BUTTER FACTORY CO. LIMITED USING RED AND BLACK INK AND BLUE PENCIL .4 1 PAGE DRAWING OF SECTION THROUG A.B .5 1 PAGE OF WAX PAPER WITH HAND DRAWN PLAN OF BRICKWORK .6 4 PAGES OF BUFF COLOURED PAPER HANDWRITTENWITH MATHEMATICAL CALCULATIONS .7 1 PAGE OF DRAWING SECTION THROUGH A.C .8 1 PAGE OF BLUE COLOURED PAPER HANDWRITTEN WITH BLACK INK AND BLUE AND ORAGE PENCIL NOTATIONS.1 LETTERHEAD J. BARTRAM & SON 18 QUEEN STREET MELBOURN .3 MACHINERY ROOM AT CLUNES DISTRICT BUTTER FACTORY CO .LIMITED .5 SCALE: 1/1/2 INCH TO THE FOOT WRITTEN IN LEAD PENCIL .7 SCALE: 2FT TO 1 INCHj bartram & son, clunes & district butter factory co. limited, lordclyde creamery -

Clunes Museum

Clunes MuseumDocument - BUTTER FACTORY

... FOR BOILER ROOM, MACHINERY ROOM, REFRIDGERATING CHAMBER 104.14.10... TENDER FORM FOR BOILER ROOM, MACHINERY ROOM, REFRIDGERATING ...CLUNES BUTTER FACTORY TENDER FORMS .1 TENDER FORM FOR BOILER ROOM, MACHINERY ROOM, REFRIDGERATING CHAMBER 104.14.10 = 15 POUNDS .2 TENDER FORM FOR CARPENTRY AND JOINERY WORK 91.18.4 POUNDS .3 COPY OF CARPENTRY AND JOINERY TENDER FORM .1-.3 DATED 02/08/1984butterfactory, tender butterfactory -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - MINE ENGINE ROOM

... black And white photograph : mine engine room showing... engine room showing machinery, brick and galvanised iron building ...black And white photograph : mine engine room showing machinery, brick and galvanised iron building. Cylinders and drive sheels. On back in pencil ' Outtrim Howitt Britiish Consolidated/ Coal Mine/ Outtrim/ Air Compressing plant.organization, business, mine machinery -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Interior, J Kitchen & Sons, Port Melbourne, Max Jeppesen, 21 Mar 2014

... Room .02 - machinery for making boxes .03 - Girls possibly... Melbourne. .01- Tankis, Pan Room .02 - machinery for making boxes ...Five black and white photographs of the interior of J Kitchen & Sons Pty Ltd factory, Port Melbourne. .01- Tankis, Pan Room .02 - machinery for making boxes .03 - Girls possibly making boxes .04 - girls at work benches, milling, Velvet Soap plodding and wrapping dept .05 - candle factory, candles on trolley and machineMax Jeppesen, commercial photographer, 65 Hardware St, Melbourneindustry - manufacturing, workers, j kitchen & sons pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Ships' Telegraph section, Milne Brothers, Copper and Brass Works, Early-to mid-20th century

This Engine Room section of a ship's telegraph system was part of the equipment of the Ports and Harbour ship the SS Rip. The vessel serviced and maintained the lights and buoys at Port Phillip Bay and Queenscliffe. The SS Rip was possibly the former gunboat "Albert". The ship’s communication system that was used from the late 19th century to early-to-mid-20th-century is called an Engine Order Telegraph (E.O.T.) or ship’s telegraph. The system has two parts, the Bridge Section and the Engine Room Section. The Bridge Section is usually mounted on top of a pedestal, and the Engine Room Section is often attached to a vertical surface. The standard commands printed or stamped onto the dial are the directions of AHEAD and ASTERN, and the speeds of STOP, FULL, EASY, STD. BY. and FIN. ENG. The ship’s pilot on the Bridge of a vessel sends his Orders for speed and direction to the to the Engine Room with the E.O.T. He moves the lever or levers, depending on the number of engines the ship has, to change the indicator on the Bridge Section’s dial to point in the new direction and speed of travel. This change causes the Orders to be duplicated on the Engine Room Section’s dial and a bell to signal the change simultaneously. The engineer then adjusts the ship’s engines and steering equipment to follow the pilot’s Order. The manufacturer, Mulne Bros., was a copper and brass works at 166 Sussex Street Sydney, in December 1892, and previously from 1870 at 128 to 130 Sussex Street. The company made and sold a wide range of equipment including machinery and gauges for the Railways.The Engine Room section is significant for being part of the communications system on the ship SS Rip, owned by Melbourne's Ports & Harbours department and used to service and maintain the navigation signals of Port Phillip Bay and at Queenscliffe in the mid-20th century. The dial is an example of marine equipment made in Australia and used for the safety of Victorian vessels. It is also significant for being made by an early Australian manufacturer, Milne Brothers of Sydney.Engine Room Section of a ship’s telegraph or Engine Order Telegraph (E.O.T.). The round metal dial has inscriptions stamped around the edges. The inscriptions are nautical terms for direction and speed and include the maker’s details. The dial was made by Milne Bros. of Sydney. It was part of the equipment on the "SS Rip" in Victoria.Black paint around dial: "MILNE BROS. / MAKERS / SYDNEY" "FULL EASY STD. BY " "FIN ENG. EASY FULL" ""ASTERN" "STOP" "AHEAD"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, marine technology, marine communications, engine order telegraph, e.o.t., ship’s telegraph, bridge section, engine room section, ship’s engine telegraph section, marine telegraph, milne bros., milne brothers, sydney, copper and brass works, ports & harbours ship, ss rip, gunboat albert, service ship, maintenance ship -

