Showing 4075 items matching "machining"

-

Federation University Historical Collection

Federation University Historical CollectionDocument, Furniture and Equipment for Ballarat School of Mines Fitting and Machining Department, Stage 2 Development, 1985

... Fitting and Machining Department, Stage 2 Development, 1985 ...A large folder of correspondence and documents relating to the Ballarat School of Mines Fitting and Machining furniture and equipment. peter shiells, ballarat school of mines, fitting and machining, vocational studies -

Melbourne Tram Museum

Melbourne Tram MuseumDocument, Melbourne & Metropolitan Tramways Board (MMTB), "Casting production and machining at Preston Workshops", 7/1963

... "Casting production and machining at Preston Workshops" ...Typed report on the use of precision casting methods at Preston Workshops foundry to reduce the amount of machining post-casting. Looks at the methods of precision casting, the type of equipment needed for this, and those companies in Melbourne using shell moulding, Includes an extensive list of items and the number of units used each year that this method could be used for. Report by J Scholtz dated 12-7-1963.Yields information about the examination of costs and methods of using shell moulding processes at Preston Workshops.Document or report 7 foolscap sheets - carbon copytramways, technical information, preston workshops, costs, foundry, castings, plate shop -

Moorabbin Air Museum

Moorabbin Air MuseumBook (item), Fitting and Machining: Grade One

... Fitting and Machining: Grade One ...Owned by H. Ware -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - CAC Commonwealth Aircraft Corporation French English Glossary, French English Glossary. Words Encountered in Machining & Processing

... French English Glossary. Words Encountered in Machining ...Commonwealth Aircraft Corporation -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (Item) - Aluminium Technology Book 3 Machining Aluminium

... Aluminium Technology Book 3 Machining Aluminium ... -

Moorabbin Air Museum

Moorabbin Air MuseumBook - Fitting and machining texts, Fitting and Machining: Grade One

... Fitting and Machining: Grade One ...Technical guide for fitting and machining worknon-fictionTechnical guide for fitting and machining workfitting and machining -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia, Sewing Machine Treadley

Treadle home sewing machine - pre-electric. rusted parts, faded gold leaf decorationBlack Pre-Electric Treadle Sewing Machine with 'Fly wheel' " Singergold floral on machine and "singer on machine -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Sewing Machine, Melber, Early 20th Century

Melber sewing machines were first sold in Australia in the late 1870s. The 'Box Cottage' Melber Treadle Sewing Machine was owned by Mary Box, nee Kloster / Closter, wife of Alonzo Box , the nephew of William and Elizabeth Box who purchased 'Box Cottage' in 1865 from a pioneer settler The machine was bought in 1909, and is a good example of its kind. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm.”, and clothes were mended, or ‘re-made’ into another garment. The cottage has both the Receipt, cat 00004.1 and Guarantee, cat 00004.2, for the sewing machine. This machine was possibly built by Wertheim Pty Ltd Hugo Wertheim (1854 – 1919) arrived in Melbourne in 1875. He became a successful agent for sewing machines manufactured by his father’s cousin Joseph Wertheim in Frankfurt, Germany. Hugo married Joseph’s daughter Sophie Emilie and they settled in Richmond Melbourne Australia. Hugo made many trips back to the main factory in Germany and, with extensive advertising, established a thriving business for sewing machines, bicycles, pianos under various ‘brand names’ - Wertheim, Electra, Planet, Griffin, Hapsburg. It has been said that Dame Nellie Melba preferred a Wertheim piano for her performances. In 1908 Hugo opened a large piano factory in Bendigo St Richmond, Victoria and his son Herbert maintained the business until 1935 The sewing machine was donated in 1985 by, a descendant of the Box family. The machine is complete, and in good condition. William and Elizabeth Box purchased 'Box Cottage' in 1865 from a pioneer settler who had bought part of the land noted in Dendy's Special Survey 1841 Brighton. They raised their family there and established a market garden to supply produce to the population of Melbourne. Their nephew Alonzo married Mary Kloster/ Closter in 1918 and she brought with her this 'Melber' sewing machine that she used to provide clothing for the family. 'Melber'Treadle Sewing Machine that was owned by Mary Box, nee Kloster/ Closter. It was bought in 1909, and it is a good example of its kind. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm.”, and clothes were mended, or ‘re-made’ into another garment. The Box Cottage Museum has both the Receipt, and Guarantee for the sewing machine. 'MELBER' stamped on sewing machine.dendys special survey, treadle sewing machine, box cottage, mary kloster, alonzo box, melber, wertheim hugo, wertheim sewing machine manufacturer, richmond melbourne victoria, -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySewing Machine - Singer

