Showing 11 items matching "marine clock"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Chronometer or Marine Clock

... Chronometer or Marine Clock...marine clock...Marine chronometer or marine clock, brass case, glass cover... Chronometerwerke marine clock "Made in Germany" and "WEMPE ...This chronometer was made around 1936 and has been on display at Flagstaff Hill for over 40 years as part of the exhibit of the ‘Reginald M’, an Australian-built, 19ss, coastal trader vessel. A chronometer is an accurate mechanical instrument used for measuring time. It is constructed carefully to remain stable even under the changing conditions of seafaring life such as temperature, humidity and air pressure. The Master or Navigator of a ship could use the chronometer and the positions of celestial bodies to calculate the ship’s latitude at sea. In 1905 the business Chronometerwerke GmbH was formed in Frankfurt, Germany, to supply the country with high-quality mechanical chronometers and ship clocks for their maritime trade, making the country independent of other international suppliers such as those in England. In 1938 the firm was renamed Wempe Chronometerwerke. The business continues today. Its products now include its well-known chronometers, battery-powered ship clocks, ship’s bell clocks, barometers, barographs, thermometers, hygrometers, comfort meters to measure temperature and humidity, and wristwatches. The company also performs chronometer testing facilities for the State’s Weights and Measures office. The article written by Givi in July 2022 “The Basics of Marine Meteorology – a Guide for Seafarers” refers to the weather’s signs and patterns being repeated over and over, and the recording of these observations helps forecasters predict changes in the weather. The chronometer is an example of a mechanical navigational marine instrument in use in the early to the mid-20th century. The maker is significant as part of a German government initiative to be self-sufficient in the production of good quality marine technology. This chronometer is significant as part of the exhibit, the Australian-built vessel, 1922 coastal trader ‘Reginald M’, listed on the Australian Register of Historic Vessels and on display for over 40 years.Marine chronometer or marine clock, brass case, glass cover, Roman numerals, 24-hour numbers beside them. Two black hands, a keyhole for winding and ventilation holes in the side. The base has a collar with four machined mounting holes. Inscriptions are on the clock’s face."Made in Germany" and "WEMPE / CHRONOMETERWERKE / HAMBURG"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, marine meteorology, horology, chronometer, marine technology, latitude, marine navigation, mechanical instrument, scientific instrument, ship clock, chromometerwerke gmbh, wempe chronometerwerke, marine clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClocks, 1939-1946

