Showing 7 items matching "noils"

-

Robin Boyd Foundation

Robin Boyd FoundationSlide, Robin Boyd

Colour slide in a mount. Image from a magazine of an advertisement for Noilly Pratt, illustrating good graphics74 (Handwritten)slide, robin boyd -

8th/13th Victorian Mounted Rifles Regimental Collection

8th/13th Victorian Mounted Rifles Regimental CollectionPhotograph - Collihole LRV

On 1 April 1991, ‘A’ Squadron 8/13 Victorian Mounted Rifles linked with 4/19 Prince of Wales’s Light Horse Regiment to form a new regiment of two squadrons: VMR Squadron and PWLH Squadron. The 4/19 Prince of Wales’s Light Horse title was retained, but the VMR Squadron continued to wear the VMR hat badge.Black and white photograph of Corporal K. Collihole, VMR squadron 4/19 Prince of Wales Light Horse checking noil level in vehicle.military -, vmr, vehicle, uniform, collihole -

National Wool Museum

National Wool MuseumSlide

... Noils ...wool processing, top making, noils -

National Wool Museum

National Wool MuseumSlide

... Noils ...wool processing, top making, noils -

National Wool Museum

National Wool MuseumSlide Folder, Wool Top Manufacturing

... Noils ...Slide folder originally containing 12 slides and 4 wool samples depicting the wool top manufacturing process. Contains information about the slides.12 COLOUR SLIDES / WOOL TOP MANUFACTURINGwool tops, scouring, carding, noble comb, noils -

National Wool Museum

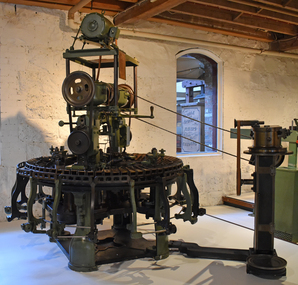

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

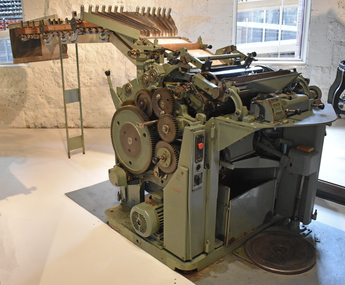

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres