Showing 421 items matching "stove"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Stove, 1960 - 1983

The Mont Eltham Pot Belly Stove History The Mont Eltham Pot Belly Stoves were first manufactured in the 1960s at the Burrowes family business The Lyn Iron Foundry in Coburg Victoria by Barry and his father Charles Thomas Burrowes. The manufacture of The Mont Eltham Pot Belly continued in Victoria as The Mont Eltham Stove Co. by Barry and Glenda Burrowes in Montmorency and later in Thomastown. The castings were produced by leading Melbourne foundries, Cox & Rosetti , and Anderson & Ritchie. They were also made in Ballarat by The Harding Bros Foundry, and in Shepparton by The Furphy Foundry. The Mount Eltham pot belly stoves were manufactured until the late 1980s. Stove; cast iron pot belly stove. Very large cylinder shape with square base, grate shelf around centre, on 4 legs. Inscription on door. "Swagman" model. Made by Mont Eltham Stoves, Victoria. "Mont Eltham Stoves Vic Swagman Aust"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, domestic heating, domestic heating, stove, pot belly stove, wood fired stove, old world stove, the mont eltham stove co., the lyn iron foundry, barry and glenda burrowes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

National Vietnam Veterans Museum (NVVM)

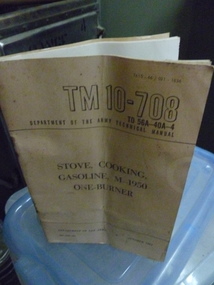

National Vietnam Veterans Museum (NVVM)Pamphlet, Stove, Cooking, Gasoline, M-1950 One Burner, 1/10/1951 12:00:00 AM

Small buff coloured instruction manual for operation of M-1950 StoveStove, Cooking, Gasoline, M-1950. One Burner. Dept Of the Army 1951/ TM 10-708stove, phamphlet -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Hexamine Stove

A small folding hinged metal portable Hexamine stove.stove -

National Vietnam Veterans Museum (NVVM)

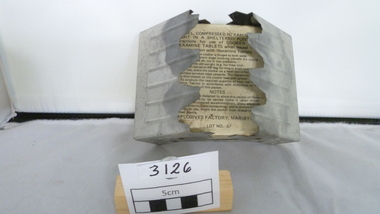

National Vietnam Veterans Museum (NVVM)Functional Object, Hexamine stove

Folding frame Hexamine stove hinged on both sides. Light pressed metal. Fuel tablets wrapped in plastic. Compressed hexamine, 4 tabletsinstructions for use on the botom of the stovehexamine stove -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Hexanine Stove

Metal Portable Stove : designed to be carried in backpack and collapsable. Green/ Black in colourstove -

National Vietnam Veterans Museum (NVVM)

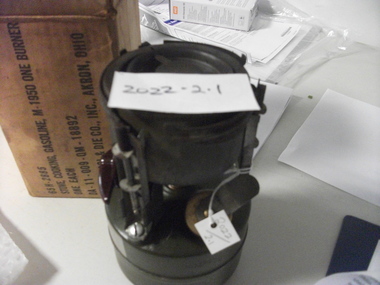

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Field Stove, 1951

Gasoline field stove with moveable legs and extendable arms for larger dixiesRogers Akron, Ohio 1951stove, field stove -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Stove, c1947

This unit was constructed by Mr. John Phillip Bennett( Sec Barbara Gardiner's uncle) to provide a small convenient stove when he and his wife were camping.Two single kerosene stove s installed in a fabricated container to give a level cooking surface and adequate wind deflector.On stove on the label|BLUE ACE Pat No. 527455 British Made No. 1940.recreations, camping -

Greensborough Historical Society

Greensborough Historical SocietyFunctional object - Camp Stove, Kerosene camp stove, 1950s

Small stove used for cooking when camping; used kerosene for fuel.Small metal camp stove with 4 legs and integrated container for fuel.stoves, camping equipment -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Domestic object - Stove