This sewing machine was bought by Alex Craig's dad in 1942 for his wife whom he married in 1943. Alex's grandmother used it in 1942. It still works (2013).Historical: Type of sewing machine used by S.E.C.V. wives living in Mt Beauty during the 1940's, 1950's and 1960's. Ladies made the family's clothes and sewed for the Annual Church and School fetes. eg. children's clothes and dolls' clothes. They bought dozens of dolls and made 'fairy' dresses for them using coloured netting.Singer sewing machine - brown wood lid & base. Handle on top of inside of lid as is the wooden bench that clips on to the side of the machine and also the steel knee lever that fits into the front of the machine. Black steel machine with silver fittings. Brown and white electric cord plugged in. "Singer" on front centre of lid. On machine - "Singer" above light. "The Singer manufacturing Co. / Manufactured in Great Britain" top of machine. "Singer" on front side of machine. Front - Gold plate - "The Singer Manfg. Co. / Trade Mark." Decoration on machine base and silver end.singer manufacturing co.. sewing. fetes. clothes. domestic. -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Wertheim Sewing Machine, c1880

Hugo Wertheim (1854–1919) arrived in Melbourne in 1875. He became a successful agent for sewing machines manufactured by his father’s cousin Joseph Wertheim in Frankfurt, Germany. Hugo married Joseph’s daughter Sophie Emilie and they settled in Melbourne. Hugo made many trips back to the main factory in Germany and, with extensive advertising, established a thriving business for sewing machines, bicycles, pianos under various ‘brand names’ - Wertheim, Electra, Planet, Griffin, Hapsburg. It has been said that Dame Nellie Melba preferred a Wertheim piano for her performances. In 1908 Hugo opened a large piano factory in Bendigo St Richmond, Victoria. His son Herbert maintained the business until the factory closed in 1935.The pioneer settlers and market gardeners of Moorabbin Shire had to be self reliant and made their own clothing and utensils. This sewing machine was one of many items they used to exhibit the skill and craftsmanship of the women in these families. A sewing machine was a necessary part of each home.A Wertheim hand–crank sewing machine c1880. The hand machine was operated by turning the handle. The hand machine could also be fitted to a stand with table and draws, the machine could then be used by hand or foot. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm”, and clothes were mended, or ‘re-made’ into another garment 'WERTHEIM' across body of machinemelbourne, clothing, brighton, moorabbin, germany, piano, pioneers, richmond, bentleigh, dressmaking, market gardeners, early settlers, craftwork, sewing machines, wertheim hugo, wertheim joseph -

National Wool Museum

National Wool MuseumPhotograph, Carding Machine, Unknown

Photographs were most likely used for promotional purposes. The photographed machine was made by Tomlinsons (Roshdale) Limited, was British machine manufacture company based in Rochdale.Black and white photo of a Rag Puller Machine in landscape format. Location of photo looks to be in a textile mill.On machine - Tomlinsons (Roshdale) Limited.textile machinery, wool manufacture, wool, timlinsons, rag pulling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Singer Sewing Machine Company, 1907 -1920 (see note section this document for further information regards model identification)

