Showing 18 items matching "shearing equipment"

-

National Wool Museum

National Wool MuseumPamphlet, New! Completely new! Electric shearing gear!

... Pamphlet advertising Cooper shearing equipment....Pamphlet advertising Cooper shearing equipment....-and-the-bellarine-peninsula Pamphlet advertising Cooper shearing equipment ...Pamphlet advertising Cooper shearing equipment.Pamphlet advertising Cooper shearing equipment.shearing shearing machinery, cooper engineering company pty ltd sunbeam corporation limited, shearing, shearing machinery -

National Wool Museum

National Wool MuseumPamphlet, New! Completely New! Electirc Shearing Gear!

... Pamphlet advertising Cooper shearing equipment....Pamphlet advertising Cooper shearing equipment....-and-the-bellarine-peninsula Pamphlet advertising Cooper shearing equipment ...Pamphlet advertising Cooper shearing equipment.Pamphlet advertising Cooper shearing equipment.shearing machinery, cooper engineering company pty ltd sunbeam corporation limited -

National Wool Museum

National Wool MuseumBooklet, The Wolseley

... shearing equipment.... shearing equipment.... of Wolseley shearing equipment. Shearing machinery Wolseley Sheep ...Booklet with drawings and specifications of Wolseley shearing equipment.Booklet with drawings and specifications of Wolseley shearing equipment.shearing machinery, wolseley sheep shearing machine co. ltd -

National Wool Museum

National Wool MuseumBooklet - Sunbeam Cooper Shearing Shed Reference Book

... shearing machinery & shearing shed equipment"... on Sunbeam and Sunbeam Cooper sheep shearing machinery & shearing... & shearing shed equipment 5... Cooper sheep shearing machinery & shearing shed equipment ...Part of Ken Galloways research material associated with his career as a woolclasser. "Sunbeam and Sunbeam Cooper sheep shearing machinery & shearing shed equipment"White binder containing a collection of research material on Sunbeam and Sunbeam Cooper sheep shearing machinery & shearing shed equipmentSunbeam and Sunbeam Cooper sheep shearing machinery & shearing shed equipment 5woolclassing shearing machinery, wool press, sunbeam, sunbeam cooper, galloway, mr ken, woolclassing, shearing machinery -

National Wool Museum

National Wool MuseumPamphlet

... Pamphlet advertising Cooper shearing plant equipment....Pamphlet advertising Cooper shearing plant equipment.... equipment. Shearing Cooper Engineering Company Pty Ltd Pamphlet ...Pamphlet advertising Cooper shearing plant equipment.Pamphlet advertising Cooper shearing plant equipment.shearing, cooper engineering company pty ltd -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

... Shearing Equipment... engine that would have powered the overhead shearing equipment... shearing equipment in shearing sheds. It was common for shearing ...Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

... Shearing equipment... of shearing equipment, made its first household appliances and branded... were not as seasonal as those of shearing equipment, made its ...With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - Shearing Hand Set

... Shearing equipment... in North East Victoria. Shearing industry Shearing equipment ...The wool industry has been critical to the Australian economy from the early days of European settlement. The increase in wool production in the mid to late 19th century led to the need to replace the hand shears with some mechanized forms of shearing.The first commercially successful sheep shearing machinery by Frederick York Wolseley in New South Wales who was granted a patent for his machine on 28 March 1877. Many of the early settlers to North East Victoria droved sheep overland from both Sydney and South Australia and established large pastoral runs in the district. Wodonga became a major service centre for the industry and established major saleyards for the pastoral and cattle industries. The handset has the company name "Heiniger" on the side. Heiniger is a Swiss company with subsidiaries in Australia and New Zealand. It was originally established in 1946.This item is connected to a major rural industry in North East Victoria.A metal handpiece for a sheep shearing. A toothed blade is held in place with metal adjustable screws at one end. A jointed metal pipe at the other end allows attachment to the shearing machine. The hinge has been covered with leather.On adjustment knob "Heinger"shearing industry, shearing equipment, shearing handset -

