Showing 70 items matching "meakin "

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Alfred Meakin

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.Earthenware dessert plate, cream colour. Made by Alfred Meakin, England. Backstamped ‘Alfred Meakin England’. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, ceramics, earthenware, kitchenware -

Melbourne Tram Museum

Melbourne Tram MuseumBook, Australian Tramway Employees Association (ATEA), Australian Tramway Employees Association (ATEA), "Memorandum of Agreement - ATEA with PMTT, NMETL, ESCo & Meakin & Thomas", 1913, 1913

Four separate agreements, one for each organisation. All details wages and conditions of work and disputes, grievances, and discipline, leave etc. Pages 1 - 10 - agreement with the PMTT - dated 14/1/1913, applied from 1/10/1912 to 1/6/1916. Signed for PMTT by Alex Cameron Chairman; Thomas King Member; and Thomas King Secretary and for Union by Lionel L. Hill President and A. C. Warton General Secretary. Pages 12 - 20 - ditto with NMELTL - dated 14/1/1913, applied from 1/1/1913 to 30/6/1916. Signed for NMETL by L. Voight, A.D. Murdoch and for Union by A. C. Warton General Secretary. Pages 21 - 32 - ditto with ESCo - dated 14/1/1913, applied from 1/12/1912 to 30/6/1916, includes rosters for Ballarat and Bendigo. Signed by William J Home for P. J. Pringle for ESCo and for Union by Lionel L. Hill President and A. C. Warton General Secretary. Pages 33 - 42 - ditto with Messrs Meakin and Thomas, Lessees of the Northcote Cable Tramways. Dated 14/1/1913, applied from 1/12/1912 to 30/6/1916. Signed by F.W. Meakin and Lena Thomas in front of Louis Waxman Solicitor and A. C. Warton, General Secretary.Yields information about the industrial agreements with Tramway operators in Victoria, except for MTOCo. Forty-Four page booklet, off-white paper, saddle-stapled, with additional dark grey colour paper cover titled "The Australian Tramway Employees' Association with the The Prahran & Malvern Tramways Trust / The North Melbourne Electric Tramways and Lighting Company Limited/ The Electric Supply Company of Victoria Limited and Messrs. Meakin and Thomas".Various doodles on some pages.tramways, ballarat, bendigo, melbourne, atea, unions, agreements, esco, nmetl, pmtt, northcote cable trams, meaking and thomas, rosters -

Anglesea and District Historical Society

Anglesea and District Historical SocietyPlate, J & G Meakin, Eagle & Eastwood Pottery Works, 'LILAC' PLATE, 1912

Basically square with indented corners. "Lilac" trees and sprigs. Green edging.Regd. SOL - 391413 / J & G MEAKIN ENGLAND / (Unreadable bottom line)meakin, plate -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Tramway Employees Association (ATEA), "Memorandum of Agreement - ATEA with PMTT, NMETL, ESCo & Meakin & Thomas", 1913

Four separate agreements, one for each organisation. All details wages and conditions of work and disputes, grievances, and discipline, leave etc. Pages 1 - 10 - agreement with the PMTT - dated 14/1/1913, applied from 1/10/1912 to 1/6/1916. Signed for PMTT by Alex Cameron Chairman; Thomas King Member; and Thomas King Secretary and for Union by Lionel L. Hill President and A. C. Warton General Secretary. Pages 12 - 20 - ditto with NMELTL - dated 14/1/1913, applied from 1/1/1913 to 30/6/1916. Signed for NMETL by L. Voight, A.D. Murdoch and for Union by A. C. Warton General Secretary. Pages 21 - 32 - ditto with ESCo - dated 14/1/1913, applied from 1/12/1912 to 30/6/1916, includes rosters for Ballarat and Bendigo. Signed by William J Home for P. J. Pringle for ESCo and for Union by Lionel L. Hill President and A. C. Warton General Secretary. Pages 33 - 42 - ditto with Messrs Meakin and Thomas, Lessees of the Northcote Cable Tramways. Dated 14/1/1913, applied from 1/12/1912 to 30/6/1916. Signed by F.W. Meakin and Lena Thomas in front of Louis Waxman Solicitor and A. C. Warton, General Secretary.Yields information about the industrial agreements with Tramway operators in Victoria, except for MTOCo.Forty-Four page booklet, off-white paper, saddle-stapled, with additional dark grey colour paper cover. titled "The Australian Tramway Employees' Association with the The Prahran & Malvern Tramways Trust / The North Melbourne Electric Tramways and Lighting Company Limited/ The Electric Supply Company of Victoria Limited and Messrs. Meakin and Thomas". Three copies held. "Ballarat Tramway Preservation Society Catalogue No. 213" in ink on top of first page, inside cover on both copies. Copy 1 - has name of "H.W.H.Collett" and "1913" on front cover, and pencil or red pencil notes against various rules in the ESCo section. Copy 2 - some minor pencil marks.trams, tramways, bendigo, ballarat, atea, unions, agreements, esco, nmetl, pmtt, northcote cable trams, meakin & thomas -