Federation University Historical Collection

Federation University Historical CollectionDocument, Indenture Between Robert M. Serjeant, Joseph Flude and the Trustees of the Ballarat School of Mines regarding Letters of Patents for the Benefit of the Ballarat School of Mines, 1877, 04/03/1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Large indenture on red bordered vellum. The indenture was regarding a patent for the benefit of the Ballarat School of Mines. Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines self-Acting Pyrites Furnace" to Robery Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell. Inscriptions and Markings Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, patent, barry, redmond barry, rogers, judge rogers, bland, rivett henry bland, john airy, warrington rogers, establishment, indenture, legal, cuthbert, ballarat school of mines trustees, william stawell, john warrington rogers -

Federation University Historical Collection

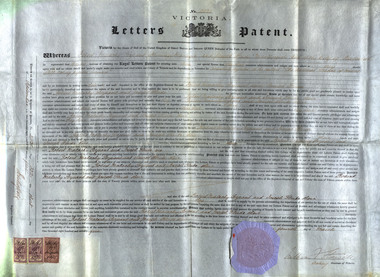

Federation University Historical CollectionDocument, Letters Patent for an Invention for Roasting Pyrites, 1875, 1875

R.M. Serjeant was listed as a mining manager and Joseph Flude as a metallurgist. In 1875 they were both living in Ballarat. The patent number is A.D.1875, 4th March. No 2031. According to the patent the hearth of the furnace is in the form of a cone revolving horizontally. The feed is supplied to the apex of the cone by an archimedian screw. The crown of the furnace comprises a double covering or roof with an intermediate chamber for receiving heated air. The inner covering is pierced to admit of the heated air being brought into contact with the pyrites on the face of the revolving hearth. The discharge of the roasted substance is affected by means of a scraper at the base of the cone. It was claimed that this was a new mode of introducing heated air, and the exclusion of flame during the operation of roasting pyrites. The self-acting charge and discharge of the furnace and the peculiar construction of the hot air chambers, and the use of perforated bricks through which the supply of air is affected were also new. (http://patentsvictoria.net/002031.html) From the Goulburn Herald, 14 September 1878 "A feature connected with the school of mines is the yet unfinished pyrites works. The extraction of the gold from pyrites and the utilization for commercial purposes of other substances connected with pyrites are peculiarly important to Ballarat, because were a simple and inexpensive method devised there are millions and millions of tons of quartz that would then be made remunerative. With this thought in their minds two scientific gentlemen invented the school of mines self-acting rotatory furnace. This, for lack of funds, has not been completed as yet, but the amount in hand for the purpose is daily increasing, and it will eventually be an accomplished fact. It is in contemplation also to erect machinery shops in connection with the school, and it is purposed to con struct a steam-engine to do at once the work of the pyrites treatment and the ma chine room. A model shaft and mine too are being prepared for on the reserve, so that practical mining of the most thorough character may be taught on the ground.'Letters Patent for an Invention for Roasting Pyrites to be called 'the Ballarat School of Mines Self-Acting Pyrites Furnace' to Robert Malachy Serjeant and Joseph Flude. The large document is on a vellum type paper complete with stamps and seal. The document is signed by Acting-Governor William Stawell.Written on verso: "Date of Patent 4th March 1875 No 2031 Letters Patent for An invention for roasting pyrities to be called "The Ballarat School of Mines Self-acting Pyrities Furnace" to Robert Malachy Serjeant and Joseph Flude Melbourne, Victoriaballarat school of mines, serjeant, r.m. serjeant, robert m. serjeant, flude, joseph flude, richard gibbs, stawell, william stawell, pyrities furnace, philately, statute stamp, seal (victoria), ballarat school of mines self-acting pyrities furnace, ballarat school of mines self-acting pyrites furnace -

Bendigo Historical Society Inc.

