Showing 18 items matching "shearing shed hands"

-

National Wool Museum

National Wool MuseumBook, Great Australian Shearing Stories

... Shearing shed hands... Shearing sheds Shearing shed hands Shearing Shearing sheds Great ...Book of stories told by shearers.shearing shearing sheds, shearing shed hands, shearing, shearing sheds -

National Wool Museum

National Wool MuseumJournal extract, Federal Pastoral Awards

... Shearing shed hands... - management Agriculture - industrial relations Shearing shed hands ...Supplement to 'Grazing', May 1958, giving wage rates for shearers and station hands.shearing sheep stations - management agriculture - industrial relations, shearing shed hands, pettitt, mr r. w., shearing, sheep stations - management, agriculture - industrial relations -

National Wool Museum

National Wool MuseumBook, The Shedhand's Manual

... Shearing shed hands... shed hands Woolclassing Shearing The Shedhand's Manual Book ..."The Shedhand's Manual: woolclassing today, book 1" - Rosalind Martel, 1989.woolclassing shearing, shearing shed hands, woolclassing, shearing -

National Wool Museum

National Wool MuseumBook, Bygoo and beyond

... Shearing shed hands... stations - establisment Shearing shed hands Pastoral Industry ..."Bygoo and beyond" - Rob Webster,1957.pastoral industry - history pastoral industry - settlement squatters sheep stations - establisment, shearing shed hands, pastoral industry - history, pastoral industry - settlement, squatters, sheep stations - establisment -

National Wool Museum

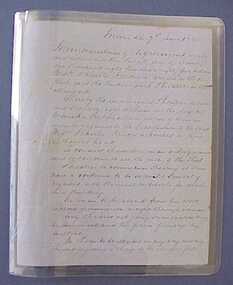

National Wool MuseumAgreement

... Shearing shed hands... Pastoral Industry history Shearers Shearing shed hands Hay Mr Jim E ...An agreement between Ballie Donald & Fraser of "Manuka" Station & 22 men to shear sheep. Written by the hand of Jim Hay, Elders Geelong.Inside 10. Verso of 10. Regional Galleries Association of Victoria Conservation Treatment report 30 August 1988shearing sheep stations, history pastoral industry, history shearers, shearing shed hands, hay, mr jim e. - elders vp, manuka new south wales, shearing, sheep stations - history, pastoral industry - history, shearers -

Federation University Historical Collection

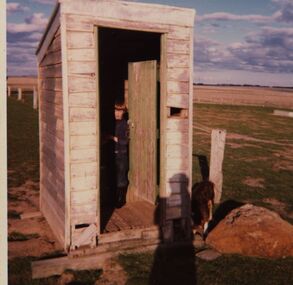

Federation University Historical CollectionPhotograph - Colour, Chatham-Holmes Collection: Andrew Chatham in the Out House, Kur-a-ruc South, Rokewood, Vic. {circa 1976)

Andrew Chatham, the youngest of Philip and Elizabeth Chatham's 5 children, was born in 1968. In this photo, he looks about 8 - 10 years old. The photo was taken at Rokewood, Victoria on his parent's Western District property, "Kur-a-ruc South" a former part of the Kur-a ruc Station, Rokewood, Victoria purchased by Philip and Elizabeth Chatham in 1964. The family lived at Ascot, 15 miles north of Ballarat, and had regular weekend day trips and Easter holidays picnicking, droving sheep, feeding stock, checking water troughs and dams, hand-weeding Patterson curse, repairing fences, collecting paddock rocks and sugar-gum wood at "Kur-a-ruc South'. Home base for these excursions was either a car, the shearing shed, sometimes a 6-berth caravan and by the mid-1980s a shearer's quarters with an inside toilet. [Jane Dyer (nee Chatham).15 June 2024] chatham-holmes collection, andrew chatham, outdoor shed, toilet facility, rokewood, kur-a-ruc south, rokewood -

