Showing 21 items matching "razor tool"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyLeather Strop

... razor tool..., in the kitchen or at the barber's shop. leather strop razor tool A gold ...Used to sharpen and polish straight edged razors or knives or chisels.Used by a resident of the Kiewa Valley possibly on the farm, in the kitchen or at the barber's shop.A flexible double - layered leather strop. This is a hanging strop which has two hooks which enable the top to swivel so that it can be turned over while hanging from a hook or peg. It has a metal ring with two hooks at one end and a padded stitched handle at the other forming a knob.A gold circle design at one end. At the other "The / Keen Edge / Strop"leather strop, razor tool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, whetstone , 'Bridestowe' with box, 20thC

... e.g. scissors, scythes, knives, razors and tools.... scissors, scythes, knives, razors and tools such as chisels, hand ...A Whetstone is a sharpening stone used for knives and other cutting tools. Sharpening stones, water stones or whetstones are used to grind and hone the edges of steel tools and implements e.g. scissors, scythes, knives, razors and tools such as chisels, hand scrapers and plane blades. Though it is sometimes mistaken as a reference to the water often used to lubricate such stones, the word "whetstone" is a compound word formed with the word "whet", which means to sharpen a blade, not the word "wet". The process of using a sharpening stone is called stoning.A square block of grey abrasive material used for sharpening steel blades , with the original boxBRIDESTOWE / Picture of ‘Kangaroo, Stag and Emu among radiating wheat stalks’ / TASMANIAwhetstones, sharpeners, steel blades, tools, cutlery, razors, moorabbin, bentleigh, cheltenham, early settlers, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor Strop

... STROPS Straight razors and cut throat razors were the major tools... the major tools for shaving before the safety razor was invented ...This razor strop is made like a leather strap. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Double Swing Razor Strop. Use for honing razors.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, swing razor strop, barber's equipment, shaving equipment, personal accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

... Straight razors and cut throat razors were the major tools... the major tools for shaving before the safety razor was invented ...This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

... Straight razors and cut throat razors were the major tools... the major tools for shaving before the safety razor was invented ...This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

... Straight razors and cut throat razors were the major tools... the major tools for shaving before the safety razor was invented ...This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, circa 1922

... . Straight razors and cut-throat razors were the major tools... the major tools for shaving before the safety razor was invented ...A razor strop such as this one was used to sharpen and polish straight-edged razors. This particular design has a swivel hook with a locking clip that allows for movement as the strop is being used. This strop is branded "Sherlite". On May 5th, 1922 the Commonwealth officially accepted and advertised the Trade Mark Application of Thomas Sherry of Victoria, for the Trade Mark of "Sherlite" to be used under the heading of "Leather, Skins unwrought and Wrought”. Thomas Sherry’s application was to use the word “Sherlite” for detachable soles made of rubberised leather. Straight razors and cut-throat razors were the major tools for shaving before the safety razor was invented in the 1880s and even today specialist shaving shops still sell straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap with a shaving brush that had boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade's edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas, or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools, and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are handheld. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish.Razor strop, leather, and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has a padded, bulbous-shaped leather grip handle, the other end has a metal, swivel hook hanger. Inscriptions painted in gold on leather at the hook end.Razor strop, leather and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather grip handle, the other end has metal, swivel hook hanger. Inscriptions printed in gold on leather at hook end.Printed gold lettering stamped “Sherlite”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, sherlite razor strop, personal effects, toiletries, thomas sherry -

Orbost & District Historical Society

Orbost & District Historical Societyleather strop, Early 20th century

A razor strop is flexible strip of leather or canvas used to maintain a shaving edge on a thin blade such as a straight razor. Fine powdered jeweler's rouge or other pastes can be added as an abrasive to polish the blade. The strop may be a hanging strip or a hand-held paddle. This one is a hanging strop. Strops were quite commonly found in barber shops and homes before the invention of the safety razor, They are still used for sharpening tool blades.This item is an example of the self-reliance shown by rural families when household necessities were not readily available.A flexible double-layered horse hide leather strop. One strip has a slightly coarser texture. This is a hanging strop which has a metal swivel on top so that the strop can be turned over while hanging from a hook/peg.On hand grip The Keen Edge Strop, genuine horse hide All Black Stropper No. 2strop razor-strop shaving personal-effects -

