Showing 11 items matching "metal cot"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Cot, Late 19th to early 20th century

... metal cot...Cot, metal, with chrome knobs and removable sides. Has... flagstaff hill maritime village great ocean road cot metal cot iron ...Iron beds made from metal or wrought iron have been around since the late 18th century when they were hand made by craftsmen and artisans. The iron castings were always hand poured and originated from sand cast molds, more ornate beds are associated with the Victorian period. Later in the Edwardian era cast iron beds and cots had much less decoration and were quite plain .An relatively early domestic piece of furniture used as a babies cot giving a snapshot into domestic life around the end of the 19th century and beginning of the 20th. The item is not associated with a significant event, person or place and would have been common place in most homes of the time made by many different manufactures.Cot, metal, with chrome knobs and removable sides. Has wheelsNoneflagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cot, metal cot, iron bed -

Clunes Museum

Clunes MuseumFunctional object - BABY COT

... HOSPITAL COT, BABY COT METAL FRAME, COT IS ON WHEELS... cot NIL HOSPITAL COT, BABY COT METAL FRAME, COT IS ON WHEELS ...USED IN CLUNES HOSPITAL, CLUNES, VICTORIA, AUSTRALIAHOSPITAL COT, BABY COT METAL FRAME, COT IS ON WHEELS, A METAL RECTANGULAR BASKET WHICH CAN BE LIFTED OUTNILhospital cot, baby cot -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Electric

From c1950s electrical irons were used. The thermostatic iron followed the electric iron used with a container that enabled water to be sprayed onto the cloth. Damp cloth was more easily pressed. This thermostatic electric iron was one of the early models.This iron was used by residents of the Kiewa Valley including those living at Mt Beauty where there was electricity and an SEC shop from c1950.This is a "General Electric" iron. It has a steel base with a chrome upper and black plastic handle. It is thermostatically controlled with water spray. The electric cord is permanently attached, at right angels, to the handle base. A red button activates the water spray when pushed. A white button slides to enable fabric selection. A metal hole in the front of the handle is used to fill the iron with water.General Electric; Wash and Wear / Wool / Cot / Lin; Australian General Electric Appliances Pty Ltd.; Notting Hill Victoria. 1100 Wats 240 Volts AC only. V/A2F Cat. No. 10 FS10iron;, electrical appliance, laundry, domestic, pressing clothes -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumCream cot in black stand and wheels, Cot - Nursery

Rectangular close woven cane box (no top wih lengths of canefollowing ventilation for base. There is a bent piece of cane screwed onto one end,doubling the height of the box,to support a mosquito net. There is a waterproof (1221) underlay - no mattress - and a folded (1201) quilt (cotton) inside. The frame is sturdy steel supporting the box - cot. Chipped black pain covering it. 2 metal handles are fastened to top side edges to help lift cot out of frame. -

Ambulance Victoria Museum

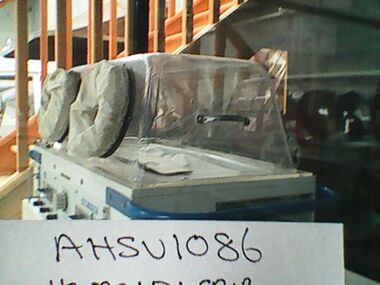

Ambulance Victoria MuseumHumidicrib, CIG, Port-O-Cot, The Commonwealth Industrial Gases Limited

... their old timber ones! infant PORT-O-COT metal box with carry ...Humidicribs are used to transport sick babies from small hospitals to major hospitals for specialist care. They work by maintaining normal body temperature and provide oxygen if needed during ambulance transit. Known by a variety of commercial names, earlier humidicribs were ones heated with water bottles. Not part of an ambulances standard equipment, humidicribs are kept in ambulance stations and carried if babies needed to be transported. In the early days before humidicribs came into use and when air ambulances did not exist, many more babies died during emergency transits than do today Manufactured by the Commonwealth Industrial Gases Limited (better known as CIG), Australian-made Port-O-Cot brand humidicribs came replaced timber home-made humidicribs. They had electrical heating and easy to control oxygen flow and humidity control equipment. CIG also noted that noted that: Once the baby has been placed inside, the cot need not be opened, all nursing operations being carried out through the iris armholes. Even though the baby is in complete isolation nursing is a straight forward matter… The iris armholes allow nurses to feed, weigh, take temperatures, change napkins or, in fact, carry out any procedures without changing or disturbing the atmosphere within the cot. Happily for ambulance officers and nurses, the new Port-O-Cots were also much lighter and easy to carry than their old timber ones! metal box with carry handles and Perspex opening top. Carry handles at each end.PORT-O-COTinfant -

Ambulance Victoria Museum

Ambulance Victoria MuseumHumidicrib, CIG, Thermocot, The Commonwealth Industrial Gases Limited, Circa 1970s