... and produced 800 clocks of marine, carriage, shelf and banjo types. He...American Clock is an 8-day marine clock made by the Chelsea...The clock is an 8 day marine clock with US Maritime... the Harvard Clock Company and produced 800 clocks of marine, carriage ...Chelsea Clock Company History: The Chelsea Clock Company is an American clock manufacturing company that started before 1880 with Joseph Henry Eastman who founded the Harvard Clock Company and produced 800 clocks of marine, carriage, shelf and banjo types. He went on to change the company name to the Boston Clock Company in 1884. After several name changes in 1897, the Chelsea Clock Company was finally founded. Clocks produced by Chelsea Clock Company have been found in the White House, on US Naval Ships, and in homes and offices around the world. After the company first began life as the Harvard Clock Company, it was named the Boston Clock Company, the Eastman Clock Company before finally becoming the Chelsea Clock Company in July of 1897. The company had developed many patents and innervations over these years and between 1939 and 1946 during World War II they were awarded contracts by the U.S Maritime Commission and produced vast numbers of clocks for both merchant and naval ships. U.S Maritime Commission History: The United States Maritime Commission (MARCOM) was an independent executive agency of the U.S. federal government that was created by the Merchant Marine Act of 1936, and replaced the United States Shipping Board which had existed since World War I. It was intended to formulate a merchant shipbuilding program to design and build five hundred modern merchant cargo ships to replace the World War I vintage vessels that comprised the bulk of the United States Merchant Marine, and to administer a subsidy system authorized by the Act to offset the cost differential between building in the U.S. and operating ships under the American flag. It also formed the United States Maritime Service for the training of seagoing ship's officers to man the new fleet. The purpose of the Maritime Commission was to formulate a merchant shipbuilding program to design and then have built over a ten-year period 900 modern fast merchant cargo ships which would replace the World War I-vintage vessels Those ships were intended to be then leased to U.S. shipping companies for their use in the foreign seagoing trades the aim was to offer better and more economical freight services. The ships were also intended to serve as a reserve naval auxiliary force in the event of armed conflict which was a duty the U.S. merchant fleet had often filled throughout the years since the Revolutionary War. From 1939 through the end of World War II, the Maritime Commission funded and administered the largest and most successful merchant shipbuilding effort in world history, producing ships for both navy and merchant marine. By the end of the war, U.S. shipyards working under Maritime Commission contracts had built a total of 5,777 ocean-going merchant and naval ships. In early 1942 both the training and licensing was transferred to the U.S. Coast Guard for administration, then later to the Maritime Service final responsibility was conveyed to the newly created War Shipping Administration which was created to oversee the operation of merchant ships being built by the Emergency Program to meet the needs of the U.S. Armed Services. With the end of World War II, both the Emergency and Long Range shipbuilding programs were terminated as there were far too many merchant vessels now for the Nation's peacetime needs. In 1946, the Merchant Ship Sales Act was passed to sell off a large portion of the ships built during the war to commercial buyers, both domestic and foreign. The U.S Maritime Commission was officially disbanded on May 24th 1950. These clocks were to be found on all ships made in American for the war effort between 1939 and 1946. They are a significant reminder of the sacrifice by those who served in the merchant marine and the navy’s during the Second World War. The item is a part of our social history that reminds us of these dark times. The loses of family members, along with the trauma that many sailors had endured and had to live with for the rest of their lives once they were released from service and allowed to go home.American Clock is an 8-day marine clock made by the Chelsea clock Co for the “US Maritime Commission” . There is a second smaller dial for the seconds and 24-hour markings. Also a fast-slow adjuster to the top of the dial. The clock is an 8 day marine clock with US Maritime Commission inscribed on face in black lettering. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, us maritime commission, chelsea clock company, horology, maratime clock -

Orbost & District Historical Society

Orbost & District Historical Societymantel clock, late 1840's

... Steamer Curlip. This clock may have been used as a marine clock. ... Steamer Curlip. This clock may have been used as a marine clock ...This clock was brought out to Australia in 1849. it was then bought in Ballarat by Samuel Richardson in 1865 and brought to Orbost when he settled there. The Richardson family was one of the very early settler families to establish themselves in the Orbost district. Samuel Richardson was builder of the Paddle Steamer Curlip. This clock may have been used as a marine clock. The Richardson family was one of the very early settler families to establish themselves in the Orbost district. Samuel Richardson was builder of the Paddle Steamer Curlip. A wooden mantle clock in a rectangular cabinet. It has pendulum striking. The face has blue and gold decorations. the numerals are Roman. The face surround is white and the numerals black.There is a glass door with red,blue and green decorations on the lower quarter. There is a faded printed label behind the clock and pendulum.Scratched onto the back: "To Australia in 1849. Samuel Richardson bought this clock in Ballarat1865" -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1867-1870

