Showing 13 items matching "sunbeam cooper"

-

National Wool Museum

National Wool MuseumBooklet - Sunbeam Cooper Shearing Shed Reference Book

... Sunbeam Cooper Shearing Shed Reference Book...Sunbeam Cooper... career as a woolclasser. "Sunbeam and Sunbeam Cooper sheep... on Sunbeam and Sunbeam Cooper sheep shearing machinery & shearing...Sunbeam and Sunbeam Cooper sheep shearing machinery..." Woolclassing Shearing machinery Wool Press Sunbeam Sunbeam Cooper ...Part of Ken Galloways research material associated with his career as a woolclasser. "Sunbeam and Sunbeam Cooper sheep shearing machinery & shearing shed equipment"White binder containing a collection of research material on Sunbeam and Sunbeam Cooper sheep shearing machinery & shearing shed equipmentSunbeam and Sunbeam Cooper sheep shearing machinery & shearing shed equipment 5woolclassing shearing machinery, wool press, sunbeam, sunbeam cooper, galloway, mr ken, woolclassing, shearing machinery -

National Wool Museum

National Wool MuseumShearing comb

... Sunbeam/ COOPER/ FLIGHT.... Shearing Sunbeam/ COOPER/ FLIGHT "Sunbeam" metal shearing comb ..."Sunbeam" metal shearing comb with ten points."Sunbeam" metal shearing comb.Sunbeam/ COOPER/ FLIGHTshearing -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyProgramme - Sports Carnival, Boxing Day, Dec 1895

William J BELLION - Grocer, N Gleeson, N McLEAN, C McLEAN, P WHAMONDE, C PEMBERTON, George Washington ROBBINS Jnr, W GIBSON - Grocer, Dr MALCOLMSON, J TATE Jnr, A T Lenihand, W ROBINSON, H H BETTS - Blacksmith, C D LENIHAN - Rose and Crown Hotel, Wearne Brothers, V McADAM - Hairdresser, L TOUTCHER - Globe Hotel, R McNAUGHTON - Graham Hotel, R BLACKMORE - Greengrocer, James KERR - Fishmonger, T J COOPER - Butcher, P GLEESON - All England Eleven Hotel, A BROWNLIE - Butcher, D Sinclair - Tobacconist, W CAMPBELL - Veterinarian, Mrs MURPHY - Naval Brigade Hotel, E BLAKE - Sunbeam Hotel, Gordon & Co - Saddlemakers, J F O'DWYER - SaddlemakerPhotocopy of 8 pg program for Port Melbourne horse racing 'Sports Carnival', Boxing Day 1895, with local ads. Includes notation of placings. Poor quality; looks like a copy of a copy(original had winners marked)sport - horse racing, business and traders, william j bellion, n gleeson, n mclean, c mclean, p whamonde, c pemberton, george washington robbins jnr, w gibson, dr malcolmson, j tate jnr, a t lenihand, w robinson, h h betts, c c lenihan, wearne brothers, v mcadam, l toutcher, r mcnaughton, r blackmore, james kerr, t j cooper, p gleeson, a brownlie, d sinclair, w campbell, mrs murphy, e blake, gordon & co, j f o'dwyer -

National Wool Museum

National Wool MuseumBooklet, Instructions for the installation operation and care of Cooper electric shearing gear and grinders

Instructions for the installation operation and care of Coooper electric shearing gear and grindersInstructions for the installation operation and care of Coooper electric shearing gear and grinders.shearing, cooper engineering company pty ltd sunbeam corporation limited -

National Wool Museum

National Wool MuseumPamphlet, Cooper Automatic Multi Spray Race

... , produced by Sunbeam. Spraying Cooper Engineering Company Pty Ltd ...Pamphlet for Cooper Automatic Multi Spray Race, produced by Sunbeam.Pamphlet for Cooper Automatic Multi Spray Race, produced by Sunbeam.spraying, cooper engineering company pty ltd sunbeam corporation limited -

National Wool Museum

National Wool MuseumPamphlet

Pamphlet for Coopers shearing table.Pamphlet for Coopers shearing table.shearing, cooper engineering company pty ltd sunbeam corporation limited -

National Wool Museum

National Wool MuseumBooklet, For the man on the land... Cooper the world's best machinery!

Catalogue advertising shearing machinery by Cooper.Catalogue advertising shearing machinery by Cooper.shearing shearing machinery, cooper engineering company pty ltd sunbeam corporation limited, shearing, shearing machinery -

National Wool Museum

National Wool MuseumPamphlet, Shearing independence costs far less than you think

Pamphlet advertising Cooper shearing machinery.Pamphlet advertising Cooper shearing machinery.shearing shearing machinery, cooper engineering company pty ltd sunbeam corporation limited, shearing, shearing machinery -

National Wool Museum

National Wool MuseumPamphlet, New! Completely new! Electric shearing gear!

Pamphlet advertising Cooper shearing equipment.Pamphlet advertising Cooper shearing equipment.shearing shearing machinery, cooper engineering company pty ltd sunbeam corporation limited, shearing, shearing machinery -

National Wool Museum

National Wool MuseumPamphlet, New! Completely New! Electirc Shearing Gear!

Pamphlet advertising Cooper shearing equipment.Pamphlet advertising Cooper shearing equipment.shearing machinery, cooper engineering company pty ltd sunbeam corporation limited -

National Wool Museum

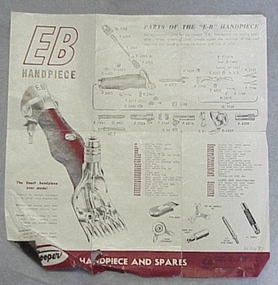

National Wool MuseumPamphlet

Pamphlet listing Cooper E-B shearing handpiece and its parts, as text and drawings.Pamphlet listing Cooper E-B shearing handpiece and its parts, as text and drawings.shearing machinery, cooper engineering company pty ltd sunbeam corporation limited -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

... Equipment Sunbeam Grinder Plate. Inscribed. “Cooper / S.E. BALL ...Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder