Showing 24 items matching "pottery - techniques"

-

Mrs Aeneas Gunn Memorial Library

Mrs Aeneas Gunn Memorial LibraryBook, Chapman & Hall, Art and craft of the potter, 1934

... Pottery - Techniques... - Description Pottery - Techniques A technical manual on the art ...A technical manual on the art of potteryIll, p.98.non-fictionA technical manual on the art of potterypottery - description, pottery - techniques -

Federation University Art Collection

Federation University Art CollectionCeramic - Ceramics, Ino Shukuho, 'Celedon Bottle' by Ino Shukuho, c1982

... pottery techniques limit production to a maximum of 3-4 pots daily..., squares or oval in shap. His pottery techniques limit production ...Ino SHUKUHO (13.02.1943- ) Born Kyoto, Japan The work of Ino Shukuho are completely handmade with the vast majority of his pots rectangle, squares or oval in shap. His pottery techniques limit production to a maximum of 3-4 pots daily. He is considered a Jaoanese 'national treasure' and he once handcrafter pottery for the Japanese emperor. In 1982 Shikuho Ino was a distinguished guest of the Gippsland Centre of Art and Design (GCAD). Wheel thrown porcelain with celadon glaze.Artist's stamp on base. jan feder memorial collection, ceramics, artist, artwork, gippsland campus, ino shukuho, jan feder memorial ceramics collection -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Jar Base

... technique, like the pottery wheel. Early ceramics were porous... pottery using the wheel-forming technique, like the pottery wheel ...Human beings appear to have been making their own ceramics for at least 26,000 years, subjecting clay and silica to intense heat to fuse and form ceramic materials. The earliest found so far were in southern central Europe and were sculpted figures, not dishes. The earliest known pottery was made by mixing animal products with clay and baked in kilns at up to 800°C. While actual pottery fragments have been found up to 19,000 years old, it was not until about ten thousand years later that regular pottery became common. An early people that spread across much of Europe is named after its use of pottery, the Corded Ware culture. These early Indo-European peoples decorated their pottery by wrapping it with rope, while still wet. When the ceramics were fired, the rope burned off but left a decorative pattern of complex grooves on the surface. The invention of the wheel eventually led to the production of smoother, more even pottery using the wheel-forming technique, like the pottery wheel. Early ceramics were porous, absorbing water easily. It became useful for more items with the discovery of glazing techniques, coating pottery with silicon, bone ash, or other materials that could melt and reform into a glassy surface, making a vessel less pervious to water. https://en.wikipedia.org/wiki/CeramicThe discovery and development of ceramics in numerous shapes, form and materials, revolutionised the world.White ceramic container, glazed with single groove around circumference near lipNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bowl, Late 19th or early 20th Century

... technique, like the pottery wheel. Early ceramics were porous... pottery using the wheel-forming technique, like the pottery wheel ...Human beings appear to have been making their own ceramics for at least 26,000 years, subjecting clay and silica to intense heat to fuse and form ceramic materials. The earliest found so far were in southern central Europe and were sculpted figures, not dishes. The earliest known pottery was made by mixing animal products with clay and baked in kilns at up to 800°C. While actual pottery fragments have been found up to 19,000 years old, it was not until about ten thousand years later that regular pottery became common. An early people that spread across much of Europe is named after its use of pottery, the Corded Ware culture. These early Indo-European peoples decorated their pottery by wrapping it with rope, while still wet. When the ceramics were fired, the rope burned off but left a decorative pattern of complex grooves on the surface. The invention of the wheel eventually led to the production of smoother, more even pottery using the wheel-forming technique, like the pottery wheel. Early ceramics were porous, absorbing water easily. It became useful for more items with the discovery of glazing techniques, coating pottery with silicon, bone ash, or other materials that could melt and reform into a glassy surface, making a vessel less pervious to water. https://en.wikipedia.org/wiki/CeramicThe discovery and development of ceramics in numerous shapes, form and materials, revolutionised the world.Plain cream ceramic bowl with flat bottom inside. Shiny glaze fades to flat texture towards base. Possibly hand thrown pottery. No backstamp. Bad crazing and staining.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Teapot, First half of the 20th century

