Showing 10 items matching "sealing tool"

-

Trafalgar Holden Museum

Trafalgar Holden MuseumTool - Sealing tool

... Sealing tool...sealing tool...boot makers sealing tool used during ca1900...boot makers sealing tool used during ca1900 boot makers ...boot makers sealing tool used during ca1900boot makers sealing tool used during leather marking as requiredmetal head with wooden handle with different size grooves on headGROOVES MARKED 8 AND 9 N KADERAW - PRAHAN - 12cobblers, sealing tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910’s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. Brown, brown glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ nipple-liker bump in the centre. Bottle is straight from base to half height then tapers to a shoulder over the next quarter, than almost straight up to the mouth. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, brown glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker, ginger beer bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This hand made, green glass bottle is representative of bottle making before mass production and is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. There is a portion of cork in the bottle’s mouth and dry remnants in the bottle’s base. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1880s to 1910s

This handmade green glass bottle was made using the turn-moulded or rotated-moulded method, a variation of the mould-blown process. The bottle has the remnants of a cork seal in its mouth. It possibly contained ginger beer, soda or mineral water, flavoured drinks, liquor or wine. The bottle’s shine has been worn from around 3/4 of its body, indicating that it has been resting horizontally on an abrasive surface, perhaps in the ground or on a river or sea bed. TURN-MOULDED BOTTLE production method This bottle was handmade using the ‘turn-moulded’ process, one of a variety of mould-blown processes that followed the earlier mouth-blown method. The maker would add a portion of hot soft glass to the end of his blowpipe then blow air through the pipe while placing the end inside a bottle mould. The mould was then turned and twisted, giving the bottle a round, seamless body, and usually a round indented base. The cooled body of the bottle would then be finished with the addition of an applied top. A small amount of soft glass would be applied to the top of the bottle and a lip would be formed using a tooling implement. A concentric ring would also form below the lip, caused by the rotated lipping tool. The bases of bottles made with the turn-moulded method were generally not embossed but would commonly have a mamelon or ‘dot’ in the centre of the base. SEALING THE BOTTLE After filling this type of bottle with its contents it is then sealed with a straight, cylindrical cork with the aid of a hand operated tool called a bottle corker. The bottle corker compresses the cork as it is driven into the bottle. Once inside the bottle the cork expands evenly into the opening to tightly seal the contents – the denser the cork the better the seal. This turn-moulded glass bottle is made distinctive due to its round seamless body and indented base.Bottle, dark green glass. Handmade turn-moulded bottle with seamless body and tooled lip. Deeply indented base has push-up mark with a ‘mamelon’ bump in the centre. Bottle is straight from base to half height, then tapers to a shoulder over the next quarter, than almost straight up to the mouth. The shine has been worn from three-quarters of the body of the bottle. There are particles adhered to the inside of the bottle. Possibly used for ginger beer. Produced in 1880s to 1910’s. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, green glass bottle, handmade glass bottle, bottle with indented base, turn-moulded bottle, rotate-moulded bottle, tooled lip on bottle mouth, applied lip bottle, bottle corker -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Rolling Pin, First half of 20th Century

