Showing 57 items matching "milking machines"

-

Cheese World Museum

Cheese World MuseumPump, dairy vacuum

... milking machines...Milking machine chain driven vacuum pump made of cast iron... milking machines Leon Miller 209 Milking machine chain driven ...From the dairy farm of Leon Miller, Swans Lane, AllansfordMilking machine chain driven vacuum pump made of cast iron, marked on the circular cylinder cap with an identification number.209allansford, machinery, dairy machinery, dairying, pumps, milking machines, leon miller -

Cheese World Museum

Cheese World MuseumPhotograph, Unknown photographer, The first mechanical milking machine public demonstration in Allansford district, 1905

... milking machine on the Ernst Uebergang property Briarwood... milking machine demonstration. Dignitories, farmers and children...Written on back of photo 'LKG Milking Machine Lawrence... mechanical milking machine on the Ernst Uebergang property Briarwood ...The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This photograph is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No. Photograph tells the story of a special celebration marking the occssion of the demonstration of the first mechanical milking machine on the Ernst Uebergang property Briarwood at Cudgee Victoria. Ernst Uebergang is inside the shed. Reported in Warrnambool Standard 5 June 1905.Photo on badly damaged brown mount board. Image depicts LKG milking machine demonstration. Dignitories, farmers and children present. Two men are inside the shed with two cows. Written on back of photo 'LKG Milking Machine Lawrence Kennedy 1902/ Mr Ernst Uebergang inside shed.'uebergang, dairy industry, rural industry, food manufacture, machinery, lkg, cudgee, briarwood, milking machine, children, cows, dignitories, farmers, bucket -

Cheese World Museum

Cheese World MuseumMilking Machine, Bartram & Son, LKG Steam Operated Machine, 1906 (estimated)

... milking machines... and pulsator) milking machine. This method is still in use today... and pulsator) milking machine. This method is still in use today ...This machine was the first double action (suction and pulsator) milking machine. This method is still in use today. Invented by Alexander Gillies,of Terang. The LKG milking machine is of State significance because it represents a high degree of technical achievement. It demonstrates the innovation developed by a Western District farmer, Alexander Gillies, that enabled dairy farms throughout Victoria to move successfully from hand milking to machine milking, thus contributing to the mechanisation of one of Victoria's major rural industries. Source: Cheese World Museum Significance Assessment, Lesley Alves, December 2009Cone shaped metal pail with a carry handle attached near the top and a tipping handle near the base. Removable top has pulsator mechanism which sealed the pail. Brass cover plateBrass cover plate inscribed Trade Mark LKG. Metal disc inscribed K136.dairy industry, machinery, milking machines, alexander gillies, terang -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Ross Motors Key Tag, Mid 20th Century

... milking machines... of vehicles as well as sales and service of milking machines and car... as sales and service of milking machines and car accessories ...Ross Motors operated a car dealership in Fairy Street in the mid 20th century. They sold a number of different makes of vehicles as well as sales and service of milking machines and car accessories.A link to a Warrnambool business.Cream oval plastic disc for key ring. Black text.Ross Motors Pty Ltd Warrnambool. Distributors of Buick, Pontiac, Vauxhall, cars and Bedford trucks. Phones : 213, 219. On Reverse: Finder of these keys please return to address on reverse side.warrnambool, ross motors, car dealership warrnambool, milking machines, buick cars. -

Marysville & District Historical Society

Marysville & District Historical SocietyPhotograph (Item) - Colour photograph, Unknown

... A colour photograph of Tino Gianforte with a milk bottle...A colour photograph of Tino Gianforte with a milk bottle...MARYSVILLE DAIRY/ TINO GIANFORTE/ MILK/ BOTTLE MACHINE... of Tino Gianforte with a milk bottle machine in the Marysville ...A colour photograph of Tino Gianforte with a milk bottle machine in the Marysville Dairy in Victoria.A colour photograph of Tino Gianforte with a milk bottle machine in the Marysville Dairy in Victoria. The Marysville Dairy was owned and operated by a local man, Tino Gianforte and was located on Falls Road in Marysville.MARYSVILLE DAIRY/ TINO GIANFORTE/ MILK/ BOTTLE MACHINE/ 1958-1960/ 600 BOTTLES PER/ DAYmarysville, victoria, tino gianforte, northern milk transport, marysville dairy -

Mansfield Historical Society

Mansfield Historical SocietyBook, "The Harbour" Newspaper & Publishing Co Ltd, Southern Cross Catalogue 1939-40, 1939

... milking machines.... windmills petrol engines kerosine engines pumps milking machines ...The Southern Cross Organisation had its origin in a small Foundry in Toowoomba, Queensland, in 1871, and has grown into a Commonwealth-wide organisation with a selling network serving the whole of Australia and supplying Southern Cross Products as far away and Deccan, in India.This object is significant because it is complete and the pages are clean, straight & unmarked with the binding is in good condition.Soft Red CoverSouthern Cross Catalogue for 1939-40windmills, petrol engines, kerosine engines, pumps, milking machines, tanks, lighting plants, home light batteries -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilking Cups - Dairy

... of milking using machines. ... rubber tubes that lead towards the main milking machine... towards the main milking machine. The metal cups have black ends ...This milking equipment was used in the early days of milking using machines. The dairy industry is and has been one of the major industries of the Kiewa Valley. This equipment was used on local farmers, P & R. Creamer's dairy farm.Set of early mechanical milking cups. 4 cups - 2 each side of 2 hollow metal (steel) rods which are attached to hollow rubber tubes that lead towards the main milking machine. The metal cups have black ends at the opening where they are attached to the cow. The outlet from the cups is via 2 metal tubes that lead into the rods that in turn lead to the tubes.At opening at end of cups: "Utility" possibly more but too difficult to read. milking machinery; dairy; kiewa valley; creamer family; -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Milking Machine Plates (2), 1950s

... Machine. Vacuum Break milking machines were popular from the 1930s... These items come from a Gordon Vacuum Break Milking Machine. Vacuum ...These items come from a Gordon Vacuum Break Milking Machine. Vacuum Break milking machines were popular from the 1930s on, with the systems interrupting or breaking the constant milking vacuum, thus avoiding or reducing the harmful effects of vacuum acting constantly on the cow’s teats. An inserted rubber section acted as a valve which affected the pinching action by closing and opening alternately. These items came from a milking machine which was used on the property of Reginald Dalton Hooker and his wife Marjorie. The property was at 155 Rooneys Road, Dennington and twenty cows were milked on land irrigated by a bore. The milk was supplied to the Nestles Factory in Dennington (now Fonterra). These two plates are of interest as they are reminders of the local dairying industry during the mid 20th century. Dairying remains today the chief industry of the Warrnambool district..1 This is a rectangular metal plate with two holes at each end for attachment to a machine and with raised metal lettering on the inside surface. The plate has been painted light brown but the paint is now peeling. .2 This is a small rectangular silver-coloured plate with raised lettering on the front. .1 GVB Gordon Vacuum Break Milker .2 GVBreginald hooker, dennington, gordon vacuum break milkers, history of warrnambool -

Cheese World Museum

Cheese World MuseumVacuum recorder, E.M.P. Engineers Ltd, c1960

... in the Allansford area to check the amount of suction in milking machines.... in the Allansford area to check the amount of suction in milking machines ...Used by first Warrnambool Cheese and Butter Factory Company Ltd Field Officer, Bruce McLaren, for on-farm testing in the Allansford area to check the amount of suction in milking machines.Phillips Rurakura Vacuum Recorder in a wooden box with lid, metal hinges and fastening clip, screw adjustment and name plate on outside. Inside has a clockwork-operated recorder with pen device to roll of paper.Internal: Trade mark Empel E.M.P. Engineers Ltd PO Box 5125, Hamilton, NZ Aust. Pat. 209 510. NZ Pat. 112 486. External: Empel Phillips Ruakura Type Vacuum recorder, Makers E.M.R. Engineers Ltd. PO Box 5125, Hamilton NZ -

Cheese World Museum

Cheese World MuseumCatalogue, To Dairymen & Agriculturalists: Milk Cream and Butter