... Lusterware is a type of pottery or porcelain.... The technique on pottery was first developed in Mesopotamia (modern Iraq ...Lusterware is a type of pottery or porcelain with a metallic glaze that gives the effect of iridescence. The technique on pottery was first developed in Mesopotamia (modern Iraq) in the early 9th century. It is produced by metallic oxides in an overglaze finish, which is given a second firing at a lower temperature in a "muffle kiln", or a reduction kiln, excluding oxygen. The Lusterware effect is a final coating applied over the ceramic glaze, and fixed by a light second firing, applying small amounts of metallic compounds (generally of silver or copper) mixed with something to make it paintable (clay or ochre). This is then fired in a reducing atmosphere at a temperature high enough to "soften" the glaze from the first firing, and break down the metallic compounds, leaving a very thin ("perhaps 10 or 20 atoms thick") layer that is fused with the main glaze, but is mainly metal. Lusterware normally only uses one colour per piece, and the range is limited a "gold" derived from silver compounds was historically the most common. The process has always been expensive and rather unpredictable, always requiring two firings, and often the use of expensive materials such as silver and platinum. The very thin layer of luster is often delicate, and many types of Lusterware are easily damaged by scratching removing the metallic layer, or by contact with acids. Lusterware has therefore always been for display and occasional use, although by the 19th century it could be relatively cheap. Many pieces show the luster effect only working correctly on parts of the surface, or not at all. An item probably made in Staffordshire UK where this type of pottery was popular in the late 19th century by unknown pottery as the subject item has no marks. The teapot at this time cannot be associated with a historical event, person, or place, provenance regards manufacture is unknown, item assessed as a collection asset given it was produced before 1950.Teapot ceramic ornate copper lusterware abstract floral design handle has a protruding sculptured bird for thumb grip. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, teapot, tea set, kitchen ware, ceramic, lusterware, pottery, staffordshire uk, pottery finishes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Beer Stein, Reinhold Merkelbach, 1945 to 1964

This mug was made by Reinhold Merkelbach. Reinhold Merkelbach was founded in 1845 by Wilhelm Merkelbach, a descendent of a long line of German potters, and the company eventually took the name of his son Wilhelm Reinhold Merkelbach, who left school early to get involved with the family business. The company became a major name in German ceramics, especially in the Jugendstil style. The company produced a large number of collectable beer steins in the late 18th and early 19th centuries, including a number of so-called “character steins.” In 1882, the firm began producing art pottery, which at that time was enjoying a revival and new appreciation in Europe in general and in Germany in particular. Reinhold Merkelbach produced ceramic objects both with and without pewter hardware but rarely altered its manufacturing techniques. Many of its products were destined for use at pubs, bars, or breweries as well as in the homes of Germany’s beer-drinking populace. It had a retail location in Munich and also sold products through its factory warehouse. In 1971, half of the company’s ownership was sold to W. Goebel KG and the firm’s name changed officially to Merkelbach Manufaktur GmbH & Co. KG. Goebel ultimately purchased the other half of the business before members of the Merkelbach family, along with a handful of collectors and former staff members, repurchased the factory in 1988. In 2007, Judith Merkelbach Engelmann decided to close the firm; demand for ceramics had been decreasing and the next generation of the family had no interest in maintaining the business. Luckily, Reinhold Merkelbach transferred its moulds to Töpferei Girmscheid Höhr-Grenzhausen to ensure that its best-known pieces of Jugendstil art pottery and steins would continue to be available to interested consumers and collectors.This beer stein was made around the mid-20th century by a popular German maker. It fits in with the context of maritime village life. At this current time, there is no particular connection with people, places and events. The German beer stein is made from ceramic ironstone. It has a bell-shaped hinged pewter lid with a leaf-shaped thumb lever. The lid has a pattern stamped on it. The design on the mug includes a woman in bright colours, a man holding a musket, and buildings in mountain settings. There are inscriptions on the mug. Marked "Made in Germany" "RM" "4070" (underside of mug) "05" to the side of mug flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, beer stein, ceramic beer stein, reinhold merkelbach, drinking vessel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Late 19th century or early 20th century