A rolling pin is a simple tool used to flatten dough. The first civilisation known to have used the rolling pin was the Etruscans. Their advanced farming ability, along with a tendency to cultivate many plants and animals never before used as food and turn them into sophisticated recipes, were passed to invading Greeks, Romans, and Western Europeans. Thanks to the Etruscans, these cultures are associated with gourmet cooking. To prepare their inventive foods, the Etruscans also developed a wide range of cooking tools, including the rolling pin. Although written recipes did not exist until the fourth century B.C., the Etruscans documented their love of food and its preparation in murals, on vases, and on the walls of their tombs. Cooking wares are displayed with pride; rolling pins appear to have been used first to thin-roll pasta that was shaped with cutting wheels. They also used rolling pins to make bread (which they called puls) from the large number of grains they grew. Natives of the Americas used more primitive bread-making tools that are favoured and unchanged in many villages. Chefs who try to use genuine methods to preserve recipes are also interested in both materials and tools. Hands are used as "rolling pins" for flattening dough against a surface, but also for tossing soft dough between the cook's two hands until it enlarges and thins by handling and gravity. Tortillas are probably the most familiar bread made this way. Over the centuries, rolling pins have been made of many different materials, including long cylinders of baked clay, smooth branches with the bark removed, and glass bottles. As the development of breads and pastries spread from Southern to Western and Northern Europe, wood from local forests was cut and finished for use as rolling pins. The French perfected the solid hardwood pin with tapered ends to roll pastry that is thick in the middle; its weight makes rolling easier. The French also use marble rolling pins for buttery dough worked on a marble slab. Glass is still popular; in Italy, full wine bottles that have been chilled make ideal rolling pins because they are heavy and cool the dough. Countries known for their ceramics make porcelain rolling pins with beautiful decorations painted on the rolling surface; their hollow centres can be filled with cold water (the same principle as the wine bottle), and cork or plastic stoppers cap the ends. Designs for most rolling pins follow long-established practices, although some unusual styles and materials are made and used. Within the family of wooden rolling pins, long and short versions are made as well as those that are solid cylinders (one-piece rolling pins) instead of the familiar style with handles. Very short pins called mini rolling pins make use of short lengths of wood and are useful for one-handed rolling and popular with children and collectors. Mini pins ranging from 5 to 7 in (12.7-17.8 cm) in length are called texturing tools and are produced to create steam holes and decorations in pastry and pie crusts; crafters also use them to imprint clay for art projects. These mini pins are made of hardwoods (usually maple) or plastic. Wood handles are supplied for both wood and plastic tools, however. Blown glass rolling pins are made with straight walls and are solid or hollow. Ceramic rolling pins are also produced in hollow form, and glass and ceramic models can be filled with water and plugged with stoppers. Tapered glass rolling pins with stoppers were made for many centuries when salt imports and exports were prohibited or heavily taxed. The rolling pin containers disguised the true contents. The straight-sided cylinder is a more recent development, although tapered glass pins are still common craft projects made by cutting two wine bottles in half and sealing the two ends together so that the necks serve as handles at each end.Tiny rolling pins are also twisted into shape using formed wire. The pins will not flatten and smooth pastry, and the handles do not turn. The metal pins are popular as kitchen decorations and also to hang pots, pans, and potholders. https://www.encyclopedia.com/sports-and-everyday-life/food-and-drink/food-and-cooking/rolling-pinThe use of the rolling pin to make thin pastry or pasta.Wooden rolling pin with some damage on cylinder section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rolling pin, cooking, pastry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Bottle Seal, circa 1843-1878

This lead sealing capsule was recovered from the tragic wreck of the sailing ship ‘Loch Ard’. It may have once been on a bottle amongst the ship's cargo, its provisions or the passengers’ personal luggage. It is now part of the John Chance collection. Bottles in the early 19th century were handmade. They were not necessarily uniform in size or shape, so sealing was not always successful. If the bottles were stored they often became contaminated by rats and mice breaking the cork or wax seals, or by insects attracted to the contents if the seal on the bottle leaked. Lead sealing capsules were used from 1843 to overcome this problem. The lead was heated until it was malleable, then moulded by hand to fit over the sealed bottle’s mouth and neck. This was more successful if wire was also used under the capsule for added security (similar to modern champagne bottles). The capsule couldn’t be re-fitted so it was discarded after the bottle was opened. Capsule designs from about 1862 used tin-plated lead foil and often had the inscriptions and trademarks of the content makers on them. Eventually it was found that the lead was toxic. The lead was replaced by tin, aluminium, and later plastic. Today’s home brewers can buy readymade plastic capsules that fit over the bottle then twist to lock it firmly into place and can be re-used. Digs at archaeological sites often reveal lead sealing capsules. These are collected and catalogued. The information gathered from inscriptions, makers’ marks, logos and descriptions of the bottle contents has provided valuable insights into the history and the dating of other items on the sites. This lead sealing capsule was made to seal a handmade glass bottle and is historically significant for representing its invention to solve a preservation and integrity issue with bottle seals in the mid-to-late 19th century. Its design has evolved and is still in use today. This sealing capsule is representative of their historical use of capsules as a tool for dating and interpreting archaeological sites around the world. The sealing capsule is also significant as it was recovered by John Chance, a diver from the wreck of the Loch Ard in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. The sealing capsule is also significant for being connected to the wreck of the Loch Ard (1873-1878), which is historically significant to both Victoria and Australia. The loss of the ship has been described as one of the ‘worst shipwreck tragedies’ and is well known in Victoria for the tragic death of 52 out of the 54 lives on board. The Loch Ard wreck's historical significance as a large international passenger and cargo clipper ship has been recognised and it is now registered on the Victorian Heritage Database, VHR S417. The wreck site is labelled as ‘one of Victoria’s most spectacular diving sites’ and the area is a popular tourist site. It is part of Victoria’s Underwater Shipwreck Discovery Trail.Bottle sealing capsule, cylindrical with thin, round top separated from thicker body (taped in place and fragile). Made from grey-white lead, uneven in thickness and shape. Remnants of a thick substance are inside the capsule.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, loch ard, bottle seal, bottle capsule, handmade bottle, antique bottle, sealing capsule, lead capsule, bottle closure, bottle foil, bottle preservation, bottle finish -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking iron, Mid-to-late 20th century