Bendigo Military Museum

Bendigo Military MuseumEquipment - WEBBING KIT, 1911; Post 1911

The 1908 pattern was used during WWI, made from woven cotton & water proofed. The kit is used for school groups.Webbing kit complete including 1908 pattern webbing, gas mask haversack, personnel items, rations. Refer attached sheet. .1) Waist belt with brass buckles & keepers. .2) Braces x 2, connects to waist belt & large pack. .3) Bayonet. .4) Bayonet carrier. .5) Bayonet scabbard. .6) Entrenching tool carrier [fits to .5)]. .7) Entrenching tool handle, wood & metal [fits to .6)]. .8) Entrenching tool, metal, combination shovel & pick. .9) Entrenching tool carrier [fits inside .8)]. .10) Cartridge carriers x 2, 1 left hand, 1 right hand. .11) Water bottle, metal, blue colour. .12) Water bottle cover, khaki wool. .13) Water bottle carrier. .14) Pack, large. .15) Great coat, wool, [inside .14)]. .16) Helmet, steel with inside liner & chin strap. .17) Mess tin carrier, replica. .18) Haversack, side pack. .19) Carry all, white cotton, for personnel hygiene items [inside .18)]. .20) Razor, cut throat [inside .19)]. .21) Comb [inside .19)]. .22) Toothbrush [inside .19)]. .23) Shaving brush [inside .19)]. .24) Laces, leather, not original, [inside .19)]. .25) Soap [inside .19)]. .26) Tin bully beef x 2, replicas, [inside .18)]. .27) Tin stew, replica, [inside .18)]. .28) Pair socks, khaki wool, not original, [inside .18)]. .29) Field dressing, WWII issue, [inside .18)]. .30) Towel, brown colour, not original, [inside .18)]. .31) Gas mask carrier bag & straps. (Cowley) .32) Water bottle, metal, blue colour, [inside .31)].Items 1 - 13, there are numerous markings all stamped on from, “A.A.O.D”, “L”, “R”, “S”, “M.E.C.O”, “49th INF”, Years examples, “8.12”, “1.13”, “1911”military history - equipment / army, medicine-first aid, personal effects - containers, toilet requisites - shaving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, Mid 19th to late 19th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the coffin pattern made by Henry Boker the item is a rare and significant example of vintage woodworking tools used in the manufacture of wooden items.Smoothing Plane Coffin design. Blade marked Henry Bokerflagstaff hill, warrnambool, maritime-museum, shipwreck-coast, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, Early 19th century

A razor strop is flexible strip of leather or canvas used to maintain a shaving edge on a thin blade such as a straight razor. Fine powdered jeweler's rouge or other pastes can be added as an abrasive to polish the blade. The strop may be a hanging strip or a hand-held paddle. This one is a hanging strop. Strops were quite commonly found in barber shops and homes before the invention of the safety razor, They are still used for sharpening tool blades. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. KEEN EDGE MANUFACTURER In March 1906 Popular Mechanics magazine included an advertisement for Keen Edge Strop. The promise given by the advertiser, Eddy Mfg. Co. (206 Broadway, New York) was “Use the Keen Edge strop for 90 days and if not satisfied return to us and we will refund your money“. The advertisement was for a Combination Razor Strop, “the only strop made which requires no dressing.” Readers were invited to send for a booklet on Razor and the Face. In 1924 Popular Mechanics, published by Hearst Magazines, displayed an advertisement seeking a sales manager “… to sell [to] drug, hardware and cigar stores Keen Edge Strop Dressing, which sharpens straight razors and safety blades and removes old razor strops.” At that time the Keen Edge Mfg. Company was in Dallas, Texas. Razor strops are of historical significance, representing personal effects of men from the time period when men relied on strops to keep a sharp edge on their shaving blade. Strops were commonly owned and used until the acceptance of safety razors.Razor strop, leather and metal. Keen Edge brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather handle, the other end has metal, swivel hook hanger. Inscriptions pressed into leather at the ends of the straps. Impressed into leather "FINEST SELECTED HIDE", "KEEN EDGE", "FINISH" (black stained side), “A SHARPENER" (red stained side), “1 2 3”warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, keen edge razor strop -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, leather strop 'Jason', c1940