... suppliers of mechanical milking machines in Victoria.... suppliers of mechanical milking machines in Victoria. The catalogue ...This catalogue belonged to Alderdice Brass Foundry in Warrnambool. It was donated to the museum by John Downing from the foundry. The catalogue is for the firm of J Bartram & Son who were suppliers of dairy equipment. They were one of the earliest suppliers of mechanical milking machines in Victoria.The catalogue is significant as it is from an early dairy supplier and shows early dairy equipment. The Alderdice Brass Foundry has been in operation since the 19th century.Blue covered catalogue booklet with white text and illustrations of a cow, separator, butter maker and butter slicer machines.To Dairymen &/Agriculturalists/Milk/Cream/and/Butter J.BARTRAM & SON. PTY. LTD./586-588 BOURKE ST./MELBOURNEcatalogues, dairy industry, j bartram & son pty ltd, dairy machinery, milk, cream, butter -

Yarrawonga and Mulwala Pioneer Museum

Yarrawonga and Mulwala Pioneer MuseumInstruction Manual, Alfa Laval, The Alfa Daisy Milker

... world producers of mechanical milking machines. The manual... world producers of mechanical milking machines. The manual ...The first centrifugal separator was invented in1878 by Dr. de Laval. This recognized the need for a mechanical milker for which patents were granted in 1894. Alfa Laval were leading world producers of mechanical milking machines. The manual was used in Tungamah during the 1940's and 1950'sPaper booklet describing the operation, parts and installation of the Alfa Daisy Milker. Inside front cover is listed the companies that distribute the milker. Australian capital cities. Illustration includes 12 pagesSee photos -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book, The Nightingale Supply Company Limited, Sydney, Successful Dairy Farming in Australia, c.1930

... breeding techniques and the maintenance of milking machines. It has... breeding techniques and the maintenance of milking machines. It has ...Information on dairy farming in AustraliaThis is a book of 71 pages. The cover is grey with a colour photograph of a jersey cow's head, black printing and dark blue binding. The pages contain black and white photographs, sketches and tables, printed text and a colour fold out of a cow showing internal organs etc. The cover is partly detached from the pages.non-fictionInformation on dairy farming in Australiadairy farming in australia, dairy cows, warrnambool, western victoria -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMilkshake Maker Set, 1940 - 1950's

... Milkshake maker machine; Vera Drummond; Tawonga Milk Bar...The milk shaker machine was used in milk bars during... shaker machine was used in milk bars during the 1940's and 1950's ...The milk shaker machine was used in milk bars during the 1940's and 1950's often using fresh milk from the local diaries. Modern machines are more compact with a variety of different settings and the ability to blend a variety of food including fruit and vegetables as well as liquids.Vera Drummond worked in the Tawonga Milk Bar where she used the Milk Shaker machine. The premises were leased out until it finally closed. The Milk Shaker machine was then lent to the Tawonga cafe which was situated opposite the Tawonga Hotel on the Kiewa Valley Highway near Mountain Creek Road. When the cafe owner bought their own milk shaker machine the original was returned to Vera who lived at the Tawonga Post Office. The milk shakes were made with fresh real milk direct from the diary and enjoyed by Vera's grandchildren and great grandchildren especially on summer holidays.This set consists of: 1 stainless steel milkshake blender with black electric cord attached; 3 moulded glasses with vertical grooves; 4 aluminium mixing beakers also with vertical grooves; 3 long handle stainless steel mixing spoons; 1 stainless steel swivel stick. The blender is heavy with an enclosed cylinder at the top containing the motor with a rotating mixer hanging below it. This is supported by a long vertical enclosed cylinder attached to a base where the electric cord is placed. This cylinder has parts attached to hold the beakers during mixing.On the cylinder with the motor - "Type D3; No. 1675; Volt 230; Watt 40; RPM A; ACDC; (the letter) R (with) G (in the top) (and) E (between the 'feet') Reg. Des.No. 24264/65 Spoons: 2 rows of embossed writing on handle end but illegiblemilkshake maker machine; vera drummond; tawonga milk bar; tawonga post office -

Warrnambool and District Historical Society Inc.