One ring stove with three stands surrounding a round cylinder. Fuel was kerosene.Companion Stovedomestic items, stoves -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, 1850-1890

In the industrialized world, as stoves replaced open fires and braziers as a source of more efficient and reliable heating, models were developed that could also be used for cooking, and these came to be known as kitchen stoves. The first manufactured cast-iron stove was produced at Lynn, Mass., in 1642. This stove had no grates and was little more than a cast-iron box. About 1740 Benjamin Franklin invented the “Pennsylvania fireplace,” which incorporated the basic principles of the heating stove. The Franklin stove burned wood on a grate and had sliding doors that could be used to control the draft (flow of air) through it. Because the stove was relatively small, it could be installed in a large fireplace or used free-standing in the middle of a room by connecting it to a flue. The Franklin stove warmed farmhouses, city dwellings, and frontier cabins throughout North America. Its design influenced the development of the pot-bellied stove, which was a familiar feature in some homes well into the 20th century. The first round cast-iron stoves with grates for cooking food on them were manufactured by Isaac Orr at Philadelphia, Pa., in 1800. The base-burning stove for burning anthracite coal was invented in 1833 by Jordan A. Mott. The subject item is a mid to late 19th century settlers stove probably of Canadian manufacture imported into Australia around this time. The stove gives us a social snapshot into what life must have been like for our early colonialists using this device for heating and cooking in their meagre homes. Cast iron stove with four-legs, 2 plates on top and a hinged front door. The door has been cast with a maple leaf design and the sides have a pattern cast into them.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, stove, domestic heating, domestic cooking, heater, cooking unit, pot belly stove, wood fired stove, wood stove -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomTechnical Manual, United States Government Printing Office, STOVE, COOKING, GASOLINE, M-1950 ONE BURNER, 10/1951

Used with single burner petrol stoves issued to vehicle crews from 1960'sUser manual. Department of the Army Technical Manual TM 10-708cooking, stove, field equipment, user manual -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, First quarter of the 20th Century

The first Australian cast iron stove was made by Charles Andrews in 1877 he patented his design and called it the “Andrews Nonpareil stove.” That for many years was the only Australian made kitchen stove on the market. When his patent expired numerous imitations were manufactured by other firms but the Nonpareil continued to earn a reputation for quality, economy and excellent cooking. The company operated at 47-10 Gheringhap Street Geelong, Victoria, they also specialised in hot water generating services.The subject item is significant as a copy of the well known design for the original Nonpareil stove by Charles Andrews. The name Andrews Nonpareil in stamped on the flue however the doors on the stove front are wrong and indicate the item is a copy by an unknown manufacturer probably made in the first quarter of the 20th century. Stove cast iron on 4 legs, two oven spaces with round doors. On flue "Andrews Patent Nonpareil".On flue "Andrew Patent Nonpareil"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, stove, iron stove, andrew patent nonpareil, cooking appliance, oven, combustion oven, cooker -

Diamond Valley Vietnam Veterans Sub-Branch

Diamond Valley Vietnam Veterans Sub-BranchEquipment - Stove, c2002

Hexamine stove used by Australian soldiers for cooking when in the field.The stove is significant to veterans for recollections of use in field for creative cooking.Metal hexamine stove for use in field, includes hexamine fuel.vietnam, vietnam war, diamond valley vietnam veterans sub branch -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, Stove Hexamine

Small folding hinged metal portable stove with unopened packet of Hexamine tablets inside stove. used by one man for heating food or waterDetailed directions on tablet packagehexamine stove, cooking, sas -

National Vietnam Veterans Museum (NVVM)

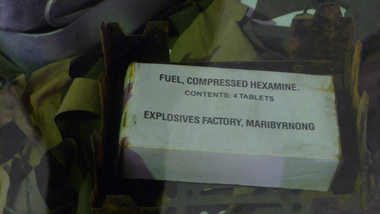

National Vietnam Veterans Museum (NVVM)Functional Object, Hexamine Stove

Metal folding stove with a box of four hexamine tabletsFuel compressed Hexamine contents contents four tablets Maribyrnong Explosives Factoryhexamine stove, field stove -