National Wool Museum

National Wool MuseumBook, Wool Sample, 1936-8

The story of 90 years of wool classing between father & son begins in 1936, when a young boy by the name of Stanley James Hucker walked through the doors of the Gordon Technical School in Geelong. Born in 1921, Stanley was 15 years of age when he began his 3-year course in Wool Classing. 30 years later, Stanley’s second son Denis completed the same 3-year wool classing course. Beginning in 1966, Denis attended the same Gordon Technical School and walked the same halls as his father before him. Stanley finished his course in 1938. He went back to the family farm in Lake Bolac for a brief period before enrolling in the Second World War. At the completion of the war, Stanley returned home and married before gaining a soldier settler allotment, north of Willaura. This enabled Stan to use his wool classing knowledge. He ran between 1,500 and 2,000 sheep for many years, while his wool classer stencil also allowed him to go out and class at various sheds around the area. He held his stencil from 1938 until he retired at the age of 60 in 1981. On retirement, his second son Denis was working in the district, managing a local property while also leasing land himself. Upon his father’s retirement, Denis had the opportunity to lease his father’s farm, an opportunity he could not refuse. Denis had finished his wool classing course at the Gordon Technical School in 1968, graduating dux of his class. He began working with a local contractor and started classing wool in his team. Denis gained a great deal of experience working as part of this team in big sheds of up to 8 stands servicing between 10 & 20,000 sheep. It was not all smooth sailing for Denis however, and he soon learnt an important lesson. Class wool the way you’re taught, don’t listen to the owner standing over your shoulder. At a clip of Corriedales near Casterton, Denis was pushing too many fleeces into the line of fine wool. This resulted in a notice from the Australian Wool Exchange (AWEX) “mixing counts too much, submit three clips for inspection”. Denis was able to submit 3 clips with no further complaints, however, this proved a valuable lesson he would never forget over his long career classing wool. In the early 1980s, when Denis was leasing two properties including his father’s, things were going well until drought struck. February 1983 was the date of the Ash Wednesday bushfires, and saw Melbourne have three days over 40 °C for only the second time on record. This period saw Denis give away farming, turning towards contracting work instead. After the difficult times of the early 1980s, the next two decades were a good time for the sheep industry. 15 micron wool was selling for prices between 4 to 5,000 cents per kilo, double what you’d expect for the same wool in 2022. In 1995 a single bale of wool sold for a million dollars. This was a good time for Denis too. His contracting work saw him employing local shearers and shed staff. His team was involved with the shearing and classing of more than 130,000 sheep. After 20 years of contracting, it was time for Denis to transition into the next phase of his life. He gave up independent contracting, preferring instead to return to being a member of someone else’s team. In 2018, having completed 50 years of wool classing, it was time to call it a day and retire completely. At the annual Gordon Wool School Old Students Association dinner held in 2018, Denis was presented with his 50 years as a registered wool classer stencil awarded by the Australian Wool Exchange (AWEX). This is a rare honour achieved by few. As of February 2020, a total of 430 wool classers had achieved this 50-year milestone. For Denis however, his proudest achievement is achieving 90 years of wool classing with his father. The National Wool Museum is proud to share the collection of objects gained from 90 years in the wool classing industry by Stanley and Denis. This ranges from Stanley’s first stencil and Wool Sample book, started when he first attended the Gordon in 1936. The collection concludes 90 years later with Denis’ 50 years of wool classing Stencil. The collection contains many more objects, all telling the story of these 90 years, and the hard work invested by this dedicated father and son duo.Large black bound book with ribbon for fastening containing 12 double-sided blue pages. Pages have several samples of shorn wool mounted and annotated to include information such as specific breeding, shearing faults, and geographical area. The book concludes with four pages without wool samples. Two of these pages relate to plans for a shearing shed and other industry related structures. The final two-pages relate to the anatomy of a sheep. Wool sample books were constructed by Wool Classing students at the Gordon Technical School as examples of what to look for when classing wool. The students were tasked with constructing these books with samples they retrieved themselves from several different farms and animals. The book would serve as a reference point for the wool classers throughout their years in the field, it was always on hand to refresh knowledge. This book was constructed by Stanley Hucker over his schooling at the Gordon between 1936 and 1938Front Cover. Handwritten, White Ink "Stanley Hucker / Samples"90 years wool classing between father & son, wool classing, gordon technical school -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

National Wool Museum

National Wool MuseumBook - Wool Sample, 1961

The donor, Brian Licence, assembled this Wool Sample Book while studying at the Gordon Institute from 1960-62. Brian studied Wool Classing and worked for a decade in this profession before moving to Melbourne which required him to change careers. The National Wool Museum accepted a donation from Brian in 2022 of several mementoes relating to his career in the wool industry. This wool sample book joins a collection of 8 others within the museum’s collection, with the oldest dating to 1870 at the time of writing in 2022. Large black bound book with ribbon for fastening containing 12 double-sided blue pages. Pages have several samples of shorn wool mounted and annotated to include information such as specific breeding, shearing faults, and geographical area. The book concludes with four pages without wool samples. Two of these pages relate to plans for a shearing shed and other industry related structures. The final two-pages relate to the anatomy of a sheep. Wool sample books were constructed by Wool Classing students at the Gordon Technical School as examples of what to look for when classing wool. The students were tasked with constructing these books with samples they retrieved themselves from several different farms and animals. The book would serve as a reference point for the wool classers throughout their years in the field, it was always on hand to refresh knowledge. This book was constructed by Brian Licence over his schooling at the Gordon between 1960 and 1962. Front Cover. Handwritten, White Ink "Wool Sample / Book. 1961”wool classing, gordon technical college, brian licence -