National Wool Museum

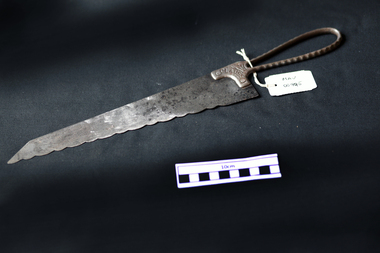

National Wool MuseumTool - Shearing Handpiece, c.1890

... Shearing Equipment... Shearing Equipment FORD & McFARLANE Wellington Lodge Tailem Bend ...Ford and McFarlane shearing handpiece c.1890. This shearing handpiece is from ‘Wellington Lodge” in Tailem Bend, South Australia. Wellington Lodge today is an Angus beef farm; however, the property has a long history which includes wool farming. Wellington Lodge has been in the McFarlane family since the 1840’s and was originally around 19000 acres. The donor, Brian Licence, assembled this handpiece out of spare parts he found while classing wool on the property in the 1960s. Brian showed the finished handpiece to the owners once his classing work was completed and was told he could keep the handpiece as a souvenir. Brian also classed wool at “Jockwar” and “Pleasant Park” in Penola for members of the McFarlane family during the 1960s. The handpiece is named after Ford, the name of the engineer who designed the handpiece and McFarlane, the owners of Wellington Lodge Station and employers of Ford. This handpiece was developed as a prototype for use on the property. The handpiece which is made of solid brass is in a “used condition” and has been patched with solder. The handpiece is stamped with the number 10. Internally, the handpiece is powered from a drive mechanism of compressed air, this compressed air was typically produced by burning mutton fat. The handpiece comes from the pre-electrical– steam engine era of shearing. Brass metal shearing handpiece. A three-pronged fitting to hold both the comb and the blade protrudes from one end. A cylindrical stem extends vertically from the other. This is likely where a connecting rod to the shearing plant would be found. Below this vertical stem, the handpiece has an additional threaded hose fitting. This is likely where compressed air was delivered into the handpiece. The inscriptions can be found on the rear, near the previously mentioned vertical stem. Around this stem is also where the repairs of solder can be found. These repairs are unique to this handpiece and are not common practise.Etched. Base of handle. “FORD & McFARLANE . SHEEP SHEARER . Etched. Base of handle. “10”sheep shearing, shearing equipment, ford & mcfarlane, wellington lodge, tailem bend, south australia, shearing handpiece, shearing -

National Wool Museum

National Wool MuseumWheel, Pulley

... See Wolsely overhead shearing equipment. ?Related to Accn...-and-the-bellarine-peninsula See Wolsely overhead shearing equipment ...See Wolsely overhead shearing equipment. ?Related to Accn. No. 6?? -

Federation University Historical Collection

Federation University Historical CollectionBook - Book - Scrapbook, Ballarat Institute of Advanced Education: Scrapbook of newspaper cutting. Book 1; December 1968 to August 1969

Newspaper cuttings relating to Ballarat Institute of Advanced Education. These are from various newspapers and include The Age, Ballarat Courier, The Australian, The Herald. The cuttings cover the period from 21 December 1968 to 12 August 1969. Book with grey cover, front. Spiral boundballarat institute of advanced education, biae, metallurgy scholarship awards, higher pay for academic staff, deep-sea housewife, jan watson, yendon bluestone for smb, building at mt helen, hepburn springs camp, cricket match, government may cut grants, quotas a must, apex scholarship to christopher dower, j m hasker of cement and concrete association, concrete course at smb, john stevens winner of gold medal, master plumbers' association, trade students prize night, education the answer, smb success depends on local support, $950000 expasion by smb, dr r schrieke, barry shearer, craftsmen receive awards, top swimmers, stephen yorke, ian ellis, apprentices on show, open night at smb, master builders' awards, first equipment at mt helen, craftsmanship awards, commonwealth must not control education, courses in computers, motor for trainee mechanics, bores under road, don skewes invents drill, bluestone blocks as terracing at smb, boost college intake, the lake relay, stuart alexander wins award, biae commands interest, ballarat gas company scholarships, smb on eve of new era, alan graham, r w richards medal, art in the sunshine, retirements from engineering firm, stan sweatman joins biae, smb diplomates in many fields, $130000 computer at biae, learning for living -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham, -

National Wool Museum

National Wool MuseumBioclip sheep net

Bioclip was developed in the late 1990s as a way of removing the wool from sheep without the need for shearing. Sheep, although mostly lambs up to 50kg, were dressed in the nets and injected with a protein which caused the wool to break at the skin. The net was used to hold the loose wool in place and left on for several days to allow the wool to continue to grow on the sheep (and offer protection against the elements once the net and wool were removed). The net was cut and destroyed during the removal process. Bioclip stopped being produced c2013. Factors for this included the cost of a shearing team was cheaper than the equipment needed for Bioclip, and it wasn't as popular with wool growers as anticipated. Those who used Bioclip would swear by it with many saying they would never go back to using a shearer, as Bioclip produced a clean and even result, with no damage or stress done to the sheep. Bioclip could only be used on young and small sheep, with a maximum size of 50kg.Cream coloured netting, stitched in a flattened cylinder shape with a hole at each end (for sheep head and tail) and four holes on underside (for sheep legs). Green stitching on one end. -

