Showing 15 items matching "sharpening method"

-

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySharpener Saw Raker/Jointer, early 1900s

... sharpening method... 1900's. This particular saw sharpening method was used ...This raker/jointer/guage set is a sharpening tool for cross cut logging saws. The logging saws used in the early 1900's for the clearing of forests required constant sharpening of their "cutting teeth". The logging of forested areas during these times was very much a "hands on" method of either one or two men by the use of saw or hand axe. Chain saws, chain and ball(clearing) and bulldozing methods came in the mid 1900's.This particular saw sharpening method was used by surveyors laying down boundaries for the S.E.C. Victoria Hydro Electricity Scheme (1920's). This item was given to a local Kiewa Valley lad who accompanied the initial surveyors. The lad was responsible for the tendering and feeding of the surveyors "pack horses". Surveys during this period and in the dense mountainous terrain of the Victorian Alps was both exhausting and hazardous. Overnight accommodation at various log cabins was not always possible and swag/tent alternative was the "fall back" This raker/jointer saw sharpener was made in the USA (DISSTON) from cast and flat iron. The main body has been painted in orange. It has three adjustment screws on the top horizontal bar and one bolt on(adjusting) leveling platform on the bottom. The small size and weight of this saw sharpener was ideal for the travelling/mobile logger or surveyor(as in this case). The main frame resembles two towers connected by two horizontal bars and the top of the towers has a horizontal bar with adjustment screws. See KVHS 0090 (B) for setting stake wedge adjusting the rake and cutting angle and KVHS 0090 (C) for a small spanner (for adjustments).On one inner supports is stamped "DISSTON" and on the other "U.S.A."hand tool, saw, sharpening method, tree felling. -

Kiewa Valley Historical Society

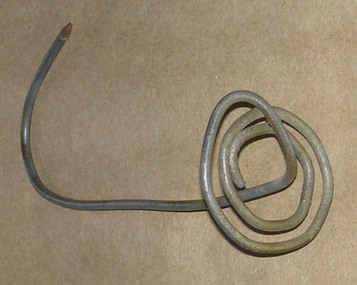

Kiewa Valley Historical SocietyTool Spring Set, circa early 1900s

... sharpening method... methods came in the mid 1900's. This particular saw sharpening ...This is part of a crosscut saw raker/jointer/guage set used to bend the tip of each cutter tooth for cross cut logging saws. The logging saws used in the early 1900's for the clearing of forests required constant sharpening of their "cutting teeth". The logging of forested areas during these times was very much a "hands on" method of either one or two men by the use of saw or hand axe. This item was used by the surveyors commissioned by The S.E.C. Victoria Kiewa Hydro Electricity Scheme project mapping the relevant Alpine region. Chain saws, chain and ball(clearing) and bulldozing methods came in the mid 1900's.This particular saw sharpening method was used by surveyors laying down boundaries for the S.E.C. Victoria Hydro Electricity Scheme (1920's). This item was given to a local Kiewa Valley lad who accompanied the initial surveyors. The lad was responsible for the tendering and feeding of the surveyors "pack horses". Surveys work during this period and in these dense mountainous terrain of the Victorian Alps was both exhausting and hazardous. Overnight accommodation at various log cabins was not always possible and swag/tent alternative was the "fall back".This cast iron Spring Setting tool has a main body of angle iron contours with one end tappered into a flat circular extension with a slit (3/32" wide) running from the top to nearly the centre(15mm). This slit is to allow the bending of each "cutter tooth" of the cross cut saw. The "bottom of this slit has a semi circular ending. Protruding from one side of the bar body, and close to the "slit" is a tounge like extension (wedge) to fasten the spring set tool into a tree stump. See KVHS 0090 (A) for its Raker/Jointer saw sharpening guage set partner. Also see KVHS 0090 (C) for the associated wrench. On one side of the bar "DISSTON U.S.A."hand tool, saw, sharpening method, tree felling -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietySpanner Small, 1920's

