Showing 54 items matching "pottery class"

-

Eltham District Historical Society Inc

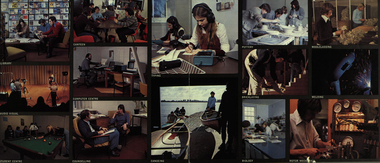

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...Pottery Class... melbourne Classes Eltham Living and Learning Centre Pottery Class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncNegative - Photograph, Grace Mitchell and Ursula Dors, Pottery Class, Eltham Living and Learning Centre, Oct. 1988

... Grace Mitchell and Ursula Dors, Pottery Class, Eltham...pottery class... and learning centre pottery class eltham living and learning centre ...Grace Mitchell, a talented artist in later life and baker managed a pastry shop business near the corner of Mt Pleasant and Main Roads Eltham in the 1950’s. Shortly after her marriage to Arthur Mitchell in 1948 he had an accident that caused a head injury and was unable to work. Grace realised she needed to be home to care for her husband as well as earn an income. She managed the bureaucracy of council permits, made modifications to her home with savings to get the business off the ground without having to borrow money. Grace and Arthur were avid gardeners and would grow, wash and mince vegetables for pasties while Grace hand made and rolled the pastry. They cooked and minced their own meat for the pies and the fruit for the sweet pies came from their orchard at the rear of the property. She also baked scones and cakes. Grace operated her pastry shop for over 16 years. She supported the Shillinglaw Cottage Preservation Campaign to preserve the cottage through its Flavour of Eltham community cookbook published in 1964 and hosted cooking classes in the new Living and Learning Centre. Grace Mitchell passed away aged 95 years in 2011.Roll of 35mm colour negative film, 6 strips and associated colour print 10 x 15 cmFuji 100classes, eltham, living and learning centre, pottery class, eltham living and learning centre, grace mitchell, ursula dors, teaching, learning -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Pottery Class, Eltham Living and Learning Centre, October 1988, 1988

... Pottery Class, Eltham Living and Learning Centre, October...pottery class... melbourne classes eltham living and learning centre pottery class ...Roll of 35mm colour negative film, 6 stripsFuji 100classes, eltham, living and learning centre, pottery class -

Vision Australia

Vision AustraliaPhotograph - Image, Robin Pleydell with female staff member and client

... Col. transparencies of Robin Pleydell in a pottery class... Pleydell in a pottery class and at a workdesk. Robin Pleydell ...Robin Pleydell looks on as an AFB worker reads from a Braille volume whilst sitting in front of a computer, and also with a vision impaired older woman working on a piece of pottery.Col. transparencies of Robin Pleydell in a pottery class and at a workdesk.association for the blind, robin pleydell -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, Ballarat School of Mines Sherry Glasses, c1951, c1951

... enrolled student, Majorie Garner attended Pottery classes... Garner attended Pottery classes at the School of Mines) run ...Marjorie Evelyn GARNER Although not a fully enrolled student, Majorie Garner attended Pottery classes at the School of Mines) run by Neville Bunning. She also took advantage of other classes offer to 'non-students' such as oil painting classes for women run by Geoff Mainwaring. These popular extension programmes promoted the Ballarat School of Mines and their Technical Art School, especially among middle-class women who would otherwise have had little connection with the institution. Majorie was married to Leslie Garner, the Principal of the Ballarat Junior Technical School, a division of the Ballarat School of Mines. Two hand thrown ceramics 'sherry glasses' with the Ballarat School of Mines shield in oxide. The glasses are houses in a small blue and white lidded box. marjorie garner, leslie garner, geoff mainwaring, neville bunning, alumni, ceramics, ballarat school of mines, ballarat junior technical school -

Ballarat Heritage Services

Ballarat Heritage ServicesCeramic - Studio Pottery, John Gleeson, Ceramic Platter, 2007

... fell in loved with pottery during a hobby class in Geelong... fell in loved with pottery during a hobby class in Geelong ...John GLEESON Living at Campbell's Creek for over 30 years, John Gleeson makes a range of functional stoneware pottery. He fell in loved with pottery during a hobby class in Geelong in 1972. He worked for a year at Canny Ridge Pottery in Harcourt. John Gleeson uses white stoneware and porcelain clay from The Bendigo Pottery, and buff clay from Bennetts Pottery in Adelaide. He mixed all his own glazes from commercially sourced raw materials, sometimes supplemented with ash from his fire and local red clay to get special effects.Large celadon platter with incised fish design. john gleason, studio pottery, ceramics, australian studio pottery, platter, plate -

Federation University Art Collection

Federation University Art CollectionCeramic - Artwork - Ceramics, "Four Part Triangular Form' by Kingsley Marks, 1984, c1984

... . He became interested in pottery after attending a class one... interested in pottery after attending a class one night a week ...Kingsley MARKS (1929 - ) Kingsley Marks trained at the South Australian School of Art before teaching secondary schools. He became interested in pottery after attending a class one night a week at the John Martins building in Adelaide. He received grants to travel and study ceramics in Mexico the US and Canada, then taught for twenty years at the Torrens and South Australian Colleges of Advanced Education. Upon his retirement in 1985, he moved to Brentwood near Minlaton and established the Brentwood Pottery, specialising in sculptural work using a range of forming, decorative and firing techniques. (https://www.flickr.com/groups/1281707@N21/discuss/72157641492795284/) Kingsley Marks was a guest at Strezleckie Spotkanie in 1984. This work is part of the Jan Feder Memorial Ceramics Collection. Jan Feder was an alumna of the Gippsland Campus who studied ceramics on the campus. She passed away in the mid 1980s. Her student peers raised funds to buy ceramic works in her memory. They bought works from visiting lecturers who became leading ceramic artists around the world, as well as from many of the staff who taught there.Electric kiln-fired slipcast decorated earthenware. Kevin Marks uses the mark "K" on his work. Gift of the Artist, 1984ceramics, kingsley marks, artwork, gippsland campus, churchill, brentwood pottery, artist, jan feder memorial ceramics collection -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - Colour, Ballarat School of Mines Students

Colour photograph showing students undertaking classeslibrary, audio visual, canteen, computer centre, student centre, counselling, typing, canoeing, pottery, woolclassing, bricklaying, welding, biology, motor mechanics, ballarat school of mines, alumni -

Federation University Historical Collection

Federation University Historical CollectionBook - Scrapbook, Ballarat School of Mines Scrapbook 1921-1924, 1921-1924

The clippings in this book relate to the Ballarat School of Mines. Hard covered scrapbook with newspaper clippings relating to the Ballarat School of Mines.ballarat school of mines, scrapbook, ballarat technical art school, clay, ceramics, pottery, native clay, maurice copland, h.h. smith, c.h. beanland, technical schools, albert e. dowling, john dulfer, jenkin swimming shield, r.s. dale, j.y. mcdonald, a.f. heseltine, stained glass windows, amalie feild, richard dale, ballarat school of mines museum, ballarat junior secondary school, war criminal trials, j.f. crichton, repatriation department, w.o.f. close, soldiers vocational classes, world war one, alexander peacock, ballarat junior technical school opening, effie holmes, cornell chemist, w.k. moss, ken moss, obituary, j. vickery, w.d. hill, r.w. richards, shackelton, antarctic exploration, t.h. trengrove, samuel mayo, vera lindsay, bessie robertson, victor greenhalgh, repatriation classes closure, repatriation classes termination, university college, vocational training, arbor day, j.b. corbet, ballarat school of mines procession, ballarat junior technical school honour board, harold herbert, albert steane, a.w. steane, francis davis, tree planting, clyde lukeis, trade classes, old boys association, alfred james higgin, blackill color and oxide company, electric supply company, state school exhibition, state education jubilee, scholarships, clay deposits, james coad, t.a. williams, copland memorial, e.j. mcconnon, alfred mica smith, ponsonby carew smyth, d. maxwell, lena rutherford, dorothy whitehead, examination results, geoffrey nicholls, robert dowling, j.b. robinson, percy trompf, j.c. bush, white flat reserve, rubbish tip, sports ground, broken hill excursion, old boy's association, school of mines procession, white flat improvements, empire exhibition, ballarat school of mines literary society, school reunion, john rowell, d.e. mullins, g. renkin, t.m. shattock, new law courts, supreme court building transferred to ballarat school of mines, buildings, ballarat state offices, ballarat school of mines museum closed, ballarat school of mines and industries, k.b. brown, sir r. garran, alf hannah, macrobertson scholarship, simone fraser, violet hambley, alfred bayley, j. heriot, c.r. pittock, i.r. bradshaw, ballarat exhbition, e. parkin, c.m. harris, mica smith bust, william henry nicholls, daniel walker, paul montford, w.h. corbould, j.w. sutherland, technical training for girls, girls education, amalie colquhoun, ken moss obituary, opening of the ballarat junior technical school, j.s. vickery, j.s. vickery obituary, ida v. johnson, john rowell exhibition, max meldrum, w.g. coates, g.f. fitches, walter white, sewerage plumbing, villers brettonneux school -