In 1867 the Singer Company decided that the demand for their sewing machines in the UK was sufficiently high to open a local factory. Glasgow was selected for its iron-making industries, cheap labour, and possibly because at the time the General Manager of the US Singer Sewing Machine Company was George McKenzie, who was of Scottish descent. The company obtained a lease on land near Queen Street Station and machinery and machine parts were shipped over from the US. Demand for sewing machines outstripped production at the new plant and by 1873 a new larger factory was completed near Bridgeton Cross. By now Singer employed over 2,000 people in Scotland but still, they could not produce enough machines. In 1882 George McKenzie, the soon to become President of the Singer Sewing Machine Company undertook the ground breaking ceremony on 46 acres of farmland at Kilbowie, Clydebank and the largest Singer factory in the world started to be built. Originally two main buildings were constructed. Built above the middle wing of the factory was a huge clock tower with the 'Singer' name displayed for all to see from miles around. Many miles of railway lines were laid throughout the factory to connect the different departments and to aid in the shipping of their goods. Railway lines from the factory connected Glasgow, Dumbarton, and Helensburgh stations. The factory was regarded as the most modern facility in Europe at that time. As different departments in the factory were completed, the workers moved from the old sites to the new one at Kilbowie and the factory was finally finished in 1885. With nearly a million square feet of space and almost 7,000 employees producing on average 13,000 machines a week, making it the largest sewing machine factory in the world. The Clydebank factory was so productive that in 1905 the US Singer Company set up the Singer Manufacturing Company Ltd. as a UK registered company. The invention of the sewing machine had several very significant impacts on the lives of many people. It changed the domestic life of many women as more households began to own sewing machines, women as the ones who traditionally stayed home to do chores including making and repairing clothing, found themselves with more free time. Previously several days a week would be dedicated to sewing clothing for herself and her family, a housewife could now complete her sewing in merely several hours, allowing for more free time to pursue hobbies and attain new skills. Sewing and clothing production, in general, became more industrialized activities, taking place less in the home and more in large factories. Industrial sewing machines, in combination with the cotton gin, the spinning jenny, and the steam engine, made clothing production much easier and much cheaper. Singer sewing machine treadle type wooden stand with six drawers plus instruction manual Lotus decoration to machinewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sewing-machine, clothes repair, singer sewing machine -

Clunes Museum

Clunes MuseumFunctional object - SEWING MACHINE, Singer Manufacturing Co, 1920

https://www.singermachines.co.uk/faq/singer-sewing-machine-company-history/Singer sewing machine, black with gold, green, red scroll pattern, hand operated, lift up machine attached to wooden base with a wooden coverIn gold on top of machine "The Singer Manufacturing Co." On metal plate base of machine "F9719565" Cover; Gold marking on front of cover "The Singer Mnft Co. TradeMark"sewing, domestic item, singer manufacturing co. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyAddressograph Machine

This metal plate machine used plates that contained names, addresses and classifications of each State Electricity Commission of Victoria employee working on the Kiewa Hydro Electric Scheme. The plates were put through the machine onto pay envelopes.See also: KVHS 1046, KVHS 1233The S.E.C.V. employed many people on the Kiewa Hydro Electric Scheme and used the latest technology of the time to pay each of them including providing each one with a pay slip. Metal table with the addressograph machine set into the middle section. The electric machine is belt driven and controlled by three 52 cm long metal pedals. The operator uses 5 stops, 2 knobs and 1 winder while sitting at the machine. There are 5 extra metal parts (or pieces) which belong to this machine. Ref. KVHS 1046 - Ink Rolls - Labelling Cartridges for Addressograph MachineMetal plate attached to front of machine which reads "Class 22000 Serial No. B-01547. Addressograph regd. Addressing machine. Patents Pending Made in England Addressograph Multigraph Limited London.addressograph machine. state electricity commission of victoria. kiewa hydro electric scheme. payroll. office work. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Rope machine, Continental Trading Corporation Ltd, ca. 1911