Glass manufacturing has evolved over thousands of years. Glass making has been traced back to 3500 BC in Mesopotamia. The earliest known glass objects were beads, perhaps made by accident while working with metal. In the late Bronze Age, several civilizations discovered how to make vessels and glass bottles by wrapping threads of melted glass around cores of sand or clay. Later, moulds were used to form dishes and table wares. Around the 1st century BC, glassblowing was discovered. This made glass containers less expensive than pottery. Mould-blown glass, the process of blowing a piece of molten glass into a wooden or metal mould, was invented during the 1st century AD. This technique was faster with more consistent results. It paved the way for mass production. It wasn’t until the late 1800s that the production process to become more efficient. In 1887, a company in England created a semi-automatic process that could produce up to 200 bottles an hour. This process has been refined to the point where modern machines can yield more than 600 containers per minute. Blown vs. Manufactured Glass Bottles Nowadays, glass bottles, jars, and cups are usually manufactured on a bigger scale than is found in individual glassblowing studios. If we still depended on hand-blown glass for all of our glass containers, we would see some major differences in the process of creating bottles and jars. First, there's the time. Hand blowing glass takes a significant amount of time, even for one simple container. In contrast, hundreds of jars per minute can be made using modern technology. This leads to the second advantage: price. Because of the automated and streamlined process, the price for manufactured containers is much lower than that of hand-blown glass. Third, manufactured bottles will be much more consistently uniform than bottles blown by hand. Automated glass manufacturing produces nearly identical batches of jars. Glass blowing is awesome for unique, beautiful pieces of art. But for lots of lower priced and uniformly shaped containers, automatic manufacturing is the preferred method to create glass bottles and jars. https://www.containerandpackaging.com/resources/glass-bottles-brief-history The invention and development of glass for domestic items including bottles, has been nothing short of revolutionary. The use of glass bottles, that could be easily washed, led to improved hygiene, and mass manufacturing of drinks of all types, including milk, cordial and alcoholic beverages.Green Glass Bottle Possibly a ginger beer bottle.Concave indentation at the base. Also on base are two raised lumps. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Lidded Container, c1988

Sweenies Creek Pottery was located at 1507 Strathfieldsaye Rd, Axe Creek. Owned and run by Graham Masters, he specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. Graham Masters graduated from Bendigo Institute of Technology in 197 with a Diploma of Art and Design in Ceramics. He operated a pottery for a year in Bendigo, before working at Maldon Pottery, Maldon, Victoria, with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1984 and has been there ever since. ceramics, sweenies creek pottery, graham masters, australian studio pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Lidded Container, c1988

Sweenies Creek Pottery was located at 1507 Strathfieldsaye Rd, Axe Creek. Owned and run by Graham Masters, he specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. Graham Masters graduated from Bendigo Institute of Technology in 197 with a Diploma of Art and Design in Ceramics. He operated a pottery for a year in Bendigo, before working at Maldon Pottery, Maldon, Victoria, with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1984 and has been there ever since. Pierced lidded container by Sweeney Creek Potteryceramics, sweenies creek pottery, australian studio pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Photograph - Colour, Ceramic Plate by Graham Masters of Sweenies Creek Pottery

Graham MASTERS Graham Masters is a potter based at Sweenies Creek, just outside Bendigo, Victoria. He specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. He obtained a Diploma of Art and Design in Ceramics from the Bendigo Institute of Technology in 1973, then operated a pottery for a year in Bendigo, before becoming an employee, then a partner at Maldon Pottery, Maldon, Victoria, with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1983 and has been there over 20 years. In 2000 Graham Masters started working at Bendigo pottery, and is one of five in the business, specialising in large works such as vases, platters and wine barrels, all handmade on the pottery wheel. graham masters, sweenies creek pottery, ceramics -

Federation University Art Collection

Federation University Art CollectionCeramic, [Untitled] by Ino Kiyoshi, c1982

Ino KIYOSHI (b 1946, Kyoto Japan, d. 2008) Worked in Australia from 1973–76 and 1978–2008 Ino Kiyoshi was to a family that has been involved in the production of pottery for some 160 years. Working in the family studio while studying at the Kyoto School of Arts and Crafts, he completed his diploma of Ceramic Art in 1969. He then attended the KyotoTechnical School for a post-graduate course in glazing. then lectured in ceramics at the KyotoTechnical School. Following in the footsteps of the famous Japanese potter, Shoji Hamada who had visited Australia in 1965, Kiyoshi Ino visited Sydney in 1973, where he worked with Japanese potter Shigeo Shiga). Kiyoshi took up an appointment as Visiting Lecturer in Ceramics at the Gippsland Institute of Technical Education, Churchill, Victoria, from 1974 to 1976 and returned there as Assistant to the Senior Lecturer in Ceramics in 1979. He ceased teaching at the Gippsland Institute in 1988. Ino was involved in the establishment of a space for artists in the old butter factory at the nearby township of Yinnar and in 1982 the Yinnar Art Resource Collective, commonly known as Yinnar ARC, was established. Ino has exhibited extensively throughout Australia. Gift of the artist, 1982impressed seal for Kiyoshi Ino on baseceramics, shikuhu ino, jan feder memorial ceramics collection, gippsland campus, yinnar, yinnar art resource collective -