Ballarat Clarendon College

Ballarat Clarendon CollegeHand painted pottery

The maker of this bowl has not been identified but we might presume it to be one of the 'Susan's' of the CPLC Class of '66. The bowl was created as a memento for the Class of '66 25 year reunion held in 1991. Tiny hand-painted pottery dish with blue and yellow borders and designAround rim of bowl: CLASS OF '66 REUNION 1991 On base: SUSANreunion, clarendon presbyterian ladies college, 1966 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Dish, Johnson Bros, Circa 1883 (very early Mark)

Johnson Brothers were a British tableware manufacturer and exporter that was noted for its early introduction of "semi-porcelain" tableware. It was among the most successful of the Staffordshire potteries which produced tableware, much of it exported from the 1890s through the 1960s. They were also important manufacturers of large bathroom ceramics. The company was founded in 1883, but from 1968 to 2015 it operated as a part of the Wedgwood Group. However, after the Wedgwood Group was acquired by Fiskars in 2015, the production of Johnson Brothers was discontinued. The company's name derives from the names of the company's founders. The four original "Johnson Brothers" were Alfred, Frederick, Henry, and Robert. Their father married the daughter of a master potter, Alfred Meakin. In 1883, Alfred and Frederick Johnson began production at defunct pottery, known as the Charles Street Works, that they had purchased at a bankruptcy sale in Hanley, Stoke-on-Trent. At first, they specialised in the manufacture of durable earthenware, which they called "White Granite". The success of this venture led to rapid expansion. In 1888, the Rev. Henry Johnson joined them, followed ten years later by a fourth brother, Robert Johnson. Having established a solid reputation producing basic "whiteware", the company developed a product known as "semi-porcelain", a range of pottery that had the characteristics of fine china, but the durability of ironstone ware. This kind of tableware soon became very popular in the United States due to its durability and low cost. In 1889, the Hanley pottery was opened, later the Alexander pottery, and in 1891 the Imperial Works Pottery. In 1896, the Trent Sanitary Works was opened for the production of non-tableware products, and Alfred Johnson left the business to establish his pottery. By 1898, Robert Johnson had relocated to New York City to manage Johnson Brothers' rapid expansion into the North American market. An item that gives a snapshot into the emerging market for tableware that was reasonably priced and serviceable. The company produced "whiteware" but the innervation of the pottery line called semi-porcelain changed the industry. This allowed potteries to produce fashionable pottery items that were affordable to all social classes of the time. Bowl white ceramic decorative with floral decoration around lip. On base, "Royal Ironside China, Johnson Bros England" & crest of lion and unicorn flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, bowl, china bowl, lion and unicorn crest, table ware, kitchen ware, white ware, johnson brothers -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Federation University Historical Collection

Federation University Historical CollectionPhotograph - Photograph - black and white, Ballarat School of Mines Ceramics Class, early 1940s

Ceramics was taught at the Ballarat School of Mines Technical Arts School. A number of ceramics students work in the Ballarat School of Mines Technical Art School Ceramics Studio. Six students sit at a work bench undertake handbuilt pottery. Five students sit at pottery wheels, while tutor Neville Bunning stands and oversees (far right corner).ballarat school of mines, ballarat technical art school, art, ceramics, pottery, neville bunning, visual arts