Geelong RSL Sub Branch

Geelong RSL Sub BranchHexamine Stove, There are no makers marks, circa 1960

This type Hexamine Stove was used by members of the AIF during postings to Vietnam.This Stove is an original issue to a member of the AIF who served in Vietnam.Painted black, metal, oblong Hexamine Stove with four fuel Tablets.There are no markings on the Stove. The Fuel Packet is marked on the front of the Box - Fuel, Compressed Hexamine Contents: 4 Tablets, Explosives Factory, Maribyrnong. On the back of the Box - Directions for Use, numbered one to four.stove, vietnam, aif -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Functional Object, Stove

Portable gasoline stove used by soldiers in Vietnam. Black metal with a maroon tap to operate.gasoline stove -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, 1965

Personal petrol one burner stove with three swing out feet, and three swing out grate arms. Petrol tank at baseStove Gasoline burner M-1950stove -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomTechnical Manual, J Williams, Stove, Cooking, Gasoline, M-1950, One Burner, 1951

Soft covered bookletTM 10-708stove, petrol -

Friends of Westgarthtown

Friends of WestgarthtownStove, Lux

Solid fuel stove, with stovetop cooking device, ash tray and oven, with two opening doors. Fire flu at back which extends up the chimney.Lux' on fuel cabinetdomestic items, cooking, stove, lux, fire, kitchen -

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Equipment - Equipment, Army, 1964

Personal petrol one burner stove with three swing out feet and three swing out grate arms. petrol tank at baseStove gasoline burner M-1950. US "Rogers" Akron, Ohiostove -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageStove

Stove portable metal with tank for liquid fuel, cork plug, window with mica cover, turning knob for temperature adjustment and top grid for placement of pots.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, stove, stove portable -

Anglesea and District Historical Society

Anglesea and District Historical SocietyClothes Iron, Coleman Lamp Stove Co Ltd, Spirit-fuelled Clothes Iron, Estimated circa 1936

Coleman Lamp Stove Co Ltd possibly making irons by arrangement with Coleman Lamp & Stove Co Ltd in Canada. Origin of these companies - started by William Coleman of Oklahoma and Kansas, USA. Iron has chrome plated sole - blue enamel body with white speckles and hemispherical tank (probably copper - has typical green verdigris appearance) for the lighting fluid that would have supplied the heat. The wooden handle is painted blue. Top screw is missing from the fuel tank.clothes iron -

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub Branch

Running Rabbits Military Museum operated by the Upwey Belgrave RSL Sub BranchStove

Hexamine Stove & Hexamine Blockequipment, vietnam, army -

Hand Tool Preservation Association of Australia Inc

Hand Tool Preservation Association of Australia IncStove

This item is part of the Thomas Caine Tool Collection, owned by The National Trust of Australia (Victoria) and curated by the Hand Tools Preservation Association of Australia.stove, soldering iron, fuel -

Red Cliffs Military Museum

Red Cliffs Military MuseumHexamine Stove, 1960s - 2000s

Stove used in the field by individual soldiers for heating food and boiling water. The stoves were provided in individual ration packs and when folded up held a packet of hexamine tablets, the fuel used in the stove.Light gauge metal folding stove using 25mm X 25mm X 10mm hexamine tablets as fuel. The stove folds up to hold a pack 0f hexamine tablets, it is gold in colour and designed to heat a mess tin in the field.stove, army rations, hexamine, field cooking -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, spirit-fuelled sad iron, c1920