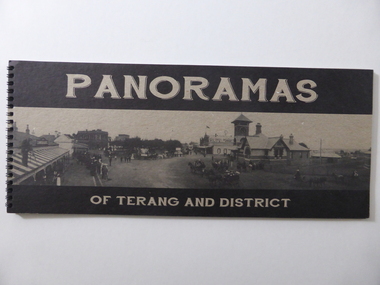

Warrnambool and District Historical Society Inc.Book, Panoramas of Terang and District, Early 21st century

... installed milking machines in the Western District and Gippsland... installed milking machines in the Western District and Gippsland ...This is a book containing early 20th century photographs of the town of Terang in the Western District of Victoria. Most of the photographs were taken by Robert Frederick Scott (1877-1953). He was born in Koroit and came to Terang in his early years. He took up coach building and in 1906 he moved to Cobden where he continued coach building with W.J. Silvester. He was regarded at the time as a clever mechanical engineer and was a pioneer in the motor garage business. In the 1930s he was a representative for the Melbourne firm of A.H. McDonald & Co. in the machinery business. He installed milking machines in the Western District and Gippsland. His hobby was photography and he took many photographs in the Western District and supplied photographs to the Victorian Railways for inclusion in the train carriages. This book is of considerable interest as a record of the town of Terang in the early 20th century. The photographs are of high quality and the book will be useful to researchers.This is a soft cover book of 52 pages. It contains black and white photographs of early 20th century Terang and district. The photographs are set in a grey-coloured frame and on the page opposite the photograph is a description of the photograph. The cover is made of lightweight cardboard and the front cover has the title of the book and a black and white photograph of the town of Terang. The book is bound with plastic spirals.history of terang, robert frederick scott, history of western district, warrnambool history -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMeter Ammeter Recorder, Circa 1950

... times (milking machines).... of defective wiring and overloading at peek operational times (milking ...This testing voltmeter recorder was last certified by SEC Vic laboratories on the 17/4/77. It was used extensively as mobile recorder placed for periods of one month at locations experiencing unacceptable fluctuations of power. These locations would cover the North East regions of Victoria. They cover voltage drops at domestic and business properties especially those that were experiencing regular fluctuations(daily) at approximately the same time of the day. As the electrical network is required to operate within a set level of voltage, fluctuations outside of this has to be investigated and necessary remedial action taken. This is especially so for rural properties where power "drainage" can occur through animal/bird and tree interference. It can also be the result of defective wiring and overloading at peek operational times (milking machines).This mobile voltage recorder is very significant to the Kiewa Valley because it highlights the difficulties that can occur in maintaining a power supply that experiences fluctuating power demands by the rural industries that it supplies. The requirement of a mobile testing apparatus to cover the various sections in the Kiewa Valley and other rural areas in the northeast region is one of necessity as electricity once connected to a rural property is a labour saving supply as generators on rural properties require a higher degree of maintenance an ultimately at a higher cost. The testing of the SEC Vic supplied electricity to rural properties,those who had previously run on generators, had to be quick and unassuming with certainty of correct supply levels.The mechanism of this voltage recorder has been installed(by the manufacturer) into its own protective wooden box. This box has a front (swing open) lockable section which permits direct access to the installed measuring equipment (for servicing and data collection). The top section of the box has two screw on terminals for access to the machine being tested. This tester has its own inbuilt ink supply facilities and a mechanical clockwork device that unwinds a roll of paper onto a second roll at a rate of 10 mm per hour. The recording chart is marked with time slots against voltage. There is a recording arm which has an ink pen at the end. Both arm and pen carry the ink supply from the ink reservoir, located on the left side of the cabinet door in specially constructed bottle holder( three small bottle capacity). To record a suspect power problem to a home or business establishment the voltmeter is connected to a power supply outlet being tested and wind the recording clockwork mechanism (gives a four week running time). Before leaving the recorder in situ the electrician checks to see if the chart is recording the correct voltage and that the clock mechanism is advancing correctly.On the front of the access "door" at the top a metal label "RECORDING AMMETER" below this "MURDAY SYSTEM" below this "ALTERNATING CURRENT" and below this the manufacturer's registered number "No. 139156" Below this is a metal tag with State Electricity Commission of Victoria Electrical Engineer's Section equipment number "338" Below these tags and above the viewing window is the manufacturer's dtails "EVERSHED & VIGNOLES Led LONDON"sec vic kiewa hydro scheme, alternate energy supplies, alpine feasibility studies temperature, rainfall, power outages -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