This rope-making machine, called The New Era Rope Machine, was patented in the USA on July 18th 1911. It was made by the Continental Trading Corporation Ltd. in Chicago, USA. The ends of the rope would be threaded through the matching and hooked onto the machine's claws on the other side. The machine's handle would be rotated manually, which would twist the rope ends together, entwining them to make one thick rope.This manually operated rope-making machine is a labour saving devise used particularly by sailmakers in their rigging and ropework tasks. Rope-making machine, metal. The model is "The New Era Rope Machine". The manually operated machine has three claws through which roping material is threaded. Internal wheels have cogs around their perimeter. The two pieces that make up the machine's case are bolted together. Made by Continental Trading corporation Ltd Chicago USA. The machine was patented on 18th July 1911."The New Era Rope Machine" " Continental Trading Corporation Ltd Chicago USA" "Patd july 18 1911" "Made in USA" "Keep oiled"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ropework, the new era rope machine, patented, 1911, textile machine, continental trading corporation ltd., chicago, rope-making machine, textile industry -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Copy of B/W photograph, Threshing machine at Scotsburn in 1940's, Not known

Photograph shows early farming method and illustrates some of the machines used at this timeThreshing machine in operation at Scotsburn in the 1940's. 3 workers and tractor visbleThreshing machine. 1940's. Note old Dominic Lorensene on stack.scene showing farm machinery in use. threshing machine vdriven by belt from stationary tractor., several man are working on the equipment, l -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine

Inlayed case has box snibbed shut with parts for sewing machine. base also inlayed home sewing machine pre electric "treadle"Black Machine on wooden base with wooden cover. rusted missing parts. On to of the machine the remains of name "THE". Light wood case lid has inlayed wood around the top of the lid. -

Cheese World Museum

Cheese World MuseumMachine - Washing machine, Early 20th century

Used by Mrs Elsie Singleton (nee Waldron) in her home at Wedderburn. The machine was invented by Samuel Osmond. The first half-yearly report of the Osmond Little Marvel Washing Machine Company was noted in the Adelaide Advertiser on 2 December 1903 when HG Prince presided. The number of directors was later reduced to 3. Osmond Little Marvel galvanised tin hand washing machine with six funnels attached to a frame and then a handle; brass name plate.Osmond Little Marvel washing machine No.3820 Patentedsamuel osmond, elsie singleton (née waldron)' wedderburn -

Lara RSL Sub Branch

Lara RSL Sub BranchPhotograph, Second Australian Machine Gun Company 1918 - Belgium, Circa 1918

The 2nd Australian Machine Gun Company was formed in Victoria, February, 1916; in Egypt a month later.Assigned to the 2nd Infantry Brigade,it was reassigned to the 1st Machine Gun Battalion,2nd March, 1918.The picture was taken in Locre (now Loker) in Belgium. For the majority of the war the village of Locre was in British hands. On the 25th April 1918,the village was captured by the enemy although it was recaptured soon after.Rectangular shaped glass covered photo frame showing photo of the 2nd Australian machine gun company.Second Australian Machine Gun Company,Photographed at Locre in Belgium on 20th February 1918. -

Bendigo Military Museum

Bendigo Military MuseumManual - VICKERS MACHINE GUN HANDBOOK, 1923

1. Manual relating to the training, in use and maintenance of Vickers Machine Gun, 2. Manual for operating a machine gun issued in UK in 1925.1. Vickers Machine Gun handbook of 162 pages plus schematics and bibliography. Stapled, faded yellow in colour. Issued 1923. 2. Handbook for machine Gun Training. Red cover and white paper. 106 pages plus bibliography. 1. Front... Handbook for .303 in Vickers Machine gun. On back page written VX26929. T. J. PATTULLO.passchendaele barracks trust, vickers machine gun, training manuals -