National Wool Museum

National Wool MuseumBook, Wool Classing Exercise Book, 1960-62

The National Wool Museum accepted a donation from Brian Licence in 2022 of several mementoes relating to his career in the wool industry. This Wool Classing Exercise Book was written by Brian in his time at the Gordon Technical College from 1960-62. Brian studied Wool Classing and worked for a decade in this profession before moving to Melbourne which required him to change careers.This Wool Classing Exercise book begins with a grey cover and a blue and silver metal binder. It has the number “240” handwritten in white pencil at the centre of the cover and “Brian Licence Animal Husbandry” written in blue ink on the top right corner. Internally, the book is handwritten with occasional hand drawn images. This work is completed on yellowed pages with faint blue lines, for assistance in clarity of handwriting. The pages are surrounded by a margin of red pen. The exercise book’s content is about basic animal husbandry for sheep that a Wool Classer may need to know while in a shearing shed. It is handwritten. A selection of pages have been photographed to give an impression of the information taught in classes 60 years ago. This includes information about: - Dentistry - Skeletal - Blood Circulation - Breathing - Internal parasites The book has 50 completed pages of handwriting on both front and back. Handwritten, white pencil. Centre of cover. “240” Handwritten, blue ink. Top right corner of cover. “Brian Licence. / Animal Husbandry” gordon institute geelong, 1960s sheep farming, wool classing, sheep dentistry, sheep skeletal, sheep blood circulation, sheep breathing, sheep internal parasites -

National Wool Museum

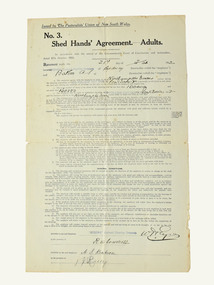

National Wool MuseumArchive - Agreement, Shed Hands' Agreement Adults, 1912

... Shearing Labour Movement Australia Shed Hands Agreement Merriwa ...Shed hand's agreement dated 21 February 1912. Merriwa Contract Company and A.S. Batson Earliest Date: 1912/2/21Large, pale green printed sheet (agreement) with signatures, names and dates written in black ink.Issued by the Pastoralists union of new south wales Shed Hands' Agreement Adultsshearing labour movement australia, shed hands agreement, merriwa contract shearing company, batson, mr stuart, shearing, labour movement - australia -

Linton and District Historical Society Inc

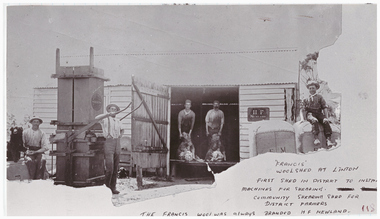

Linton and District Historical Society IncPhotograph, Francis Woolshed at Linton

An inscription written across the lower right of the photograph says that the Francis woolshed was the first shed in the district to install machines for shearing, and that it was used as a community shearing shed for district farmers. Early LDHS index to photographs identifies Jack Francis, holding wool press; Jim Francis shearing, nearest door; Henry Francis, lad on bale of wool.Black and white copy of original photograph of five men, two dogs and two sheep posing outside a wool shed. With wooden hand wool press and bales of wool.francis wool shed, h.f. newland [brand on francis wool bales], 'newland' (francis property], shearing, wool press -

Linton and District Historical Society Inc

Linton and District Historical Society IncShears, Hand Shears

... Used in shearing shed near Linton. Sheep shearing Hand ...Used in shearing shed near Linton.Metal blade hand shears used for shearing sheep. String-bound handles and leather strap.sheep shearing, hand shears, rural activity -

Darebin Art Collection

Darebin Art CollectionPainting, Pro Hart, Tired Shed Hand, 1979

... shearing Tired Shed Hand Painting Pro Hart ...shearing -

Linton and District Historical Society Inc

Linton and District Historical Society IncPhotograph, 'Glenfine' Shearing Shed, 1890