A razor strop (or razor strap) is a flexible strip of leather or canvas used to straighten and polish the blade of a straight razor, a knife, or a woodworking tool like a chisel. Unlike honing or sharpening a blade, in which a whetstone removes metal bent out of alignment from the blade's edge, stropping the blade re-aligns the indentations without removing any material. The strop may be a hanging strop or a hand-held paddle. Various abrasive compounds may be applied to the strop to aid in polishing the blade while stropping to obtain a mirror-like finish. The properties of the compound applied will alter the polishing result. Jeweller's rouge is a very fine abrasive compound. The green Chromium(III) oxide compound is most often used as an abrasive compound. Sprays containing diamond particles are another option. Stropping is primarily done with straight razors, used for shaving, as these are the thinnest blades in everyday use, and require stropping at each use, due to the thinness of the blade Two points are key to stropping: Draw the blade spine-first along the strop. By contrast, honing is done edge-first. When you turn the blade at the end of a stroke, turn it over the spine, so the edge moves away from the strop and faces you, and the spine rests on the strop. This preserves the edge – if the blade is turned over with the edge against the strop, this will roll the blade edge, defeating the purpose of stropping As the use of safety razors increased in popularity this 'Jason' strop prolonged the life of each razor blade thus making them economical.A leather 'Jason' strop, for sharpening safety shaving razor blades, with box. Top of Box: J / The JASON / STROP/ Reg. Trade Mark / for SAFETY RAZOR BLADES / Reg. Patent No. 25435/35 ; Back : How to operate the JASON STROP ( instructions) Side: JASON / Razor Strop Dressing / A keen smooth blade will always be assured by the / occasional use of JASON RAZOR STROP DRESSING/ Side: FIFTY SHAVES WITH ONE BLADE ! / by using - JASON and JASON / Razor Blade Strop Razor Blade Dressing. End: JASON / Made by MEIK BROS. Pty. Ltd. / 15-17 Bedford St., Collingwood, and / 287 Flinders Lane, Melbourne, Vic. End: JASON / SAFETY RAZOR BLADE STROP.safety razors, the jason strop, shaving equipment, personal effects, strops, meik bros pty ltd, gillette, collingwood melbourne -

Orbost & District Historical Society

Orbost & District Historical Societyrazor strop, first half 20th century

A razor strop is flexible strip of leather or canvas used to maintain a shaving edge on a thin blade such as a straight razor. Fine powdered jeweler's rouge or other pastes can be added as an abrasive to polish the blade. The strop may be a hanging strip or a hand-held paddle. This one is a hanging strop. Strops were quite commonly found in barber shops and homes before the invention of the safety razor, They are still used for sharpening tool blades. This one was owned and used by Mr Bill Weston, an early Orbost sleeper cutter.This item is an example of the self-reliance shown by rural families when household necessities were not readily available.A brown leather (probably horse hide) razor strop with a double hook at one end. It consists of two strips of leather with padded 'tongue' at bottom. This is a hanging strop which has a metal swivel on top so that the strop can be turned over while hanging from a hook/peg Front top in gold : MALWA Base in gold: 910razor-strop shaving personal-effects -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Cooper’s Hollowing /Jigger Knife, William Greaves & Sons, 1823 -1850