Federation University Art Collection

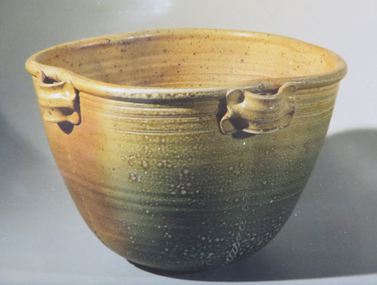

Federation University Art CollectionCeramic, 'Salt Glazed Bowl' by John Edye, c1983

John EDYE (1944- ) John Edye trained in London at Harrow School of Art in the 1970s, and worked with Peter Dick in Yorkshire and Colin Pearson in Aylesford, Kent before returning to Australia to head the Sturt Pottery at Mittagong from 1974 to early 1978. At Sturt, his trainees included Piers Laverty, Wim Boot, Will Castle, Ruth Elder, Colin McNeill, Penelope Carr, Patrick Forman and Malcolm Campbell. Edye introduced them to salt-glazing, a technique at that time not widely used by studio potters. After leaving Sturt, he established the Little Forest Pottery at Yerrinbool in the Southern Highlands of NSW with Penelope Carr, who moved to Hazelbrook to set up her own pottery in 1983. Edye ran his pottery on a production scale for many years, making reduced and salt glazed stoneware and tutoring part time at East Sydney Technical College. Recently he has been working in Egypt as a technical advisor to an aid project, and he was a speaker at the Australian Ceramics Triennale 09. His works are marked with an impressed 'JE' and/or with the three-lobed tree emblem of Little Forest Pottery. John Edye was a visiting lecturer to the Gippsland Centre of Arts and Design (GCAD).Salt Glazed BowlTwo Stamps on basejohn edye, ceramics, jan feder memorial ceramics collection, gippsland -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Salt Glazed Pot by Janet Mansfield, 1984, 1984

Janet MANSFIELD (1934-2013 ) Born Sydney, New South Wales Janet Mansfield studied Ceramics at the National School of Art, East Sydney Technical College in 1964 to 1965. She received a Crafts Board Grants in 1974 to study in the United States of America; to research salt glaze technique in 1975; to exhibit in Japan in 1985; to travel to Hungary fir a symposium, and an Australia-Japan Foundation Grant in 1977 to study in Japan. She was a visiting lecturer to the Gippsland Centre for Art and Design in 1980 and a Spotkanie guest in 1984. Her work was fired to wood kilns and taken to stoneware temperatures. She used salt for shorter firings, or in the anagama kiln depended on the ash and flame for glaze effects. Janet Mansfield has been editor of 'Pottery in Australia' and 'Ceramics: Art and Perception'. In 1987 she was awarded an Order Of Australia Medal for services to art and ceramics. In 1980 Janet Mansfield was a visiting lecturer at the Gippsland Institute of Advanced Education. She was a guest at Spotkanie in 1984.Wheel thrown wood fired and salt-glazed stoneware.jan feder memorial ceramics collection, ceramics, janet mansfield, gippsland campus, visiting lecturer, spotkanie -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, "Four Part Triangular Form' by Kingsley Marks, 1984, c1984

Kingsley MARKS (1929 - ) Kingsley Marks trained at the South Australian School of Art before teaching secondary schools. He became interested in pottery after attending a class one night a week at the John Martins building in Adelaide. He received grants to travel and study ceramics in Mexico the US and Canada, then taught for twenty years at the Torrens and South Australian Colleges of Advanced Education. Upon his retirement in 1985, he moved to Brentwood near Minlaton and established the Brentwood Pottery, specialising in sculptural work using a range of forming, decorative and firing techniques. (https://www.flickr.com/groups/1281707@N21/discuss/72157641492795284/) Kingsley Marks was a guest at Strezleckie Spotkanie in 1984. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.Electric kiln-fired slipcast decorated earthenware. Kevin Marks uses the mark "K" on his work. Gift of the Artist, 1984ceramics, kingsley marks, artwork, gippsland campus, churchill, brentwood pottery, artist, jan feder memorial ceramics collection -

Federation University Art Collection

Federation University Art CollectionCeramic, Stoneware by Jan Feder, c1980

Wheel thrown reduction-fired stoneware with feldspar hoc crackle and tenmoku glaze. This collection of work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there. The reduction fired stoneware includes feldspathic crackle and Tenmoui glazes. ceramics, jan feder, jan feder memorial ceramics collection, churchill, gippsland campus, stoneware -

![Ceramic, Malcolm Boyd, Untitled [Male Form] by Malcolm Boyd, 1977](/media/collectors/530576742162ef0fa09a2288/items/556e8b9f2162f1015460fbfb/item-media/62a9b7295a061b9db7f1e053/item-fit-380x285.jpg) Federation University Art Collection

Federation University Art CollectionCeramic, Malcolm Boyd, Untitled [Male Form] by Malcolm Boyd, 1977

MALCOLM BOYD Born Gippsland, Victoria In 1977 Malcolm Boyd graduated with a Diploma of Visual Arts from the Gippsland Institute of Advanced Education. It was at this time that he presented this work to the Jan Feder Memorial Ceramics Collection. Over thirty years later he still has a passion for ceramic history and design. Boyd operated the Black Cockatoo Pottery from around 1980-1995, starting in Essendon, then moving to Ascot Vale, Stratford, Bairnsdale and finally Fernbank in Gippsland. His handbuilt stoneware pots and clay sculptures are wood fired at his East Gippsland studio. He often uses ochre coloured dam banks on his property at Fernbank. The local clays are crushed, screened and blended with a white stoneware body to produce a number of shades and textures. All Malcolm Boyd's pot's are hand built using moulding, coiling, slabbing, and modelling techniques, and are high temperature fired (1300C) to allow some of the very ancient oriental glazes to mature. All works spend at least 20 hours in the wood fired kilns. This work is part of the Jan Feder Memorial Ceramics Collection which was amassed with funds raised by Jan Feder's student peers at the Gippsland Centre for Art and Design in the mid 1980s after Jan Feder passed away. Although many of the works are donated the intention of the collection was to purchase from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Churchill Campus. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.malcolm boyd, ceramics, artist, artwork, jan feder memorial ceramics collection, gippsland campus, alumni -

Federation University Art Collection

Federation University Art CollectionCeramic, Malcolm Boyd, Stoneware sculptured sphere, 1977

MALCOLM BOYD Born Gippsland, Victoria In 1977 Malcolm Boyd graduated with a Diploma of Visual Arts from the Gippsland Institute of Advanced Education. It was at this time that he presented this work to the Jan Feder Memorial Ceramics Collection. Over thirty years later he still has a passion for ceramic history and design. Boyd operated the Black Cockatoo Pottery from around 1980-1995, starting in Essendon, then moving to Ascot Vale, Stratford, Bairnsdale and finally Fernbank in Gippsland. His handbuilt stoneware pots and clay sculptures are wood fired at his East Gippsland studio. He often uses ochre coloured dam banks on his property at Fernbank. The local clays are crushed, screened and blended with a white stoneware body to produce a number of shades and textures. All Malcolm Boyd's pot's are hand built using moulding, coiling, slabbing, and modelling techniques, and are high temperature fired (1300C) to allow some of the very ancient oriental glazes to mature. All works spend at least 20 hours in the wood fired kilns. This work is part of the Jan Feder Memorial Ceramics Collection which was amassed with funds raised by Jan Feder's student peers at the Gippsland Centre for Art and Design in the mid 1980s after Jan Feder passed away. Although many of the works are donated the intention of the collection was to purchase from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Churchill Campus. Jan Feder Memorial Collection Presented by the artist in 1977. malcolm boyd, ceramics, stoneware, artists, artwork, jan feder memorial ceramics collection, alumni, woodfire -

Federation University Art Collection

Federation University Art CollectionCeramic, Tony Nankervis, 'Woodfired Cylindrical Vessels' by Tony Nankervis, 1986, 1986