National Wool Museum

National Wool MuseumTool

For moving running belt from fixed to free pulley, probably from shearing corunder. See Wolsely overhead equipment. May be related to Accn. No. 6. -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Bicycle Tool and Repair Kit, c1935

The first bicycles arrived in Australia in the 1860s. They gradually gained in popularity and by the 1890s they offered a cheap and relatively comfortable mode of transport. Far being just a means of leisure, long distance cycle travelling became a fact of life in rural areas for people such as sheep shearers and other agricultural labourers with migratory work. The bicycle and swag travelled much of Australia on dusty dirt tracks, long before the automobile was introduced. Today the bicycle continues to be an important item for general, cheap transport, sport and leisure. Tool kits such as those shown in the item, were and important piece of equipment for bicycle enthusiasts, particularly on a longer ride where assistance may not be close by if the rider experienced a punctured tyre. John Bull Rubber Co. Ltd. was a British tyre manufacturer based in Leicester. It was established in 1906 and was originally named Leicester Rubber Company. In 1915, a new factory was built in Evington Valley Road as indicated on the repair outfit tin in this kit. It was renamed John Bull Rubber in 1934 after its popular product of the same name. In 1958, the company was acquired by Dunlop Rubber. A leather bag containing tools and 2 tins containing rubber patches to repair bicycle tyres. The bag has 2 straps and metal buckles to attach it to the back of the bicycle seat.On tin 1: "The John Bull / Repair Outfit/ John Bull Rubber Co. Ltd./ Evington Valley Mills, Leicester" On tin 2: "ZENITH Repair Outfit / For Cycle and Rubber Repairs/ Self Vulcanizing" On tin 3: Around the DUNLOP logo "Six Self Lighting/ Patch Heat Units / For Cycle Tube/ Vulcaniser"bicycle history, bicycle repairs, john bull rubber, cycling leisure -

Wodonga & District Historical Society Inc

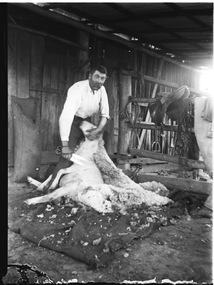

Wodonga & District Historical Society IncNegative - Haeusler Glass Negatives Collection - Harry Schuster blade shearing

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s. The Schuster family were also of German migrant background. Johannes Edward Schuster was born in Hoyles Plains, South Australia and with his wife Johanna and young family moved to Victoria circa 1882. He took up farming land in Wodonga West. The St John’s Lutheran Church Sunday school hall was erected from part of the proceeds of the sale of some 41 acres of land at Wodonga West, which had been bequeathed to the Wodonga congregation by the late Johannes Edward Schuster. This land was the original home site of the Schuster family on arrival from South Australia. Shearing - Although the first mechanised sheep shearing machine was created by James Higham, from Melbourne in 1868, the use of blade shears were more common well into the early 20th century. Pastoralists on smaller holdings continued to either shear their own sheep or employ blade shearers rather than outlay the cost of machines. In large sheds, professional shearers worked as they travelled the country. They would earn around 17 to 20 shillings per day in the early days of the wool industry. However mechanisation continued and by 1915 most sheep shearing sheds in Australia contained sheep shearing machines. The original machines were powered by steam and later combustion engines were used. This digital image was produced from one of the glass negatives that form part of the collection, probably taken by Louis Haeusler (b.1887) with the photographic equipment in the Wodonga Historical Society Haeusler Collection.This item is unique and has well documented provenance and a known owner. It forms part of a significant and representative historical collection which reflects the local history of Wodonga. It contributes to our understanding of domestic and family life in early twentieth century Wodonga, as well as providing interpretative capacity for themes including local history and social history.Digital image created from the Haeusler Glass negative collection. Harry Schuster shearing sheep using blade shears. wodonga pioneers, haeusler family, glass negatives, dry plate photography, blade shearing, schuster family -

Clunes Museum

Clunes MuseumEquipment - SHEARING HAND PIECES

... . Equipment SHEARING HAND PIECES ....1 Hand piece complete with one comb cutter and leather covered hand piece grip. (thin top comb missing from bracket). Also has rubber guard tied on with leather thong. .2 One shearing hand piece without comb cutter metal. shearing, sheep, mechanical