Anglesea and District Historical Society

Anglesea and District Historical SocietyBowl, Alfred Meakin (Tunstall) Ltd, Royal Albert & Newfield Potteries

Small bowl-dish with rim. Brown daisy pattern.Glo-White-Ironstone / crown symbol / Alfred Meakin / Englandplate, bowl, meakin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Serving Dish, J & G Meakin, 1880 to 1900

J & G Meakin was an English pottery manufacturing company founded in 1851 and based in Hanley, Stoke-on-Trent, Staffordshire. In the 19th century, J & G Meakin was known for the vast quantities of cheap ironstone china it produced for the domestic English market and export to Australia, Canada, New Zealand, and the United States and one of these pottery lines was called "EMPRESS" and was in production through the 1930s. From around 1970, designs included Liberty, Sterling, Trend, Classic, and Heirloom. Some of these were influenced by earlier designs. The newer wares can be distinguished by back stamp markings such as 'permanent colours', 'everlasting colour', or 'dishwasher proof'. J & G Meakin had close family and corporate affiliations to the potteries Johnson Brothers, and Alfred Meakin Ltd, which explains why many patterns are similar, if not almost the same. There was a takeover by J. & G. Meakin in 1968 of Midwinter Pottery. The firm was then taken over by the Wedgwood Group in 1970. In 2000 production under the Meakin name ceased and their long-established works, Eagle Pottery, was then used for the production of Johnson Bros pottery. Eagle Pottery closed in 2004 when production was transferred abroad; the works were demolished in 2005.Item is significant as today the "EMPRESS" china pattern from the 1930s by Meakin is today a collectable item and a good example of the Meakin range of china.Serving vegetable bowl with two handles on either end, plus a lid with a handle on the top lid also has a pattern around the edge.Inscription to base "J & G Meakin Manley England " warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, staffordshire potteries, iron stone pottery, serving dish -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Ewer and Bowl, J & G Meakin, 1912 - 1925

J & G Meakin was an English pottery manufacturing company founded in 1851 and based in Hanley, Stoke-on-Trent, Staffordshire. In the 19th century, J & G Meakin was known for the vast quantities of cheap ironstone china it produced for the domestic English market and export to Australia, Canada, New Zealand, and the United States. From around 1970, designs included Liberty, Sterling, Trend, Classic, and Heirloom. Some of these were influenced by earlier designs. The newer wares can be distinguished by back stamp markings such as 'permanent colours', 'everlasting colour', or 'dishwasher proof'. J & G Meakin had close family and corporate affiliations to the potteries Johnson Brothers, and Alfred Meakin Ltd, which explains why many patterns are similar, if not almost the same. There was a takeover by J. & G. Meakin in 1968 of Midwinter Pottery. The firm was then taken over by the Wedgwood Group in 1970. In 2000 production under the Meakin name ceased and their long-established works, Eagle Pottery, was then used for the production of Johnson Bros pottery. Eagle Pottery closed in 2004 when production was transferred abroad; the works were demolished in 2005.Item is significant as it is believed to be an early example of the SOL trademark made between 1913-1925.Ironstone wash jug and bowl set, white, often referred to as a ewer and bowl. Both jug and bowl have matching raised embossing of panels with floral motifs within them.Both items have marks "Ironstone China Reqd SOL 39/4/3 STG Meakin England" Trademark of J & G Meakin with sun emblem .flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug china white and basin, jug, jug and basin, jug & bowl, ewer, bowl, ewer & bowl, j and g meakin, ironstone ware, bathing, washing, personal hygiene -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Chamber Pot, 1912

In the 19th and early 20th centuries, J. & G. Meakin were important, large-scale producers of good quality, ironstone tableware (‘White Granite’ ware) that met a ready market in the United States, South America, Australia, and other traditional British markets. By the 1890s the company was one of the world’s largest earthenware manufacturers. Although export teaware and tableware was the factory’s staple commodity, Meakin also manufactured toilet ware, kitchen ware and a wide range of fancy earthenware. The company was amongst the first British pottery firms to experiment with modernist designs associated with the art deco period. The Moderne' range was introduced in 1929 consisting of an angular shape decorated design with geometric patterns and often highlighted with silver or gold. This range remained in production through the 1930s. Post 1945 the company introduced the streamlined Studio shape (1953) and Horizon shape (1955) both heavily influenced by the Russell Wright ‘American Modern’ tableware. In 1964 a new Studio shape was released with tall streamlined coffee pots used as the background for many contemporary patterns now associated with the 1950s and 1960s. Designs by Jessie Tate and Eve Midwinter, some originally found on Midwinter shapes, also appear on 1970s Studio ware. The Studio range was one of Meakin’s most successful and continued in production until the late-1970s. The enormous range of floral, geometric, and abstract designs make Studio Ware collectible in its own right. In the 1970s and 1980s as part of the Wedgwood Group Meakin produced contemporary products under the ‘Bull in a China Shop’ and ‘Creative Tableware’ names. ‘Sol’ (c.1912-1963), ‘Studio’ (1953 on) and ‘Royal Staffordshire’ (post 1968) were important J. & G. Meakin Ltd trade names. Meakin marks are numerous, but all include the J. & G. Meakin name. The significance of this item and pottery generally is that often earthenware is portrayed as being a landmark in the evolution of humanity. This is because these items are the few things from the past that have survived in a tangible form. Pottery is an important functional part of society and it has a critical role to play as it helps archaeologists to date other artefacts of the same time period. Also, the decorations on pottery have told much about the beliefs, lifestyles and lives of the people who bought them and used them. In other words it gives us today a snapshot of society from the past and how people used these items in their daily lives, their likes as well as societal and design trends. Earthenware white glazed ironstoneJ & G Meakin Hanley England stamped to base, with white flora designwarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pottery, earthenware, iron stone, alfred meakin, james meakin, george meakin, earthenware manufactures, chamber pot -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumDomestic object - Tableware Set, Meakin, Alfred

Alfred Meakin 'Haven' pattern tableware set of 2 oval platters, 2 covered and 2 handled circular dishes and 1 gravy boat. Gravy boat with high handle and wide spout. White ground with gilt outline geometric and floral design in blue, green and yellow.Green glazed on base: ALFRED MEAKIN / ENGLAND / Indecipherable and then in black glaze: HAVEN In gilt: 9, 14, 18 & 12 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBowl, J & G Meakin

Large white ironstone china bowl. Made by J & G Meakin. Hanley England. 15' in diameter.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, china bowl, bowl -

Mont De Lancey

Mont De LanceyMeat Dish and Gravy Boat, Alfred Meakin Ltd

Oval China meat dish with dark blue rim and gold design on edge, with matching Gravy boat. "Bleu de Roi China'."Bleu de Roi Alfred Meakin Ltd England?gravy boats -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Serving Plate, Alfred Meakin, 1930s

J & G Meakin was an English pottery manufacturing company founded in 1851 and based in Hanley, Stoke-on-Trent, Staffordshire. In the 19th century, J & G Meakin was known for the vast quantities of cheap ironstone china it produced for the domestic English market and export to Australia, Canada, New Zealand, and the United States and one of these pottery lines was called "EMPRESS" and was in production through the 1930s. From around 1970, designs included Liberty, Sterling, Trend, Classic, and Heirloom. Some of these were influenced by earlier designs. The newer wares can be distinguished by back stamp markings such as 'permanent colours', 'everlasting colour', or 'dishwasher proof'. J & G Meakin had close family and corporate affiliations to the potteries Johnson Brothers, and Alfred Meakin Ltd, which explains why many patterns are similar, if not almost the same. There was a takeover by J. & G. Meakin in 1968 of Midwinter Pottery. The firm was then taken over by the Wedgwood Group in 1970. In 2000 production under the Meakin name ceased and their long-established works, Eagle Pottery, was then used for the production of Johnson Bros pottery. Eagle Pottery closed in 2004 when production was transferred abroad; the works were demolished in 2005.Item is significant as today the "EMPRESS" china pattern from the 1930s by Meakin is today a collectable item and a good example of the Meakin range of china.Plate china white oval with a pattern inscribed along the edge Inscription to base "EMPRESS" warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alfred meakin, staffordshire potteries, iron stone pottery, serving dish -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Chamber Pot, J & G Meakin, Early to mid 20th century

In the 19th and early 20th centuries, J. & G. Meakin were important, large-scale producers of good quality, ironstone tableware (‘White Granite’ ware) that met a ready market in the United States, South America, Australia, and other traditional British markets. By the 1890s the company was one of the world’s largest earthenware manufacturers. Although export teaware and tableware was the factory’s staple commodity, Meakin also manufactured toilet ware, kitchenware and a wide range of fancy earthenware. The company was amongst the first British pottery firms to experiment with modernist designs associated with the art deco period. The Moderne' range was introduced in 1929 consisting of an angular shape decorated design with geometric patterns and often highlighted with silver or gold. This range remained in production through the 1930s. Post 1945 the company introduced the streamlined Studio shape (1953) and Horizon shape (1955) both heavily influenced by the Russell Wright ‘American Modern’ tableware. In 1964 a new Studio shape was released with tall streamlined coffee pots used as the background for many contemporary patterns now associated with the 1950s and 1960s. Designs by Jessie Tate and Eve Midwinter, some originally found on Midwinter shapes, also appear on 1970s Studio ware. The Studio range was one of Meakin’s most successful and continued in production until the late-1970s. The enormous range of floral, geometric, and abstract designs make Studio Ware collectible in its own right. In the 1970s and 1980s as part of the Wedgwood Group Meakin produced contemporary products under the 'Bull in a China Shop' and 'Creative Tableware' names. 'Sol' (c.1912-1963), 'Studio' (1953 on) and 'Royal Staffordshire' (post-1968) were important J. & G. Meakin Ltd trade names. Meakin marks are numerous, but all include the J. & G. Meakin name. The significance of this item and pottery generally is that often earthenware is portrayed as being a landmark in the evolution of humanity. This is because these items are the few things from the past that have survived in a tangible form. Pottery is an important functional part of society and it has a critical role to play as it helps archaeologists to date other artefacts of the same time period. Also, the decorations on pottery have told much about the beliefs, lifestyles and lives of the people who bought them and used them. In other words it gives us today a snapshot of society from the past and how people used these items in their daily lives, their likes as well as societal and design trends. Chamber pot ceramic white with handle at side and decoration around top. Unclearwarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, champer pot, personal hygiene, personal item, ceramic pot, domestic object -

Mont De Lancey

Mont De LanceyFurniture - Commode

Bedroom commode of stained wood, with short legs and wheels, and a Meakin white enamel chamber pot inside.Meakin printed on bottom of chamber pot.commodes, storage furniture -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Ironstone China Wash bowl and jug

Ironstone china pieces were common domestic items during the 19th to mid 20th century in many Australian households. This kind of china is not porcelain but porous earthenware, made of clay mixed with feldspar. Patented in 1813 by Charles James Mason in Staffordshire, England, it was an immediate success and became widely produced by a range of Staffordshire potters. J & G Meakin Pottery dates back to 1845 when James Meakin started a pottery business at Lane End in Staffordshire.nIn 1848 he moved the business to Hanley in Staffordshire, before retiring in 1852 and handing the business over to his two sons James and George, who carried on with the pottery, trading as J & G Meakin. The "SOL" and sun face trademarks were registered in 1912. The firm was taken over by the Wedgwood Group in 1970. In 2000, production under the Meakin name ceased. W. H. Grindley was founded at the Newfield Pottery in 1880 by William Harry Grindley (principal partner). Mr Turner and Mr Alfred Meakin were also involved. Early advertisements stated that they produced Earthenware and Ironstone China - particularly for the Canadian, United States, South American and Australian markets. The mark on this jug was used from c1891 until 1925. W. H. Grindley China was manufactured until 1991, making it one of the last Stoke on Trent potteries.These items are representative of a common domestic item used by households in the Wodonga district and throughout Australia, many manufactured specifically for the Australian market.A white ironstone jug and bowl. The jug features a leaf design embossed on the surface. The bowl has a small circle pattern around the rim. They are not as set as the jug bears the mark W. H. Grindley and the bowl was made by J & G Meakin.Underneath Bowl: above and below image of the sun: "IRONSTONE CHINA/ REGD. SOL 391413/ J & G MEAKIN/ENGLAND Underneath jug: above and below the royal insignia: ROYAL IRONSTONE CHINA / W.H. GRINDLEY & CO. / ENGLAND"ironstone, domestic items, staffordshire pottery -