... for separating cream from milk, with the machine speed being 70 revs per...Separator machine. Hand-crank operated milk separator... for separating cream from milk, with the machine speed being 70 revs per ...Hand-cranked separating maching, made in Sweden for Melbourne Crown Separator Co. Pty Ltd. Machine is used for separating cream from milk, with the machine speed being 70 revs per minute.Separator machine. Hand-crank operated milk separator, small, painted red, Crown Separator Co Pty Ltd. Base and spinning mechanism only (mechanism spins very rettly). Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" Stamped on handle "70 per minute", Stamped on body "S7071", Manufacturer plate "SYLVIA NO. 19/ MADE IN SWEDEN / CROWN SEPARATOR CO PTY LTD / 547 FLINDERS ST, MELBOURNE" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, cream separator, dairy machinery, farming machinery, crown separator co pty ltd -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, early 1900's

... farms introduced milking machines in the late 1930's. The great... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them.Around the bottom side of the bottle and blown into the glass "ONE PINT" and on the opposite side "MILK". Below these markings is "This BOTTLE BELONGS TO MILK BOTTLES RECOVERY LTD" below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION. On the base of the bottle is molded a big "M". An identification mark of "90" over "9" is beneath the "M". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles, milk, dairy, farms, kiewa valley -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... introduced milking machines in the late 1930's. The great increases... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid 1800's (1834 Victorian dairy industry was founded) to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the large volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36"This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against sunlight penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it 6/33 and next to this "ONE PINT" and under this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, circa mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... milk bottle was manufactured and used mid to late 1900's (1834 ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head was manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle which contained milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "3"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... milk bottle was manufactured and used mid to late 1900's (1834 ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under house at 1 Beauty Ave., Mt Beauty.This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/36" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "15" glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle a circle within it "6/18" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "4"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... milking machines in the late 1930's. The great increases in dairy... and machine) before final consumption. Milk was delivered by the "milk... milk bottle was manufactured and used mid to late 1900's (1834 ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded), until the time that cheaper containers were invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one pint capacity and is made from "light green" coloured glass(a protection against light penetration). There are other milk bottles that do not have a "green" tint in them. This thick glass bottle, to contain milk, required its thickness because of the extensive handling (man and machine) before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the bottom end of this bottle is a circle within it "6/35" and next to this "MILK" and opposite "ONE PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base "M" underneath this "20"milk, dairy, glass bottle -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, mid to late 1900's

... farms introduced milking machines in the late 1930's. The great... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up until the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons). In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co.Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" Found under the house at 1 Beauty Ave., Mt BeautyThis heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottle along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a half pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them and this tint was to protect the contents from sun damage. This thick glass bottle to contain milk required its thickness because of the extensive handling before final consumption. Milk was delivered by the "milk man" direct to the homes of consumers. During this period delivery to homes in cities and towns was made initially by horse and cart and later by truck.On the top half of this bottle is "MILK" and opposite "HALF PINT". Below this "THIS BOTTLE BELONGS TO MILK BOTTLE RECOVERY LTD" and below this "AND CANNOT BE USED WITHOUT WRITTEN PERMISSION" on the base is "2 M" underneath this "8/11" and underneath is "ISM -169"glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

... farms introduced milking machines in the late 1930's. The great... milking machines in the late 1930's. The great increases in dairy ...This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Federation University Historical Collection

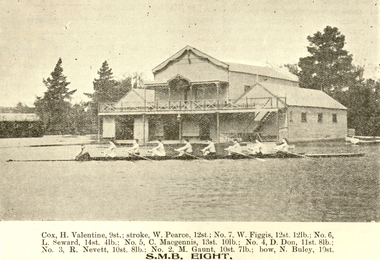

Federation University Historical CollectionBooklet, Ballarat School of Mines Students' Magazine, Term 4, 1905, 1905

