Showing 10 items matching "sunbeam appliances"

-

Greensborough Historical Society

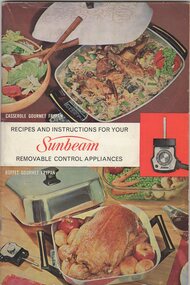

Greensborough Historical SocietyBook - Digital Image, Sunbeam Corporation, Sunbeam Removable Control Appliances: instruction manual, 1965_

... Sunbeam Removable Control Appliances: instruction manual...sunbeam appliances...Covers from "Sunbeam Removable Control Appliances... advertisements recipes electric appliances electric frypans sunbeam ...Covers from "Sunbeam Removable Control Appliances instruction manual". An example of 1960s advertising through cooking and homemaker books. In this book, instructions and recipes are given for using various Sunbeam Removable Control Appliances, such as frypans, and deep fryers. The back cover shows photographs of Sunbeam deep fryers.An example of mid 20th century advertising through 'how-to' books.Digital copy of front and back covers of a book.historic advertisements, recipes, electric appliances, electric frypans, sunbeam appliances, deep fryers -

Greensborough Historical Society

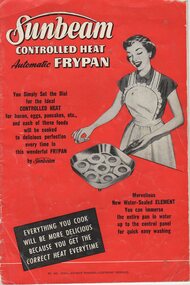

Greensborough Historical SocietyBook - Digital Image, Sunbeam Corporation, Sunbeam Frypan instruction manual, 1959_

... sunbeam appliances... of other Sunbeam appliances.... shows examples of other Sunbeam appliances. An example of mid ...Covers from "Sunbeam Frypan instruction manual". An example of 1950s advertising through cooking and homemaker books. In this book, instructions and recipes are given for using a Sunbeam controlled heat electric frypan. The back cover shows examples of other Sunbeam appliances.An example of mid 20th century advertising through 'how-to' books.Digital copy of front and back covers of a book.historic advertisements, recipes, electric appliances, electric frypans, sunbeam appliances -

Orbost & District Historical Society

Orbost & District Historical Societycake mixer, circa 1948

... mixmaster sunbeam kitchen-appliance food-technology... The Mixmaster 9B in 1948 was the first Sunbeam appliance... gippsland The Mixmaster 9B in 1948 was the first Sunbeam appliance ...The Mixmaster 9B in 1948 was the first Sunbeam appliance to be made in Australia. It was designed in the USA.After years of rationing and shortages, the 1950s were a period of economic prosperity, high employment and great technological development. During this period, Australians enthusiastically adorned their homes with a dazzling range of new domestic appliances. Hire-purchase schemes allowed people to take products home and pay for them in instalments. The American-designed Mixmaster 9B was the first Sunbeam appliance manufactured and sold in Australia in 1948. An early Sunbeam Mixmaster. It is an electronic stand mixer with a black metal base in the shape of a rounded teardrop with two holes for the turntable. It has a cream enameled metal arm, cream coloured metal motor housing with a black plastic handle on the top. On the back of the motor housing is a black plastic knob with ten speed options for the mixer, and the "OFF" position. a black electric cord is attached under the motor housing with a black switch beneath the cord. The motor housing is able to tilt backwards on a hinge which is attached to the top of the stand arm. It is worked on AC or Dc power 240 On the bottom are the words "MODEL 9B". mixmaster sunbeam kitchen-appliance food-technology -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Lady Sunbeam Home Hair Dryer, Sunbeam Corporation Australia, c1960

... convenient. Sunbeam Australia domestic appliances Hair dryers On lid ...Sunbeam produced a wide range of hair dryers in a variety of sizes and shapes throughout the 1960s. Lady Sunbeam was promoted as providing unequalled efficiency as well as extra convenience and comfort. Whilst you dried your hair, you were able to sit and relax, read a book, write letters, knit or apply your nail enamel. The added convenient shoulder strap enabled you to complete other small household chores such as ironing - as long as they could be carried out within the distance of the power cord. Sunbeam History The Sunbeam Corporation began in Australia in 1902 as a small branch of the American group, Chicago Flexible Shaft Company.In 1946, this company changed its name to Sunbeam Corporation and developed the slogan "Best Electric Appliances Made". The company became publicly traded in 1952 and came into Australian ownership in 1987. In 1948 the company launched the Sunbeam Mixmaster®, the first small electrical appliance to be manufactured in Australia. In 2020, the company changed its name to Newell Australia.This item is representative of a range of domestic appliances used across Australia in the 1960s to make home life simpler and more convenient.Hair dryer in portable round plastic hinged case with motor fitted within the base. Plastic wire coiled hose is attached to the motor. A plastic hood edged with elastic and lace adjustment is fitted to the end of the hose. The hood has a pattern of gold embossed flowers. The motor has settings off, cool, warm, med, hot. An electric cord and plug are attached to the motor. The lid closes with a sprung knob and has a plastic carry handle. The "Lady Sunbeam" Logo is embossed on the lid.On lid: Lady Sunbeam / HAIR DRYER Underneath unit: MODEL AHD-7 220-250V 50CYC 300W.AC. ONLY/ PATENT PENDING RD.NO.42.338 MADE IN AUSTRALIA / Sunbeam CORPORATION LIMITEDsunbeam australia, domestic appliances, hair dryers -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMix Master