Tony NANKERVIS A graduate student from the Gippsland Centre for Art and Design (GCAD), Tony Nankervis has been a pioneer of the long wood-fired ceramics technique in Australia. He retired from lecturing at Southern Cross University after working there for 19 years in 2004. He describes his work as 'one-off functional table ware', which includes highly-individualised everyday table items. Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. The wood ash and salts blush the ceramic pieces in the kiln, with finished work taking on the nature of the firing process, which has been described as painting with fire.Two woodfired earthernware cylindrical forms by Tony Nankervis. tony nankervis, woodfire, jan feder memorial collection, jan feder, ceramics, gippsland campus, jan feder memorial ceramics collection, alumni -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Jan Feder, Lidded Stoneware Casseroles with iron glaze by Jan Feder, 1981

Jan FEDER ( - 1981) Jan Feder is an alumna of Federation University having studied ceramics at the Gippsland Institute of Advanced Education (now Federation Univesity Gippsland campus). Jan Feder was respected by all students for her diligence and technical ability. Her tragic death in 1981 evoked an immediate response from her peers for a memorial. Students discussed a number of memorial options, such as funds for equipment, scholarships and awards. The decision to commence a collection was made based on the idea that all future students culd benefit from the availability of a collection, whereas only a very few individuals could benefit from a scholarship. Students immediately set about raising money by selling 'seconds' called 'Junque Sales'. a total of $760.00 was raised and the first two works purchased were by Victor Greenaway and Victoria Howlett. Ceramic works were purchased from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Gippsland Campus. The Artist in Residendence Program assisted the collection, with many resident artists conrtibuting to the Collection (ie Robin Welch, Anna Zamorska, Sandy Brown), as well as international guests. Ceramic events such as 'Strzelecki Spotkanie 1984' and 'Woodfire 86' also resulted on major contributions to the collection. Three lidded pots by Jan Feder made in 1981.jan feder, jan feder memorial ceramics collection, ceramics, gippsland campus, alumni, casserole -

Federation University Art Collection

Federation University Art CollectionCeramic - Stoneware, [Group of Vessels] by Jan Feder, 1980

Jan FEDER Born Barmera, South Australia Jan Feder was a student at the Gippsland Centre of Art and Design in the 1980s. She had started studying ceramics in Adelaide, deciding to continue here study at Churchill under Hedley Potts' tutelage after moving to Strezlecki. In her final year Jan was an on-campus weekday resident to save on the travel time. This work is part of the Jan Feder Memorial Ceramics Collection which was amassed with funds raised by Jan Feder's student peers at the Gippsland Centre for Art and Design in the mid 1980s after Jan Feder passed away. Although many of the works are donated the intention of the collection was to purchase from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught at the Churchill Campus. A group of ceramic vessels by Jan Feder, an alumna of the Gippsland Centre for Art and Design (GCAD). After her death in the mid 1980s her student peers amassed funds to create a memorial collection. jan feder, jan feder memorial ceramics collection, gippsland campus, alumni, ceramics -

Federation University Art Collection

Federation University Art CollectionCeramic, Tony Nankervis, Three Lidded Woodfired Cylinders by Tony Nankervis, 1986

Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire."(https://www.strathnairn.com.au/studios/artist-in-residence/montessa-maack-ursula-burgoyne-jen-lyall-and-vicki-grima-5ndd6, accessed 09 July 2021)Tony NANKERVIS Tony Nankervis taught ceramics from 1984 when the university was the Northern Rivers College of Advanced Education from 1984. before moving to Southern Cross University (SCU) in 1994. He retired from full time teaching in 2004. Nankervis was a pioneer of the long wood-fired ceramics technique in Australia: a technique he has been practising since the late 1970s Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire. There are particular qualities that only come from firing in that way, he said. "If you see some of these older ceramics, particularly from Asia, the surface qualities are discernible from the surfaces generated by post-Industrial fuels." (https://www.scu.edu.au/engage/news/latest-news/2004/leading-australian-potter-who-paints-with-fire-retires-from-lecturing-at-scu-after-19-years.php, accessed 09 July 2019)Three Lidded Woodfired Cylinders ceramics, jan feder memorial ceramics collection, tony nankervis, tony nankervic -

Federation University Art Collection

Federation University Art CollectionCeramic, Tony Nankervis, Dry Glazed Lidded Form by Tony Nankervis, 1986

Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire."(https://www.strathnairn.com.au/studios/artist-in-residence/montessa-maack-ursula-burgoyne-jen-lyall-and-vicki-grima-5ndd6, accessed 09 July 2021)Tony NANKERVIS Tony Nankervis taught ceramics from 1984 when the university was the Northern Rivers College of Advanced Education from 1984. before moving to Southern Cross University (SCU) in 1994. He retired from full time teaching in 2004. Nankervis was a pioneer of the long wood-fired ceramics technique in Australia: a technique he has been practising since the late 1970s Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire. There are particular qualities that only come from firing in that way, he said. "If you see some of these older ceramics, particularly from Asia, the surface qualities are discernible from the surfaces generated by post-Industrial fuels." (https://www.scu.edu.au/engage/news/latest-news/2004/leading-australian-potter-who-paints-with-fire-retires-from-lecturing-at-scu-after-19-years.php, accessed 09 July 2019)Presented by the artistLidded Raku fired box, dry glazedceramics, jan feder memorial ceramics collection, tony nankervis, tony nankervic -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionDecorative object - Ceramic platter, Bendigo Pottery, Strathfieldsaye Shire 1866 - 1991, 1991

Graham Masters is a potter based at Sweenies Creek, just outside Bendigo, Victoria who specialises in a patented technique of low relief stoneware depicting Australian animals and landscapes. He obtained a Diploma of Art and Design in Ceramics from the Bendigo Institute of Technology in 1973, then operated a pottery for a year in Bendigo, before becoming an employee, then a partner at Maldon Pottery, Victoria with Neville Wilson and Thomas Metcalf. He left Maldon to set up his own pottery at Sweenies Creek in 1984. (1.) (Judith Pearce). Built in 1869, the (former) Strathfieldsaye Shire Hall is one of The City of Bendigo's earliest surviving public buildings. Designed by George Steane and built by George Pallett in 1869 the Strathfieldsaye Shire Hall has aesthetic significance as a purpose built Shire Hall designed in the Free Classical manner. It is also of importance as an early example of the novel system of cavity wall construction. The building is largely intact and unaltered. Other important elements include the arched portico of the main entrance with brick arched features on either side; the brick quoining and dressings to the round arch windows; the three gabled roof; and the matching chimneys that reinforce the symmetrical design. The Hall has social significance as a temporary schooling facility in the 1870s and as a flood refuge in 1889. The Strathfieldsaye Shire Hall is a brick building designed in the Free Classical manner. This style was favoured by the Public Works Department for a number of public buildings including Shire Halls and courthouses. The form includes a central taller volume flanked by matching smaller gables. In the case of the Shire Hall these would be occupied by the Shire Secretary and Shire Engineer whilst the larger volume was the council chamber. The portico at the front is designed with a flat arch in the centre and matching smaller arches each side. The face red brick is unadorned apart from a plain string course at the roof springing point, brick quoining and dressings to the round arch windows. There are matching chimneys that are located to reinforce the symmetrical design and the original roof is believed to have been slate but is now corrugated iron. Large wheel thrown ceramic platter with a shallow well, broad flaring ledge and raised on a high foot rim. Rim decorated with slab rolled gum trees protruding on centre left and right sides of plater. which reflect the low relief image of trees and the Strathfieldsaye Shire Hall on the surface of the plate. Glazed with golden brown and cream. Front centre top; 'Shire of Strathfieldsaye'. Front lower centre '1866 - 1991 - 125 Years'. Signed 'G Master / 1991' on rim centre right. Reverse; signed 'G Master' / 1991. Bendigo Pottery stamp.shire of strathfieldsaye, bendigo pottery -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic, Platter celebrating the 125th anniversary of the Shire of Strathfieldsaye, 1991

Graham MASTERS, Sweenies Creek Pottery Potter Graham Masters was based at Sweenies Creek outside Bendigo. He specialised in a patented technique of low relief stoneware depicting Australian animals and landscapes. He obtained a Diploma of Art and Design in Ceramics from the Bendigo Institute of Technology in 1973, then operated a pottery for a year in Bendigo before becoming an employee, then a partner at Maldon Pottery with Neville Wilson and Thomas Metcalf. Masters left Maldon to set up his own pottery at Sweenies Creek in 1984. A stoneware plate commemorating the 125th anniversary of the Shire of Strathfieldsaye. It features the Shire Hall and courthouse, with gum trees to the left.graham masters, sweenies creek pottery, shire of strathfieldsaye, strahfieldsaye shire hall, anniversary