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Late in the 19thC designers experimented with heat retaining fillings for these irons. William Coleman began selling Kerosene lanterns in 1900 in Kingfisher, Oklahoma, USA. He moved to Wichita, Kansas in 1902 and the company became world wide. The company also produced a range of cooking stoves and domestic irons. This spirit- fuelled flat iron was very popular in 1920s - 30s These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin ShireA) spirit- fuelled, sad iron with chrome plated sole c1920, and metal trivet The iron is blue enamel with a white speckled body, with a hemispherical tank for the Coleman 'Lighting Petrol' that provided the heat for smoothing the material B) Coleman Fuel measuring can and funnellMetal Trivet/stand " COLEMAN" ; Petrol can " COLEMAN" / MEASURING CAN / for INSTANT LIGHTING IRON/ with printed instructionssad iron, kitchen equipment, coleman william, kansas, oklahoma, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, petrol fuelled irons, spirit flat irons, coleman lamp stove co. ltd. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron Hand Kerosene, mid to late 1900s

The 1950's saw a revolution in small appliances for use in the average household. This hand held self heating(kerosene) iron was introduced as a time saving and more convenient iron for pressing clothes and other cloth fabrics. It replaced irons needing a separate fire source to heat the ironing plate. These irons continued to be in service, even when electricity was available in cities and larger rural towns (domestic electric steam irons were invented in 1938). This item was used before and during the electricity supplies available from the Kiewa Hydro Electricity Scheme. These irons remained in use within regional rural areas that had limited or unreliable electrical reticulation.In the 1950s and later the Kiewa Valley was still a relatively isolated region which was home to rural properties and small settlements. The availability of electricity and or the financial means to afford new types of electric hand irons ensured that older and sometimes less efficient ironing remained for an extended period covering the 1960s to 1970s. Kerosene products, such as this kerosene iron was a cheaper method for farm based domestic and other rural activities requiring a heat source. The use of kerosene as a heat/light source was able to be supplied in bulk and able to be used when floods severed vital roads into this region. The supply of electricity was in summer time subject to interruption from bush fire damaged wooden poles carrying the electrical cables. Self sufficiency by rural populations was the backbone of survival and the ability to store energy sources "on the farm" was a prerequisite of isolated regions, such as the Kiewa Valley, circa 1950s.This Coleman kerosene iron has a solid steel chrome plated(press) base with a painted (blue) wooden handle. The handle is stud fastened onto an oblong shaped rolled steel handle frame and screwed (two screws) onto the base plate. Both the heating plate and the top securing plate are shaped similar to a river boat. The main housing enclosing the heating element is enamel coated(blue in colour) steel and has a half hole for lighting the kerosene at the rear end. Behind the handle and protruding upwards is a stainless steel fully enclosed container (bowl shaped) for the main supply of kerosene to the burner or generator(enclosed within the main body of the iron. The bowl has an air valve and inlet for pressurised air intake (hand pump) On the bottom rear of the fuel bowl there is a screw regulated fuel pump. The fuel heated base plate provides the heat for this advertised "self heating iron(instant lighting). See KVHS 0347B- Instruction sheet; KVHS 0347C- Wrench; and KVHS 0347D Fuel can.Stamped on the base plate of the handle, front region "COLEMAN LAMP & STOVE CO." below this "WICHITA KAN" below this"TORONTO CAN". In the middle of the handle base and in larger print "COLEMAN Instant-Lite" At the rear location in large print "MODEL 4" in smaller print below "MADE IN U.S.A." below this "PAT#1718473"household appliances, alternative non electrical ironing appliances, domestic appliances, kerosene appliances -

Rutherglen Historical Society

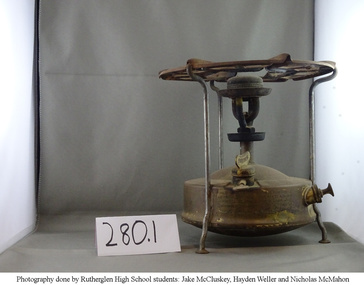

Rutherglen Historical SocietyFunctional object - Primus Stove, Svea, 1935 (Approximate)

Primus stove of a type pre-heated by methylated Sprits, 3 legs and has a pumpThe original Svea stove is guaranteed made in Sweden on underside the king of stoves . Original Svea No. 5