William Greaves was once a prolific company that highly prospered in the 19th century during the boom of the tool and cutlery trades in Sheffield England as steel became more commercially available. William Greaves's works were situated at the Sheaf Works in the heart of Sheffield, at Maltravers Street, opening in 1823 and was known to be the largest business in this area at this time. The Sheaf Works made a range of tools and saws including cutlery, penknives and razors and also even made its steel in-house. The factory used its perfect position for water power being built on the edge of the Sheffield canal and also used the railway line nearby giving them the perfect opportunities for transporting its goods. The factory itself was also a revolution because it attempted to bring together as many cutlery manufacturing processes as possible together in one place, something that had not been attempted before. The money to build these huge works came from Greaves' trade with America, where they sent razors, table cutlery and sturdy Bowie knives. This allowed the Greaves’ to build the factory and expand their production, which made them even more money. This made William Greaves very rich indeed, and it was reported that when he died in 1830 he left each of his five surviving daughters £30,000 each, an astronomical sum at the time. In today’s money that is approximately £2.3 million. The firm finally dissolved in 1850, but Sheaf Works continued to be used by many cutlery manufacturers until the 1980s. With most of the buildings still standing today.A significant item made by a successful cutlery manufacturer in England during the first half of the 19th century. This company undertook many new processes to streamline cutlery production and introduced innervations regards working with steel that are still in use today. This item is now regarded as a collector's item given the company ceased trading in 1850. jigger/hollowing knife with internal bevel, Electro Boracic Steel. Stamped 3.1/2″ William Greaves, Sheaf Works, Sheffield flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cooper's jigger, howeling knife, wm greaves & sons -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Heinrich Boker, late 19th to early 20th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. Henry Boker Maker: Heinrich "Henry" Böker of Reimschied-Solingen, Germany and his family was making tools in the 17th century. In 1829 Hermann and Robert Böker added sabres to the company's offerings, in 1837 they emigrated to New York City and established a firm to import German cutlery. H. Boker sabres would be eventually supplied to some American soldiers during the Civil War. Heinrich Boker in 1869 , a relative of Hermann and Robert, established a cutlery firm in Solingen, a centre of industry and cutting tool manufacturing in Germany. The company became a leader in the manufacture of razors, scissors and eating utensils. As early as 1900 the majority of tools produced by Boker were distributed in the U.S. market by the New York branch of the family, and pocket knives became the company's most important product line. During WWII the Solingen factory was destroyed and all the equipment and inventory was lost. After the war the factory was rebuilt and the company resumed operations, but in the early '60s the company was sold to the scissors manufacturer Wiss & Sons, and in the early 70s Wiss sold out to Cooper Industries. At some point Heinrich Boker adopted the Americanised version of his name, Henry Boker and was used as a brand name for the company's products. A vintage smoothing plane of the Bismark pattern made by Henry Boker the this plane is now regarded as a collectors item and is an example of vintage woodworking tools used in the manufacture of wooden products.Smoothing Plane Bismark design. Blade marked Henry Bokerflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, smoothing plane, heinrich boker, carpenters tool, cabinet makers tool -

Bendigo Historical Society Inc.

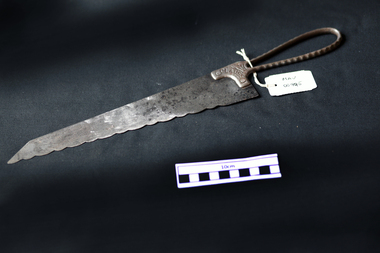

Bendigo Historical Society Inc.Tool - RAZOR STROP

... leather mounted on wood, gold eagle emboosed on handle. Tool RAZOR ...Leather razor strop for sharpening cut throat razors, black leather mounted on wood, gold eagle emboosed on handle.Gold Eagle specially preparedpersonal effects, shaving, razor strop -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: THREE CUT-THROAT RAZORS

Three cut-throat razors, boed units in deteriorated condition: 22b - box marked Pittock,blade marked Bengall, manufacturers name on reverse side T. R. Cadman & Sons, Sheffield England 22c - red box has remains of Sheffield England marked on the smaller end of box. Blade is damaged and rusted. Blade black handle is notated with Bengall, while blade itself is etched Made Specially for A. Edments Pty. Ltd.; reverse notes manufacturer as T. R. Cadman & Sons, Sheffield England 22d - box has no discernible markings, but has minor taped repair on larger section. Black handle is unmarked, blade is marked Bengall, the reverse notes manufacturer as T. R. Cadman & Sons, Sheffield England. Items stored in Pittock coach builders box, reference 13000. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: STAINLESS RAZOR BLADES

... Pittock Collection ; Stainless razor blades Original packaging ...Pittock Collection ; Stainless razor blades Original packaging for Democrat stainless steel razor blades (packet of five); six blades within the packet. One additional angled blade. Items stored in coach builder's box, reference 13000.1. -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncRazor

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.Razor, cutthroat (with changeover blade) -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Razor Sharpening Stone, Norton Pike Company, Pike Wireless Razor Hone

This sharpening stone was likely manufactured in the late 1940's to 1950's in Littleton.In 1932 the NORTON Company purchased the PIKE Manufacturing Company and changed the name to Norton Pike Company. In 1946, ground was broken for a one story brick and steel factory building in Littleton, New Hampshite was completed and occupied in the next year.Emery carborundum stone for honing shaving razors, produced by Norton Pike Company USA after 1932. It is contained in a cardboard box with directions for use on the cover. On the left hand side of the cover are numbers: '4/9', '5/45' and lettering: EK, with a backward arrow underlined underneath and below that a 'H' shaving, barber tools, norton pike co, christenson harry