Clunes Museum

Clunes MuseumDomestic object - PLATE, J & G MEAKIN

.1 WHITE EARTHENWARE SOUP PLATE, SOME DECORATION ON THE MOLDED EDGE .2 WHITE EARTHENWARE SOUP PLATE, SOME DECORATION ON THE MOLDED EDGE .3 WHITE DINNER PLATE WITH SIMPLE MOLDED EDGE AT THE RIM.1 BACK STAMP IN GREEN - UNABLE TO IDENTIFY DUE TO POOR QUALITY .2 BACK STAMP IN BLACK: J&G MEAKIN HANLEY ENGLAND. IN TEXTA: 106 .3 BACK STAMP IN GREEN: JOHNSON BROS ENGLANDsoup plate, dinner plate -

Bendigo Historical Society Inc.

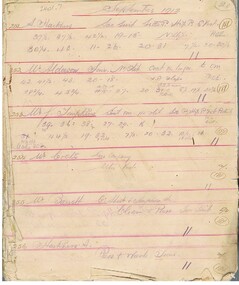

Bendigo Historical Society Inc.Document - GEORGE MEAKIN COLLECTION: TAILOR'S MEASUREMENT AND ORDER BOOK, Sep. 1912 to May 1913

Document : Part of a lined exercise book in poor condition. Entries hand written in pencil by date and name. Measurements for Masonic clothing? Geo. Meakin, tailor.Geo. Meakin, tailor, High St Bendigoorganization, retail, tailor, geo. meakin, tailor, clothing measurements, masonic lodge -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Domestic Object - LARGE CHINA JUG

Large white china jug with scalloped top, decorated with relief of wheat & vines. Shown on base makers marks showing a sun with wording J & G Meakin 50L Ironstone China Reg Limited 43758 Hanley England.J & G Meakindomestic equipment, ablutions, water jug, k110 -

Orbost & District Historical Society

Orbost & District Historical Societydish

Used as a vegetable dish and donated by Alice Slatter.White oval-shaped china dish with lid. Lid has handle. Bottom has broken handles. Raised base. dish china domestic-storage meakin-j&g -

Mont De Lancey

Mont De LanceyChamber pot

Grey chamber pot with decorative pattern. Part of 1909 Bedroom set.chamber pots -

Mont De Lancey

Mont De LanceyWash jug and bowl, J & G Meakin

White jug and wash bowl with decorative pattern. Part of 1909 bedroom set.jugs, water pitcher -

Mont De Lancey

Mont De LanceyVegetable dishes, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).Two oval shaped vegetable dishes - White with blue rose design. Fluted edge with gold trim. Two decorative handles on base. On decorative handle on lid.vegetable dishes, serving dishes -

Mont De Lancey

Mont De LanceyGravy boat, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White gravy boat with blue rose design. Fluted edge with gold trim. Decorative handle.sauce boats, dinnerware -

Mont De Lancey

Mont De LanceyGravy tureen, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White gravy tureen with blue rose design. Gold fluted edge. Decorative handles on base and lid. Plus spoon with decorative handle.tureens, dinnerware -

Mont De Lancey

Mont De LanceyServing platter, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White oval shaped serving platter with blue rose design. Fluted edge with gold trim. (Part of set of five serving platters).platters, serving dishes, dinnerware -

Mont De Lancey

Mont De LanceyServing platter, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White oval shaped serving platter with blue rose design. Fluted edge with gold trim. (Part of set of five platters).platters, serving dishes, dinnerware -

Mont De Lancey

Mont De LanceyServing platter, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White oval shaped serving platter with blue rose design. Fluted edge with gold trim. (Part of a set of five serving platters).platters, serving dishes, dinnerware -

Mont De Lancey

Mont De LanceyServing platter, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White oval shaped serving platter with blue rose design. Fluted edge with gold trim. (Part of set of five serving platters).platters, serving dishes, dinnerware -

Mont De Lancey

Mont De LanceyServing platter, J & G Meakin

Wedding gift to Mr. & Mrs. Wilms, 5th January 1910. (Dorothy Adamson's parents).White oval shaped serving platter with blue rose design. Fluted edge with gold trim. (Part of a set of five serving platters).platters, serving dishes, dinnerware