In July 1840, Glenfine, consisting of 31,440 acres, was acquired by Thomas Downie. In March 1842 the 'Right of Run' was taken up by Thomas Chirnside who with an imported stallion 'Delapre' ran a horse stud. He apparently lived here for ten years and employed a gardener with a wife and five children from Hobart, Tasmania. Only some blocks of stone and a few trees remain of their homestead. In 1853 the property was transferred to Dr. John Chirnside, an elder brother of Thomas Chirnside. In 1857, William Rowe of Naringal purchased Glenfiine where he and his family lived until 1904 when it was bought by Richard Howell's estate. It was then 39,000 acres. The present house was built by the Rowes in 1872 of bluestone quarried on the property with a cement render overall. The architect was H.R. Casselli. Gold was found on the property and by 1898 the township of Hollybush was first reported, situated at either side of the front entrance, on the Cressy Road. The land for the township was given by William Rowe. In 1911 R.C. Howell, son of Richard Howell, became the owner, followed by his son in 1960. By 1990 Hollybush had a population of 426 persons. All of the early history of Glenfine, documents etc., were destroyed when Naringal homestead was burnt down in 1944. Glenfine was classified by the National Trust in 1974 and is on the Heritage Commission Register. Mounted black and white image of a large group of men and boys in front of a weatherboard shearing shed. The men are each holding a pair of hand shears. One young man is kneeling on top of a wool bale. A small blue biro 'x' identifies W. Todd. Glenfine was a pastoral station, and the original homestead still stands.shearing sheds, shearers, rural activity, william todd, glenfine pastoral station, thomas chirnside, thomas downie, richard howell, william thomas rowe -

Churchill Island Heritage Precinct

Churchill Island Heritage PrecinctMachine - Wool Press

The Churchill Island collection includes objects from the 18th and 20th centuries. The collection is presented in sets and series, of which this object belongs to the National Trust sub-collection.Wool presses were used in shearing sheds around the country to create bales of wool by hand in preparation for transport to the wool markets for purchase and distribution. Bales have been used to store and were a standard trading unit for wool for centuries. A standard wool bale holds about 60 compressed wool fleeces and weighs a minimum of 120 kgs. The square shape and weight enabled them to be stacked on wagons or in warehouses, and a large pack horse could carry one on each side. Large, retangular upright metal wool press, unpainted with some surface rust.farm machinery, wool, wool press, hand operated, shearing, national trust -

National Wool Museum

National Wool MuseumTextile - Tapestry, Monica Baker, Weighing The Fleece, 2001

Hand-stitched tapestry by Monica Baker in 2001. Tapestry represents part of the family history of working in the wool industry as owners of a sheep property for five generations. The family ran Corriedale sheep in Lismore, Victoria.Brown timber framed woollen tapestry with cream mounting board. Tapestry is handstitched and features various colours. Scene depicts four men and a woman in a shearing shed. Two of the men are handling sheep, one man is weighing a fleece while the last man and woman look on. Back of frame has a horizontal hanging wire, a framers stamp at the bottom centre and a handwritten creators name and date at the top right corner.Back: [handwritten] "WEIGHING THE FLEECE" / BY MONICA BAKER / 02/03/01lismore, sheep breeding, tapestry, monica baker, shearing, hand made, corriedale -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncAlbum - Ringer's River by Des Martin - Cast, Credits & Introduction

Des Martin lived all his life in Wodonga, except for his years of service during World War Two. He was raised on the family property Aherlo in the Huon Creek Valley. In 1937 he joined the 8th Light Horse Regiment but in May 1940 led his Wodonga Troop into the 2/2nd Australian Pioneer Battalion, which saw service in Syria, Java, New Guinea and Borneo. After the war, Des returned to Aherlo and his horses. He was granted permission by the Victorian Racing Club to participate as an amateur “gentleman” rider. He was a founder of the Victorian Amateur Riders Association and also the Murray Valley Hunt Club, for which he was Master for 21 years. He was a prolific writer, cartoonist, photographer and poet, contributing to The Border Morning Mail, The Age, and the Herald and Weekly Times amongst other publications. Des Martin’s other literary works included Australia Astride (1959), A Tale of Twin Cities, Part One (1981) and Backing up the Boys (1998). In 1976, Des wrote an historical novel, “Many a Mile”, based on a fictional region which highly resembled the Albury-Wodonga and Upper Murray area of Victoria. It was set in the last 10 years leading up to Federation. Throughout this period tensions (caused by fluctuating border duties, including an infamous impost on cattle and horses) occasioned the intermittent posting of heavily armed police detachments along the River Murray. Des also wrote eight 50-minute scripts from “Many a Mile” as a television series and were presented to Michael Pate, one of Australia’s leading actors and producers. Also, funding was sought through the Australian Broadcasting Commission ... unfortunately the series never came to fruition. This album is a pictorial precis, including photos and scene descriptions, created to promote the concept of the series and have it produced locally in North Eastern Victoria featuring local settings, skilled horsemen and actors. It was to be called “Ringer’s River” ... Ringer being the title accorded to either a top cattle hand, or the fastest shearer in the wool shed. Des Martin died on 12th April 1995.These albums and images are significant because they document literature written by a prominent member of the Wodonga community. The presentation of this precis was supported by several significant district families and individuals.Documents written to introduce the concept of "Ringer's River" to gain interest for the development of a television seriesdes martin, many a mile, ringer's river, northeast victoria stories