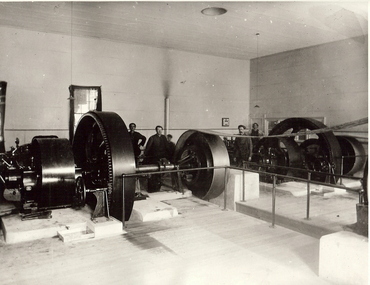

Bendigo Historical Society Inc.Photograph - MACHINERY INCLUDING LARGE GEARED WHEELS, c.1900

Black and white photograph. Machinery consisting of large gear wheels, driving wheels with belts in wooden board lined room. Five males included. Rails along and across part of floor at waist height (safety?) Two sets of similar gear. Electric motors. Rubber belts driving machinery out of picture. Building clean - new? Electric lights and switches.topic, objects, machine, machinery, workers, males -

Bendigo Historical Society Inc.

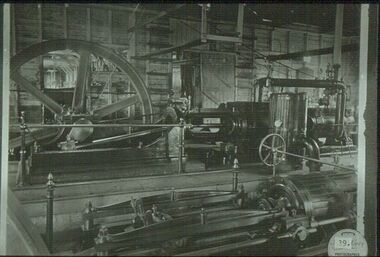

Bendigo Historical Society Inc.Slide - ALBERT RICHARDSON COLLECTION: VIRGINIA CRUSHING BATTERY ENGINE ROOM

Slide.Engine at the Virginia Crushing Battery. Large flywheel on LH side, machinery in front. Possibly stampers visible through window at rear of engine room.No. 39 printed on bottom of slide. Photographer's name covered by number.mine, gold, virginia machinery., bendigo mines-jack hattam collection. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - ALBERT RICHARDSON COLLECTION: WINDING ENGINE NEW MOON GOLD MINE, EAGLEHAWK

Slide. Winding engine at the New Moon Gold Mine. Image shows interior of engine room with winding equipment.No 37 printed on bottom of slide.mine, gold, moon machinery., bendigo mines-jack hattam collection. -

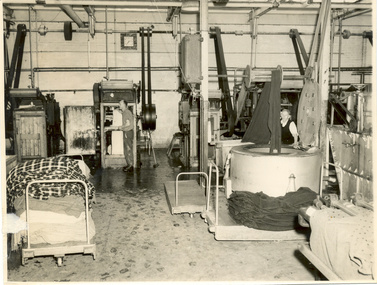

National Wool Museum

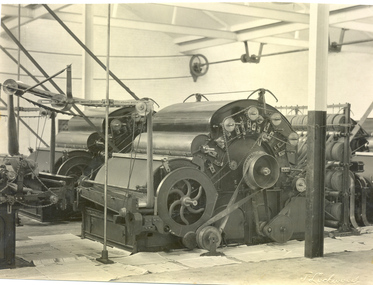

National Wool MuseumPhotograph, Milling and scouring in the woollen and finishing R S & S

Milling and scouring in the woollen and finishing room, R S & S mill.Milling and scouring in the woollen and finishing R S & Stextile machinery textile mills, returned soldiers and sailors mill, scouring, milling, kidman, mr g. l., textile machinery, textile mills -

National Wool Museum

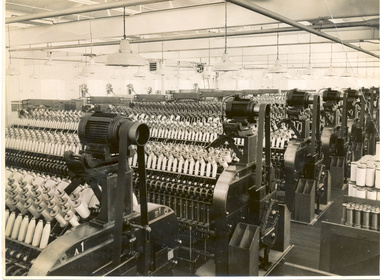

National Wool MuseumPhotograph, Intermediate section of the carding process in the R S & S carding room

... in the R S & S carding room Textile Machinery Textile Mills ...Intermediate section of the carding process in the R S & S carding roomCarding / R S & Stextile machinery textile mills - history textile mills, returned soldiers and sailors mill, carding, kidman, mr g. l., textile machinery, textile mills - history, textile mills -

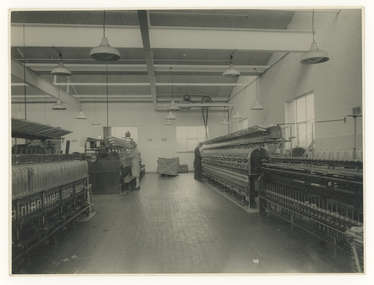

National Wool Museum

National Wool MuseumPhotograph, Worsted room

Worsted room, R S & S mill.Worsted room R S & S /worsted spinningtextile machinery textile mills - history textile mills, returned soldiers and sailors mill, spinning machinery, cloth - worsted, kidman, mr g. l., textile machinery, textile mills - history, textile mills -