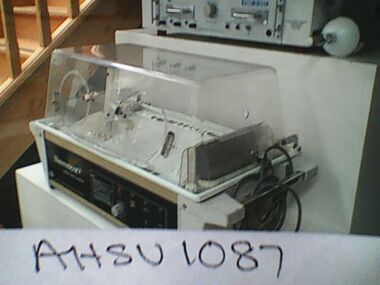

Humidicribs are used to transport sick babies from small hospitals to major hospitals for specialist care. They work by maintaining normal body temperature and provide oxygen if needed during ambulance transit. Known by a variety of commercial names, earlier humidicribs were ones heated with water bottles. Not part of an ambulances standard equipment, humidicribs are kept in ambulance stations and carried if babies needed to be transported. In the early days before humidicribs came into use and when air ambulances did not exist, many more babies died during emergency transits than do today The Thermocot Developed from the Port-O-Cot, CIG later produced the Thermocot. The new humidicrib had a number of advantages over the Port-O-Cot. Most importantly it had an over-temperature alarm and cut out. It was also calibrated in degrees Celsius as by then the metric measuring system had been introduced to Australia. It also had a front opening canopy which was easier for nursing staff to use. Metal box with Perspex opening top section. Carry handles at each end.Thermocot portable infant incubator CIGinfant -

Ambulance Victoria Museum

Ambulance Victoria MuseumHumidicrib, CIG, Thermocot, The Commonwealth Industrial Gases Limited, Circa 1970s

Humidicribs are used to transport sick babies from small hospitals to major hospitals for specialist care. They work by maintaining normal body temperature and provide oxygen if needed during ambulance transit. Known by a variety of commercial names, earlier humidicribs were ones heated with water bottles. Not part of an ambulances standard equipment, humidicribs are kept in ambulance stations and carried if babies needed to be transported. In the early days before humidicribs came into use and when air ambulances did not exist, many more babies died during emergency transits than do today The Thermocot Developed from the Port-O-Cot, CIG later produced the Thermocot. The new humidicrib had a number of advantages over the Port-O-Cot. Most importantly it had an over-temperature alarm and cut out. It was also calibrated in degrees Celsius as by then the metric measuring system had been introduced to Australia. It also had a front opening canopy which was easier for nursing staff to use. Metal box with Perspex opening top section. Carry handles at each end.Thermocot portable infant incubator CIG -

Mont De Lancey

Mont De LanceyBaby Safe Cot and Play Pen, Circa 1928

The safety cot was used in the 1930's and kept out the mosquitos and the other children.Wooden, light green baby safe cot and play pen, with flywire and hinged side door with metal bolts. Has a vinyl mattress, and linen. With two dolls = 1 large and 1rag doll.cots -

Mont De Lancey

Mont De LanceyLeisure object - Dolls Cot, Unknown

These wooden handmade toys were used by young children to play 'House' with their dolls.A lilac and white painted wooden dolls cot with an eight railed drop side, a wooden base with four white slats. The drop railed side has thick wire rungs to slide it up and down with metal clips to engage it up or down. There is bedding in the cot.toys, children's toys, toy accessories, dolls bed, dolls furniture -

Vision Australia

Vision AustraliaFunctional object - Object, Cane basket on wheels

Basket weaving and brush making was a source of income for those who worked in the workshops at RVIB and other institutions in New South Wales and Queensland. A diverse range products could be produced with cane, such as cane chairs, cots, washing baskets and trolleys, and the Institution sought to highlight these in the annual report. Over time the demand for, and supply of, cane changed - particularly during World War 2 when Asian sources were under attack or destroyed. At home, other materials such as plastics as well as the ability to import cheaper pre-produced products further reduced the demand for workshop pieces. This cane basket was used at QBIC for transporting heavy items. The side has been reinforced with wood and four metal bands to help the cane keep it's shape and take the weight of heavy items. The base has two pieces of board and rotating wheels are attached to the middle of the lower board which allows it to sit above ground level and be wheeled over flat surfaces. A rope handle is attached to two sides as well.1 deep cane basket with two wheelsQBIC Industries - Asset Number: 1430-1 Description: Push Trolley 7 Location: 18R Block Cane Shop employment, qbic industries -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Royal blue double breasted cardigan 'Reefer Jacket' with short sleeves in a textured rib stitch with six chrome metal buttons in two rows down centre front. Style 319/J .2 is sample tag with manufacturing information, including sizes and colours available.1) [white label at back neck with blue stitching] KATHRYN REGD. CREATED BY ALL COTTON / 24 / ROBERT BLAKE .2) [sample label] [OBVERSE] STYLE: 319/J – Reefer Jacket – Combed Cot. SIZE: 22” 24” 26” 28” 30” 32” PRICE: 20/- 21/- 22/6 24/- 26/- 27/6 COLOR: NAVY ONLY. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, children's knitwear, clothing, children's clothing, cardigan, manufacturing, fashion textile production, machine knitting, fashion cotton