National Wool Museum

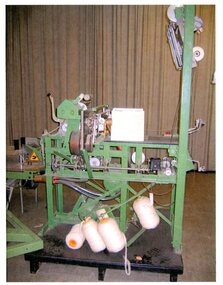

National Wool MuseumMachine - Spinning Machine Prototype, CSIRO et al, 1960s

Self-twist spinning machine prototype developed by CSIRO in the 1960's. Made by CSIRO Division of Wool Technology in conjunction with an Australian engineering company REPCO and the International Wool Secretariat. Prototype developed in 1960's and since 1970 over 3500 have been produced and sold.Self-twisting spinning machine (protoype).Label with machine: Prototype SELF-TWIST SPINNER / This prototype spinning machine was built / at Division of Wool Technology in the mid 1960's as / part of the program which developed the Self-Twist spinning / process. / Self-Twist was commercially released in / 1970 by The Division in conjunction with the Australian / engineering company Repco, and The International Wool / Secretariat. / Since 1970 more than 3500 Self-Twist / machines have been sold. / The process offers advantages in the / speed of spinning, machine size, maintenance and energy / consumption.engineering, manufacturing, wool processing, spinning, csiro, prototype, invention, wool technology, self-twist, repco, international wool secretariat -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Instruction Manual, Illustrated Directions for using the New High Arm Davis Vertical Feed Sewing Machine, 1883-1885

This book of Illustrated Directions was produced for use with the Davis New High Arm Vertical Feed (VF) Sewing Machine. The first model of the High Arm was produced in 1881, and the ‘New’ model, Model 2 VF, was introduced from 1883 and continued at least until 1885, when the Model 3 VF was manufactured. Job Davis, an inventor, showed his Davis Sewing Machine to two brothers in Watertown. The brothers, John and Joseph Shaldon, who founded the Davis Sewing Machine Company in February 1868 in Watertown, New York. The firm moved to Ohio in the 1890. Its early sewing machines were known as the Vertical Feed machines. These machines differed from others, in that there were two presser feet that moved and held the cloth as the needle went in and out of it. This type of action was also called ‘walking foot’ by makers of similar machines. Other machines used a feed dog below the machine’s bed to move the fabric. The Davis Company was awarded a Patents for its improvement to sewing machines. London offices were set up at 54, Queen Victoria Street, London in 1982. It was known as the Vertical Feed Sewing Machine Company. An article published in March 1885 states that the London Manager of the Vertical Feed Sewing Machine Company has 300,000 machines world-wide, including 4,000 in England alone. It claimed that the Auxiliary Forces Uniform and Equipment Company in Limerick, Ireland, was running its machines with steam power and could produce first-class work at the rate of 1,500 stitches per minute. The hand stitched binding of the manual is an example of early book binding processes. The is significant for its relationship to the Davis New High Arm Vertical Feed sewing machine, which was invented in 1866 and became popular in the domestic market. It was also used in industrial conditions as a labour-saving machine, one of the many machines that were part of the Industrial Revolution when steam power replaced manual power in many factories. Paper book with stitched binding. Printed text and illustrations contained within the 42-page booklet. The manual includes drawn diagrams and instructions for use of the Davis New High Arm Vertical Feed Sewing Machine, a foot treadle machine made in the 1880s. Front cover: "ILLUSTRATED DIRECTIIONS for the NEW HIGH ARM DAVIS Vertical Feed Sewing Machine and its Accessories and Attachments"flagstaff hill maritime museum and village, great ocean road, shipwreck coast, sewing machine manual, davis sewing machine, new high arm sewing machine, model 2 vf, vertical feed, sewing machine instructions, sewing machine directions, job davis, john sheldon, joseph sheldon, high arm sewing machine, watertown, new york, vertical feed sewing machine company, treadle, steam sewing machine, auxiliary forces uniform and equipment company, limerick, ireland -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object, Sewing Machine Treadle

Treadle home sewwing machine. pre-electric - rusted missing parts rusted gold leafBlack pre-elctric Treadle sewing machine with silver coloured rim on fly wheel.Gold leaf floral design on machine. Shield of gold leaf. fastened to wooden table -

Marysville & District Historical Society

Marysville & District Historical SocietyPhotograph (Item) - Colour photograph, Unknown