... Clock, marine, in octagonal rosewood veneer case. Roman... variety of Office and Home Clocks and Time Pieces". Clock, marine ...Chauncey Jerome (1793–1868) was an American clock maker in the early to mid 19th century. He made a fortune selling his clocks, and his business grew quickly. Jerome was born in Canaan USA in 1793 son of a blacksmith and nail-maker. He began his career in Plymouth, making dials for long-case clocks where he learned all he could about clocks, particularly clock cases, and then went to New Jersey to make seven-foot cases for clocks mechanisms. In 1816 he went to work for Eli Terry making "Patent Shelf Clocks," learning how to make previously handmade cases using machinery. Deciding to go into business for himself, Jerome began to make cases, trading them to Terry for wooden movements. In 1822 Jerome moved his business to Bristol New Haven, opening a small shop with his brother Noble and began to produce a 30-hour and eight-day wooden clocks. By 1837 Jerome's company was selling more clocks than any of his competitors. A one-day wood-cased clock, which sold for six dollars had helped put the company on the map. A year later his company was selling that same clock for four dollars. The company also sold one line of clocks at a wholesale price of 75 cents and by 1841 the company was showing an annual profit of a whopping $35,000, primarily from the sale of its brass movements. In 1842 Jerome moved his clock-case manufacturing operation to St. John Street in New Haven. Three years later, following a fire that destroyed the Bristol plant, Jerome relocated the entire operation to Elm City factory. Enlarging the plant, the company soon became the largest industrial employer in the city, producing 150,000 clocks annually. In 1850 Jerome formed the Jerome Manufacturing Co. as a joint-stock company with Benedict & Burnham, brass manufacturers of Waterbury. In 1853 the company then became known as the New Haven Clock Co, producing 444,000 clocks and timepieces annually, then the largest clock maker in the world. Jerome's future should have been secure but in 1855 he bought out a failed Bridgeport clock company controlled by P.T. Barnum, which wiped him out financially, leaving the Jerome Manufacturing Co. bankrupt. Jerome never recovered from the loss. By his admission, he was a better inventor than a businessman. When Jerome went bankrupt in 1856 the New Haven Clock Company purchased the company. One of the primary benefits of Jerome purchasing New Haven in the first place was the good reputation of the Jerome brand and the network of companies that remained interested in selling its clocks. In England, Jerome & Co. Ltd. sold Jerome clocks for the New Haven company until 1904, when New Haven purchased the English firm outright. After his involvement with the New Haven Company in 1856, Jerome traveled from town to town, taking jobs where he could, often working for clock companies that had learned the business of clock making using Jerome's inventions. On returning to New Haven near the end of his life, he died, penniless, in 1868 at the age of 74. The company struggled on after Jerome's bankruptcy until after World War II, when the company endeavored to continue through disruptions caused by a takeover along with poor sales, finally having to fold its operations in 1960 a little more than 100 years after it had been founded. The item is significant as it is associated with Chauncey Jerome who had made a historic contribution to the clock making industry during the 19th century when he began to substitute brass mechanisms for wooden mechanisms in his clocks. This was said to be the greatest and most far-reaching contribution to the clock industry. Because of his discovery of stamping out clockwork gears rather than using castings, Jerome was producing the lowest-priced clocks in the world. That can only add to his significance as the major clock manufacture of the 19th century. Jerome may have made and lost, a fortune selling his clocks but was perhaps the most influential and creative person associated with the American clock business during the mid-19th century. Also, he had served his community as a legislator in 1834, a Presidential elector in 1852 and mayor of New Haven, Connecticut from 1854 to 1855.Clock, marine, in octagonal rosewood veneer case. Roman numerals to dial, has a seconds dial. 2 key-winding holes slow-to-Fast adjustment pin through dial. Small lever in lower edge of case activates a chime. "8 day, 8 inch, Lever Striking escarpment " Paper label on the back of the clock "Jerome & Co, New Haven, Conn" "Manufacturers of every variety of Office and Home Clocks and Time Pieces".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, jerome & co, new haven, clock maker, chauncey jerome -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Hourglass