Caulking is the use of cork or other substances to seal the seams and joints of the vessel to make them watertight. Caulking lasts for quite some time but eventually dries out and needs to be replaced. A hammer is often used with a caulking iron to drive it along the seams. The caulking iron’s blade is tapered to be narrower at the tip to make it easier to remove it from the joint. The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings. You can see Laurie’s inscription on the tool called a ‘bevel’. Laurie worked for Ports and Harbours, Melbourne, for over 50 years, beginning in the early 1960s. He and a fellow shipwright inscribed their names on a wheelhouse they built in 1965; the inscription was discovered many decades later during a repair of the plumbing. Many decades later Laurie worked on the Yarra moving barges up and down the river and was fondly given the title ‘Riverboat Man’ His interest in maritime history led him to volunteer with the Maritime Trust of Australia’s project to restore and preserve the historic WWII 1942 Corvette, the minesweeper HMAS Castlemaine, which is a sister ship to the HMAS Warrnambool J202. Laurie Dilks donated two handmade displays of some of his tools in the late 1970s to early-1980s. The varnished timber boards displayed the tools below together with brass plaques. During the upgrade of the Great Circle Gallery Laurie’s tools were transferred to the new display you see there today. He also donated tools to Queenscliffe Maritime Museum and Clunes Museum.The shipwright’s tools on display in the Great Circle Gallery are connected to the maritime history of Victoria through their past owner, user and donor, Laurie Dilks. Laurie began his career as a shipwright at Ports and Harbours in Melbourne in the mid-1900s, following in the wake of the skilled carpenters who have over many centuries used their craft to build and maintain marine vessels and their fittings.Caulking iron, or broad chisel, wooden handle with reinforcing on the ends, metal shaft that tapers down from the handle to the end of the blade. It has an inscription. It once belonged to shipwright Laurie Dinks.Stamped into metal " - - WARD /(image of crossed swords) WEFT / WARRANTED"flagstaff hill, warrnambool, great ocean road, shipwreck coast, maritime museum, maritime village, shipwright, carpenter, shipbuilding, ship repairs, hand tool, equipment, ship maintenance, cooper, tool, marine technology, caulking iron, jerry iron, broad chisel, caulking, sealing, laurie dilks, l dilks, port and harbours melbourne -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - LETTER SEALING SET

... . Donated by 'Wiegard 6.11.69' Tool LETTER SEALING SET ...The 'Georgian' sealing set, in a blue leather covered box with brass clasp, contents include a crucible, wax seals, matches & spirit burner. Inside box lid lined with blue silk with gold writing reading, patent No 30394/10 Third Hand Patents Ltd 881 City Rd E.C. Donated by 'Wiegard 6.11.69'Third Hand Patents Ltdcommunication, postal, letters -

Bendigo Historical Society Inc.

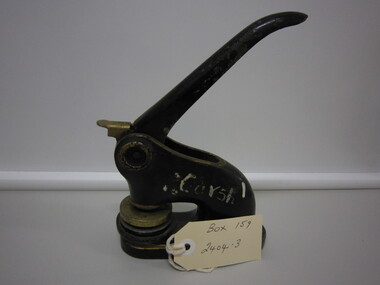

Bendigo Historical Society Inc.Tool - MCCOLL,RANKIN,STANISTREET COLLECTION: COMPANY SEAL Forbes Carshalton G.M

Collection McColl, Rankin, Stanistreet. Cast iron hand press company seal for the Forbes Carshalton Gold Mining Company, used for sealing all official documents pertaining to the Forbes Carshalton Gold Mining Company. Black enamelled base and handle with brass seal & gold trim, painted in white paint 'Carsh'.commerce, office equipment, company seal