... sunbeam mix master; kitchen appliance; cooking; ron white... and use electrical appliances. The mix master was popular ...The Kiewa Hydro Electric Scheme (KHES) produced electricity for the people living in the Kiewa Valley and beyond to many parts of Victoria. The people and their families working on the scheme were encouraged by their employer the State Electricity Commission of Victoria to purchase and use electrical appliances. The mix master was popular for mixing food for baking and for making juice drinks. Ron White owned this 1950s vintage Sunbeam model 9 mixer with stand, milk glass bowls and complete juicer. Ron was a senior member of staff during the construction and operation of the KHES.This mix master was owned by Ron White who was appointed Area Operations Engineer Kiewa in June 1956. Ron was later appointed General Superintendent and then in 1974 to principal Hydro Engineer of the recently titled Hydro Division.White electrical food mixer with six parts. 1. Motor upright - white, on black stand horizontal. Black dial at back with speeds numbered and type of mix eg. mash. Front switch on/off. Black electric cord attached. Long black handle on one side. 2 Two beaters, silver 3. Bowls, white one small and one large. The small one has a spout. 4. Squeezer, white - fits on top for juicing. Parts as with orange juicer and with funnel at the front for juice to flow into a bowl.'Sunbeam' (in red) / 'Mix Master' in (black) on gold oblong 'emblem' sunbeam mix master; kitchen appliance; cooking; ron white; kiewa hydro electric scheme; food preparation -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyMixmaster and attachments

... . See KVHS 1282 kitchen appliance blender vitamiser Mixmaster ...Household item used in the kitchen for mixing food. It belonged to Ron White.Ron White (1920 - 2019) worked for the SECV and was superintendent engineer of the Kiewa Hydro Electric Scheme after its completion. He lived in Mt Beauty and worked until he retired in 1985. See KVHS 1282 Mixmaster blender box made by Sunbeam, Australia Cat. No. AMB-O. It includes a rectangular glass container with a black bakelite lid. It fits onto a steel attachment and is held by 4 black bakelite stands. Second box consists of - Sunbeam / Meat Grinder / and / Food Chopper / Attachment / with Power Transfer Unit / for Sunbeam Mixmaster / Cat No. FC 6 / Made in Australia Attachments are boxed inside.kitchen appliance, blender, vitamiser, mixmaster sunbeam, ron white, meat grinder, food chopper -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

... of shearing equipment, made its first household appliances and branded... first household appliances and branded them Sunbeam. In 1933 ...With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

... of shearing equipment, made its first household appliances and branded... appliances and branded them Sunbeam. In 1933, changes in exchange ...Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Robin Boyd Foundation

Robin Boyd FoundationDocument - Manual, Appliance brochures

A collection of appliance manuals, warranties, receipts, post 1971. They include Sunbeam electric blankets, Sunbeam automatic kettle, Sunbeam iron, Breville toaster, Bosch gas hotplate, Rheem electric hot water, Actron air conditioner, Dishlex dishwasher, B&D Australia repair, Goodguys invoice.Assorted manuals and warranties and invoices. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Foot Warmer, Hecla Electrics Pty Ltd, c. 1920

From Museum Victoria: Made in about 1927 by Hecla Electrics Pty Ltd and sold under the model name 'Foot Warma'. The foot warmer was made from the late 1920s until the 1950s and did not change substantially in design during this time. The Hecla brand name and logo was registered in 1918 by Clarence Marriott. It was inspired by the recent eruption of Iceland's volcano Mt Heckla. Clarence and his father James were metal workers who had made Australia's first carbon filament electric radiators in 1899, and also built an early steam car. As electricity use exploded in the 1920s and 1930s, 'Hecla' became a household name in Melbourne. They made a wide range of appliances for the home, and supplied commercial appliances to cafés, hospitals and offices. In 1927, the company shifted from small premises in the city to a bigger, electric-powered factory in South Yarra. Hecla had no retail stores of its own - instead it sold products through wholesalers and retailers, including the State Electricity Commission (SEC). The company promoted its goods through advertisements in home magazines and displays in shop windows, home shows and the 1935 All-Electricity Exhibition. A popular advertising slogan in the 1930s was 'Hecla household helps make happy healthy housewives!'. Hecla ceased manufacturing in Melbourne in the 1980s.Documentation of how people lived and is an example of early domestic electrical appliances. From Museum Victoria: Hecla Electrics Pty Ltd were a significant Melbourne manufacturing company, who became a household name in the 1920s making small electric appliances such as heaters and kettles. They also made a variety of other electrical appliances for domestic, commercial and military use. The company manufactured electric appliances in Melbourne from about 1922 until the 1980s, although Clarence Marriott, who formed the company, had begun making radiators with his father James in 1899. The company had a reputation for quality products. The company also played an important role within the Australian domestic and commercial appliance industry, both as a leading innovator and through its role in training skilled staff, many of whom went on to work for competitors such as Kambrook, Electrolux and Sunbeam. This electric coffee percolator represents the typical small domestic appliance that the Hecla company was famous for. Along with other items in the Hecla Collection, it highlights the diversity of electric appliances that the company made. This object also highlights the legacy of high quality design and metal construction work that Clarence and James established for the company, stemming from their early work as talented art metal workers. It also represents the first major period of the take-up of electricity use in the home. This take-up began in the 1920s and 1930s with the use of small appliances, and by the 1950s electricity had become commonplace in the home, and large appliances such as refrigerators and stoves became standard.Square metal object. The top surface is heavy cast iron and patterned with floral motifs. In the centre is a circle with the words ' Hecla Foot Warma' inside. Under the top is a black metal base with two feet at either end which extend the length of the base. The back foot is higher than the front foot. There is a circular disk from which extends the electrical cord. The cord is brown and white checks. At the end of the cord is a plug on which is printed 250V AMP S.2 EARTH 5. The plug is brown and made from Bakelite. On the base is a rectangular label which has words printed - HECLA Australia.Top: HECLA/-FOOT-/WARMA Base: Volts / 230/250 / WATTS / 80 / HECLA / Australia / CAT. NO. F26domestic, city of portland, glenelg shire council, electrical, foot warmer, heating, hecla, manufacture