... , Estimation of Fat in Milk by the Babcock Machine, first Ballarat... Purdie, Electric traction, Estimation of Fat in Milk ...The Ballarat School of Mines Students' Magazine in 1905 was an unofficial journal edited by the students.Twenty-eight page booklet known as the Ballarat School of Mines Student's Magazine. Contents include: A jaunt to South Australia; Tests for the Assay Lab; Huntingdon-Heberlein Process; Slag Calculation; Electrical Laboratory; Hydrochoric Acod-Phenolph-thalein; Ballarat scientific Society; James W. Hawthorne; Maryborough Excursion; Prof Alexander Purdie; School Dirge; Compound Engines; Sister Institutions; Trafalgar, Acrobates Pymgaeus, Pigmy Flying Phalangerobituary for Alexander Purdie, Electric traction, Estimation of Fat in Milk by the Babcock Machine, first Ballarat School of Mines Annual Dinner; Crytallography Images include; Electrical Laboratory; Professor Dawbarn; James W. Hawthorne; Ballarat Rowing Eight on Lake Wendouree (H. Valentine, W. Pearce, W. Figgis, L. Seward, C. McGennis, D. Don, R. Nevett, M. Gaunt, N. Buley). Advertisements: Craig, Williamson Pty Ltd; Ballarat Baths (B. McCausland); W. Gribble & Co., H.B. Silberberg & Co; F. Jago - Ballarat Boot Palace; John Slater & Co., Kiels Motor & Cycle Stores; Alex Miller & Sons; Thomas McPherson & Son; W. Cornell; Brush Electrical Engineering Co; Ballarat School of Mines; Harry Davies & Co; Stansfield & Smith; Craig's Royal Hotel.ballarat school of mines, south australia; adelaide, valentine, pearce, figgis, seward, mcgennis, don, nevett, gaunt, buley, adelaide school of mines, kerr grant, arizona, jack adam, adam, j.a. reid, reid, jager, rowing, h. valentine, w. pearce, w. figgis, l. seward, c. mcgennis, d. don, r. nevett, m. gaunt, n. buley, cycling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSeparator

... Separator machine. Hand-crank operated milk separator...-museum shipwreck-coast flagstaff-hill-maritime-village milk ...Separator machine. Hand-crank operated milk separator, Crown Separator Co Pty Ltd. Multi-part separator stand with bowls (2) and attachments including a spanner small cone shaped objects on homemade stand. ."42D022" stamped on 2x separator chutes.Manufacture's plate "MADE IN SWEDEN" , "CROWN SEPARATOR / HEAD OFFICE 547 FLINDERS ST MELBOURNE". ."42D022" stamped on 2x separator chutes. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, milk separator, farm machinery, dairy machinery, dairy industry, crown spearator co, cream -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyCream Separator

Dairy farms used cream separators to separate the milk and the cream before using it themselves or selling it to the dairy companies, shops or directly to the public.This cream separator was used by P & R Creamer on their dairy farm in the Kiewa Valley.3 parts - top brass lid with hollow cylinder enclosed across its top and extending beyond its circumference. 2. Stainless Steel hollow cylinders that fit the base and the lid but has 2 long curved spouts extending out - one for the milk and one for the cream to come out 3. Black cast iron stand that houses the gear mechanisms that drive the separator cones. The gear speed reduction wheel is on one side. "Alfa-Laval MOB / 80 Gall Capacity per hr / 48 Rev of Crank per Minute / Alfa-Laval Separator / Co. Ltd / 299 Sussex St. / Sydney" - on bottom side of the machinedairy; cream separator; kiewa valley; creamer family -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bottle, 1850's - 1900's

This bottle is sometimes referred to as a black glass 'Gallon' bottle. It is used for storing and transporting liquor such as stout, porter or ale. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases and other medical issues before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, glass, solid dark brown (black), round, matt surface. Glass ring below mouth, neck is slightly bulbous, seam line around shoulder, body tapers slightly inward from shoulder to base. Base is concave with pontil mark. Bottle has a white mark down the side. No inscription. Generally used for storing stout, porter or ale.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, handmade bottle, handmade english beer bottle, pontil bottle, black glass, gallon -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle, c. 1850's - 1900's

This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in 1850's - 1900's. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in our Collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases etc before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s-1900s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, solid colour brown glass,concave base, tapering slightly wider towards shoulder then inwards towards neck; ring of glass just below opening. Base is blown glass; pontil mark on base. Label "c.1850's STUBBY ALE", "ENGLISH HAND MADE, CORK & WIRE SEAL", "PONTIL MARK ON BASE $6" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, handmade beer bottle, handmade late 19th century bottle