... 1800’s by the more accurate chronometers (marine clocks) when... 1800’s by the more accurate chronometers (marine clocks) when ...An hourglass or sandglass is an instrument for measuring a defined time and can be used perpetually by simply turning it over immediately the top bulb empties. The clear blown glass is shaped into two equal sized bulbs with a narrow passage in the centre and contains uniform sized sand or glass particles in the lower bulb. The width of the neck regulates the constant flow of the particles. The glass is held in a stand with top and bottom of equal shape and size. Hourglasses can measure an infinite variety of time by gauging the size of the particles, the shape and size of the bulbs and the size of the passage between the bulbs, thus measuring hours or minutes or even seconds. Generally an hourglass sits between discs of wood at the ends, which are joined by long wooden spindles between the ends and tightened by screw caps. The length of time can be adjusted by adding or removing sand particles. The use of the marine sandglass (or hourglass) has been recorded in the 14th century in European shipping. A one minute sandglass was used in conjunction with the ship’s log for ‘dead reckoning’, (see below) that is, for measuring the ship’s speed through the water. They were also used to regulate ringing the ship’s timetable; for example a 4 hour sandglass was used for the length of the sailors’ watch, and a half hour timer for taking of readings for the ship’s log; the ship’s bell would be rung every half hour. It was usually the role of the cabin boy to watch and turn the sandglasses over at the exact time of them emptying their upper chambers and to ring the ship’s bell. Hourglasses have been used historically for many hundreds of years. Some have been used for timing church sermons, in cooking, in industry and at sea. Even today they are used for measuring the cooking time of eggs and timing a player’s turn in games such as Boggle and Pictionary. The sandglasses at sea were gradually replaced in the late 1700’s to early 1800’s by the more accurate chronometers (marine clocks) when they became reliable instruments. DEAD RECKONING (or Deduced Reckoning) Dead reckoning is the term used to describe the method of calculating the ship’s position from its speed and direction, used in early maritime travel, mostly in European waters. Both the (1) speed and the (2) direction of travel were recorded on a Traverse Board at half-hourly intervals during a helmsman’s watch of 4 hours. The navigator would record the readings in his ship’s log, plot them on his navigational chart and give his updated course directions to the next helmsman on watch, along with the cleared Traverse Board. This was a very approximate, but none-the-less helpful, method of navigation. The wooden Traverse Board was a simple pegboard with a diagram of a compass with eight peg holes along the radius to each of the compass points, plus a grid with ascending half hours in the left column and increasing ship’s speed in knots in a row across the column headings, with a peg hole in each of the intersecting cells. A number of wooden pegs were attached to strings on the board. By placing one peg consecutively in the direction’s radius hole, starting from the centre, and the speed holes when the half hourly reading was taken, a picture of speed and direction for the whole 4 hour watch was created. (1) To measure the ship’s speed a one minute hourglass timer was usually used to measure the ship’s speed through the water and help to calculate its longitude. A rope, with knots at regular standard intervals and a weight such as a log at the end, would be thrown overboard at the stern of the ship. At the same time the hourglass would be turned over and a seaman would start counting the number of knots on the rope that passed freely through his hands as the ship travelled. When the timer ran out the counting would be stopped. A timer of one minute (one-sixtieth of an hour), knots spaced one-sixtieth of a nautical mile apart, and simple arithmetic easily gave the speed of the ship in nautical miles per hour ("knots"). This would be recorded every half hour. The speed could however be inaccurate to the travel being affected by ocean currents and wind. (2) To calculate the ship’s direction a compass sighting would be recorded each half hour.Marine hourglasses or sandglasses were used from around the 14th to 19th century during the time of sailing ships. This hourglass is representative of that era, which is during the time of the colonisation of Australia. Hourglass or sandglass; an instrument used to measure time. Two equal sized clear glass bulbs joined with a narrow passage between them, containing equal sized particles of sand grains in lower bulb. Glass sits in a brass collar at each end, in a frame comprising 3 decorative brass columns or posts, each attached top and bottom, using round screw-on feet, to round brass discs. Disc have Roman numerals for the numbers 1 - 12 pressed into their inner surfaces and hieroglyphics on the outer surfaces. Roman numerals on inner surface of discs " I II III IV V VI VII VIII IX X XI XII " Hieroglyphics impressed on outer surface of discsflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, horology, hourglass, hour glass, sandglass, sand glass, timing instrument, dead reckoning, deduced reckoning, finding latitude at sea, sandglass with hieroglyphics and roman numerals, hourglass with hieroglyphics and roman numerals, brass hourglass -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClock, 1940's