... sharpening method... sharpening tool and method was used by surveyors laying down ...This spanner, part of a raker/jointer/guage set which is a sharpening tool for cross cut logging saws. The logging saws used in the early 1900's for the clearing of forests required constant sharpening of their "cutting teeth". The logging of forested areas during these times was very much a "hands on" method of either one or two men by the use of saw or hand axe. Chain saws, chain and ball(clearing) and bulldozing methods came in the mid 1900's.This particular spanner was part of a crosscut saw sharpening tool and method was used by surveyors laying down boundaries for the S.E.C. Victoria Hydro Electricity Scheme (1920's). This item was given to a local Kiewa Valley lad who accompanied the initial surveyors. The lad was responsible for the tendering and feeding of the surveyors "pack horses". Surveys during this period and in the dense mountainous terrain of the Victorian Alps was both exhausting and hazardous. Overnight accommodation at various log cabins was not always possible and swag/tent alternative was the "fall back"This small spanner is part of the Raker/Jointer Gauge saw set and is made from forged steel. The nut grip is of the two tightening nuts on the main construction frame. See KVHS 0090 (A &B) for the other items making up the sharpening tools.hand tool, saw, sharpening method, tree felling. -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - Artefact, Sharpening stone

... and is kept for displays. It is an example of tool sharpening methods ...This is an early sharpening stone of unknown origin . Stones have been used for hundreds of years to sharpen metal blades on a wide range of tools from scythes, scissors plane blades and knives. More recent examples come with particular grades according to the fineness of the grit in the stone.This item is of antiquarian interest only and is kept for displays. It is an example of tool sharpening methods which have been used for many years.This is a small square stone with a polished surface used to sharpen small bladestrade, sharpening stone, warrnambool -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyGrinder / Pounding Stone, Dhudhuroa language Aboriginal tribe, pre British/European colonisation

This stone Grinder or pounder was used as part of an indigenous grinding food preparation method, by the original inhabitants of the Kiewa Valley and its region. In conjunction with its grinding stone was used not only to grind seeds and but also to dig up eatable roots and leaves and served with the regions Bogong moth. This method of food preparation has survived in its basic form for centuries and is still used by master chiefs in modern eateries. This item has been registered with Aboriginal Affairs in Wangaratta, Victoria. Dhudhuroa elder Alan Murray has examined this tool, in Feb 2015, and said it was also used for sharpening axe heads as well as pounding food items. This item has a very significant historical and social aspect to it. Firstly it demonstrates the division of labour within a indigenous tribe. It was an era when the female had a definitive role within the family and the broader social indigenous tribal group of, gathering and preparing non animal(hunted) food. Hunted food was the domain of the initiated males of the tribe.Secondly it demonstrates the ability to fashion implements from raw materials(rock) into effective tools for the purpose of preparing a meal for human consumption. This was in an era where inter family and intra family participation in an indigenous tribal social protective environment was at a very high level. The Kiewa Valley/Mount Bogong region was an area where annual "get together" indigenous tribes for feasting, bartering and settling of disputes highlighting the importance of a regional gathering. Grooved stone, carved to a cylindrical shape with a relative pointed end tip one side (grinding or pounding end) and a rough other end (holding end} Made from Rhyolite stoneThere is a worn grove in the top side due to this tool being used for axe sharpening. indigenous, aboriginal, stone grinding, meal preparation, natural environment, pounding stone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, circa 1922

A razor strop such as this one was used to sharpen and polish straight-edged razors. This particular design has a swivel hook with a locking clip that allows for movement as the strop is being used. This strop is branded "Sherlite". On May 5th, 1922 the Commonwealth officially accepted and advertised the Trade Mark Application of Thomas Sherry of Victoria, for the Trade Mark of "Sherlite" to be used under the heading of "Leather, Skins unwrought and Wrought”. Thomas Sherry’s application was to use the word “Sherlite” for detachable soles made of rubberised leather. Straight razors and cut-throat razors were the major tools for shaving before the safety razor was invented in the 1880s and even today specialist shaving shops still sell straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap with a shaving brush that had boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade's edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas, or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools, and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are handheld. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish.Razor strop, leather, and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has a padded, bulbous-shaped leather grip handle, the other end has a metal, swivel hook hanger. Inscriptions painted in gold on leather at the hook end.Razor strop, leather and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather grip handle, the other end has metal, swivel hook hanger. Inscriptions printed in gold on leather at hook end.Printed gold lettering stamped “Sherlite”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, sherlite razor strop, personal effects, toiletries, thomas sherry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