National Wool Museum

National Wool MuseumPhotograph, Worsted spinning R S & S

Worsted room, R S & S mill.Worsted spinning /R S & Stextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, spinning machinery, cloth - worsted, kidman, mr g. l., textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumPhotograph, Finishing room R S & S

Milling and drying machinery, R S & S mill.R S & S finishing room/ L-millimg & scouring machines/ with wring-dryer ROBERT POCKLEY/ PHOTOGRAPHER/... G Kidmantextile machinery textile mills - history textile mills - staff textile mills, returned soldiers and sailors mill, dyeing, milling, scouring, finishing, kidman, mr g. l., textile machinery, textile mills - history, textile mills - staff, textile mills -

National Wool Museum

National Wool MuseumPhotograph - Mending Room

James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Black and white photograph of the mending room in a textile millF Murgatroyd ALSC [?] KODAK PRINTtextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

National Wool Museum

National Wool MuseumPhotograph

Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionF Murgatroyd Weaving room/ Mr H [K}ealingtextile machinery textile mills weaving mills textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills -

National Wool Museum

National Wool MuseumPhotograph, Federal Mill: dyeing room c.1918-1920

James Murgatroyd worked in the textile industry in England, and in Victoria and New South WalesF Murgatroyd Federal Mill/ Dyeing Room/ c.1918-1920textile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

National Wool Museum

National Wool MuseumPhotograph, Federal Mill: winding room .c1918-1920

James Murgatroyd worked in textile mills in England, Victoria and NSW. His son Fred worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.F Murgatroyd Federal c1918-1920/ Winding Roomtextile machinery textile mills weaving mills textile mills - staff textile mills, federal woollen mills ltd tweedside woollen mills yarra falls mill collins bros mill pty ltd, carding, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills, weaving mills, textile mills - staff -

![Photograph, [No 1 Carding Room Machines c30's]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f599821f50e3cc9f4d6/item-media/54065f599821f50e3cc9f4d7/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [No 1 Carding Room Machines c30's]

Acquired when "Classweave Industries" closed downNo 1 Carding Room Machines c30's still in use until 1960's 15 7A 14/57 74%textile machinery woollen mills, classweave industries pty ltd federal woollen mills ltd, carding, textile machinery, woollen mills -

![Photograph, [Main weaving shed]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065f5e9821f50e3cc9f4fa/item-media/54065f5e9821f50e3cc9f4fb/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumPhotograph, [Main weaving shed]

Acquired when "Classweave Industries" closed down17 Main weaving room 22/87 p?honetextile mills woollen mills, classweave industries pty ltd federal woollen mills ltd, weaving machinery, textile mills, woollen mills -

National Wool Museum

National Wool MuseumPhotograph, Scouring Machines, Unknown

Photographs were most likely used for promotional purposes. Room filled with wool scouring machines in an unknown textile mill.Sepia photo of a room filled with Scouring Machines in landscape format, located a textile mill.textile machinery, wool manufacture, wool, scouring -

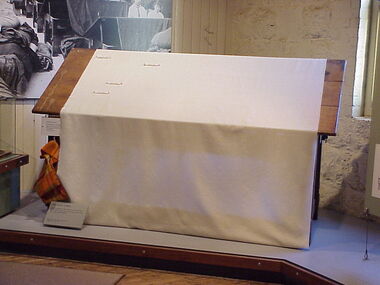

National Wool Museum

National Wool MuseumFunctional object - Mending Table, c1930

Any faults in the final product can be repaired by mending. Prior to more advanced machinery, fabric was draped over a mending table and carefully inspected for faults. Quick eyes and nimble fingers were needed. Repairing faults was a highly skilled manual operation. Any knot or thickness had to be removed without affecting the quality of the fabric and mending had to be invisible. In the 1930s to make the day pass faster, popular records were played to the factory workers in the mending room. The top of the table is propped up to make it a well-lit surface over which bolts of fabric were unrolled to check for faults. Menders repaired them with invisible hand stitching. Each weaver stitched a coloured thread in the selvage to show the start of their shift, therefore if mistakes were found the company could easily find who was responsible. This table was used by Gail Morris in teh 1960s. Large wooden table with tilted top. mending table, wool processing, fabric, textile industry -

National Wool Museum

National Wool MuseumPhotograph

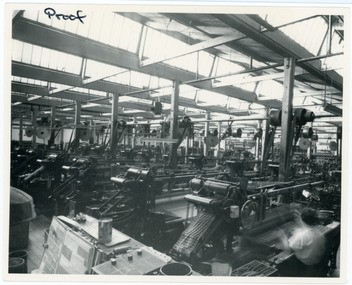

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the weaving room in one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, weaving machinery