A colour photograph of Tino Gianforte with a milk bottle machine in the Marysville Dairy in Victoria.A colour photograph of Tino Gianforte with a milk bottle machine in the Marysville Dairy in Victoria. The Marysville Dairy was owned and operated by a local man, Tino Gianforte and was located on Falls Road in Marysville.MARYSVILLE DAIRY/ TINO GIANFORTE/ MILK/ BOTTLE MACHINE/ 1958-1960/ 600 BOTTLES PER/ DAYmarysville, victoria, tino gianforte, northern milk transport, marysville dairy -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Razor Stropper and Box

This machine was used to sharpen men’s razors several decades ago and is thus a vintage item of historical interest. It belonged to a local Warrnambool man, Henry Cain. This item has local provenance and it is retained for this reason. Also it is an interesting memento of times past when men used razors and razor blades and needed some sort of sharpening or stropping device to keep the razors sharp. Today men mostly use disposable razors or electric razors. This is a silver-coloured oval-shaped metal object with a hinged lid and a catch.Inside the machine are two rotating brown leather pieces which form the sharpening aspect of the machine. A razor blade is inserted between the two rotating pieces.There is a turning handle on the outside of the machine and part of this folds back into the inside of the machine when the lid is closed. The handle has a wooden end. The machine is in a rectangular-shaped cardboard box. The base is white and the top is dark blue with an image of the machine on the top and the side and gold and white printing. One section of the top of the box is missing. The name of the owner is printed in black ink on the inside of the machine. ‘Abziehappart fur Rasierklingen, Barba No. 740’ ‘Stropping Machine, Barba No. 740, Made in Germany’ ‘Afilador Barba No. 440’ ‘H. Cain’ henry cain -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Laundry Equipment, washing machine, c1919

Eduard Lehman, Zurich Switzerland patented a metal barrel shaped hand washing machine with a hand crank to operate a metal plunger in 1919. Such hand washing machines were used by settlers in Moorabbin Shire An 83 year old Visitor on site remembers using this type of washing machine. He had to push the agitator for 5 minutes. Prior to his mother buying the washer, all laundry was hand washed in troughs.Such hand washing machines greatly reduced the workload of the women of pioneer familes in Moorabbin ShireThis hand washing machine c1919 consists of a metal barrel, standing on 4 legs, and has a hand crank to operate a cone shaped metal agitator.THE / LEHMAN/ COMPRESSED AIR AND / VACUUM WASHING MACHINE / Pat. No. 50614/30lehman eduard, hand washing machines, laundry equipment, pioneers, early settlers, market gardeners, moorabbin, brighton, cheltenham -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing machine kit

Used by donor until replaced by modern machine equipped with inbuilt button attachmentSewing machine attachments in red plastic box. Buttonhole attachment cream coloured with red measures and knobs for adjustments. A total of 4 items in the set.Singer; Singer Sewing Machine (on box)|Singer Bight Space (on attachment)domestic items, sewing -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia, New National Treadle Sewing Machine

Treadle home Sewing machine - pre-electric. Rusted partsBlack "pre-electric treadle sewing machine with "fly wheel" "New national"Gold leaf floral design on machine and flat greyhound trademark inside floral circle, fastened to wooden lid of tableclothing manufacture -

Greensborough Historical Society

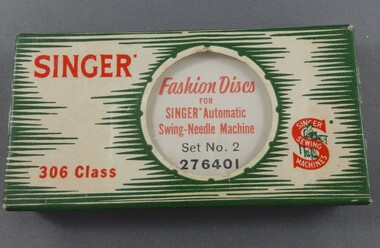

Greensborough Historical SocietySewing machine accessories, Singer Manufacturing Company, Singer Sewing Machine Discs, 1960c

Commonly used removable cams from a Singer sewing machine of the 1960s. These cams enabled the home sewer to use fancy stitches in their work and were later superseded by integrated electronic controls.Box containing four sewing machine cams and leaflet containing sewing patterns and instructions for use. Accessories to a Singer sewing machine.Fashion discs for Singer Automatic swing-needle machine. Set no. 2, 276401, 306 class. Shell, Solid scallop, Icicle and Banner singer sewing machines