Smiths began with a craftsman named Samuel Smith who in 1851 opened a shop in Newington Causeway, London, where he made and sold watches, clocks and precision instruments. Samuel had a son, Samuel Jnr who was apprenticed in his fathers business. Samuel Jnr eventually opened his own business at 85 Strand and later opened other premises at 9 Strand, Trafalgar Square and 68 Piccadilly. In 1899 he turned his business into a private limited company, S. Smith & Son Ltd. Samuel Jnr son, Sir Allan Gordon-Smith, joined him as Manager at 9 Strand in 1903 and laid the foundation of the vast Smiths organisation of the future, leading the company towards the supply of accessories for the then developing motor industry making car clocks and the first speedometers patented in 1904. In July 1914 a new company was formed under the name S. Smith & Sons (Motor Accessories) Ltd., to take over the motor accessory business of S. Smith and Son Ltd. and this became the main company of the group which eventually grew to become Smiths Industries Ltd. The original company S Smith and Sons Ltd., continued as jewelers and clock and watchmakers until 1930 when the company was taken over by Bravingtons retail jeweller chain. In 1931 Smiths decided to enter the domestic clock market and formed a new company, Smiths English Clocks Ltd., as the Clock and Watch division of S Smith & Sons (Motor Accessories) Ltd. This is the start of "Smiths Clocks" because this is when they began to manufacture domestic clocks in quantity. Moreover, they set out to produce these clocks at a price that the average householder could afford. S Smith & Sons (Motor Accessories) was at this time was the main company in the Smiths group of companies and their business developed both in the motor vehicle field and outside it. Smiths began to make automatic pilots for aircraft and, through the acquisition of a majority interest in Henry Hughes & Sons Ltd., entered the field of marine instruments. During the war from 1939 to 1945, Smiths' production expanded. There was a demand for motor, aircraft and marine instruments for the Services and the production of industrial instruments and it is at this time that our item was made. In 1944 many changes were made to the Smiths' organisation. The name of the principal company was changed from S Smith & Sons (Motor Accessories) to S. Smith & Sons (England) Ltd. and four new subsidiary selling companies were set up. These were Smiths Motor Accessories Ltd., Smiths Aircraft Instruments Ltd., Smiths Industrial Instruments Ltd., and Smiths English clocks Ltd. The manufacture of clocks and watches ceased in 1979 and 1983 saw Smiths withdraw from producing items for the motor industry.An item that is now regarded as a vintage, sought by horology collectors worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by the Smith company a well known British clock manufacture. Its provenance is well established and it was made during the world war II era specifically for merchant and naval vessels of the time. Naval brass ships bulkhead clock. The clock face is of white enamel with black Roman numerals, an outer minutes ring and black steel hands. There is a subsidiary seconds dial with sweeping hand just above the centre and a fast/slow adjustment lever above that. There is no manufactures name on the dial. There are a beveled glass and brass hinged lid to the front of the clock. The clock is housed in a heavy brass case with screw holes around the circumference for mounting. There are no markings on the clock or mechanism flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, s smith and sons, clock, maritime clocks, clock makers, bulkhead clock -

Flagstaff Hill Maritime Museum and Village

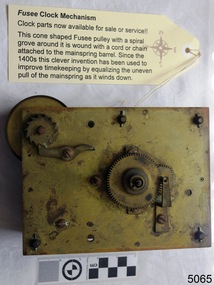

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - Donald Cunneer and David Milner, n.d

Port of Portland Authority archivesFront: (no inscriptions) Back: Don Cunneer/ + David Milner/ Marine Dep (blue pen, upper left)port of portland archives, donald cunneer, david milner, presentation -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph, n.d

Port of Portland Authority ArchivesFront: White Sticker - Marine Dept. 3 - black biro Back: Farewell Dave Milner Skipper Trewalla / Tarragal --blue biroport of portland archives, tug, trewalla, tarragal, skipper -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph, 1988c

colour photo showing western view of Bi-Centenial clock Lakes Entrance Victoriajetties, public utilities -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912