Federation University Historical Collection

Federation University Historical CollectionTool, Handshears

Hand shears needed to be very sharp and often had a leather strap or ‘driver’ which passed over the hand. Others had sheepskin bound around the grip. Blades had to be regularly sharpened on a grinding stone. Most hand shears were made in Sheffield, England, with various models produced offering wide or narrow blades, sharp or rounded points, and various grips and bows. The technique of Australian hand shearing gradually developed from the 1830s using the old English method of cutting the flank with hand shears in a series of circular cuts from the sheep’s neck to the tail. In the early 1930s the Ballarat School of Mines introduced a wide-ranging Wool Classing Course as jobs were in extremely short supply during the Great Depression. Metal handshears used for shearing sheep.ballarat school of mines, shearing, woolclassing, sheep -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor Strop

This razor strop is made like a leather strap. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Double Swing Razor Strop. Use for honing razors.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, swing razor strop, barber's equipment, shaving equipment, personal accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

Bendigo Historical Society Inc.

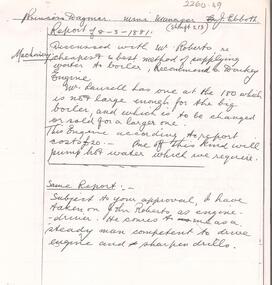

Bendigo Historical Society Inc.Document - ALBERT RICHARDSON COLLECTION: PRINCESS DAGMAR MINE, GARDEN GULLY LINE

4 page handwritten document, (copy) detailing some of the Mine Manager's reports for Princess Dagmar mine 1881 - 1914. Example: Reportof 8.3.1881, shaft 213, Mine Manager J. Ebboth. 'Discussed with Mr. Roberts re cheapest and bst method of supplying water to boiler, recommend a donkey engine. Mr. Lansell has one at the 180 which is not large enough for the big boiler and which is to be changed or sold for a larger one. This engine according to report costs 20 pounds. One of this kind will pump hot water which we require. Subject to your approval I have taken on John Roberts as engine driver. He comes to me as a steady man competent to drive engine and sharpen drills.'bendigo, mining, princess dagmar -

Heyfield & Districts Historical Society

Heyfield & Districts Historical SocietyBill spike, George Edward Barraclough (1906-1981), 1940s-1950s

George Barraclough (1907-1981), a landholder from north of Licola, in the Victorian Great Divide, made a number of these spikes, as needed. As accounts were paid, receipts were pasted to the account, the account was impaled on the spike, and the spike was rehung on a nail on a wall stud. All transactions dealing with money were filed in this manner, as an orderly way of tracking items that were usually remotely ordered and delivered on the mail car. George Barraclough used No8 in a number of creative ways, and his durable and untilitarion toasting forks are still in family use today. After George died in 1981 the spikes with their accounts passed to his daughter Linda Barraclough, who archived the accounts and later made copies available for study. Those accounts form a record of the businesses of Heyfield for 1940s and 1950s.This bill hook is of historical significance as a survivor of bush ingenuity and bush filing systems. Commercially made bill spikes were in common use in offices, where they usually consisted of a heavy metal base with an upright pointed piece of wire. Number 8 fencing wire was an important and readily accessible repair commodity for rural dwellers, and achieved iconic status as the most generic method of repair for cars broken down (resort to nearest fence) and was even used to hold houses together. Referring to "No 8 fencing wire" became a type of Australian shorthand for bush ingenuity. It is no longer available, being replaced by 4mm high tensile wire. This item is important both as an example of inventive use of No8 wire, and also as an example of the bush filing methods in use in the 1940s and 1950s. No 8 fencing wire holds a similar position in New Zealand - see Wikipedia NZ at http://en.wikipedia.org/wiki/Number_8_wire A section of number 8 fencing wire twisted to form a bill spike. It has a rounded.base made from several twists of wire in a flat platform, with the remaining wire rising from the centre to form a stem that terminates in a hook with a sharpened point.wire, bush ingenuity, barraclough, licola north -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder